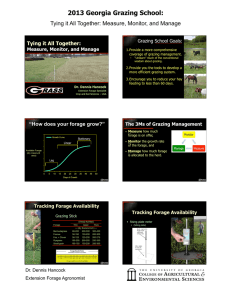

2013 Georgia Grazing School: Managing forage surplus and deficit deficit

advertisement

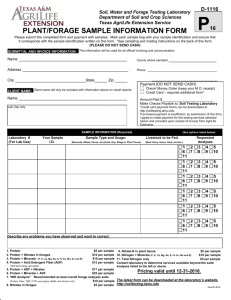

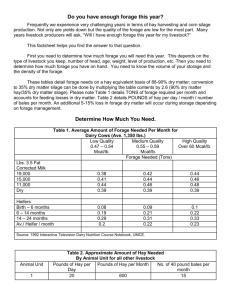

2013 Georgia Grazing School: Managing forage surplus and deficit Yield Distribution of Tall Fescue Complemented with Bermudagrass in Athens, GA 2013 Georgia Grazing School &!!!" Managing forage surplus and deficit =>+3?"@3,AB/C" %#!!" %!!!" 52.032A" $#!!" <+E7>8" $!!!" #!!" !" Dennis Hancock Extension Forage Specialist UGA – Dept. of Crop and Soil Sciences Reasons for surplus forage: '()" *+," -(." /0." -(1" '2)" '23" /24" 5+0" 678" 9:;" <+7" -:)8D"" Options •! Do nothing, let it stay !! !! Time of Year •! Mow to uniform height Pre-top (prior to grazing) Post-top (after grazing) !! Dealing with residual !! Rapid Forage Growth !! Low Stocking Density Selective Grazing Interference with growth? Lower forage quality •! Mow and remove Hay Baled silage !! Nutrient removal !! !! Dr. Dennis Hancock Extension Forage Agronomist 2013 Georgia Grazing School: Managing forage surplus and deficit Efficiencies of Grazing and Mechanized Harvest Method Efficiency Continuous Stocking Slow Rotation (3-4 paddocks) 30-40% 50-60% Moderate Rotation (6-8 paddocks) 60-70% Strip Grazing, Daily Rotation 70-80% Grazing Mechanical Hay 30-70% Silage 60-85% Green Chop 70-95% Hay Production !! Discontinue the use of a tedder when leaf shatter is occurring. (~10 a.m.) •! Bale at target moisture !! < 15% for round bales !! < 18% for square bales Drying Times Vary 80 Moisture (%) •! Cut forage to maximize drying time •! Cut at appropriate height •! Allow swath to be spread wide to maximize drying rate. •! Ted the forage morning of next day(s) 60 40 Poor Drying Conditions Good Drying Conditions 20 0 Hay Moisture Problems 1 Extension Forage Agronomist 3 Days 4 Hay Moisture Probe Contacts Dr. Dennis Hancock 2 5 6 2013 Georgia Grazing School: Managing forage surplus and deficit The True Cost of Storage and Feeding Losses Determining Moisture Methods: 3. Hay Moisture Testers/Probes 2. By feel (if calibrated). 1. Microwave moisture test About 3 billion dollars of hay is lost per year from storage and feeding in the U.S. (37.5 million tons) Storage Losses 70.0% Can I afford to build a barn? Bale diameter = 4 ft. (% of Total Volume) Weathered Loss 60.0% 5 ft. 50.0% 40.0% 6 ft. 30.0% 20.0% 10.0% 0.0% 2 4 6 8 10 Inches of Weathered Loss Source: Forage Crop Pocket Guide Feeding Losses Other Storage Options Elevated Stacks Tarped Stacks Hay Sheds Hoop Structures $1.50 – 2.50 Method $3.50+ 1 day 7 day ---- % Waste---- Unrolled $2.00 – 3.00 Dr. Dennis Hancock Extension Forage Agronomist Ring 12.3 43.0 4.9 5.4 2013 Georgia Grazing School: Managing forage surplus and deficit Feeding Losses Item % Waste Cone 2-5 Ring 4-7 Trailer 10 - 13 Cradle 15 - 20 Baled Silage Adapted from: Southern Forages (4th ed.) and Buskirk et al., 2003. J. Anim. Sci. 81:109-115 Baled Silage Can be more efficient… Fewer Losses Accumulate With Each Step Advantages: !! !! !! !! Minimize harvest loss Decrease influence of weather Capture high-quality Flexible system Disadvantages: End Result: 90% of Original DM Bale at the Right Moisture 70% 40% Moisture (Clostridial, Listeriosis) Rule of thumb: bale when the forage is no longer wet enough to wring juice out of a handful. Dr. Dennis Hancock Extension Forage Agronomist Potential for ‘operator error’ Cost of materials Added labor Keeping vermin out Feed the Bales w/in 9 Months •! Bales will squat and be difficult to handle. Ideal Range, 50-65% Moisture Potential for Spoilage or Toxicosis !! !! !! !! Poor Fermentation •! Plastic will deteriorate over time. •! Bales will begin to spoil. 2013 Georgia Grazing School: Managing forage surplus and deficit Feeding Baled Silage •! Whole silage bales !! ring feeder •! Mixed rations !! tub-ground Baled Silage – An Option for Harvesting High Quality !"#$%&#'%( )*( !+,( 2( 2( F+.G2?("H(1" !"#!$%$ "&#'$($ !!"$)$ I1+4.(AA"F(3+(4+" !"#+$%$ "*#'$%$ !,-$%$ !#'-$%$ I1+4.(AA"H(1" !-#,$($ "&#-$)$ !++$($ !#&"$($ .#&&$ .#+*$ +#&$ .#+-!$ J5<!K$!" Resources Dr. Dennis Hancock Extension Forage Agronomist Resources -./( 0+1( 345678979:( !#*"$($