ME EFFECT OF ALEALI TREATMENT ON THE YIELD OF LIGNI N '

advertisement

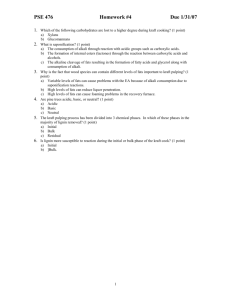

ME EFFECT OF ALEALI TREATMENT ON THE YIELD OF LIGNI N ' March 193 3 t .. f Oha".; : ' No. 8990 UNITED STATES DEPARTMENT OF AGRICULTUR E FOREST SERVIC E FOREST PRODUCTS LABORATOR Y Madison, Wisconsi n In Cooperation with the University of Wisconsin THE EFFECT OF ALcALI TREATMENT ON THE YIELD OF LIGNIN ? By ELWIN E . HARRIS, Associate Chemis t Several investigators (2, 3, 6, 7) have reported that the treatmen t of wood with dilute alkali removes a portion of the lignin . Their experi mental work was done, however, before it was found that rigid control o f temperature and time were required for an accurate determination of ligni n (4, 5, 8) . It was desirable, therefore, to repeat, with proper control o f time and temperature conditions, the experiments previously reported i n order to determine whether the decrease in lignin yield after alkali treat ment was the result of the removal of lignin or of some carbohydrate mate rial readily charred and made insoluble by the action of 72 percent sulfuri c acid . There was also the possibility that a part of the extraneous matte r was not removed by the neutral solvents commonly used in the analytica l method, that this residue was insoluble in the sulfuric acid and was remove d by the alkali treatment, thus lowering the apparent lignin yield . Cohen and Dadswell (1) have found that certain eucalypts contain large quantities o f such extraneous material and that the lignin obtained after extraction wit h neutral solvents only was contaminated with extractives . In the determination of lignin in these woods they found it necessary to extract with dilut e alkali in order to obtain any reasonable figures and they suggest that ex traction with alkali precede the lignin determination in all cases . They state that the slight decreases observed by them in lignin yield from hem lock and spruce after preliminary treatment with alkali are also due t o extraneous materials and not the removal of true lignin . When only small differences in lignin yield are caused by alkali ex traction it is difficult to decide from the lignin yields alone whether th e differences are due to the actual removal of lignin or to the removal o f extractives that would otherwise be segregated with the lignin . It is onl y by determining whether there is a change in the chemical composition of th e lignin residue that any satisfactory conclusion can be reached . The plan of the present work, therefore, included the determinatio n of the lignin by the more accurate new methods (5) and the determination o f the methoxyl content of the isolated lignin for evidence of change i n chemical composition . -Published in Analytical Edition, Industrial and Engineering Chemistry , March 15, 1933 . Report No, R990 -1- r,. Experimental Air-dried maple sawdust was used for this work . It was extracted i n a special metal extractor with hot alcohol-benzene mixture (1-2) for 4 8 hours, dried to remove the benzene, and then extracted in the same extracto r with hot water . The total loss by alcohol-benzene and water extractions wa s 13 percent of the weight of the oven-dry sawdust . The first alkali treatments were made according to the method used by Cohen and Dadswell (1) i n which the sawdust was treated with a small volume of alkali (100 cc . to 2 grams) . The loss of lignin in these treatments was roughly proportional t o the amount of solution used . Accordingly, it was necessary to increase th e volume of alkali until variations due to differences in volume would b e small . A volume of 1,200 cc . of alkali for each 6 grams of sawdust gav e results that checked within the limit of error . Two temperatures have been used most commonly by various investigator s for treatment with alkali ; namely, room temperature (about 220 C .), and on a boiling water bath (about 95° C .) . A series of treatments using 0 .5, 1 .0 , 5.0, and 10 .0 percent alkali were made at each of these temperatures . The sample, which comprised 5 to 6 grams of maple sawdust, was weighe d into a flask and 1,200 cc . of , the alkali solution was added . One group o f samples was allowed to stand 24 hours at a temperature of 22° C . and the