Nichromet Cyanide-Free Gold Extraction Technology

advertisement

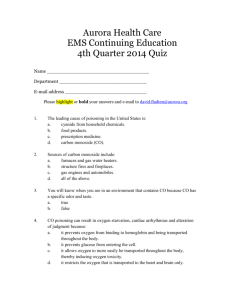

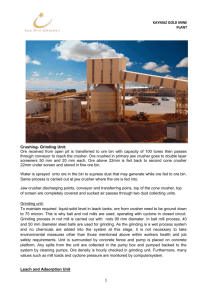

Nichromet Extraction Gold Technology 10/31/07 1 Nichromet Cyanide-Free Gold Extraction Technology A green alternative to the classical cyanide approach Give access to ores refractory to cyanidation Nichromet Extraction Inc. 3700, Lac Noir Street Thetford Mines (Qc) 418-423-7247 www.nichromet.com 10/31/07 Less costly than the classical processes without environmental mortgage on residues Can be implemented as modular plant 2 Vision Develop an economic alternative to classical cyanide process for gold extraction, while keeping a sustainable development approach minimizing the impact on the environment. 10/31/07 3 Overview of the Process Sulphides Ores Controlled Oxidation Sulfuric Acid Acid Leaching Base Metals Halogens Treatment Precious Metals Inert Tailings Nichromet Process Flowsheet Copper Removal To Atm From Concentrtor Oxidation Pre-Treatment Bag House Concentrate Copper Extraction Arsenic Scrubber SO2 Scrubber Oxidation Fluidized Bed Gypsum Gold Circuit To Arsenic Stabilization Iron Precipitation Concentrated Brine Holding Tank Chlorination Reactor Polished Brine Holding Tank Hypohalides Holding Tank Deaeration Tank Reverse Osmosis Electrolysis Cell Ca(OH)2 Na2CO3 Hematite Larox filter Tailings Iron Precipitator Calcium Precipitator Copper Cementation Pregnant Brine Holding Tank Carbon In Column Polishing Filtration Carbon to Gold Recovery # DE DESSIN Iron Removal TITRE Sector 00 : General Flowsheet REALISE PAR Blister Copper David Lemieux PAGE 1 SUR 1 DATE DE MODIFICATION 2013-02-12 Advantages Over Cyanide Faster Reaction Time Process time of few hours instead of few days Legal issues Cyanidation has been banned in many countries and some States in USA (ex:Wisconsin) Extraction of silver and PGM if present 10/31/07 6 Environmental Advantages No cyanide No tailings pond (elimination of spillage hazard) No liquid effluent Solids residues devoided of sulphides and base metals No acidic lixiviate or contaminants from tailings site 10/31/07 7 Characteristics of the Nichromet Technology Fast • Leaching time of 2 hours instead of 2 days for cyanide Flexible •Can handle base metals (bulk flotation : higher efficiency) •Can treat carbonaceous ore •Can handle telluride contamination Green • Cyanide-free process • Sulfide is recycled as sulfuric acid • No waste water, no tailing pond and no air pollutants • Solid wastes : inert and stable, even when using high arsenic ores Profitable • Process cost ($/oz gold) similar to cyanide • Capital cost lower (10-15%) than cyanide 8 Successfully piloted at the ton scale on a wide range of materials Sources Type Grade (g/T) Barren Solid (g/T) Yield (%) 1: Canada (Quebec) Ore 2,58 g/T 0,07 g/T 97,5 % 2: Canada (Quebec) Ore 3,45 g/T 0,34 g/T 93,2 % 3: Canada (Quebec) Ore 13,9 g/T 0,79 g/T 95,4 % 4: Canada (Ontario)* Conc. 55,3 g/T 4,79 g/T 94,0 % 5 : Eastern Europe* Conc. 7,5 g/T 1,48 g/T 91,0 % 6: Canada (Quebec)* Conc. 53,5 g/T 3,56 g/T 94,1 % *Flotation concentrates requiring pre-treatment by oxidation Environmental Recognition Grant of 700 k$ from Green Technologies Demonstration Program of Quebec Government in 2011-2012 Grant of 5 M$ from Sustainable Technology Development Fund of Federal Governement in 2013 10/31/07 10 Somine Haïti Project vs Nichromet Technology Current gold estimated resources (3,2 MT) Gold : 339 000 oz Au @ 3,27 g Au/T Copper : 28 Mlbs @ 0,4 %Cu Exploitation permit in force Mining plan Near surface resources (open pit potential, low operating cost) 20 M$ investment done in exploration to date 10/31/07 Great Potential for a Nichromet plant in Haïti Phase I Bring the top layer of the deposit into production with a modular plant to process oxides concentrate 15 M$ investment for the modular plant only Potential of 25 000 oz Au/year Phase II 1000 TPD Mine and full scale processing plant Gold production rate of 35 000 oz Au/yr Investment for Nichromet processing plant of 35 M$ Nichromet is currently conducting a demonstration program for the application of its technology on the Faille B deposit. 10/31/07 Toward a Greener Gold Industry 10/31/07