CYANIDE LEACHING O F CHALCOCITE by Robert Francis

advertisement

OPEN FILE REPORT 65

CYANIDE LEACHING O F CHALCOCITE

by

Robert Francis Shantz

A Dissertation Submitted to the F a c u l t y of the

DEPARTMENT O F METALLURGICAL ENGINEERING

In Partial Fulfillment of the R e q u i r e m e n t s

For the D e g r e e of

DOCTOR O F P H I M S O P H Y

WITH A MAJOR I N METALLURGY

In.the Graduate College

THE UNIVERSITY O F ARIZONA

1 9 7 6

In recognition of the support received from theNew Mexico

Bureau of Mines and Mineral Resources, this dissertation is available

a s 0% 6 5 .

P e r m i s s i o n is hereby granted by the author to copy the

dissertation o r sections thereof provided only that proper acknowledgement is made.

Signed:

STATEMENT BY AUTHOR

This dissertation has been submitted in partial fulfillment of

requirements for an advanced degree at The University of Arizona

and is d e p o s i t e d i n t h e U n i v e r s i t y L i b r a r y t obe made available to

b o r r o w e r s u n d e r r u l e s of the Library.

Brief quotations from this dissertation are allowable without

special permission, provided that accurate acknowledgment of s o u r c e

is made. Requests for permission for extended quotation from or

reproduction of t h i s m a n u s c r i p t i n whole o r i n p a r t m a y be granted

by the head of the major department or the Dean of the Graduate

College when in his judgment the proposed use of t h e m a t e r i a l is in

t h e i n t e r e s t s of scholarship. In all other instances, however,

p e r m i s s i o n m u s t be obtained from the author.

- ...

..

ACKNOWLEDGMENTS

The author wishes to express his appreciation to

Dr. Walter

F i s h e r f o r his patience and untiring efforts during the last three

years.

His advice and support were instrumental in the successful

completion of this project.

The initial portion of the work was supported by a r e s e a r c h

g r a n t from the United States Bureau

of Mines. The New Mexico

Bureau of Mines & Mineral Resources provided facilities-and time

for the completion of the research.' The author is deeply indebted

to the staff of the Bureau for the preparation of the final manuscript.

.. .

111

TABLE O F CONTENTS

Page

.............. ..

LIST O F ILLUSTRATIONS . . . . . . . . . . . . . .

ABSTRACT . . . . . . . . . . . . . . . . . . . .

LIST O F TABLES

.

1

2

.

;

..................

Leaching

with

Cyanide

.............

........

Development of t h D

e issertation

INTRODUCTION

REVIEW O F THE

LITERATURE

............

Copper a s a Cyanicide in Precious

Metal . Cyanidation

LeachingCopperMineralswith.Cyanid

e.

TheNature of theCopperComplexes

Dissolution of Chalcocite and Covellite

i n Cyanide

Solution

Electrowinning

from

Cyanide

Solutions

Proposed Processes for Cyanidation

o f Copper-BearingMaterials

S u m m a r y of the

Literature

.............

....

.......

3

.

THE

CHEMISTRY

...........

.....

.......

............

O F THE

SYSTEM

.........

The Defining Equations for Ionic

Concentrations

The

Thermodynamic

Quantities

Temperature

Dependence

of the

Constants

TheDebye-HuckelConstants

Discussion

.............

........

...

..........

...................

iv

vii

Xi

xiii

1

5

9

13

13

14

15

18

20

23

24

25

25

35

42

44

46

V

TABLE O F CONTENTS..

Continued

Page

4

.

EXPERIMENTALEQUIPMENT

PROCEDURES

AND

.................

Equipment . . . . . . . . . . . . . . . . .

..................

............

. . . . . . . . . . . . ;. . .

5.

COMPUTATIONAL

TECHNIQUES

.........

Chemicals

The Chalcocite Sample

T e s tP r o c e d u r e

The Calculation of the Ionic

Concentrations

Solution of the Copper and

CyanideSystems

The Sulfur. Hydroxide. Cyanide. . and

Hydrogen Cyanide Concentrations

The Activity Coefficient Ratios and

Mean Ionic Strength

Curve Fitting for Copper

ConcentrationVersusTime

Calculating the Reaction Rates

Surface Area

CopperExtraction

Summary

............

...... ....

6

.

I

....

..........

......

........

................

..............

..................

THEEMPIRICALRATE

EQUATION . . . . . . . .

Cyanide

Dependence

............

Sulfide IonDependence

...........

TheRateConstant

.............

Initial Cyanide Addition . . . . . . . . . . .

Sodium Sulfide Addition . . . . . . . . . . .

Initial Size Effects

.............

Initial Copper Additions . . . . . . . . . . .

Agitation . . . . . . . . . . . . . . . . . .

pH E f f e c t s . . . . . . . . . . . . . . . . . .

Temperature . . . . . . . . . . . . . . . .

Alternate Models for Surface Area . . . . . .

Effects of O t h e r I o n s . . . . . . . . . . . .

Summary . . . . . . . . . . . . . . . . . .

49

49

52

52

53

60

60

68

70

74

75

79

82

84

85

86

86

88

92

94

94

97

9 'i

100

100

103

108

111

112

'

TABLE O F CONTENTS..

7

8

.

.

Continued

Page

EFFECTS OF THE PROCESS

VARIABLES ON EXTRACTION

.........

Initial CyanideConcentration

........

Initial Size . . . . . . . . . . . . . . . . .

Initial SulfideAddition

............

Temperature . . . . . . . . . . . . . . . . .

Initial Copper Concentration . . . . . . . . .

pH Effects . . . . . . . . . . . . . . . . .

Summary . . . . . . . . . . . . . . . . .

CONCLUSIONS AND RECOMMENDATIONS

......

113

115

115

122

122

122

127

130

136

APPENDIX I: DERIVATION O F SELECTED

EQUATIONS

.................

140

APPENDIX 11: TABULATION OF CONCENTRATIONS

AND ACTIVITY COEFFICIENT RATIOS FOR

THE IMPORTANT AQUEOUS IONS

147

......

APPENDIX 111: THE EXPERIMENTAL DATA

REFERENCES

....

....................

161

192

LIST O F TABLES

Table

.

Page

1. Solubility of Copper Minerals from Leaver

and Woolf '(1931)

I6

Solubility of Copper Minerals from Lower.

and Booth (1965a).

17

Cathode Potential and Current Efficiencies

f r o m G l a s s t o n e (1929) for Solutions

0 . 1 N i n KCN

21

............:..

2.

3.

4.

5.

..............

.................

The

Activity

Coefficient

Ratios

.........

Thermodynamicfhantitiesforthe

0

Cuprocyanide

Complexes

C at 25

and AH f o r HCN f r o mI z a t t et al.

.......

(1062) . . . .

6.

K

7.

Equilibrium Constants for the Sulfide

. S y s t e mf r o mS i l l &a n dM a r t e l l

(1964)

8.

9.

A

34

36

38

.....

39

Dissociation Constant of W a t e r f r o m

Ackerman (195.8)

...............

40

Dissociation Constant of Acetic Acid from

. Harned

andEhlers(1933)

41

............

10. Debye-Huckel Constants from Bockris

and

Reddy

(1970)

45

11. IonicRadiiUsedin

47

...............

this Study . . . . . . . . . .

3.48 F r a c t i o n

12.

Composition of the-35,

13.

Copper

Content

14.

Major X-Ray Diffraction Lines Arranged

i n O r d e r of DecreasingIntensity

54

......

55

........

56

of the

Size

Fractions

vii

.......

.

viii

LIST O F TABLES

--

Continued

Table

15.

Page

. . . . .......

Reproducibility of Copper Concentrations

AmongReplicateTests

16.

TheEquationsThatDescribetheConcentrations

17.

G l o s s a r y of Symbols

18.

Typical Experimental and Calculated Copper

Concentrationsingpl

19.

59

.

..............

. ...... .....

for Rate

. . . .. .. . ... .....

Typical Regression Constants Used

Calculations

............

62

66

78

80

Typical Calculated Reaction Rates in Moles

perLiterperMinute

81

21.

Geometric Mean Diameters f o r t h e S i z e F r a c t i o n s .

83

22.

Typical Calculated Areas in Square Centimeters

for an Initial Sample Weight of 25 G r a m s

87

23.

PointsUsedtoPrepareFigure

90

24.

5

Typical Rate Constants x 10 Showing the

VariationThroughout a T e s t :. . .

