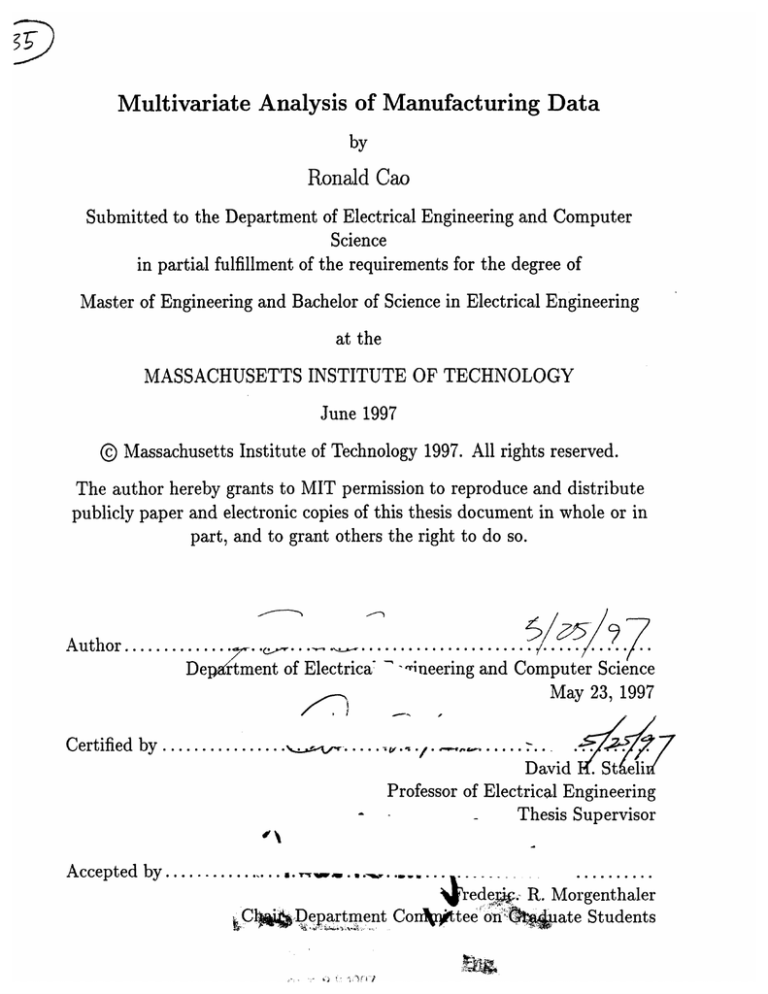

Multivariate Analysis of Manufacturing Data

by

Ronald Cao

Submitted to the Department of Electrical Engineering and Computer

Science

in partial fulfillment of the requirements for the degree of

Master of Engineering and Bachelor of Science in Electrical Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 1997

@ Massachusetts Institute of Technology 1997. All rights reserved.

The author hereby grants to MIT permission to reproduce and distribute

publicly paper and electronic copies of this thesis document in whole or in

part, and to grant others the right to do so.

..

.....

.........n

....... ""

.

Author .............. ..

Department of Electrical " ineering and Computer Science

May 23, 1997

Certified by .................~...

..

-,. . ......

David

Professor of Electrical Engineering

SThesis Supervisor

1\

Accepted by.................

:C

......

..........

"rederig- R. Morgenthaler

,Department Con~itee onorn

ate Students

/

Multivariate Analysis of Manufacturing Data

by

Ronald Cao

Submitted to the Department of Electrical Engineering and Computer Science

on May 23, 1997, in partial fulfillment of the

requirements for the degree of

Master of Engineering and Bachelor of Science in Electrical Engineering

Abstract

With the advancement of technology, manufacturing systems have become increasingly complex. Currently, many continous-time manufacturing-processes are operated by a complicated array of computers which monitor thousands of control variables. It has become more

difficult for managers and operators to determine sources of parameter variation and to

control and maintain the efficiency of their manufacturing processes.

The goal of this thesis is to present a sequence of multivariate analysis techniques that can

be applied to the analysis of information-rich data sets from web manufacturing processes.

The focus is on three main areas: identifying outliers, determining relationships among variables, and grouping variables. The questions asked are 1) how to effectively separate outliers

from the main population? 2) how to determine correlations among variables or subprocesses? and 3) what are the best methods to categorize and group physically significant

variables within a multivariate manufacturing data set?

Results of various experiments focused on the above three areas include 1) both normalized Euclidean distance and principal component analysis are effective in separating the

outliers from the main population, 2) correlation analysis of Poisson-distributed defect densities shows the difficulties in determining the true correlation between varibles, and 3) both

principal component analysis with robust correlation matrix and principal component analysis with frequency-filtered variables are effective in grouping variables. Hopefully these

results can lead to more comprehensive research in the general area of data analysis of

manufacturing processes in the future.

Thesis Supervisor: David H. Staelin

Title: Professor of Electrical Engineering

Acknowledgments

It has been an incredibly meaningful and fulfilling five years at MIT. The following are just

some of names of the people who have made tremendous contributions to my intellectual

development and my personal growth.

* My advisor, Professor David Staelin, who provided me with the guidance that I needed

on my research and thesis. He has inspired me with insightful ideas and thoughtprovoking concepts. In addition, he has given me the freedom to explore my ideas as

well as many valuable suggestions for experimentations.

* My lab partners: Junehee Lee, Michael Shwartz, Carlos Caberra, and Bill Blackwell.

Many thanks to Felicia Brady.

* Dean Bonnie Walters, Professor George W. Pratt, Professor Kirk Kolenbrander, Professor Lester Thurow, and Deborah Ullrich.

* All the friends I have made through my college life, especially my good friends David

Steel and Jake Seid and the brothers of Lambda Chi Alpha Fraternity.

* Most of all, I would like to thank my parents for their endless love and support. They

have been there through every phase of my personal and professional development.

Thank you!

Contents

1 Introduction

17

. ..

1.1

Background ...................

1.2

Previous Work

1.3

O bjective

1.4

Thesis Organization ................................

..

..

17

.....

.....

18

..................................

. . . . . . . . . . . . . .... .

. . . . . . . . . . . . . . . . . . .

19

21

2 Basic Analysis Tools

......

2.1

Data Set .............

2.2

Preprocessing ..............

2.3

19

....

........

....

....

.....

..

........

. .

21

. .

22

2.2.1

M issing Data ...............................

22

2.2.2

Constant Variables ............................

22

2.2.3

Norm alization ...............................

22

24

Outlier Analysis ..................................

2.3.1

Definition . ..

......

...

..

2.3.2

Causes of Outliers

2.3.3

Effects of Outliers ..............................

2.3.4

Outlier Detection .............................

..

..

...

. ...

..

. ..

.. .

............................

2.4

Correlation Analysis

2.5

Spectral Analysis .................................

2.6

Principal Component Analysis ...................

24

..

Basic Concept ...............................

2.6.2

Geometric Representation ...................

2.6.3

Mathematical Definition ...................

7

25

25

...............................

2.6.1

24

26

28

.......

29

29

.....

......

29

31

35

3 Web Process 1

3.1

Background ..........................

3.2

Data ......................

3.3

Preprocessing ....................

3.4

Feature Characterization .............................

3.5

3.6

3.7

4

...

......

..

................

3.4.1

In-Line Data

. ..

3.4.2

End-of-line Data

Correlation Analysis

..

35

................

...

..

..

..

36

36

..

...

..

..

..

..

..

. .. .

36

..

37

............

...............

....................

...........

39

39

........................

3.5.1

Streak-Streak Correlation

3.5.2

Streak-Cloud Correlation .........................

3.5.3

Interpretation ....................

Poisson Distribution

35

41

42

.....

.......

