TFL believes in a strong future for enzymes

advertisement

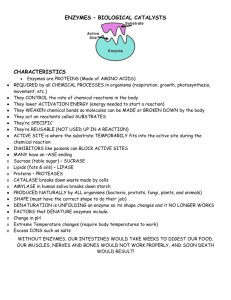

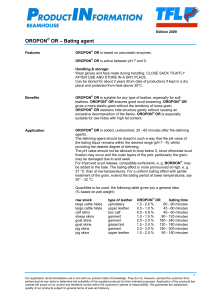

TFL believes in a strong future for enzymes By Dr Jürgen Christner, TFL USA/Canada Inc. The use of enzymes in the leather industry has been increasing continuously over the past few decades. TFL (and one of its predecessors, the former Röhm GmbH), industry leader in enzymes for leather, has contributed a lot to this development. Several landmarks were set through major innovations while further focusing on enzyme applications. Soaking. Modern soaking acids consist of certain proteolytic enzyme preparations which are applied at alkaline pH. They are formulated to speed up rehydration of the hide by removing blood, dirt, grease and proteoglycans from it. At the same time they help degreasing. Shorter soaking times (4-6hrs) and improved layout with reduced draw and wrinkling are the major advantages which can be achieved by using products such as PELLVIT C®. There is another feature which makes this product outstanding: its high dependability of results. Even ten-fold the usual working concentration will not entail grain damage, impair physicomechanical properties or aggravate damage caused by poor preservation. Degreasing. Lipases can be advantageous for processing hides into waterproof leather or low fog leather for automotive applications. They break down the natural grease into partially selfemulsifiable soaps and so reduce the need for surfactants. At the end of the eighties TFL successfully introduced an alkaline lipase into the soaking and liming process. Synergistic formulations of proteases and lipases ,as in PELLVIT LP®, work well when used in the soaking process. Hides with a low to medium high fat content can be processed without addition of further surfactants. The sole use of lipase however may result in lower softness but a tighter grain. Acid lipases can be used for post degreasing of poor wet blues. This may be important when surfactants could impair leather quality, as in the case of waterproof leathers. Unhairing. Four decades ago Röhm, now TFL, introduced the famous Arazym products for unhairing small skins like sheep and goat. The enzymes concerned were based on fungal proteases from certain Aspergillus strains. The products were used at neutral to slightly alkaline pH and resulted in almost complete unhairing. The process paid off when saving of the wool was the primary goal. It even covered the cost of the extra manual labor involved in scraping off the loosened hair. In the case of bovine hides unhairing with this type of enzymes was less complete and sulfides were still needed to pulp the residual hairs. In the 1970's a further milestone was the introduction of high alkaline proteases. They helped to cut back on sulfide and to shorten the liming process by almost half. Layout was greatly improved and in most cases a higher area yield was obtained. The dosage of these proteases has to be chosen very carefully to avoid sueded grain, pronounced defects, looser grain and empty flanks, depending on the state of the hides and the specific process conditions. More specific enzymes greatly helped to make enzyme assisted unhairing much safer. Enzymes like the new ERHAVIT MC® have brought about many improvements. Its gentle proteolytic action does not impair leather quality. ERHAVIT MC strongly assists the removal of sebaceous grease and thus enables liming chemicals to penetrate more evenly from both sides of the hides. The result is not only cleaner hides (fig 1) but also excellent flatness. The product is effective not only in hair pulping but also in hair saving processes. It helps to lower the COD and sulfide load in the liming effluent. A very specific application of ERHAVIT MC is in TFL's patented shower process. High amounts of the product are applied for a short time (2-3hrs) together with lime and a low amount of sulfide. After the hair is off the hides are washed and relimed. Process times are much shorter, flatness, cleanliness and area yield are improved, and dependability of results is high (fig 2). In addition, the leathers from the shower process show excellent penetration of the dyes. When further reduction of the sulfide is necessary ERHAVIT MC is combined with ERHAVIT FS®, which is a strong reducing agent based on formamidine sulfinic acid. Sulfide can almost be dispensed with, depending on the amount of ERHAVIT FS used . The hides processed in this way are very clean with a full temper and a regular break. Because sulfide is considered the least environmentally friendly chemical in a tannery a lot of R&D effort is still being put into research to find the ideal unhairing enzyme