20.

25.

26.

27.

28.

5

...

. . . . :. . .

......

93

...... .....

95

Rate Constants in Relation to Initial Sodium

Cyanide

Concentration

.

.......

Rate Constants in Relation to Initial Sodium

Sulfide

Addition

..

.' . .

....

96

Relation of the Rate Constant to the Initial

P a r t i c l eS i z e

98

Relation of the Rate Constant t o Initial

Cuprous

Cyanide

Addition

99

...............

.... .....

ix

LIST O F TABLES --'Continued

Table

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

Page

. .. . . . . . . . . . . .

pH ChangesDuringLeachTests

. . . . '. . . . .

R e s u l t s of Monitoring pH . . . . . . . . . . . .

pH EffectsontheRateConstant

.........

RateConstantsinRelationtoTemperature

....

PointsUsedtoPreparetheArrheniusPlot

....

Experimental Reproducibility of Replicate Tests

.

Effect of Impeller Speed on Percent

CopperExtraction.

'

..........

Effect of Initial Sodium Cyanide. Concentration on

Percent.CopperExtraction

Effect of I n i t i a l P a r t i c l e S i z e o n P e r c e n t C o p p e r

E x t r a c t i o n f o r T e s t s With an Initial Sodium

CyanideConcentration of 16 g p l .

.......

Effect of I n i t i a l P a r t i c l e S i z e o n P e r c e n t C o p p e r

E x t r a c t i o n f o r T e s t s With an Initial Sodium

CyanideConcentration of 12 g p l .

101

104

105

106

107

110

114

116

118

.......

119

.........

123

.................

124

..........

126

....... ......

129

Effect of Initial Sodium Sulfide Addition on

PercentCopperExtraction

.

Effect of Temperature on Percent Copper

Extraction

.

41.

Effect of Initial Copper Concentration on

PercentCopperExtraction

42.

Effect of Initial pH on the pH Change a s a

Function of T i m e

.

.

X

LIST OF TABLES

--

Continued

Table

Page

.

43.

Effect of Initial pH on Percent Copper Extraction

44.

Effect of Initial pH on Cyanide Ion Concentration

a s a Function of Time

132

Effect of Initial pH on Sulfide Ion Concentration

as a Function of Time

133

45.

.............

............

131

,.

LIST O F ILLUSTRATIONS

Figure

Page

..........

4

........

22

...............

51

1.

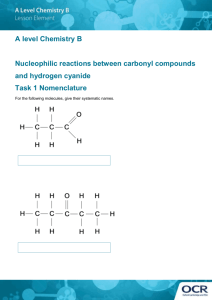

Polished Section of a Vein from a Typical

Chalcocite Ore Body(125X)

2.

Electrode Potentials for the Cuprous

Cyanides from Glasstone (1929)

3.

Schematic Diagram of the Cyanide

Leaching System

4.

A Typical Graph of Total Copper

Concentration Versus Time

5.

...........

...............

Reaction Order for Free Cyanide

IonDependence.

6.

Effect of Agitation on Percent Copper

Extraction

7.

8.

10.

89

...................

102

Temperature Dependence of the Rate

Constant from 3OC to 69OC

..........

109

Copper Extraction as a Function of Time

for Several Initial Sodium Cyanide

Concentrations

117

.................

9.

76

Effect of Initial Size on Percent Copper

Extraction in Solutions with an Initial

Sodium Cyanide Concentration of16 gpl

Effect of Initial Particle Size on P e r c e n t

Copper Exqraction in Solutions with an

Initial Sodium Cyanide Concentration

of 1 2 gpl

.....

..................

xi

120

121

,

'

xii

LIST O F ILLUSTRATIONS- -Continued

Figure

Page

11. Effect of T e m p e r a t u r e on Percent Copper

Extraction in Solutions with an Initial

SodiumCyanideConcentration

of 16 g p l

. . . .'.

125

Effect of Initial pH on Percent Copper

Extraction in Solutions with an Initial

SodiumCyanideConcentration

of 24 gpl

.,...

134

12.

.

.

ABSTRACT

The leaching of chalcocite concentrates with sodium cyanide

under nonoxidizing conditions

is shown to have several advantages:

the leaching rate is high, the cyanide does not react with the pyrite

contained in most chalcocite concentrates, the copper remains in the

lower oxidation state, and the sulfur reports

as bisulfide. These

considerations make a study of the process promising.

A literature search was performed to accumulate information

on cyanide leaching of copper minerals and the aqueous chemistry of

the copper-cyanide-sulfide system; Although

a large amount of

research has been reported for copper cyanide extraction, there have

been no investigations reported for leaching chalcocite under

nonoxidizing conditions. Values

of the required thermodynamic data

were given in the literature. However, the published equilibrium

constants showed considerable variation from one report to another.

A s e r i e s of equilibrium and masa balance equations were

written to describe the concentrations of the aqueous species to be

expected in the leaching system.

A finite ionic radius form of the

Debye-Huckel equation was used to calculate the activity coefficients.

A numerical method for solving these equations is presented that is

slow, but stable. These calculations show

xiii

that t h e c o p p e r o c c u r s a s

xi v

t h e t e t r a - and tricyanide complexes and the sulfur primarily as the

bisulfide ion. The coupling

of the cyanide and sulfur systems through

a common hydrogen ion dependence complicates the s y s t e m

.

.

considerably.

The material used in the study was a m a s s i v e c h a l c o c i t e f r o m

t h e New Cornelia Mine in Ajo, Arizona, After dry grinding and

sizing, a detailed analysis was made which showed that the sample

was approximately 97 percent chalcocite with minor amounts of

q u a r t z and hematite.

. .

Various empirical rate equations were tested. Although there

was considerable scatter in the data which may have concealed some

. .'

minor effects, the following were found to

be significant for a pH o v e r

10 and a total cyanide concentration from 0. 16 M t o 0.6 M.

The

activation energy of 2.5 k c a l / m o l e of copper suggests that the reaction

is diffusion controlled. It

is first order in free cyanide concentration

and exhibits a low order inverse dependence on sulfide ion concentration. Microscopic examination

of the leached particles showed

a

definite increase in the shape factor during the experiment. However,

it was found that a shrinking core model based on perfect spheres

gave an adequate approximation up to an extraction of about 80 percent.

0

Thus, at 25 C, t heem p i r i craalet eq u a t i o n

is:

..

xv

7.5 x lo5 A [CN"]

R=

M/min

Several significant pH effects were noted.

'

A s a consequence

of the large differences between the hydrogen cyanide and, bisulfide

dissociation constants and the high consumption of cyanide during the

e x t r a c t i o n , t h e r e is a pH above which pH i n c r e a s e s d u r i n g t h e l e a c h

and below which

it d e c r e a s e s . T h e r e i s a l s o

a maximum in the

leaching rate at about the same point. Under the conditions used in

this study, this pH was about 10.

The actual extraction data is presented s o that the major

.

variables to be encountered in a c o m m e r c i a l p r o c e s s c a n be evaluated.

E x t r a c t i o n s a s h i g h a s 90 percent in fifteen minutes were obtained o n

the -28, $35 m e s h f r a c t i o n when there was a l a r g e e x c e s s of f r e e

cyanide. In view

of the difficulty in reducing copper from the higher

complexes, it is doubtful that such high cyanide to copper ratios could

be u s e d i n a c t u a l p r a c t i c e . T h e e f f e c t s

of t h e m a j o r p r o c e s s v a r i a b l e s

on extraction rate are discussed in some detail.'

CHAPTER 1

INTRODUCTION

. .

The hydrometallurgical tr'eatment of copper concentrates has

. .

received considerable attention in recent years as a r e s u l t of the

emission standards that have been imposed

more, an increased awareness

upon s m e l t e r s . F u r t h e r -

of resource conservation has prompted

studies of methods that can produce higher recoveries or treat lower

g r a d e m a t e r i a l s t h a n c a n be economically treated at the present

time. Hydrometallurgical processes

are, i n g e n e r a l , b e t t e r s u i t e d

for treating mineralogically complex ores. Finally, the development of p r o c e s s e s t h a t a r e o p t i m a l f o r p a r t i c u l a r o r e t y p e s r a t h e r

than treating all copper ores by a single process is becoming increasingly important.

Thus, processes that offer an improved

m e a n s of t r e a t i n g a limited group of concentrates with resultant

lower pollution problems o r h i g h e r o v e r a l l c o p p e r r e c o v e r y m e r i t

serious consideration. Such consideration should also be given to

the recovery of by-products which may become economically important in the future.