43

...............................

43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

3.6.1

M ethod

3.6.2

Results.............

.....

...................

Principal Component Analysis ............

..

.....

.......

44

45

.

3.7.1

PCA of the End-of-Line Data ......................

45

3.7.2

PCA of the In-Line Data .........................

45

3.7.3

Interpretation ..................

47

..

...........

49

Web Process 2

.

49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Background ........

4.2

D ata . . . . . ....

4.3

Preprocessing ..........

4.4

Feature Characterization .................

4.5

4.6

..

.

In-Line Variables ......................

..

...

...........

4.4.2

..

....

.......

.. ......

...

50

51

............

52

. . . ................

52

Outliers Analysis .................................

4.5.1

Normalized Euclidean Distance

4.5.2

Time Series Model - PCA .. .....

4.5.3

Identifying Outlying Variables .............

...

50

............

Quality Variables ........

...

50

..........

.............

4.4.1

Variable Grouping

.........

.......

.......

....

4.1

..............

............................

....

. . . . . . . . . .

53

58

62

5

4.6.1

Principal Component Analysis .......................

4.6.2

PCA with Robust Correlation Matrix . .................

4.6.3

PCA with Frequency-Filtered Variables.

Conclusion and Suggested Work

...

. . . . .

. ..

62

64

.......

72

79

List of Figures

30

2-1

(a) Plot in Original Axes (b) Plot in Transformed Axes . ...........

3-1

Time-Series Behavior of a Typical In-Line Variable

3-2

Cross-Web Position of Defects Over Time . ..................

3-3

Streak and Cloud Defects

3-4

The 10 Densest Streaks Over Time .......................

3-5

Correlation Coefficients Between Streaks Using a) standard time block, b)

. . . . . . . . . . . . . .

.

40

41

Correlation Coefficients Between Streak and Cloud with Time Blocks of length

1 to length 100

3-7

37

38

............................

double-length time block, c) quadruple-length time block . ..........

3-6

37

. . ..

..

. ..

..

..

..

. . . ..

..

. . ..

. . . . . .. .

42

(a) Cloud Distribution Using Fixed-Length Time Blocks, (b) Ideal Poisson

Distribution Using the Same Fixed-Length Time Blocks . ...........

43

3-8

Distributions of Cloud Defects Using x2, x4, and x6 Time Blocks .......

44

3-9

Ideal Poisson Distributions Using x2, x4, and x6 Time Blocks

44

3-10 First 3 Principal Components of the End-of-Line Data

. .......

46

. ...........

3-11 Percent of Variance Captured by PCs ......................

46

3-12 First 4 PCs of the In-Line Data .........................

47

4-1

Ten Types of In-Line Variable Behavior ...................

..

4-2

Normalized Euclidean Distance ...................

4-3

Outlier and Normal Behavior Based on Normalized Euclidean Distance . . .

54

4-4

First Ten Principal Components of Web Process 2 Data Set

55

4-5

High-Pass Filters with Wp=0.1 and Wp = 0.3 . ................

56

4-6

First Ten Principal Components from 90% High-Pass Filterd Data ......

57

......

. ........

51

53

4-7

First Ten Principal Components from 70% High-Pass Filtered Data ....

.

57

4-8

Variables Identified that Contribute to Transient Outliers in Region 1 and 4

60

4-9

The First Principal Component and the Corresponding Eigenvector from Process 2 Data .......

.

..............

..............

4-10 The First Ten Principal Components from 738 Variables

. ..........

61

4-11 The First Ten Eigenvectors from 738 Variables . ................

4-12 First 10 Eigenvectors of 738 Variables ........

61

. ..............

4-13 Histograms of the First 10 Eigenvectors of 738 Variables

60

.

63

. ..........

63

4-14 Magnitude of Correlation Coefficients of 738 Variables in Descending Order

in (a) Normal Scale, (b) Log Scale ........................

65

4-15 1st 10 Eigenvectors of Calculated from Robust Correlation Matrix with Cutoff

= 0.06 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

4-16 Histograms of the first 10 Eigenvectors Calculated from Robust Correlation

M atrix with Cutoff = 0.06 .........

66

....................

4-17 1st 10 Eigenvectors of Calculated from Robust Correlation Matrix with Cutoff

= 0.1 . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .. .

.

67

4-18 Histograms of the first 10 Eigenvectors Calculated from Robust Correlation

67

M atrix with Cutoff = 0.10 ............................

4-19 First 10 Eigenvectors calculated from Correlation Matrix with Cutoff at 0.15

68

4-20 Histogram of First 10 Eigenvectors calculated from Robust Correlation Matrix

with Cutoff at 0.15 .......

68

........

.................

4-21 First 10 Eigenvectors calculated from Robust Correlation Matrix with Cutoff

at 0.18 ...

....

.....................

..

.........

..

69

4-22 Histogram of First 10 Eigenvectors calculated from Robust Correlation Matrix

with Cutoff at 0.18 ........

...

......................

69

4-23 A Comparison of Eigenvectors Calculated from (a) Original Correlation Matrix (b) Robust Correlation Matrix with Cutoff=0.06, (c) Robust Correlation

Matrix with Cutoff=0.10, (d) Robust Correlation Matrix with Cutoff=0.15,

(e) Robust Correlation Matrix with Cutoff=0.18 . ...............

4-24 A Comparison of Histograms of the Eigenvectors

. ..............

71

71

4-25 (a) High-Pass Filter with Wp = 0.3 (b) Band-Pass Filter with Wp=[0.2, 0.4]

72

4-26 First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.1) Variables

73

4-27 Histograms of First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.1)

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

73

4-28 First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.3) Variables

74

4-29 Histograms of First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.3)

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

4-30 First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.4) Variables

75

4-31 Histograms of First 10 Eigenvectors Calculated from High-Pass Filtered (Wp=0.4)

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

75

4-32 First 10 Eigenvectors Calculated from Band-Pass Filtered (Wp=[0.2, 0.4])

V ariables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

76

4-33 Histograms of First 10 Eigenvectors Calculated from Band-Pass Filtered (Wp=[0.2,

0.4]) Variables ....................

.....

..

..

......

76

4-34 First 10 Eigenvectors Calculated from Band-Pass Filtered (Wp=[0.2, 0.3])

Variables . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .... .

77

4-35 Histograms of First 10 Eigenvectors Calculated from Band-Pass Filtered (Wp=[0.2,

0.3]) Variables . . . ..

..

...

. . . . . . . . ..

. . . . . . . . . . . . .. .

77

List of Tables

2.1

12 Observations of 2 Variables.............

..... .......

.....

29

Chapter 1

Introduction

1.1

Background

With development of technology, manufacturing systems are getting increasingly more complex. A typical continous-time manufacturing process may be controlled and monitored by

thousands parameters such as temperature and pressure. With higher customer standards

and higher operating cost, manufacturing companies are constantly creating new ways to

deal with the problem of how to increase efficiency and reduce cost.

The Leaders for Manufacturing (LFM) Program is a joint effort among leading U.S. manufacturing firms and both the School of Engineering and the Sloan School of Management

from the Massachusetts Institute of Technology. The goal of LFM is to identify, discover,

and translate into practice the critical factors that underlie world-class manufacturing. MIT

faculty and students and participating LFM companies have identified seven major themes

of cooperation.

These research themes are Product and Process Life Cycle, Scheduling

and Logistics Control, Variation Reduction, Design and Operation of Manufacturing Systems, Integrated Analysis and Development, Next Generation Manufacturing, and Culture,

Learning, and Organizational Change.

The research and analysis presented in this thesis is directly related to Leaders For

Manufacturing Research Group 4 (RG4) whose focus is variation reduction in manufacturing

processes. Understanding variations and methods to reduce them can help companies to

improve yields, reduce defects, decrease product cycle time, and generate higher quality

products.