other was heated for 2 hours at a temperature of 95 0 C, in a water bath , after which a supernatant liquor was decanted through an alundum crucible . Cold water was added to both groups and removed by decantation until the filtrate was practically neutral . This treatment was followed by washing wit h hot water, neutralizing the absorbed alkali with 5 percent acetic acid solution, and another washing with hot water until acid free, The sample wa s then washed into an alundum crucible and dried at 105° C,, after which th e loss in weight was determined . The lignin was determined according to the modified procedure in us e at the Forest Products Laboratory (5) ; the methoxyl was determined by the standard method (9) . Discussio n The results shown in table 1 confirm the previous observations that lignin was removed by alkali treatment, The lignin removed had the sam e percentage content of methoxyl as that remaining ; therefore the apparent loss of lignin was not due to nonlignin substance of the wood carried ove r into the lignin residue because of its insolubility in 72 percent sulfuri c acid . Had there been a nonlignin substance in the lignin isolated fro m untreated wood there should have been an increase in methoxyl afte r extraction . Report No . 8990 -2- A comparison of the methoxyl content of the treated wood with th e methoxyl content of the isolated lignin shows that, after the origina l treatment with alkali which would remove all methoxyl attached as in a n ester or as in pectin, the ratio is constant . The difference between th e methoxyl content of the treated wood and that of the lignin isolated fro m it may be due to a methyl-glucoside type linkage which is stable in alkal i • ?Alt hydrolyzed by acid. The values given in table 1 show that there is a close relationship between the total loss in weight and the loss in lignin . this same rati o may not be characteristic of other varieties of wood, The t`adt is establishe d that if the isolated lignin is to be. representative ell bald dquhl to the native lignin, the wood must not be treated: with alkali of any concentration before . the isolation or determination is made , Summary ti , . • f . . Previous observations on the decrease in the yield of lignin from woo d as a result of extraction with dilute alkali have been confirmed using a mor e accurate method of lignin determination . The material removed from wood by alkali treatment is really ligni n and not insoluble residues of extractives . This is shown by the constan t methoxyl content of the lignins before and after alkali treatment of th e wood . Literature Cite d (1) Cohen, W. E., and Dadswell, H . E . Chemistry of Australian Timbers , Part I . Technical Paper No . 3 (1931) . (2) Horn, O . Cellulosechemie 11, 151-2 (1930) . (3) Hawley L . F ., and Campbell, W. G . J. Ind . Eng . Chem. 19, 742 (1927) . (4) Peterson, C . J ., Walde, A . W., and Hixon, R . M . J . Ind . Eng . Chem . , anal. ed., 4, 216 (1932) . (5) Ritter, G . J ., Seborg, R . M., and Mitchell, R. L . J . Ind . Eng . Chem. , anal . ed ., 4, 202 (1932) . (6) Ross, J . H ., and Hill, A . C, Pulp and Pager fviag, of Can ., 27, 15 , 541 (1929) . (7) Routale., 0 ., and Seven, J . Ann. Acad . Sci . Fennicae, 29A, 50 (1927) . (8) Sherrard, E . C„ and Harris, E . E . Ind. Eng . Chem ., 24, 105 (1932) . (9) Tech . Assoc, Papers, Series 15, No, 1 . p . 200 (1932) ; Paper Trade J . , 94, 18, 243 (1932) . Report No, 8930 3 Table I .-Loss by alkali treatment and determinations of ligni n and methoxyl using treated maple sawdus t Alkali used : : Alkali : soluble : Lignin MeO in : NeO i n : MeO from : isolated : isolated : treate d : lignin : lignin : wood Percent - : Percentl- : Percent) - : Percent).- ; Percent - : Percentl - EXTRACTION AT 2 20 C . (1,200 cc ., 24 hours ) 0.0 .5 1.0 5 .0 10.0 0,0 8 .0 10,4 19.0 19 .2 : : 20 .9 19 .2 18.7 17 .7 17 .2 •: 4 .35 3,84 3,75 3.62 3.60 : . 6.5 4.9 4.6 4.6 4.6 21.0 20.0 20.0 20 .3 20.9 EXTRACTION AT 95 0 C . (1,200 cc ., 2 hours) 0 .0 .5 1 .0 5 .0 10 .0 : : : : 0,0 14.3 17 .4 26 .0 30 .0 : : 20.9 17 .5 17.3 16.3 15 .5 4.35 3.55 3.47 3.34 3.20 : : : : 21.0 20 .0 20 .0 20.4 20 .8 ; ': 6.5 4. 5 4.3 4. 1 3. 9 'Percentages are expressed on the weight of the original sawdus t when oven dry . Report No . R99 0