The commercially important copper minerals may

be divided

into three distinct categories with regard to their hydrometallurgy:

oxides,sulfidesotherthanchalcopyrite,andchalcopyrite.The

1

2

leaching of oxides with sulfuric acid is well established and will not

be considered here.

The s e p a r a t i o n of chalcopyrite from chalco-

cite, covellite, and bornite is based on'its .much lower leaching rate.

A few mining operations produce other minerals such as enargite or

which s e r i o u s l y

concentrates containing impurities such as bismuth

affect smelting, Despite the significant tonnages

of chalcopyrite

concentrates that are produced, the production

of concentrates con-

taining most of the copper values

as chalcocite is sufficiently large to

justify a p r o c e s s t h a t is unable to d i r e c t l y t r e a t c h a l c o p y r i t e . I t

should be noted, however, that

Hiskey and Wadsworth (1974) have

r e p o r t e d a method of .altering chalcopyrite t o chalcocite which might

enable many processes that will not tre'at chalcopyrite concentrates

d i r e c t l y t o be successfully adapted to such use.

In Arizona and New

Mexico alone the Tyrone, Morenci and Metcalf operations

Phelps Dodge Corporation, the Chino Mines Division

Copper Corporation, and the Inspiration Branch

Consolidated Copper Company produce

of the Kennecott

of the Inspiration

m o s t of t h e i r c o p p e r f r o m

chalcocite. The daily concentrate tonnages

are approximately 1 5 0 0 ,

1600, 1000, 8 0 0 , and 225 respectively.Before

the Copper Queen Branch

of the

its r e c e n t c l o s u r e ,

of the Phelps Dodge Corporation also

produced a chalcocite concentrate.

.

.

e

e

3

In most ore bodies where chalcocite is the dominant. copper

m i n e r a l it o c c u r s a s a rim on pyrite grains. Figure

typical section of a chalcocite-pyrite vein.

1 shows a

Even considering that

the final concentrates are typically finer than 50 percent mi;nus 325

mesh, the difficulty in separating the chalcocite and pyrite

tation is r e a d i l y s e e n . P a r t l y a s

by flo-

a consequence of this intimate

association of chalcocite and pyrite, most concentrators treating

such ores have copper extractions as low a s 80 percent with the

70 percent. Because pyrite

pyrite in the final concentrate as high as

is 53 percent sulfur, the load imposed

on the sulfur removal facilities

a t a smelter is considerable. Furthermore, since the iron must

be

r e m o v e d a s a i r o n s i l i c a t e s l a g , a high flux usage and large copper

loss in the slag result. These major effects on smelter economics

often require the adjustment of concentrator operating conditions to

produce a concentrate grade that is suitable for smelting at the expense of copper extraction. Consequently, alternatives to smelting

t h a t do not affect pyrite would probably allow a higher copper extraction in the concentrator.

Since cyanide leaching of chalcocite does not produce atmospheric pollution and cyanide does not attack pyrite, the topic

of t h i s

d i s s e r t a t i o n is relevant to an important environmental and resource

conservation need. The following sections

of this chapter give

brief outline of the proposed process for producing copper

by

a

4

Pyrite

F i g u r e 1.

n'

Chalcocite

Polished Section of a Vein f r o m a

Typical Chalcocite 0re.Body (125X)

5

cyanidation and a description of the topics covered by this dissertation.

A more detailed discussion of previous work with t h e p e r - '

tinent references is given in Chapter 2.

Leaching with Cyanide

The general response of the copper minerals to cyanide leaching has been reported in the literature.

For t h e p r e s e n t t i m e i t is

sufficient to note that the oxides and sulfides, with the exception of

chalcopyrite, are readily soluble. However, those minerals such

as covellite, cuprite, and azurite having copper in the higher oxidation state cause the oxidation of cyanide to cyanogen and conse. .

quently consume significant quantities of cyanide. There has been

some unreported work by the Treadwell Company using sulfur

dioxide as a reductant to circumvent this problem but no definite results are available. Because

of t h e l o s s of cyanide to cyanogen with

many minerals, the relative i.nsolubility of chalcopyrite, the ready

solubility of the oxides in acid, and the large tonnages

of chalcocite

concentrates available for possible treatment, this dissertation

considers only the leaching of chalcocite.

In the presence of oxygen

numerous side reactions occur which considerably complicate the

system and consume cyanide.

,

A s will b e shown later, chalcocite

dissolves rapidly in cyanide solutions under nonoxidizing conditions.

These facts indicate that the optimum commercial approach will

6

probably be leaching under nonoxidizing conditions.

A s a conse-

quence of t h e s e c o n s i d e r a t i o n s only the leaching of chalcocite under

nonoxidizing conditions was studied.

There are several advantages to leaching chalcocite in a

cyanide solution. First is the major advantage associated with

hydrometallurgical methods: the elimination

tion. Considering that

all

of atmospheric pollu-

a recent report indicates that

82 million

.

dollars was spent on pollution control equipment at the Hidalgo

s m e l t e r of the Phelps Dodge Corporation alone (Cousland, 1975), the

potential capital savings could be very significant for this reason by

i t s e l f . F u r t h e r m o r e ,. cyanide

.

does not reactwith the pyrite that is

commonly associated with chalcocite. Consequently,

a cyanide leach

d o e s n o t l i b e r a t e t h e s u l f u r f r o m t h e p y r i t eas smelting does thus

reducing the quantity of sulfur oxides that must be treated, Modification of mill practice to maximize extraction of c o p p e r a l m o s t

without regard to concentrate grade may thus become feas.ible in

many operations since. the economic penalty for the increased pyrite

i n t h e c o n c e n t r a t e would be much less with cyanide leaching than with

smelting. Unlike many other hydrometallurgical processes, cyanide

leaching will recover the precious metal values except those locked

in either the pyrite or the

gangue. Becaus,e copper enters the solu-

tion as cuprous ion, only half as much reductant i s r e q u i r e d f o r a

cyanide off-.solution compared to acid or ammonia leach solutions.

7

Since the extraction rate is high, i t m i g h t b e p o s s i b l e t o t r e a t t h e

coarse, rougher Concentrate directly thus eliminating

the r e g r i n d

and cleaner flotation stages in the concentrator resulting in

a

major capital and power savings.

The pyrite concentrate that could be easily produced from the

leach residue i s a potential source of both iron and sulfur. Habashi

(1969) describes the Duisburger Kupferhiitte plant which has treated

pyrite cinder from sulfuric acid production since 1876. Pyrite concenkrates are purchased worldwide from sources as f a r a s Canada

and shipped to sulfuric acid plants throughout Germany. The resulting cinder is thewtreated at Duisburg to recover the nonferrous

metal values and produce iron oxide pellets for blast furnace feed.

Guccione (1965) outlines practices at Montecatini's plant at

Follonica, Italy, which produces sulfuric acid, magnetite pellets,

and electrical power from pyrite concentrates.

A similar p r o c e s s

at Kokkola by Outokumpu Oy produces elemental sulfur and iron

oxidepellets(Guccione,

1966). Finally,Remirez

(1968) d e s c r i b e s

a Japanese plant for producing sulfuric acid and iron oxide pellets.

.. The Tyrone concentrator alone could produce about one thousand

t o n s p e r day of p y r i t e c o n c e n t r a t e s a s r e s i d u e f r o m a cyanide leach.

Consequently, the values obtained from the production

of by-product

iron obtainable with cyanide leaching but not smelting might offset

m u c h of the higher operating costs of the cyanide leach.

8

The following are the primary drawbacks to cyanide leaching.

First, the recovery of the metal from the cyanide complexes formed

during the leach appears to be difficult. The high free energies

of

the complexes lead to high voltages and low current efficiencies

during electrowinning while direct acidification reprecipitates

cuprous sulfide. The latter approach

would allow rejection of the

pyrite in the feed even though it would require smelting of the synthetic chalcocite s o produced. Upgrading the leach solution by

solvent extraction has not been investigated although some reports

indicate that it should be possible. The direct reduction

of c o p p e r b y

hydrogen or other reductants has likewise not bel-n reported.

.

.

Cyanide losses in the presence of oxidants including Cu(I1) could be

..

significant with some concentrates.

Air introduction into the system

could result in the formation of a s e r i e s of polythionates which would

react with cyanide to form cyanate.