In order to gain this understanding, RG4 attempts to answer questions such

as 1) how to effectively determine which process parameters to monitor and control? 2)

what are useful technique to determine multivariate relationship among control and quality

variables? 3) How to best communicate results and findings to managers and engineers at

the participating companies?

There are many types of manufacturing processes in industry. The type of processes

that this thesis focuses on are referred to as web processes. The particular characteristic

associated with a web process is that the end product is in the form of sheets with the

appropriate thickness, width and length and can be packaged into rolls or sliced into sheets.

Although multivariate analysis methods are applied to two data sets collected from web

processes, most of the tools discussed in this thesis can also be applied to analyze data from

other types of processes.

1.2

Previous Work

My research builds on the work conducted by previous LFM RG4 research assistants. In his

Master's thesis titled "The treatment of Outliers and Missing Data in Multivariate Manufacturing Data", Timothy Derksen developed strategies for dealing with outliers and missing

data in largý, multivariate, manufacturing data.[2] He compared the effectiveness of statistics based on standard versus robust estimates of the mean, standard deviation, and the

correlation matrix in separating the outliers from the main population.

In addition, he

developed maximum likelihood methods to treat missing data in large multivariate manufacturing data. Mark Rawizza's "Time-Series Analysis of Multivariate Manufacturing Data

Sets" [4] discussed various data analysis tools used in engineering and applied them to manufacturing data sets. He used fundamental preprocessing and data-reduction techniques such

as principal component analysis to present and reorganize manufacturing data. Furthermore,

he experimented with ARMA models and neural networks to assess the predictability of data

sets collected from both web processes and wafer processes.

1.3

Objective

The objective of this thesis is to apply series of multivariate techniques to analyze informationrich data sets from continous web manufacturing processes. In particular, a lot of the analysis is based on having an understanding of the physics behind the manufacturing process.

Combining multivariate analysis tools with an understanding of the underlying physics can

produce results and insights that can be very valuable company managers.

The questions asked in this thesis are: 1) how to effectively separate outliers from the

main population?

2) how to determine relationships among variables and subprocesses?

and 3) what are the best methods to categorize and group variables within an informationrich multivariate data set? Results of various experiments focused on these three areas are

discussed. Hopefully they can lead to more comprehensive research in the general area of

data analysis of manufacturing processes in the future.

1.4

Thesis Organization

This thesis is divided into four major sections. Chapter 2 presents an overview of the major

multivariate analysis tools and methods used in the rest of the thesis. These tools deal with

preprocessing of the original data, outlier identification and analysis, correlation analysis,

spectral analysis, and principal component analysis.

Chapter 3, the second major section, utilizes the multivariate tools presented in Chapter

2 to analyze a web manufacturing data set. With the data set divided into in-line variables

and quality variables, the objective is to perform multivariate analysis on these two sets

of variables separately and to determine multivariate linear relationships between them. In

addition, correlation analysis is performed on Poisson-distributed defect densities.

Chapter 4, the third section, applies the basic tools to analyze a data set from a different manufacturing web process, where the in-line variables and the quality variables are

not identified. The analysis focuses on experimenting with ways to more effectively separate variables utilizing principal components. Experimental results show that PCA with

robust correlation coefficients and PCA with frequency-filtered variables are more effective

in grouping and identifying the variables that are correlated with each other.

Chapter 5, the final section, summarizes the important insights gained and suggests

possible areas of continued research.

Chapter 2

Basic Analysis Tools

2.1

Data Set

A data set contains information about a group of variables. The information is the values

of these variables for different times or situations. For cxample, we might have a data set

that consists of weather information for 50 states. There might be 20 variables such as

rainfall, average temperature, and dew point temperature, and 50 observations of these 20

variables representing the 50 states. The data set might also be the same 20 variables and

50 observations representing daily measurements of each of these 20 variables for one state

over 50 days. Both data sets can be represented as a m x n matrix, where m = 50 is the

total number of observations and n = 20 is the total number of variables.

The data sets used in this thesis are recorded from continous-time web manufacturing

systems. A typical data set may consists of measurements of thousand of variables for

thousands of observations recorded over days. The variables can be categorized as either inline variables or end-of-line variables. The in-line variables of a manufacturing system control

and monitor the operation of the manufacturing process. Some typical in-line variables are

temperature, pressure, volume, speed, and so on. Furthermore, end-of-line variables, also

referred to as quality variables, provide managers and technicians with information on the

quality of the end product of the manufacturing process. Some typical quality variables are

defect size, defect location, thickness and strength.

2.2

Preprocessing

Preprocessing the data is an integral part of data analysis. Very rarely can large new data

sets be used unaltered for multivariate analysis. The following are three major parts of

preprocessing:

2.2.1

Missing Data

Within a raw manufacturing data set, very rarely are all the observations complete, especially when measurements are collected over days. Often, parts of machines or subprocesses

are shut down for maintenance or testing purposes. As a result, certain parameters are not or

cannot be recorded. These missing observations need to be treated before any multivariate

analysis. Timothy Derksen, in "The treatment of Outliers and Missing Data in Multivariate

Manufacturing Data", investigated methods of detecting, characterizing, and treating missing data in large multivariate manufacturing data sets.[2] In general, if a variable has most

of its observations missing, the variable should be removed completely from the data set.

Otherwise, the missing observations can be estimated using the EM algorithm described by

Little.[6]

2.2.2

Constant Variables

Multivariate analysis allows for understanding variable behavior in a multi-dimensional

world. Any variables that are constant over time do not exhibit any information relevant to

multivariate analysis. As a result, variables that have zero variance should be removed from

the data set.

2.2.3

Normalization

For a web process data set that contains n variables and m observations, the n variables

can consist of both control and quality parameters such as temperature, pressure, speed,

thickness, density, and volume. Since all these variables are most likely measured in different

units, it is often very difficult to compare their relative values. To deal with this comparison

problem, normalization is applied to the variables.

For a given mxn matrix with i = 1, 2, . .. , m observations and j = 1, 2, . .. , n variables,

where the value of any ith observation and jth variable is denoted as Xej, the corresponding

value in the normalized data set is denoted as Zij.

Normalization is commonly defined as the following:

Zi = Xi - 9

'Tj

(2.1)

where

xij

Xj = '=1=

m

(2.2)

m -1

(2.3)

In words, to calculate the normalized Zaj for any ith observation and jth variable, we take

the corresponding value Xij and subtract the mean Xj of the jth variable, and divide the

result by the standard deviation aj of the jth variable. In the rest of this thesis, a variable

that is said to be normalized is normalized to zero mean (Zi = 0) and unit variance (oa = 0).

There are benefits and drawbacks with performing normalization before multivariate

analysis. The following are reasons for normalization:

* Normalization causes the variables to be unit-less. For example, if the unit of Xij is

meters, Xij - Xj is also in meters. When the result is divided by aj, also measured

in meters, the final value Zii will be unit-less. As a result of normalization, variables

originally measured in different units can be compared with each other.

* Normalization causes all the variables to be weighted equally. Since the normalized

variables are zero-mean and unit-variance, each variable is weighted equally in determining correlations among variables. Normalization is especially important before

performing multivariate analyses such as principal component analysis, because it gives

each variable equal importance. More on normalization and principal component analysis will be discussed in Section 2.6.

* Normalization is a way of protecting proprietary information inherent in the original

data. By taking away the mean and reshaping the variance, the information that is

proprietary can be removed. Protecting proprietary information is a very important

part of LFM's contract with its participating companies.

The following is one of the drawbacks of normalization:

* Normalization may increase the noise level. Since normalizing causes all the variables

to have unit variance, it is likely that some measured noise will be scaled so that it rivals

the more significant variables. As a result, normalization may distort the information

in the original data set by increasing the noise level.