suitable for sulfide free unhairing. It has to be said however that such a product is not yet in sight. It has been found that even when very specific enzymes are used a very small amount of younger and shorter hair is still left on the hide. Although this hair is loosened it is actually entrapped and not easily removable by mechanical means. To remove this residual hair it has to be pulped with a fairly high amount of sulfide. Bating. The bating process was actually the first technical process in which industrially manufactured enzymes where used. These enzymes, introduced by Otto Röhm in 1907 under the famous OROPON® brandname, were based on pancreatin. Despite the availability of modern bacterial and fungal enzymes manufactured by fermentation the pancreatic bating agents have been able to maintain their strong position down to the present and they are still the most commonly used bating enzymes for several reasons. The pancreatic enzyme complex has a well balanced mixture of different proteases (trypsin, chymotrypsin, elastase and various peptidases ) with a considerable content of lipase as well, enabling it to perform several tasks at the same time. The grain layer and the collagen fibre structure are relaxed without damaging them, residual hair, pigments, fat and unstructured proteins are removed gently but efficiently. This improves the tensile strength, tear resistance and the elastometre values. Only a few years ago TFL introduced the second generation of pancreatic bating agents. By modifying the extraction techniques the proportion of certain enzymes in the complex can be increased and that of others reduced. With this improved specificity better slackening of the hide structure could be achieved without impairing the grain enamel and grain pattern. This means better softness while maintaining a uniform fine, tight break, including in the flank areas of the hide. The elastin and collagen in the grain layer are hydrolyzed more specifically and perhaps to a lesser extent than with some of the bacterial proteases in use. This means the supportive function of these proteins is maintained and the hair pores remain well opened, giving a finer and cleaner grain without the danger of looseness (fig 3). Elastin is a component of the blood vessels and if it is aggressively broken down the blood vessels fold up. The cavity created results in the vein patterns becoming visible on the hide surface. TFL's new range of OROPON bating agents is composed of specifically designed products. There are different bating products available for bovine, goat, sheep and pig skins. All have a fairly broad pH activity range in common, usually between 6.5 and 9.5. To allow safe handling all powder products are dedusted. Ten years ago a breakthrough in liquid pancreatic product formulations was achieved when TFL introduced its OROPON FM®. Pancreatic enzymes with their very limited stability in liquid form could be made stable for a minimum of one year with an activity loss lower than 10% at a storage temperature of 25°C. The same applies to products based on bacterial proteases and lipases. Acidic proteases from fungi with a pH optimum of 2-4 such as OROPON WB® were developed for bating pickle pelts and to upgrade poor quality wet-blues. In the case of pickle pelts the overall flatness is improved with fewer fold marks. The post treatment of wet-blues results in improved dye levelness and less pronounced wrinkles. The enzyme treatment is often given following an initial oxalic acid incubation. Addition of special surfactants or acidic lipases (for waterproof leathers) can improve the removal of residual excess natural grease. Waste treatment. Several patents taken out by Röhm, now TFL, in the late 70's dealt with the use of certain proteases, e.g. ERHA PH 3985 for the treatment of lime fleshings, hide trimmings and wet blue shavings. Lime fleshings and trimmings can be hydrolyzed at higher temperature and alkaline pH into protein hydrolysate and fatty acids . The same is true for wet blue shavings from which a higher quality chrome can be recovered in addition to the protein hydrolysate. As can be seen major improvements in enzyme technology for leather have been made during the past three decades. Enzymes have become much more specific, safer and reliable. They are an indispensible tool in the modern beamhouse. An exciting field of research besides the quest for the perfect unhairing enzyme could well be enzymatic tanning. Enzymes can not only hydrolyse peptide bonds but also help to form new ones. Although such enzymes are already available they have yet to prove a serious alternative to existing tanning methods. Click here to view the figures (bilder>bad quality).