N o studies have been made on

removing the sulfide ion produced during the leach. Finally,

the

toxicity of cyanide solutions requires care in handling and special

precautions to prevent the discharge of cyanide-bearing solutions

. .

f r o m t h e plant.

If these difficulties can be overcome, cyanide

leaching of chalcocite concentrates could be a v e r y a t t r a c t i v e p r o c e s s .

e

9

Development of t h e D i s s e r t a t i o n ,

In the original proposal for the dissertation topic a comprehensive study of leaching copper sulfides in alkaline cyanide solution

envisioned.

A s the work progressed, an improved knowledge

was

of the

complexities of the system and the difficulties involved in dealing

considerably.

with them made it apparent that the study needed to be considerably

more limited. An examination

of the literature indicated that chal-

cocite would dissolve in cyanide solutions without oxidation

sulfide ion. However, 'when

of the

air w a s i n t r o d u c e d i n t o t h e s y s t e m

numerous poorly defined but demonstrable side reactions .resulted in

t h e l o s s of cyanide by cyanate formation (Coghill, 1912; Hedley and

Kentro, 1945; Lower and

Booth,1965aand

Tabachnick, 1968). Since cyanide loss

196513; Hedley and

and

,

would be an additional expmse

i n a c o m m e r c i a l o p e r a t i o n , a n d e n c l o s e d r e a c t o r s c o u l d e a s i l y be used

t o p r e v e n t air oxidation, a detailed study of cyanide leaching of chalcocite under oxidizing conditions appeared to be of l i t t l e p r a c t i c a l

i n t e r e s t and was therefore not attempted. In view

of the oxidation of

cyanide by Cu(I1) a study of leaching a c u p r i c m i n e r a l u n d e r r e d u c i n g

conditions would probably be a m o r e r e a s o n a b l e n e x t s t e p .

T h e c h e m i s t r y of the system was investigated and w a s found t o

be dominated by the equilibria among the copper cyanide complexes,

free cyanide ion,

and hydrogen cyanide. The cyanide ion-hydrogen

cyanide equilibria couples with the sulfide-bisulfide-hydrogen sulfide

10

system through their common hydrogen ion dependence. ConsequentSince significant pH

l y s e v e r a l i n t e r e s t i n g pH effects were found:

changes were noted during the leach as

the sulfide ion produced

a r e s u l t of t h e h y d r o l y s i s of

by the dissolution of chalcocite, a s y s t e m of

nine simultaneous nonlinear equations was required to describe the

it be-

concentrations of the ionic species. During the data analysis

came apparent that the concentrations could not be u s e d d i r e c t l y f o r

activities of the solution strengths

of practical interest. Consequently,

Debye-Hiickel equations of the following f o r m

were introduced. This improvement led to an additional seven simultaneous nonlinear equations for the required activity coefficient

ratios. These equations contained nine ionic size parameters which

w e r e e s t i m a t e d .but not optimized. The values

of the thermodynamic

constants obtained from the literature showed considerable variation.

. .

Since the literature clearly indicated that these variations resulted

from the inherent difficulties in determining the equilibrium constants, and consequently, that

a m a j o r r e s e a r c h e f f o r t would be

necessary to improve upon the reported values,

no effort was made

t o experimentally determine these constants during this

author believes that the improvements in the calculations

stud,y. The

of the

concentrations that would result from improved equilibrium

'

11

constants would be of m i n o r i m p o r t a n c e f r o m a practical standpoint

since such variables as the particle geometry

of actual concentrates

would contribute significantly larger errors.

Since the system described above-could not be solved and inte'

grated analytically to obtain an expression for total copper as

a

function of t i m e , a derivative method had to be used to study the

kinetics., To accomplish this, the total copper versus time curve

was fitted with an exponential equation and the rate

at each sampling

point'calculated by the derivative of the fitted curve. The -solution

the sixteen simultaneous equations for the concentrations

of

of the ionic

species at each sample point during the leach together with the rates

obtained as described'above allowed determination of a n e x p e r i m e n t a l

r a t e law that adequately describes the data in t h e r a n g e of cyanide

concentration from 0. 01M to 0. 5M, pH f r o m 9 t o 13, sulfide ion

0

concentration from 0. O O O O l M to O.lM, and t e m p e r a t u r e f r o m 3 C t o

0

70 C.

The uncertainties in the above data made

p r e c i s e m e c h a n i s m of reaction could not

it c l e a r t h a t a

be verified. Consequently,

a general explanation of t h e r e a c t i o n r a t e i n t e r m s of the solution

chemistry was developed. The author believes that such treatment

is adequate at this point in the development

of t h e p r o c e s s and that

the immediate ne'ed i s f o r w o r k on o t h e r p r o c e s s s t e p s .

Finally, for the benefit

of those who c o u l d u t i l i z e t h e r e s d t s

of the leach tests for rough approximations in studies

of proposed

p r o c e s s e s , a discussion of c o p p e r e x t r a c t i o n i n t e r m s of the process

v a r i a b l e s is presented in Chapter 7.

The r a w d a t a f r o m t h e l e a c h

t e s t s a r e given in Appendix III should anyone wish to attempt a

different analysis of them.

CHAPTER 2

REVIEW O F THE LITERATURE

This chapter will trace the major developments in the understanding of copper cyanide chemistry and its application to copper

metallurgy. Because most

of the early experimental work was con-

c e r n e d with obtaining a reasonable leaching rate with precious metal

ores containing copper rather than the leaching

themselves, the early work will be sketched

of the copper minerals

only briefly.

Copper as a Cyanacide in Precious Metal Cyanidation

A fairly comprehensive review of previous experience with

copper in cyanide leach solutions is given by Virgoe

states that the high cyanide consumptions

(1901).

Virgoe

in such solutions is a r e s u l t

of the formation of the double and triple salts, KCU(CN)~ and

K2Cu(CN)andtheoxidation

3’

salts present.

of cyanide to cyanogen by any cupric

In addition, Virgoe explains the

low p r e c i o u s m e t a l e x -

tractions commonly reported as resulting from errors in determining

the free cyanide concentration by t h e c l a s s i c a l s i l v e r n i t r a t e t i t r a t i o n .

..

Virgoe (1901) e l a b o r a t e s on his previous paper indicating that it

opinion that the double and triple salts are the only ones

of concern to

the cyanide plant operators and that the double salt exists only

absence of free cyanide. Coghill

is h i s

i n the

(1912), a f t e r p r o p o s i n g s e v e r a l

13

e

14

possib,le r e a c:tions.conclu .des that sulfides may lead to the formation

of thiocyanate and that the cyanide consumption may range from

2.0

t o 3 . 6 p a r t s p e r part of copper depending on the particular copper

mineral involved. Halferdahl (1929) describes many methods including

acidification and electrowinning that had been proposed or u s e d t o

regenerate cyanide from solutions fouled by copper. Halferdahl's

paper is fairly'comprehensive and covers most of t h e r e a g e n t s o r

methods that have been proposed recently for copper recovery from

cyanide solutions.

In t h i s r e s p e c t i t is .also interesting to note that

Richmond (1907) reports commercial electrowinning

of copper and

precious metals at the San Sebastian Mine, San Salvador. The copper

and gold were first electrowon together then separated in an e l e c t r o refining operation.

In all, 24, 391 pounds of copper cement were pro-

ducedbetweenMay,1905,andApril,1906.Severalmorerecent

papers including McLachlan, Ames, and Morton

(1946), Hedley (1946),

and Hedley and Tabachnick (1968) also discuss the role

of copper in

the cyanidation of p r e c i o u s m e t a l o r e s .

Leaching Copper Minerals With Cyanide

Leaver and Woolf (1931) reported the results of a series of tests

run on artificial ores made by mixing crushed copper minerals with

sea sand.' The tests were made with varying amounts

oxidizing conditions. The results

of cyanide under

of a few of the,ir experiments are

,

15

presented in Table

and Booth (1965a,

1.

The leach time was twenty-four hours. Lower

196513) r e p o r t r e s u l t s of a n o t h e r s e r i e s of t e s t s on

in Table 2.

various copper minerals. Their results are presented

T h e l e a c h t i m e s w e r e six hours except as noted. These

tests clear.ly

indicate that all commercially important copper.minera1s except chall

copyrite leach readily in the presence of adequate cyanide.

The Nature of the Copper Complexes

T h e e a r l y i n v e s t i g a t o r s of cyanide chemistry proposed various

copper cyanide salts on the basis of the cyanide loss in p r e c i o u s m e t a l

leach solutions with the molar ratio of cyanide to copper usually

being given a s two or three to one.