2.3

Outlier Analysis

The detection and treatment of outliers are an important pre-step to performing statistical

analysis. This section defines outliers, names the causes and effects of outliers, and presents

some univariate and multivariate tools of detecting outliers.

2.3.1

Definition

Outliers are defined as a set of observations that are inconsistent with the rest of the data.

It is very important to understand that outliers are defined relative to the main population.

2.3.2

Causes of Outliers

The following are the causes of outliers:

1. Extreme members - Since manufacturing data consist of variables recorded over thousands of observations, it is possible that some observations can occasionally exhibit

extreme values.

2. Contaminants - These are observations that should not be grouped with the main

population. For example, if the main population is a set of observations consisting the

weight of apples, the weight of an orange is considered a contaminant if it is placed

in the same group. In a manufacturing process, a contaminant can be an observation

made while a machine is broken amidst observations made while the machine is properly

operating.

2.3.3

Effects of Outliers

Statistical analysis without the removal of outliers can produce skewed and misleading results. Outliers can potentially drastically alter the sample mean and variance of a population. In addition, outliers, especially contaminants, can incorrectly signal the occurrence

of extreme excursions in a manufacturing process when the process is actually operating

normally.

2.3.4

Outlier Detection

For a data set with n variables and m observations, a potential outlier is a point that

lies outside of the main cluster formed by the general population. The following are some

methods used to determine outliers.

Univariate Method

An univariate method of detecting outliers is the calculated the

univariate number of standard deviations from the mean.

zij =

(2.4)

where xij is the value of observation i and variable j, Tj is the sample mean of the variable

j, and aj is the sample standard deviation of the variable j. Observations where zij > Kj,

where Kj is a constant for variable j, can be categorized as outliers. Depending on the range

of the values of observations for each variable, the value of Kj can be adjusted. To determine

gross outliers, the value of Kj can be set to be large.

Multivariate Methods

Equation 2.4 can be extended so that it represents a multivariate

measure of the distance of all the variables away from the origin. Observations where zj >

K, where K is a constant, can be treated as points lying outside of a n-dimensional cube

centered on the sample mean. This multivariate method is very similar to the univariate one,

except the value of K is constant for all variables. Similarly, this method can be effective in

determining gross outliers, but in a manufacturing environment where most of the variables

are correlated, this method is limited in its effectiveness in identifying outliers.

A more robust multivariate method to detect outliers involves calculating the Euclidean

distance to the origin of the n-dimensional space after all n variables are normalized to zeromean and unit-variance. The square of the normalized Euclidean distance is defined as the

following:

d2 =

N

2

--

(2.5)

j=1 si

where xij is the value of observation i for variable j, and sj is the sample variance of variable

j. Observations with d? > K, where K is a constant, lie outside of an ellipsoid centered

around the origin and are considered as outliers.

2.4

Correlation Analysis

In a multivariate manufacturing environment, it is often desirable to measure the linear

relationship between pairs of variables or among groups of variables. By understanding these

relationships among variables, managers can gain insights into the manufacturing process.

One method of determining the linear relationship between variables is to calculate their

covariance and correlation.

Given two variables i and j, with m observations, the sample covariance sij measures the

linear relationship between the two variables and is defined as the following:

sij

e = v)rs -

a 1i)(eke (ki

k=l

-

s

(2.6)

For n variables, the sample covariance matrix S = (sij) is the matrix of sample variances

and covariances of combinations of the n variables:

S = (si) =

S11

312

...

Sin

821

S22

...

S2n

(2.7)

Sn1

Sn2

*..

Snn

where the diagonal of S represents the sample variances of the n variables, and rest of the

matrix represents all the possible sample covariances of pairs of Variables. The covariance of

the ith and jth variables, sij, is defined by Equation 2.6, and the variance, sij = s?, of the

same pair of variables is defined as the following:

i

" m=

- 1

(ki

- -i)

2

(2.8)

k=l

Since the covariance depends on the scale of measurement of variable i and j, it is difficult

to compare covariances between different pairs of variables. For example, if we change the

unit of a variable from meters to miles, that covariance will also change. To solve this

problem, we can normalize the covariance by dividing by the standard deviations of the two

variables. The normalized covariance is called a correlation.

The sample correlation matrix R can be obtained from the sample covariance matrix and

is defined as:

1

r12

Rr21

1

...

r2n

rnl

rn2

...

1

... rln

(2.9)

where rij, the sample correlation coefficient of the ith and jth variable, is defined as the

following:

rn =

(2.10)

Since the correlation of a variable with itself is equal to 1, the diagonal elements of matrix R

in Equation 2.9 are all is. In addition, please notice that if the variables are all normalized

to unit variance such that s;i =1 and sjj = 1, then the correlation matrix R is equal to the

covariance matrix S. Since most of the multivariate analysis discussed in this paper deals

with normalized variables, R is often substituted for S.

2.5

Spectral Analysis

Fourier Transform

Fourier transforms can be an excellent tool to gain insight into the

behavior of variables in the frequency domain. For the jth variable observed at time i =

1, ..., m, the Fourier transform is defined as:

m

xiie -

Xj(ew) =

jwn

(2.11)

i=1

Autocorrelation Function

The autocorrelation function looks at a variable's correlation

with itself over time. A typical random signal is more correlated with itself over short time

lag versus long time lag. The autocorrelation of variable xj is:

R j(r) =E[xizx(i-,,)]

Power-Spectral Density

(2.12)

Power-Spectral Density (PSD) is the Fourier transform of the

autocorrelation function of a random signal xj(t).

Payr(w) = F(Rxx,(r))

(2.13)

where F is the Fourier transform operator and Rxj, (7) is the autocorrelation of the random

signal xj(t). For simplicity, the ensemble average of xj(t) is assumed to be zero without

any loss of generality. The calculation of autocorrelation requires the ensemble average of

xj(t)xz(t - r). Since our data consist of one sample sequence for each variable, this ensemble

average is impossible to get. One technique to get around this problem is to assume the

sequence is ergodic. Then the PSD is the magnitude squared of the Fourier transform.

P=xj(w) = IF(xj(t))12

(2.14)

2.6

2.6.1

Principal Component Analysis

Basic Concept

Principal components analysis (PCA) is a mathematical method for expressing a data set in

an alternative way. The method involves using linear combinations of the original variable

to transform the data set onto a set of orthogonal axes. The main objective of principal

component analysis is two-fold: 1) data reduction, and 2) interpretation.

Principal components analysis is often referred to as data reduction rather than data

restatement, because it preserves the information contained in the original data in a quite

succinct way. Principal component analysis takes advantage of the relationship among the

variables to reduce the size of the data while maintaining most of the variance in the original

set. A data set with n variables and m observation can be reduced to a data set with k

principal components and m observations, where k < n. In addition, since PCA transforms

the original data into a new set of axes, it often reveal relationships that are buried in the

original data set. As a result, PCA is a powerful tool in multivariate analysis.

2.6.2

Geometric Representation

Principal components analysis can be best understood in terms of geometric representation.

We can start with a simple two-dimensional example. Table 2.1 shows 12 observations of 2

variables, X1 and X 2 .

1 2

3

4

5

X1

8 4 5

3

X2

4 6

2 -2

6

7

8

9

10

11

12

1 2

0 -1 -3 -4 -5

-8

3

0

-3

-2

2

-2

-6

-1

Table 2.1: 12 Observations of 2 Variables

Figure 2-1 represents the data in Table 2-1 using two different sets of axes. The points

in Figure 2-la are interpreted relative to the original set of axes, while the same points

I

I

'

'

'

'

m

·

·

·

· I

.

