HISTORIC WINDOWS AND SUSTAINABILITY: A COMPARISON OF HISTORIC AND REPLACEMENT WINDOWS

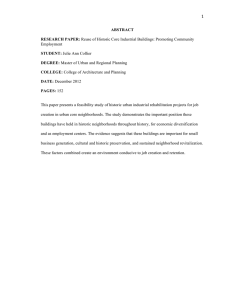

advertisement