'

Based on measurements of vapor

p r e s s u r e , pH, and conductivity, Britton and

thespeciesformed

2-

is Cu(CN)

3

.

Dodd (1935) s t a t e t h a t

A study of t h e s i l v e r n i t r a t e

t i t r a t i o n of cyanide solutions by W i l l i s and Woodcock (1950) showed

21that C U ( C N ) ~andCu(CN)existinequilibrium.

3

It wastheiropinion

that typical precious metal cyaniding solutions contain a negligible

3concentration of Cu(CN) An

4 '

infrared absorption study by

Penneman and Jones (1956) identified peaks which they assigned to

.

23CU(CN)~andCU(CN)~

Whilethedicyanidecomplexwasobserved,

its low extinction coefficient made

its measurement difficult.

In the

following years other authors also identified these complexes. In

studies of t h e R a m a n s p e c t r a of the copper cyanides both Chantry

16

TABLE 1

SOLUBILITY O F C O P P E R M I N E M L S

.FROM LEAVER AND WOOLF (1931)

(%)

Name of Mineral

Extraction

.

Azurite

100.

Bornite

94.

Chalcocite

100.

Chalcopyrite

6.4

Chrysocolla

16. 9

Cuprite

Enargite

Malachite

Tetrahedrite

Metallic Copper

1.00.

96.9

100.

40.3

100.

17

SOLUBILITY OF COPPER MUVERALS

FROM LOWER AND BOOTH (1965a)

a

Ratio CyanideMineral

Chalcocite

Extraction (%)

2.76

Cuprite

4.94

4.4899.7

Malachite

Azurite

3.62

b

Covellite

95.6

91.8

5. 15

Chalcopyrite'

b

Bornite,

5. 13

a

G r a m s NaCN p e r g r a m of contained copper.

b

C

Four h o u r l e a c h i n t h e s e t e s t sonly.

Minus 325 mesh mineral used in this test.

96.0

18

(1966) reported identification of

and Plane (1960) and Cooper and Plane

the three complexes. Rothbaum (1957) used the ultraviolet absorption

0

0

s p e c t r a and static electrode potentials at 20 C and.at 80 C t o d e t e r mine both the nature and equilibrium constants

and Waind (1958) studied the system

of the system. Simpson

by ultraviolet absorption spectra

a s did Baxendale and Westcott (1959). The latter authors also

described the kinetics of t h e r e a c t i o n of Cu(I1) and cyanide. Brenner

(1965) studied the equilibria of the 'complexes 'calorimetrically and

reported values for the equilibrium constants. FinalIy, Izatt

et al.

(1967) reported log K, AHo, and ASo values f o r the Cu(1) complexes of

cyanide.

It has therefore been rather clearly established that the

23complexes Cu(CN) 1- , C U ( C N ) ~, and C U ( C N ) ~

, cqexist in cyanide

2

solutions and that the relative dominance of a n y p a r t i c u l a r s p e c i e s is a

function of the cyanide to copper ratio,

pH, and the values of t h e

equilibrium constants. Since cuprous cyanide

is e s s e n t i a l l y i n s o l u b l e ,

t h e r e i s a low solubility of copper for the lower cyanide to copper

ratios. The values

of the equilibrium constants will

be d i s c u s s e d i n

d e t a i l i n C h a p t e r 3.

Dissolution of Chalcocite and Covellite in Cyanide Solution

Potashnikov and Kakovskii (1962) made

a preliminary study of

the dissolution of chalcocite in a cyanide solution in the presence of

oxygen. They observed both sulfur and covellite

films o n t h e i r

19

rotating disk and reported confirmation of the following reactions.

2Cu2S t 6CN1- t H 0 t *O =2CuS t ~ C U ( C2N )t ~2.0H1. 2

2

2CuS t 6CN1- t HZO t %02= 2 S o t ~ C U ( C N )t~20H13

They indicate that thiocyanate formed

(2.1)

(2.2)

. .

but did not d e t e r m i n e t h e r e a c -

tion by which it formed. In addition, their experiments demonstrated

In a later paper, Kakovskii and Potashnikov

(1964) determined

the kinetics of the dissolution of covellite in cyanide solution with a

rotating disk. The existence

of the following two competing reactions

was reported and the predominance

. .

of one o r the other related to the'

oxygen partial pressure.

2CuS t 8CN1- t O2 t 2H 0 = ~ C U ( C N )t~ 2So

t (CN)2 t 40H1- (2.3)

2

3

2CuS t 7CN1=ZCu(CN);-

t S2- t CNS 1-

(2.4)

These authors also state that covellite, chalcocite, and argentite all

'

exhibit first order kinetics with regard to'cyanide ion, that the kin e t i c s a r e r e a c t i o n c o n t r o l l e d f o r c o v e l l i t e a n d a r g e n t i t e but diffusion

controlled for chalcocite, and that the rate

of d i s s o l u t i o n d e c r e a s e s

with increasing time for the copper sulfides in the presence

No r e p o r t w a s m a d e of studies under nonoxidizing conditions.

of oxygen.

A

special note was made that the increase in reaction rate with temperature was markedly less for chalcocite than for the other minerals.

. .

20

These reports clearly indicate that oxygen will lead to thiocy-,

anate formation during the leaching

of chalcocite. In view

.

of the high

extraction rates reported later in this dissertation for chalcocite

under nonoxidizing conditions, the economic 'advantage

of excluding

a i r o r other oxidants is ,clear.

Electrowinning from Cyanide Solutions

Since it was anticipated that

a study of electrowinning copper

from the chalcocite leach solutions

would be m a d e l a t e r , a s h o r t lit-

erature search was made

on t h e s u b j e c t t o d e t e r m i n e w h e t h e r o r

not

any constraints would be imposed on t h e l e a c h s y s t e m by subsequent

. ..

electrowinning.Richmond(1907)r'eportedcommercial-scaleelectro-

winning but did not

discuss either current efficiencies or energy con-

sumption. Because the primary values involved were gold rather than

copper, it i s quite likely that low current 'efficiencies would have been

tolerated. Glasstonk (1929) reports curr,ent efficiencies ranging from

0 t o 100 per cent, some

of which a r e p r e s e n t e d i n T a b l e 3.

Glasstone further reports that current efficiencies increased with

temperature. From Figure

2 and the reported cathode potential for

hydrogen reduction in cyanide solution o f -0.65 volt, one can readily

s e e t h a t m o l a r r a t i o s of cyanide t o copper over about 3 . 2 : l result in

formation of hydrogen and consequent low c u r r e n t e f f i c i e n c i e s .

Clevenger (1916) also reports

low current efficiencies in experiments

.

.

.

81

TABLE 3

CATHODE POTENTIAL AND CURRENT EFFICIENCIES

FROM GLASSTONE (1929) FOR SOLUTIONS 0 . 1 N.IN KCN

Current Density

Solution la

Cathode

Current

Potential

Efficiency

Potential

Efficiency

(amps/cm2)

(amp/ft2)c

x1 04

(%I

(VI

0.09

.

1.0

4; 0

-0.39 0.56

0.37

1.4

100.

9.3

a

b

C '

d

.

.

"-

-0.93

62

- 1.05

36

47

- 1.27

21

22

-1.43

9

"-

-0.34 .

100

-1. 13

-1.41

,

d

Cyanide t o copper ratio 2:l

Cyanide to copper ratio 4:l

Calculatedfromtheoriginaldata

(% 1

(VI

-0.77

-0.29

6.0

15.

Solution 2 b

Cathode

Current

'

Current efficiencies not reported in original article

d

0

I

-.

I

0

m

I

0

\D

I

0

w

N

0

0

N

+

0

+I

0

I

22

.

on copper-bearing precious metal le'ach solutions.Thus,

that while high current efficiencies can

23

it a, p p e a r s

be obtained under some condi-

tions, the conditions most favorable for-leaching

will r e s u l t in

exceptionally low current efficiencies.

Proposed Processes for Cyanidation of Copper-Bearing Materials

With the exception of the previously noted work at San Sebastian

(Richmond, 1907), no r e f e r e n c e w a s found t h a t r e p o r t e d c o m m e r c i a l

extraction of copper' from cyanide solutions. Many processes involving cyanide leaching have been proposed,

but none tested on any

reasonable scale.

