Pressure Distribution in Ergonomic Car Seats MASTER OF SCIENCE TRAVIS D. STENGER

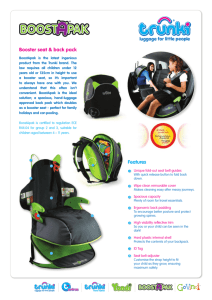

advertisement