.

-6

.

-4

.

-2

· I

0

.

2

.

4

.

6

.

8

-8

(a)

I

(b)

Figure 2-1: (a) Plot in Original Axes (b) Plot in Transformed Axes

are interpreted relative to a new set of orthogonal axes in Figure 2-lb. The information is

preserved as the axes are rotated.

Similar to Figure 2-1b, principal components are defined as a transformed set of coordinate axes obtained from the original data used to describe the information content of the

data set. In a 2-dimensional data set. The first principal component is defined as the new

axis that captures most of the variability of the original data set. The second principal component, perpendicular to the first one, is the axis that captures the second biggest variance.

The principal components are calculated in a minimal squared-distance sense. The distance

is defined as the perpendicular distance from the points to the candidate axis. The first

principal component is the axis where the sum of the squared-distance from the data points

to the axis is minimal among all possible candidates. The second principal component is

taken perpendicular to the first one, for which the sum of the squared distance is the second

smallest.

In a multivariate data set that extends over more 2 dimensions, PCA finds directions

in which multi-variable data contain big variances (therefore, much information). The first

principal component has the direction in which the data have the biggest variance. The

direction of the second principal component is that with the biggest variance among the

directions which are orthogonal to the direction of the first principal component, and so on.

After a few principal components, the remaining variance of the rest is typically small enough

so that we can ignore them without losing much information. As a result, the original data

set with n dimensions (n variables) can be reduced to a new data set with k dimensions (k

principal components) where k < n.

2.6.3

Mathematical Definition

Principal component analysis takes advantage of the correlation among variables to find new

set of variables which reduce most of the variation within the data set to as few dimension

as possible. The following is the mathematical definition [3]:

Given a data set with n variables and m observations, the first principal components

must satisfy the following conditions:

1. z1 is linear function of the original variables.

zi = w11X 1 + W12 X 2 + ... + wlnXn

where w 11, w12 ,

.

. .

(2.15)

, w• are constants defining the linear function.

2. Scaling of new variable z l .

w1 + 2 + ...+ n=1

(2.16)

3. Of all the linear functions of the original variable that satisfy the above two conditions,

pick zl that has the maximum variance.

Consequently, the second principal component must satisfy the following conditions:

1. z 2 is linear function of the original variables.

Z2 = w 2 1X

where w21 , w22 ,

1

+ w 2 2X

2 +-...-

+

2 n Xn

(2.17)

• • , w2n are constants defining the linear function.

2. Scaling of variable z 2.

2w +

w2 + " + w2 = 1

(2.18)

3. zl and z 2 must be perpendicular.

Wllw21 + W12

22

+

...-+

WlnW2n = 0

(2.19)

4. The values of z 2 must be uncorrelated with the values of zj.

5. Of all the linear functions of the original variable that satisfy the above three conditions,

pick z 2 that captures as possible of the remaining variance.

For a data set with n variables, there are a total of n possible principal components. Each

component is a linear combination of the original set of variables, is perpendicular to the

previously selected components, with values uncorrelated with the values from the previous

set of values, and which explains as much as possible of the remaining variance in the data.

In summary,

zl = W'1X = w11X 1 + wl 2 X 2 + ... + wi,X,

(2.20)

z2 = w'2X = w21XI + w 22 X 2 + ... + w2,Xn

z, = w',X = w l1X 1 + wn 2 X 2 + ... + WnX,

where random variable X' = [X 1, X 2 , X 3 ,..., Xn] has a covariance matrix S with eigenvalueeigenvector pairs (A1 , ex), (A2 , e 2 ), . •

, (An, e,) where A1 >X

2

> ... > A, > 0. The

principal components are uncorrelated linear combinations zi, z2 , z3 , . . . , zn, whose

variances, Var(zi) = wýSwi, are maximized.

It can be shown that principal components solely depend on the covariance matrix S of

X 1, X 2 , X 3 , . . ., Xn. This is an very important concept to understand. As described earlier,

the axes of the original data set can be rotated by multiplying each Xi by an orthogonal

matrix W:

zi = WXi

(2.21)

Since W is orthogonal, W'W = I, and the distance to the origin X is unchanged:

z:zi = (WX,)'(WXi) = X W'WX, = XX,

(2.22)

Thus an orthogonal matrix transformed Xi to a point zi that is the same distance from the

origin with the axes rotated.

Since the new variables zi, z2 , z3 , * . • , z, in z = WX are uncorrelated. Thus, the

sample covariance matrix of z must of the form:

s2z 1

Sz

0

0

...

Sz 2 ...

0

0

0

0

(2.23)

... s2,n

if z = WX, then S, = WSW', and thus:

WSW' =

s2 Z

0

...

0

0

S2 z2

...

0

0

0

(2.24)

... S2zn

where S is the sample covariance matrix of X. In linear algebra, we know that given C'SC

= D, where C is an orthogonal matrix, S is a symmetric matrix, and D is a diagonal matrix,

the columns of the matrix C must be normalized eigenvectors of S. Since Equation 2.24

shows that orthogonal matrix W diagonalizes S, W must equal the transpose of the matrix

C whose columns are normalized eigenvectors of S. W can be written as the following:

I

W

W=

(2.25)

W'

.

where w! is the ith normalized eigenvector of S. The principal components are transformed variables zl = w'X, z2 = w'X,.

. . , z = w'X in z = WX. For example, zl =

wllX 1 + W12X 2 + ... + WlnXn

In addition, the diagonal elements in Equation 2.24 are the eigenvalues of S. Thus the

eigenvalues A1, A2 ,

. . .

, An, of S are the variances of the principal components zi =W!X:

s2zi = Ai

(2.26)

Since the eigenvalues of S are variances of the principal components, the percentage of the

total variance captured by the first k principal components can be represented as:

% of Variance Captured =

A1

+2

..

+ Ak

2i=I Sii

(2.27)

The following is a summary of some interesting and useful properties of principal components.(Johnson, Wichern, p. 342)

* Principal components are uncorrelated.

* Principal components have variances equal to the eigenvalues of the covariance matrix

S of the original data.

* The rows of the orthogonal matrix W correspond to the eigenvectors of S.

f)A

Chapter 3

Web Process 1

3.1

Background

The data set used in this chapter is collected from a continous web manufacturing process

where more than 850 in-line control parameters are constantly monitored.

The end-of-

line data comes from an optical scanner sensitive to small light-scattering defects where 8

important quality parameters are measured with high precision. In this chapter, some of the

analysis tools described in Chapter 2 are ultilized to characterize the multivariate behavior

of the in-line data, the multi-variate behavior of the end-of-line data, and the statistical

relationship between the two.

3.2

Data

The data set from Web Process 1 consists of two major groups of variables: in-line variables

and end-of-line variables. The in-line data set consists of physical parameters that control

the production process, while the end-of-line data are parameters that indicate the quality

of the end product. The combined data set represents information for the manufacturing of

115 rolls of the end product.

The in-line data set contains 854 control parameters, measured approximately every 61

seconds for 4320 observations. The end-of-line data consist of 4836 measurements of 8 quality

parameters. The values of these quality parameters are collected by a real-time scanner that

sweeps across the web at constant frequency. One of the 8 quality variables is an indicator

of the type of defect that occurs at the end-of-line.

3.3

Preprocessing

As discussed in Chapter 2, raw data sets often need to be preprocessed before any multivariate analysis are performed. In the following two sections, techniques are applied to both

the in-line and end-of-line data in order to present more effectively the information in the

original data.

End-of-Line Data

Sometimes the values of variables are not numeric. As a result, the

information contained in the variables must be encoded before any analysis. How to encode

these non-numeric values depends on the type of information they convey. For example, the

end-of-line data contains a variable that categorizes the different types of defects. There are

a total of 8 defect types, and each one of them is simply assigned a numeric value.