Lower and Booth (1965a and

would use cyanide to leach

196513) d e s c r i b e a method that

a copper ore. Copper would then

be

precipitated as cuprous sulfide concurrently with recovery of the

cyanide as hydrocyanic acid by the addition of sulfuric acid to the pregnant solution. The high-grade cuprous sulfide

would then be t r e a t e d

by conventional methods. The major problems appear to

be economic:

t h e l o s s of cyanide by oxidation, complexation, and entrainment in the

tailings, together with the high capital costs

of leaching the entire low-

grade feed. The Engineering and Mining Journal staff (1967) reviewed

. .

five inventions for the recovery

of copper with cyanide. The

first w a s

the Treadwell process which essentially upgraded an acid solution of

cupric sulfate by precipitating cuprous cyanide.

A second Treadwell

24

patent leaches the ore'with cyanide, then precipitates cuprous sulfide

by acidification. The other three are basically similar to those patents already described. Chamberlain,

Newton,andClifton

(1969)

have described a p r o c e s s f o r t r e a t i n g a copper-bearing silver leach

residue.

A s in many of the preceeding processes, the copper

is

precipitated as cuprous sulfide which is then treated conventionally.

S u m m a r y of the Literature

The copper-cyanide complexes have been clearly shown to

Cu(CN);-,

be

.

C U ( C N2 )- ,~ and C U ( C N3 -) ~ Reasonable values of t h e t h e r m o -

dynamic quantities for the equilibria have been reported. The kinetics

of the dissolution.of covellite have been reported as has some information for chalcocite under oxidizing conditions. ,There is general

agreement that, in the absenceof oxygen chalcocite leaches with the

A short review

formation of the cuprous complexes and'sulfide

ion.

of electrowinning indicates that the molar ratio

of cyanide to copper

in the leach off-solution will be critical in. obtaining acceptable current

efficiencies. The reported processes have been primarily aimed at

upgrading~ other products rather than recovering copper metal directly

from the cyanide leach solution.

CHAPTER 3

THE CHEMISTRY O F THE SYSTEM

T h e s y s t e m t h a t r e s u l t s f r o m t h e d i s s o l u t i o n of chalcocite in

alkaline cyanide solution is fairly complex when conditions are such

that few of the.ionic species present can

be neglected. Several

a t t e m p t s w e r e m a d e d u r i n g t h e e a r l i e r s t a g e s of this study to avoid

some of the complexities by carefully choosing initial conditions, but

it soon became apparent from the experimental results that

a simpli-

fied approach would be unacceptable. The 'following sections will

describe the chemical species present in the leach solution

interrelationships. The discussion

and t h e i r

of react.ion rates will be presented

in Chapter 5.

The Defining Equations for Ionic Concentrations

The reaction for the dissolution of chalcocite in cyanide solutions under nonoxidizing conditions is usually given as follows.

Cu2S + 6CN1-= ~ C U ( C N )t~ S22-

However, the situation

(3. 1 )

is in reality considerably more complicated.

The many ionic species present are related

to one another. The

r e s u l t s of t h e l i t e r a t u r e s u r v e y r e p o r t e d i n C h a p t e r 2 clearly indicate

that there are three cuprocyanide complexes present in solution that

are in equilibrium. First, the dicyanide complex dissociates to

25

'

-

27

Th.e respective equilibr :ium consstants i n t e r m s of the ionic ac i t i yrities

are then defined as follows.

UCu(CN)i'

aCN1:

L

Since significant amounts of copper can occur only as the three

complexes, the copper. mass balance may

be written as follows where

FuT] is the concentration of cuprous ion that would r e s u l t i f a l l t h e

, .

copper present in solution were in that form.

[

.

u

T

]

= [c.(CN)i-]

+

bu(CN)i-] t

[Cu(CN)'-]

2

(3.9)

The concentration of a particular copper complex may be v e r y s m a l l

a t a n y g i v e n t i m e d u r i n g t h e t e s t a sa r e s u l t of the test conditions.

All, however, need to

be c o n s i d e r e d a s a r e s u l t of the range of

conditions used.

The stepwise dissociation of hydrogen sulfide can be t r e a t e d in

a similar manner. This treatment

i s r e q u i r e d a s a r e s u l t of the

hydrolysis of the sulfide ion formed during the leaching of the chalcocite. The stepwise hydrolysis can

be r e p r e s e n t e d by the following.

28

S2- t H 0 = HS1- t OH12

HS1-

t H 2 0 = H2S t OH

(3.10)

1-

(3. 11)'

The f i r s t d i s s o c i a t i o n of hydrogen sulfide may be written as follows.

1+

K1

H S =

2

t H

HS1-

(3.12)

The- equilibrium constant is then given by equation 3 . 13.

aHsl- aHl+

K

1

=

(3. 13)

U

H,S

L

Similarly, the second dissociation follows.

( 3 . 14)

aHlt

aS2K, =

( 3 . 15)

L

uHS1A sulfur.mass balance can then be w r i t t e n a s shown below where

is the total concentration of all sulfur species.

[ST] =

[.zS]

t [HS1-]

t [S2-]

(3. 16)

The relation between the total sulfur concentration and the copper

e x t r a c t i o n m a y be derived from the net reaction stoichiometry.

cu

s =

2

2CUlt

t

s2-

I

(3.17)

29

Consequently, the total sulfur concentration is given

by the sum of the

initial concentration, [Sd, and one-half the molar copper concentra.

taion resulting from the leaching

of the chalcocite.

Moles

(3. 18)

Vol

In solutions below a pH of about '11 a significant amount of

cyanide ion hydrolizes t o hydrogen cyanide as illustrated by equation

3. 19.

CN1-

t H 2 0 = HCN

+

OH1-

(3. 19)

The dissociation of the hydrogen cyanide may be e x p r e s s e d a s follows.

HCN

KA

KA

Z

-

CN

1-

i

t .H

aH CN

(3.20)

(3.21)

The cyanide mass balance can then be w r i t t e n a s i n d i c a t e d below

where [.NT]

is the concentration of f r e e c y a n i d e that would r e s u l t i f

all the cyanide were present in this form.

Because it i s computationally simpler to deal with the hydroxyl ion

concentration than the hydrogen ion concentration in the higher pH

raltse, the dissociation of water must be considered.

30

K

H 2(3.23)

0 -w

OH1-

a,1+

K

W

=

'

aoH1-

(3. 24)

6

H2°

The mass balance for the hydroxyl ion is somewhat more difficult to

write since the dissociation

of water is involved. In solutions whose

pH is 8 or greater, the hydrogen ion concentration is less than

10

-8

M.

This concentration is much less than that required to hydrolize the

sulfide ion formed during the leaching of the chalcocite under the test

conditions that were used. Consequently,' one may assume €hat the

concentration of hydrogen ion is negligible and the following mass.

balance can be w r i t t e n w h e r e t h e s u b s c r i p t-j r e f e r s t o s o m e t i m e at

which the concentrations

of a l l s p e c i e s a r e known and -j t 1 t o t h e

t i m e a t w h i c h t h e c o n c e n t r a t i o n s a r e t o be calculated.

[OH"].

J + 1

- .[OH"Ij

= [HCNIj

-

kCNlj

(3.25)

Early attempts to determinea rate expression indicated that

t h e u s e of concentrations for activities would be insufficient.

T h e r e f o r e , a finite ionic radius form of the Debye-Hiickel equation

was used to calculate activity coefficients. .For species

i, the

natural

31

logarithm of the activity coefficient,

Y ,is given by equation 3. 26

where A and B

- a r e Debye-Hiickel constants, z. i s the charge on the

.

-1

p is the ionic strength.

ion, a. is the ionic radius, and

-1

(3.26)

The mean ionic strength, p , is given by the following equation when

the solution density is essentially the same as the density of water.

The c. are the concentrations

-1

fJ

=

of the ionic species.

2

(3. 27)

c.2.

i

1 1

K

=

4,3

[Cu(CN)i-]

’

Defining an activity coefficient ratio,

equation.

YCu (CN)2 - YcNl3

‘YC U ( C N3-) ~.

F4, 3’

(3.28)

leads to the following

*

32

Equzition 3. 30 then follows by s t1bstittuti on intc) equai:ion 3. 28.

[Cu(CN):-]

[CN”]

F

(3.30)

4,3

Similarly, the dissociation constant for the tricyanide,

K3, 2’

can be

written as follows.

