CORIPOL SLG - Fatliquoring agent for all types of soft and... articles, particulary automotive and shoe upper

advertisement

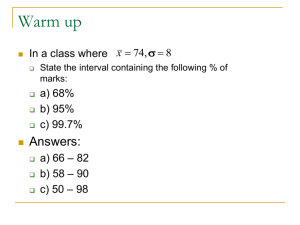

Edition 2009 CORIPOL® SLG - Fatliquoring agent for all types of soft and tight grain articles, particulary automotive and shoe upper leathers Features CORIPOL® SLG is a yellowish to dark brownish emulsion based on a combination of natural and synthetic fatty substances. Charge: Anionic Lightfastness & heat resistance: Good Handling: Wear gloves and goggles during handling & close containers tightly after use. ALWAYS STIR BEFORE USE. Storage stability: Can be stored for about 1 year (from date of production) if kept between 10°C and 35°C. In any case, protect from frost and heat above 40°C. Note: the product may change colour (permanently lighter) from ‘dark brown’ to ‘light brown’ when exposed to extremes of heat or cold. This change in colour does not have any impact on the products quality or its performance in application. If product becomes frozen, warm to approx. 20 °C and stir before use. Method of diluting: CORIPOL® SLG is diluted with water at 60°C in a ratio of approx. 1 : 4 or, it can be added to the drum without dilution. Benefits CORIPOL® SLG imparts softness making it suitable for all soft and tight grain leather types, particularly automotive and shoe upper leathers from wet blue, wet white and vegetable retanned materials. As it exhausts very well, it contributes little to COD values in tannery waste water. CORIPOL® SLG has a low bleaching-effect on dyes. CORIPOL® SLG is stable in the presence of chrome and electrolytes. For automotive leather CORIPOL® SLG is offering • Excellent fogging behaviour (gravimetric and reflectometric) • Pleasant touch • Resistance to heat yellowing according to EN ISO 17228 • Good print retention • Free of formaldehyde • Neutral odour For shoe upper leather COROPOL® SLG provides an excellent ratio between softness and tightness and imparts an attractive, smooth surface, appropriate for shoe upper and hand bag leather. CORIPOL® SLG supports moisture regulation due to a special component. CORIPOL® SLG imparts a silky nap and good buffing properties. CORIPOL® SLG is highly suitable for making leathers which pass the WHITE LINE® specifications. 1 Our application recommendations are in line with our present state of knowledge. They do not, however, exempt the customer from performing his own tests to determine the suitability of the supplied products for their intended purposes. Application of the products lies outside the scope of our control and therefore comes within the customer’s sphere of responsibility. We guarantee the satisfactory quality of our products subject to general terms of sale and delivery. Product INformation continued Edition 2009 CORIPOL® SLG - Fatliquoring agent for all types of soft and tight grain articles, particulary automotive and shoe upper leathers Application Automotive leathers 8.0 – 10.0% CORIPOL® SLG 2.0 – 4.0% CORIPOL® A Shoe nappa 1.0 - 3.0% CORIPOL® SLG as prefatliquor 6.0 - 8.0% CORIPOL® SLG as main fatliquor with 4.0 -6.0% CORIPOL® MK Nubuck 3.0 - 5.0% CORIPOL® SLG 2.0 - 4.0% CORIPOL® DX-1202 Wet-white vegetable type 3.0 % CORIPOL® SLG as prefatliquor 3.0 - 4.0% CORIPOL® SLG in main fatliquor Product INformation continued Edition 2009 CORIPOL® SLG – Product characteristics Trade form at 20°C liquid Appearance at 20°C yellowish to dark brown emulsion * pH Value (10%) approx. 6 Solids Content (%) approx. 50 This information is for guidance only. A Product Specification is available on request. * During storage, the product can change from dark brown to a yellowishbrown, milky emulsion. This change in appearance has no effect on the products performance in application. 3 Regarding toxicological and ecological data see the safety data sheet of above product. ® ® CORIPOL and WHITE LINE are registered or filed trademarks owned by or licensed to TFL in most countries. Above data are based on the current state of knowledge. However, buyer is not released from his obligation to examine the material on receipt. Seller makes no warranty of merchantability or fitness for practical use or application