In-Line Data

There are a total of 854 in-line parameters, measured approximately every

61 seconds for a period of 3 days. Of all these parameters, 194 variables are constant over

the entire period. These 194 variables can be discarded without any further investigation.

In addition, 222 variables are also eliminated, because they are simply averages of other

parameters. Consequently, 438 in-line parameters are left for analysis.

3.4

Feature Characterization

Before performing any multivariate analysis, much insight can be obtained from examining

the data in the time and space domain.

3.4.1

In-Line Data

The in-line variables show fluctuations over time. This means the physical process does not

remain steady. It tends to change "significantly" over time. The following is a plot of the

behavior of a typical in-line parameter over time.

---

Figure 3-1: Time-Series Behavior of a Typical In-Line Variable

3.4.2

End-of-line Data

The end-of-line data, include the sizes, shapes, positions and times of defects. Figure 3-2 is a

visual representation of the positions and times of the defects. The horizontal axis represents

the cross-web position, and the vertical axis represents the times when defects occur. Each

point on the graph represents a defect spot at a particular time and at a particular position

across the web. One can simply imagine Figure 3-2 as one big sheet of the end-product where

the defects location are marked by dots. If the web moves at a fairly constant speed, the

variable, time, on the vertical axis is highly correlated with down-web position of defects.

Position of Defects

on Web

I,.

I~J4 ;*i7*'

EI.r

·

JI-

· i'·- I

1

Ii ::z:t.:.

5'.

10

U~

·

·

·

...

:.:

.

I:,.

20

30

WKdh

40

50

Figure 3-2: Cross-Web Position of Defects Over Time

Figure 3-2 shows a number of interesting features:

n"~

* Defects can be categorized into streaks and cloud. Some defects tend to occur at

the same cross-web position over time (streaks), while others appear to occur fairly

randomly on the web (cloud).

* Defects are significantly denser on the left side of the web than the right side.

* For certain periods of time, there are no defect occurrences across the web. The

could represent 'perfect' times when the manufacturing process is running without any

defects.

Perfect Observations

Figure 3-2 shows that there are certain periods of time where

no single defect occurs across the web. There are two possible scenarios that can explain

these 'perfect' observations: 1) At these observations, the manufacturing process is running

perfectly and all the control parameters are at their optimal levels. Consequently, there are

no defects. 2) These 'perfect' observations are simply the result of the process being shut

down and the scanner recording no information.

After some investigation, it was discovered that the manufacturing process is occasionally

shut down for various maintenance reasons, such as the cleaning of rollers, etc. Since the

scanner continues to operate during these periods, no defects are recorded on the web. As

a result, it was determined that the 'perfect' observations are simply contaminants that do

not have any physical significance.

01loued

4=

35M

awo

i·z

).·

~':·;

'·'

i·5

· ~':.··

:.

··

f··L

··

·'

'

~

-:z~~ . L

,· ~c':'

' -~··P

"000

1S

r:

:··

V

· ··

--

0

''

~·:·'

_l;~_ri·.

~·I·~

'' ~':.·~:'

~. · ·

· I·

`rr..

· · r·4·i

.· 'r ='

C r.

2o

30

Sekec

·

· i

·.:"

-··

···

,·

·

a40

i

a

Oft-k0.1"

:010

*rjH

3500.

1

2000.

0

10

20

0

40

so

00

Figure 3-3: Streak and Cloud Defects

Cloud and Streak Defects

Figure 3-3 shows the end-of-line defects can be separated

into streak defects and cloud defects. The threshold for differentiating between streak and

cloud defects is 10 defects counts per unit distance across the web, where this distance is

0.1 percent of the web width. In other words, if there are more than 10 defect counts for

all times that occur within a certain unit distance block across the web, then these defects

within this block are counted as a defect streak. Defects within any blocks totaling less than

10 are categorized as cloud defects.

3.5

Correlation Analysis

In order to improve quality and reduce defect rate, an interesting question that a plant

manager might ask is "are the occurrences of streak and cloud defects related to some

common physical factors or they caused by separate physical phenomenon?"

Figure 3-3 shows that these two types of defects can be clearly separated from each other

and seem to resemble two separate physical processes. The cloud defects seem to be fairly

randomly distributed, while the streak defects are concentrated on the left side of the web and

seem somewhat correlated. Correlation analysis is a good method to apply here to determine

the relationships between streaks and between streak and cloud defects. Understanding the

correlations among streaks and clouds is a good beginning to understanding the underlying

physics that causes the defects.

3.5.1

Streak-Streak Correlation

Figure 3-3 indicates that most streaks occur near the left edge of the web. This suggests

that streak defects are not randomly generated.

Some physical characteristics particular

on the left side of the web could be causing the streak defects. To test this hypothesis,

the correlation coefficients between all 45 combinational pairs of the 10 densest streaks are

calculated. If the streaks are caused by some common factor, the correlation coefficients

between streak would be close to 1 or -1. Conversely, if the streaks are not caused by some

common factor, the correlation coefficient should be closer to 0.

Mejor3tkr

400-0

Defeaf

·

·

I

5.

~

I'

;I

'Ii

as=o

;I

'4

2000

Ii

f

:

som

-

.!I.

-

11

I

1

1

.

a

'

'I

i.

ji

'9

-

.2

--

--

3.s

4

4.5

Figure 3-4: The 10 Densest Streaks Over Time

Method

Figure 3-4 shows the ten densest streaks on the web, which are used for correlation

analysis. In order to calculate the correlation coefficients between streaks, each streak is

divided into approximately 257 time blocks. Consequently, a single streak can be represented

as a 257-element vector, where each element is the total defect count within each time block.

The correlation coefficient between any two 257-element vectors can be calculated using

Equation 2.10. Furthermore, each streak can also be divided into time-blocks of other length.

The same procedure can be applied to calculate the correlation coefficients of the streaks

using different length time-blocks.

Results

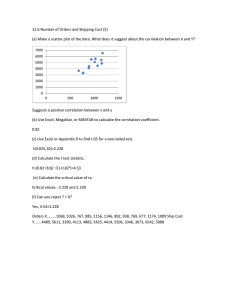

Figure 3-5a shows the correlation coefficients for all 45 combinations of the 10

defect streaks using the standard-length time blocks. Although most of the streaks are

positively correlated, the average correlation coefficient is only 0.08652.

Figure 3-5b and Figure 3-5c show the correlation coefficients of the 10 defect streaks using

double-length and quadruple-length time blocks respectively. There is a small but steady

increase in the correlation coefficients as the length of the time blocks are increased. For

double-length time blocks the average correlation coefficient is 0.1054, and for quadruplelength time blocks, the average correlation coefficient is 0.122.

The increase in correlation coefficients with increasing time blocks indicates that while

the streaks are somehow correlated, most of the correlations are buried in high frequency

noise. As the time block lengthens, some of the high frequency noise are filtered out, resulting

Streak Correlations

I.T TTTTTT TT

T

_T

TT T

TTT.T

·

01

mean - 0.086552

-0.5

O

5

10

16

20

25

m

0

mean

0.105224

30

35

40

Streak Correlations

0.5-

-0.5

-

0

5

10

15

20

25

30

SS

40

Figure 3-5: Correlation Coefficients Between Streaks Using a) standard time block, b)

double-length time block, c) quadruple-length time block

in higher correlation coefficients. But due to the uncertainty of the signal-to-noise ratio of

the process, the 'true' correlation coefficients between the streaks are still uncertain.

3.5.2

Streak-Cloud Correlation

This part of the analysis focuses on determining correlations between the cloud defects and

the streak defects. If the two types of defects are highly correlated, there should exist some

common process parameters that cause the occurrence of both streak and cloud defects. If

they are not highly correlated, the two types of defects are most likely caused by separate

process parameters.