[Cu(CN)i-]

[C.N”]

(3.31)

Solving equation . 3.24

which gives the dissociation of w a t e r f o r

.

the hydrogen ion activity, assuming that the activity

of w a t e r i s 1, and

defining an activity coefficient ratio similar to the preceeding equations

givesthefollowingequation

.

f o r thehydrogenionconcentration.

,

Kw

(3. 32)

Substituting this result into those equations involving the hydrogen ion

concentration, 3. 13, 3. 15, and 3. 21,and defining activity coefficient

ratios analogously to the preceeding gives the following equations for

the sulfide and cyanide equilibrium constants.

KW.[HS1-]

K

1

K

2

=

(3.33)

=

(3.34)

KW [CN"]

K

A

=

-2

[HCN]

[OH1-]

(3.35)

A

Substituting equation 3. 26 for the pertinent species into the

definitions of the activity coefficient ratios gives the equations

presented in Table 4.

Equation 3.27 for the mean ionic strength can

be w r i t t e n a s shown in equation 3.36

by neglecting those species such

as hydrogen ion whose concentrations are.always negligible under the

conditions used.

t 4[S2-]

t [OH'I

t [.at]

t [CN"]

}

In o r d e r to run tests at higher hydrogen ion conce.ntrations than

t h o s e r e s u l t i n g f r o m t h e h y d r o l y s i s of the cyani.de and sulfide ions,

several tests 'were made using acetic acid to adjust the

pH.

Acetic

TABLE 4

THE ACTIVITY COEFFICIENT RATIOS

F1

F2

-

1

.

EXP{A$[

.

1

-

1 1- Bp2a

HS1-

+

1 t Bp'a

HS

1-

1

1

1 t Bp'a

OH11

1

1 t Bp'a

F

W

=

. .

CN1-

-

1

4

1 -t Bp'a S2-

I)

W

t&

35

a c i d wa.s used since it i s nor!toxidizin.g and do e s n o t f o r m str on

complexes with copper.

In a manner. similar to the previous sections

the following equations result.

KAc

KW [Acl-]

-

.F

(3.37)

Ac

[HAC]

[OH”]

(3.38)

In addition,. [Acl-] m u s t be added to equation 3. 36 f o r t h e i o n i c

strength and

[HAC. J.

-

]to equation 3. 25 for the hydroxyl

p c j + l

ion mass balance.

The Thermodynamic Quantities

Many authors reported widely varying values ,for the dissociation constants of the cuprocyanide complexes. The values for

K3,2’

5.

K

4,3‘

a n d s o m e r e p o r t s f o r t h e r e l a t e d e n t h a l p i e s a r e given in Table

The values given

by Izatt et ai. (1967) were used for

tation since they appeared to

this d i s s e r -

be the most consistent. In particular;

the difficulty in measuring the absorption of Cu(CN)’- caused signifi2

c a n t p r o b l e m s f o r t h espectrophotometric.studiess u c h a s Penn- -man

and Jones (1956) and Baxendale and Westcott (1959).

Izatt et al. (1967)

36

L A D U D

J

THERMODYNAMIC QUANTITIES FOR THE

CUPROCYANIDE COMPLEXES

.

AT 25OC

3,2

Source

K

493

3-2

AH,, 3a K

Penneman

Jones

and

(1956)b

0.020

12

2.6

20

(1957) Rothbaum

andSimpson(1958)Waind

.

Baxendale

and

Westcott

(1959)

23

a

1 to 1'0

Woodcock

Willis

and (1950)

0.01

0.0005

5

x 1A0H

(1965)

7.9

.

0. 018

0. %5

Brenner

Izatt. et a l .

a

b

b

(1967)

0.5011.2

0.032

Kilocalories per mole.

V a l u e s c o r r e c t e d t o p = 0. A l l o t h e r s w e r e not reported.

11.1

37

determined their constants calorimetrically and,

in addition, had the

advantage of the previous study of hydrocyanic acid described below.

The values reported for the dissociation of hydrogen cyanide

(1966, p. 312)

also show considerable variation. Cotton and Wilkinson

r e p o r t 2. 1 x

Penne.manandJones(1956)obtainedtwoaverages

4 x 10

f r o mt h el i t e r a t u r e :

-10

and 7 x 10

Selby (1961, p. 1757) list 4.93 x 10

6.2 x 10

- 10

.

- 10

- 10, Hodgman,

, andIzatt

Weast, and

et al. (1962) r e p o r t

et al.

Sincetheexperimentalvaluesreportedby,Izatt

w e r e o b t a i n e d ' b y n u m e r o u s . e x p e r i m e n t s o v e r a range of t e m p e r a t u r e s

and were corrected to an ionic strength of z e r o , t h e y w e r e u s e d in

this study. Table

6 gives the values

of K a t v a r i o u s t e m p e r a t u r e s .

A

_ .

The equilibrium data for the other species were obtained from

a

v a r i e t y of sources. Data compiled by'Sill6n and Martell (1964) on the

,sulfide system are given in Table 7, the dissociation of water f r o m

Ackerman (1958) in Table 8, and the dissociation

of a c e t i c a c i d f r o m

..

HarnedandEhlers(1933)inTable

9.

A s canbereadilyseenby

,

'

examining the tabulated data,a considerable amount of additional work

needs to be done just defining the required equilibrium constants.

Such work, however,

quently, the best

is beyond the scope of this dissertation. Conse-

estimates of t h e c o n s t a n t s w e r e t a k e n f r o m t h e

available data with the realization that considerable scatter

introduced into the rate constant calculations.

'would be

It is unlikely, however,

e

e

38

TABLE 6

KAAND AH FOR,HCN FROM IZATT ET AL. (1962)

Temperature,

O c

10

K x 10

A

kcal/mol

..

.

AH,

.

8

11.3

10

2.34

15

3. 25

20

4.37

25

6. 17

30

7.76

35

10.2

40

13. 2

45

16.6

..

10. 4

.

.

39

TABLE 7

'

EQUILIBRIUM CONSTANTS FOR. THE

S U L F I D E S Y S T E M F R O M S I L L 6 NAND M A R T E L L (1964)

Temperature,

0

C

-log K

-log K

0

7.57

10

7.26

20

6.87

25

-7.60

6.99 12.89 -4.42

25

7.07

25

7.06

5'0

6.'66

35

6.99 12.05 -3.65

40

6.81

12.24

45

6.59

12.43

50

6.82

50

6.91

60

a

a

1 A H l ,2

- 14.40.

12.60

-5.10

12.94

12.20

12.76

-5.15

- 1.80

12.43

11.91

12.28

80

6.54

10.68

90

6.52

10.32

120

6.59

9. 27

Units a r e K c a l / m o l e .

a

2

.

.

40

TABLE 8

DISSOCIATION CONSTANT O F WATER

FROM ACKERMAN (1958)

TemperatuC

re,

.

.

0

-log K,

0

14.955

10

14.534

20

14.161

25

.

.

13.999

30

13.833

40

13.533

50

13.263

60

13.015

70

12.800

80

12.598

90

100

12.422

12.259

e

41

TABLE 9

DISSOCIATION CONSTANT O F ACETIC ACID

FROM HARNED AND EHLERS (1933)

Temperature,

0

C

-log K

Ac

0

4.7807

.5

4.7696

10

4.7622

15

4.7582

20

4.7562

25

4.7560

30

4.7570

35

4.7625

40

4.7688

45

4.7773

50

4.7870

55

4. 79.89

60

4. 8 1 1 9

e

42

that erroneous conclusi.ons as to the reaction order would r e s u l t f r o m

the variation in these data.

Temperature Dependence of the Constants

The general temperature dependence of the equilibrium

constants i s given by the following expression.

d In K

AH

-.

-

(3.40)

dT

When

AH i s

RT

2

constant this equation can be integrated to give equation

3 . 4 1 where C

- i s the constant of integration.

AH

In K

=

I.

"

: .

+ c

(3.41)

RT

When both AH and K a r e known at a given temperature, C

- can be

found by solving equation 3.4.1.

The equilibrium constant

as a

function of t e m p e r a t u r e c a n t h e n be written as follows.

K = EXP

AH.

{

C

-

-}

'.

'

(3.42)

RT

'

Using the values given by Izatt. et al. (1967) of 0.0316 f o r

K

and5.02

4,3

kcal/mole

for

x 10

AI1

-6

4,3

.

for K

392

at 2 5 O C togetherwith

11.2 and 11.1

and

AH

respectively,

the

following.expres372

sions were calculated for the cuprocyanide equilibrium constants.

