SOLID WASTE MANAGEMENT IN PUERTO RICO: A THESIS

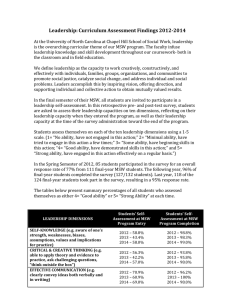

advertisement