In addition, comparing the correlation coefficients calculated using

different time-blocks can present some information as to the frequency range where the two

types of defects are most correlated or uncorrelated.

Results

By using time blocks varying from length 1 to length 100, the correlation coeffi-

cients are calculated between the streak and cloud defects. Figure 3-6 shows that the streaks

and cloud defects are positively correlated. For time blocks on the order of length 1 to length

20, the correlation coefficient is approximately 0.2. As the length of time blocks increase

to the order of 70 to 100, the correlation coefficient gradually increases to an average of

Correlaton Coelficients Between Cloudand StreakDetects

Figure 3-6: Correlation Coefficients Between Streak and Cloud with Time Blocks of length

1 to length 100

approximately 0.35.

The positive correlations between the streak and cloud defects indicate that they are

related some common underlying physics. In addition, the analysis shows that the correlation

is higher when longer time blocks are used. This suggests that some of the high-frequency

noise is filtered out as the time block increases, resulting in a more accurate representation

of the correlation coefficients between the streaks and clouds.

3.5.3

Interpretation

The defect data show the difficulties in determining the correlation coefficients between two

processes when the true signal-to-noise ratio is unknown. For example, in section 3.5.1, it

is shown that the correlation coefficients between the streaks increase as the time blocks

are lengthened. Lengthening the time blocks, in effect, removed some of the high frequency

Poisson noise component, resulting in a more accurate representation of the correlation

coefficients. More analysis needs to be done to quantify the effect of Poisson noise on the

correlation coefficient so that the 'true' correlation coefficients between streaks and between

streaks and clouds can be identified.

3.6

Poisson Distribution

Figure 3-3a shows that cloud defects seem to be randomly generated and fairly evenly distributed across the web, representing a Poisson distribution. In this section, analyses are

performed to look at the distribution of cloud defects over time. The key is to find out

whether or not the cloud defects exhibit a Poisson distribution, and if they do, over what

frequency range.

3.6.1

Method

Similar to the method utilized for determining correlations between streak and cloud defects,

the entire set of cloud defects is divided into time blocks of a certain length. Once the total

cloud defect count is determined for each time block, a histogram of the total defect count in

each time block is presented and compared to a plot of a typical Poisson distribution. Time

blocks with different length can be used to determined if there are certain frequency ranges

where the cloud defects resemble Poisson distributions.

Cloud Distribution using 5 min Time Blocks

5

10

Number of Defects in a Time Block

Poisson Distribution using 5 min Time Blocks

_·Y·|

I

std=19.Z2

td= 17.52

8

200

std=14.18

Sstd=9.381

E

= 100"

'''

0

0

--

-~-----

-----

I

10

5

Number of Defects ina Time Block

Figure 3-7: (a) Cloud Distribution Using Fixed-Length Time Blocks, (b) Ideal Poisson Distribution Using the Same Fixed-Length Time Blocks

3.6.2

Results

A time block of a certain fixed length is selected to determine the histogram of the defect

density. For the selected standard length, the average number of cloud defects in each standard time block is approximately 2. Figure 3-7a shows the histogram of these cloud defects

using these fixed-length time blocks, and Figure 3-7b shows an ideal Poisson distribution

generated with the same average defect density using the same standard-length time blocks.

A comparison of Figure 3-7a and 3-7b show that the cloud defect distribution does not

resemble a Poisson distribution for these standard-length time blocks.

Mioc.

k

Cloud Mitibuton u..hg 10 mlN Tn

I

40

lo-

00

2

0

14

10

12

0

8e

NumbFroDefDects in a Ti6 Block

4

2HD

16

18

16

1U

20

m

Cloud Distributionus"lg 30 rnn Trne Block

2

4

6

8

Nu.bLr ofDalect

12

10

, . TimBo.

14

20

Figure 3-8: Distributions of Cloud Defects Using x2, x4, and x6 Time Blocks

I

Pot

n DCidbon urno 30 r-n TW- Block.

Nu"Ir

r

of Dil ctflF in Tir-

Block

Figure 3-9: Ideal Poisson Distributions Using x2, x4, and x6 Time Blocks

Figure 3-8 presents the histograms of cloud defect density using 2 times, 4 times and

6 times the length of the standard time blocks used in Figure 3-7. Figure 3-9 shows the

ideal Poisson distributions with the same average defect density as the cloud distributions

generated using time blocks x2, x4, and x6 the standard length in Figure 3-7. A comparison

of Figure 3-8 to Figure 3-9 shows that the cloud defect density does not exhibit a Poisson distribution when measured using small time blocks. But as the length of the time

block is increased, the distribution of the cloud defects becomes similar to that of a Poisson

distribution.

3.7

Principal Component Analysis

As discussed in Section 2.6, principal component analysis (PCA), also referred to as the

Karhunen-Loeve transformation (KLT), is a powerful tool in multi-variable data analysis. In

a multi-variable data space, the number of variables that have to be observed simultaneously

can be enormous. As a result, PCA is applied to reduce the number of variables without

losing much information and to interpret the data using a different set of axes.

3.7.1

PCA of the End-of-Line Data

Principal component anlaysis is applied to the 7 of the 8 end-of-line quality variables, excluding the variable that characterizes the defect type. Figure 3-10 shows the time-series

behavior of the first 3 principal components. Figure 3-11 shows the accumulated variance

captured as a function of the number of principal components used. One can see that approximately 90% of the information contained in the 7 in-line variables are captured by the

first 3 principal components.

3.7.2

PCA of the In-Line Data

Principal component analysis is applied to 438 in-line variables. Figure 3-12 displays the

first 4 principal components of the in-line data. Changes in the principal components imply

that the production process fluctuates over time.

10

di

5

-5-

0

o

500

o

1000

1 ooo

1500

2000

25M0 3000

5oo

2000

200

Figureoo

3

Principal

1003-10

Firsoo

Tie

Tk-

2ooo

Components

3000

3=0

4000

45'00 5000

3500

4000

4500

of

the

000

End-oo

sof-Line

Data

Figure 3-10: First 3 Principal Components of the End-of-Line Data

I

j

Figure 3-11: Percent of Variance Captured by PCs

10CLi0

-10.

-201

5/15pm

6/4noon

524pm

5A8Smm

20

0-I

5I10aM

5/2 dam

5/1 5pm

5/32amn

24pm

54 10Opm

5/3 noon

5/4lam

Figure 3-12: First 4 PCs of the In-Line Data

3.7.3

Interpretation

A comparison of the two sets of principal components presented in Figure 3-10 and Figure 3-12 can reveal some interesting insight into the nature of the relationship between the

in-line and the end-of-line data. Since the principal components are another way of representing the process variables, fluctuations in the principal components indicate fluctuations

in the underlying process. As indicated before, the principal components of the in-line data

fluctuate noticeably in time. Assuming there exists a close relationship between the in-line

data and the end-of-line data, the principal components of the end-of-line data should also

show similar fluctuations. However, Figure 3-10 does not confirm this. Instead, the principal

components of the end-of-line data seem to behave completely independently of the principal components of the in-line data. As a result, PCA shows that there is no strong linear

relationship between the in-line and the end-of-line data from web process 1.

Chapter 4

Web Process 2

4.1

Background

Web process 2 is a multi-staged manufacturing system that takes raw materials and transforms them into the final product through a number of sequential subprocesses. Raw materials are introduced into the first stage, and after going through certain chemical and physical

changes, the desired output is produced. Next, the output from the first stage becomes the

input for the second stage. Again, under certain control parameters, input is transform into

output. This process is repeated a number of times, as input turns into output, and output

becomes input. The output of the final stage of this multistaged manufacturing process

becomes the final product. It must be noted that the output from each stage can be very

different from the input. As a result, the final product or the output of the final stage is

often nothing like the initial input.