43

(3.43)

K

3,2

= EXP

{ 6.54

-

(3.44)

Since the equilibrium constants for the other equilibria were

a v a i l a b l e a t s e v e r a l t e m p e r a t u r e s a n d t h e r e p o r t e d AH values often

showed considerable variation with t e m p e r a t u r e , r e g r e s s i o n a n a l y s i s

was used to f i t a straight line to an equation of the following form.

-Log K = a t b

(-9

(3.45)

L e a s t s q u a r e s a n a l y s i s of

the data in Table 7 gave the expressions for

- .

.the sulfide equilibria. The data from Table

6 were used to generate

a n e x p r e s s i o n f o r t h e d i s s o c i a t i o nof hydrogen cyanide while that for

the dissociation of water was obtained from data reported in Table 8.

Finally, the data in Table

9 indicated that the acetic acid constant

could be r e a s o n a b l y r e p r e s e n t e d bya mean value. Furthermore, ai1

the tests made with acetic acid

quently, KAc w a s t a k e n a s

a s a buffer were run

1.75 x 10

these p r o c e d u r e s are given below.

K

1

=

I< =

2

EXP

-10.1

- 1790

EXP

(-19.8

-

2717

-5

,

0

at 25 C. Conse-

Theequationsobtained

by

44

KA = E X P ,

{

-.4.36 - 5031($)

KW = E X P (-11.2

- 6286($)

}.

(3.48)

}

(3.49)

The Debye-Hiickel Constants

The constants for the finite ionic size form of the DebyeHuckel equation were obtained as follows. Bockris and Reddy (1970,

list the values of A

- and B- presented in Table

pgs. 211-212)

10.

. s q u a r e s a n a l y s i s of these data gave the following equations for

Least

A

- and

as functions of t e m p e r a t u r e .

.

.

A = 0.3519 t 1.808

X

B = (0.2576 .t 2.40

x

Theionicradius

a

-

is

10

-6

*

T

2

.(3.50)

.

T ) x IO 8

(3.51)

difficulttodefinetheoreticallysince

it

r e p r e s e n t s a distance of closest approach. Bockris and Reddy (1970,

p. 226) state: "'To circumvent the uncertainty in the quantitative

0

definition of a, it is best to regard it a s a p a r a m e t e r i n Eq. (3. l o b ) ,

i. e . , a quantity, the numerical value of which is left to be calibrated

o r a d j u s t e d o n t h e b a s i s of experiment.

for the cyanide ion, Izatt et

I'

Izatt et al. (1962) used 4

al. (1967) used 4

a

f o r all s p e c i e s s i n c e

they reported that it gave the least variation with the ionic strength,

and Penneman and Jones (1956) used 3.7

a for cyanide ion and

6.6

1

45

T A B L E 10

DEBYE~HGCKEL CONSTANTS

FROM

,

BOCKRIS AND REDDY (1970)

Temperature,

0

0

.

C

-8

.

10 B

A

.

0.4918

0.3248

10

0.4989

0.3264

20

0.5070

0.3282

25

0.5115

0.3291

30

0.5161

0.3301

0.3312

35

40

0. 5'262

0.3323

0.5373

0.3346

60

0.5494

0.3371

80

0.5767

0.3426

100

0.6086

50

.

.

'

.

0.3488

46

for the cuprocyanide complexes. The computations requiredto adjust

the ionic radii were beyond t h e r a n g e o f t h e p r e s e n t r e s e a r c h and only

a cursory attempt at adjusting them was made. Those value's that

seemed to agree best with the experimental results, especially the

11.

are given in Table

pH,

This subject would obviously be worth

considerably more attention in future work..

Discussion

On the basis of the equations presented in the preceding

sections, the following general trends can

be expected.

A s chalcocite

leaches to produce cuprous ion and sulfide ion, cyanide will

consumed t o produce the tetracyanide complex.

be r a p i d l y

A s the reaction pro-

ceeds, the free cyanide ion concentration will eventually drop resulting in the stepwise formation

of the tri- and dicyanide complexes.

If

sufficient chalcocite is leached, the formation of a cuprous cyanide

precipitate could

be expected.The

free cyanide ion concentration

w i l l d e c r e a s e r a p i d l y a s t h e m o l a r r a t i o of cyanide to copper drops

below 4:l with

a resultant decrease in the reaction rate. However,

some free cyanide will be present and a high specific reaction rate

could offset the very

low cyanide ion concentrations. The sulfide ion

formed during the leach will hydrolize to bisulfide ion with a r e s u l t a n t

i n c r e a s e i n pH as the reaction proceeds.

The concentration of sulfide

ion will be significant only in solutions of high pH while that of

'

47

TABLE 11

IONIC RADII USED I N THIS S T U D Y

0

Ionic Radii, A

Species

CN1-

4

Cu(CN):-

4

2-

Cu(CN13

1-

Cu(CN12

.HS1-

.

5

'

6.

4

-

20

OH1-

20

H1+

20

S2

20

48

hydrogen sulfide only

significantquantity

in the nearly neutral solutions.

of hydrogencyanidewill

chalcocite leaches, the formation

At lower pH, a

be present.

A s the

. .

of the cuprocyanide complexes will

result in the dissociation of the hydrogen cyanide'at a r a t e f a s t e r than

t h a t a t which the sulfide ions formed will consume hydrogen ions.

Consequently, there exists some

pH above which the pH w i l l i n c r e a s e

during the leach and below which the pH will decrease during the

leach. Since the cuprocyanide equilibrium constants decrease with

. .

i n c r e a s i n g t e m p e r a t u r e and the free cyanide ion concentration is

approximately proportional to the 'constants, the reaction rate will not

i n c r e a s e a s r a p i d l y w i t h t e m p e r a t u r e a s one might otherwise expect.

. .

The preceding sections have clearly demonstrated the need

for better thermodynamic values

if t h e s y s t e m i s t o be clearly defined.

F o r example, a s p r e a d of o v e r 200 p e r c e n t i s o b s e r v e d i n t h e v a l u e s

in Table 5 even neglecting the two exireme results..

reportedfor K

4,3

When the concentration of Cu(CN)1- can be neglected, the free cyanide

2

ion concentration is approximately proportional

to K

4,3

andtherate

expressions that depend on this concentration will be subject to

considerable error. Many

of t h e o t h e r c o n s t a n t s a r e ,

subject to even greater error.

if anything.

While the expressions used for the

. activity coefficients were sufficient for this study, the use

expressions might give better results.

of o t h e r

F o r the more concentrated

s o l u t i o n s , f u r t h e r w o r k i n t h i s a r e a would be fruitful.

CHAPTER '4,

EXPERIMENTAL EQUIPMENT AND PROCEDURES

The rapid leach rates encountered required the development

of

test equipment and procedures that differed significantly

f r o m those

commonly used to study hydrometallurgical systems. Several

approaches were iried before the approach described below was

.

.

adopted.

Equipment

The leach study was carried

out in a specially built three-liter

reactor that was made from a seven-inch length of six-inch diameter

acrylic plastic tubing. The

nylon bolts and

t o p was secured to the reactor

wing nuts and sealea with

horsepower motor was mounted

body with

a neoprene O-ring.

on the reactor giving

A 1/70

a d i r e c t d r i v e to

t h e s t a i n l e s s s t e e l i m p e l l e r t h r o u g h a doubly-sealed ball bearing.

A

V a r i a c w a s u s e d to control motor speed. Numerous ports through the

top of the reactor allowed the mounting

of a sampling probe and return

line, thermometer, nitrogen inlet and exhaust lines, and

a sample

introduction funnel.

A sample stream was drawn continuously from the reactor

through two f i l t e r s by a variable-speed positive displacement

pump.

The first filter, which was located inside the reactor, was simply

a

49

e

'e

50

200 m e s h nylon screen secured to the end of a 3 / 8 i n c h d i a m e t e r g l a s s

tube with rubber bands. The second filter,

and pump, consisted

in-Line between the reactor

of a fine stainless steel screen supporting

glass-wool mat. These filters insured that

a

a clean sample was

'delivered to the sample vials. The in-line filter

w a s changed often

during a t e s t a s i t t e n d e d t o plug with fine, unreacted material composed principally of hematite. Since the filters were made

from

quick-disconnect couplings, a new filter could be installed with about

ten seconds downtime. The pump discharge passed through

way stopcock and then .returned to the reactor.

a three-

The s a m p l e s w e r e

taken at the desired time by turning the stopcock t o d i r e c t t h e s t r e a m

. .