Each stage in this multi-staged manufacturing process can be treated as a subprocess.

Although the subprocesses can be occasionally shut down for maintenance or testing purposes, they are continous processes with real-time controlling and monitoring parameters.

But between these stages, there can be certain amount of delay as material is transferred

between subprocesses. The output of one stage often does not immediately become the input

for the next stage. Due various factors such as supplier power and customer demand, production within certain stages can be speeded up or slowed down, resulting in delays between

subprocesses. Understanding these delays can be important when performing multivariate

data analysis.

4.2

Data

The data set for web process 2 contains 1518 variables recorded every time unit for a total of

2000 observations. These variables can be either control or monitor variables. As mentioned

in a previous chapter, control variables are also referred as in-line variables, and monitor

variables can be called quality variables. Since the variables in the data set are arranged in

alphabetical order, the order of the data does not have any physical significance. In other

words, the variables from all the different subprocesses are scrambled together. In addition,

they are not separated into either in-line or quality variables nor are they grouped according

to subprocesses.

4.3

Preprocessing

A major fraction of the data set containing 1518 variables and 2000 observations are either

corrupted or missing. After unwanted variables and observations are removed, the remaining

working data set contains 1010 variables and 1961 observations, which is about 65 percent

of the original data set. Next, variables whose sample variance is zero are deleted from the

data set, because they contain no useful information. The remaining data set contains 1961

recordings of 860 variables, which include both control and quality parameters. Before applying multivariate analysis, the variables are all normalized to zero mean and unit variance

using methods discussed in section 2.3.1.

4.4

4.4.1

Feature Characterization

Quality Variables

Unlike web process 1, the quality variables for web process 2 do not record the actual physical

location of defects. Instead, the quality variables are various modified physical parameters.

As a result, no one figure can capture the quality of the final product.

4.4.2

In-Line Variables

Since there are many in-line variables, it would be very difficult to analyze them in depth one

by one. But a simple look at the behavior of individual variables over time could provide

some valuable insight before performing any multivariate analysis. The following are 10

typical types of behavior associated with the in-line variables:

Variable Behavior Over Time

o

2-

0

500

'

'

2

-- 2

1000

1500

Observation a

2000

iIOIJo..U

0

Observation 0

10

500

1000

Observation

1500

2000

:Li-i1l-ziii

10o

-o

'L

'

0

OOio.

iloloo

6500

1000

Observation

1500

6

2000

0

6oo

1000

1500

Observation 0

2000

•-00

500

1000

1500

Observtion N

2000

0

500

1000

1500

Observaton 0

2000

2

0

0

1000

100

2

E

tea

0

0

A-5Fu

0

Observation

0oo

1000 U 1500

Observation 0

500

-

1000

Soo Observation

1000

2000

1500

2000

W1500

2000

•

Figure 4-1: Ten Types ofIn-Line Variable Behavior

These graphs present some interesting features with regards to the behavior of the manufacturing process. Each of the above 10 plots represents a group of variables with a particular

type of behavior. Almost all the in-line variables can be categorized into one of the ten types

of behavior described below:

1. Variable 1 - represents the set of variables whose values remain fairly constant except

for sharp transient outliers at certain observations.

2. Variable 2 - represents a set of variables that increase linearly and reset themselves

periodically.

3. Variable 3 - belongs to a group of variables that tend to remain constant for a period

of time before jumping to another value.

4. Variable 4 - generally low frequency quantatized behavior with sharp transient outliers.

5. Variable 5 - linear time-series behavior.

6. variable 6 - high-frequency oscillatory behavior that drifts over time.

7. Variable 7 - high-frequency periodic behavior that is confined tightly within a certain

range.

8. Variable 8 - fairly random high-frequency behavior.

9. Variable 9 - high-frequency behavior with relative small amplitudes compared to sharp

transient outliers.

10. Variable 10 - high-frequency behavior with a lower bound.

4.5

Outliers Analysis

As defined in Section 2.3.1, outliers are observations that are inconsistent with the rest of

the data. Identifying and understanding outliers in a manufacturing setting can be very

important to plant managers whose goals are to eliminate variation and to reduce defects.

The plant managers are interested in knowing the answer to the following questions:

1. Are the outliers simple extensions of the normal behavior?

2. If not, are there any physical significances behind the outliers?

3. If so, can the outliers be grouped according to these physical significances?

4.5.1

Normalized Euclidean Distance

The normalized Euclidean distance method, as explained in Section 2.3.4, is a good way to

identify outliers. In this case, this method is applied to 860 variables and 1961 observations.

The plot of the normalized Euclidean distance in Figure 4-2 shows that there are at least

two distinct populations in the data set. One group of observations, where the normalized

Euclidean distance is above approximately 1000, shows sharp and spiky behavior over time,

Ofn

8000

7OOOO

4000

--

S4ooo

r:' -

o200

,

400

r

?-

.

600

,r;

8

.

G

Ob

o000

.

'120

nmatlan

.

'14oo

1600oo

180

2000

Figure 4-2: Normalized Euclidean Distance

while the other group of observations, where the normalized Euclidean distance is less than

1000, shows slow-moving and fairly constant time-series behavior.

In order to define outliers, it can be assumed that in a properly functioning multivariate

manufacturing environment, all the process parameters operate within a certain normal range

of values both individually and collectively. Consequently, behavior outside this certain

normal range can be categorized as outlier behaviors contributed mostly by containments.

Figure 4-2 shows that an appropriate normal range of behavior can be defined as observations with normalized Euclidean distance less than 1000, and the outliers set corresponds

to observations with normalized Euclidean distance greater than 1000. Figure 4-3 is a plot

of these two separated groups: 1) the normal set, and 2) the outliers set. The time-series

behavior of the normalized Euclidean distance of these two sets of behaviors do not seem

to be extensions of each other. The normal set exhibits fairly constant and stable behavior,

while the outlier set is transient and very unstable.

4.5.2

Time Series Model - PCA

In addition to normalized Euclidean distance, various time-series methods, such as principal

component analysis (PCA), can also be good methods to identify outliers. PCA groups together variables that are correlated with each other. Since multivariate outliers are produced

by sets of variables that exhibit the similar 'outlying' behavior at certain times, PCA should

I-

7000

6000

5O00

2000

1000

o

200

48

00

80

Obtse ro00ation 01200

1400

1600

1800

20 00

1400

1600

1800

2000

8000

7000

6000

95000

O00

2000

0ooo

"7ru~·s~hkut~,*c~,r;~.h+~liirirr3

O

200

400

600

Boo800

1000

1200

Figure 4-3: Outlier and Normal Behavior Based on Normalized Euclidean Distance

be able to group together the variables contribute to the same outliers. PCA should be

more effective in grouping outliers than the normalized Euclidean distance method, because

it groups variable that are physically significant together rather than simply grouping the

observations into two populations.

Principal Component Analysis

Figure 4-4 represents the first 10 principal components

calculated from the data set containing 860 variables and 1961 observations. Similar to the

plot of the normalized Euclidean distance in Figure 4-2, Figure 4-4 shows that principal

components also exhibit sharp discontinuities at certain observations where the their values

jump very sharply. A more careful look at Figure 4-4 shows that the first ten principal

components exhibit two major types of outliers.

* 1st type - Step outliers. This set of outliers is associated with the 1st and 3rd principal

components, where the values of the principal components between approximately

observation 970 and 1220 are substantially different than the values of most of the

other observations.

* 2nd type - Transient outliers. They are associated with the 3rd through the 10th

principal components, where the outlier values are very different from the rest of the

population only for very brief periods of time.