Document 10904983

advertisement

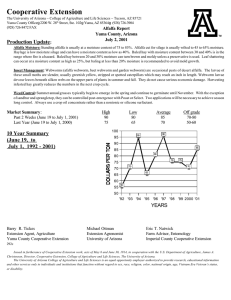

2011 Southeast Hay Convention Hay Preservatives and Baled Silage The other extreme… Hay Moisture Probe Contacts Determining Moisture Accuracy of Various Hay Moisture Probes – 4th cutting Bermudagrass Methods: 4. Hay Moisture Testers/Probes 3. By feel (if calibrated). 2. Microwave moisture test 40 Actual FtP JD Hay Moisture (%) 35 30 DW FtW PA 25 20 15 10 5 0 10 a.m. 1 p.m. Dr. Dennis Hancock Extension Forage Specialist 3 p.m. 1 2011 Southeast Hay Convention Hay Preservatives and Baled Silage Determining Moisture Losses During Storage • Even when hay is baled at the target moisture (15% moisture for round bales; 18% for squares), the forage will go through a “sweat” for 2-3 wks. Methods: 4. Hay Moisture Testers/Probes 3. By feel (if calibrated). 2. Microwave moisture test 1. Moisture tester (e.g., Koster) Moisture is driven off, heat is given off, and DM dec. A 1% decrease in moisture ≈ 1% decrease in DM Moisture tends to equilibrate at 12% during storage 20% Moisture H2O + CO2 1000 lbs DM HEAT 12% Moisture 920 lbs DM Causal Agents of Hay Heating Mold Spores 70 110 150 190 230 270 310° F Plant Respiration Aspergillus Penicillium Fungi and Bacteria Heat-Resistant Fungi O2 + H2O CO2 CO2 CO2 Carbohydrates (sugars) Exothermic Chemical Reaction (combustion) Bale Moisture Effects Bale Temp 70 110 150 Normal Range Safe 190 230 270 Heat Damage Temperature, °F Hay Temperature | Risk Levels 310° F Fire Danger 150 33% Moisture 125 25% Moisture 100 75 17% Moisture 0 10 20 Days Dr. Dennis Hancock Extension Forage Specialist 2 30 40 Small Squares Coblentz et al., 2000. Crop Sci. 2011 Southeast Hay Convention Hay Preservatives and Baled Silage Organic Acids are Corrosive HEAT Aspergillus Penicillium O2 + H2O Carbohydrates (sugars) CO CO2 2 Bacterial CO2 Decomposition Same baler, 2 months later. Hay Preservation Additives Hay Preservation Additives • Bacterial/microbial inoculants • Rock Salt Those tested have no consistently demonstrable effect. No effect on mold growth Increases palatability Some have had inconsistent effects (some positive, some no change). Not recommended. Effectiveness in Humid South is questionable (high humidity) Requires real-time moisture measurement (rate adjustment) Hay Preservation Additives • Organic acids • Buffered acids Prevents heating, but maintains moist environment for microbial activity. DM losses often offset DM gains. Beneficial when moisture is 18 – 25% Dr. Dennis Hancock Extension Forage Specialist 3 2011 Southeast Hay Convention Hay Preservatives and Baled Silage Quality Advantages Silage & Haylage • Enables timely harvest • Lowered SILAGE - Forage that has undergone anaerobic fermentation • Less • Higher Less dependent on weather Makes use of some forages that other-wise wouldn’t work. risk of rain damage shatter loss forage quality1 Lower NDF, ADF, ADL Higher CP Increased digestibility Increased palatability • However, “Garbage in = Garbage out!” 1 Han, et al. 2005; Hancock and Collins, 2006. Baled Silage – An Option for Harvesting High Quality Baled Silage Can be more efficient… Fewer Losses Accumulate With Each Step Treatment End Result: 90% of Original DM CP TDN % % Bermuda Hay 16.1 a 62.9 b 116 c Ryegrass Baleage 16.3 a 65.9 a 174 a 1.94 a Ryegrass Hay 14.7 b 62.4 c 133 b 1.26 b 0.22 0.35 3.2 0.341 LSD0.10 Details Dr. Dennis Hancock Extension Forage Specialist 4 RFQ ADG (lbs/hd/d) 1.56 b 2011 Southeast Hay Convention Hay Preservatives and Baled Silage Silage Fermentation Bale Wrapper Selection Silage pH pH 6.0 pH 4.2 Acetic acid bacteria 1 2 3 4 7 Consider: Cost, Labor, Speed, Volume pH 3.8 Lactic acid bacteria 14 Days after ensiling 20 28 Acetic acid, like propionic acid in hay preservatives, is an antagonist to yeast/fungal growth. Plus, there is very little oxygen for the fungus to grow. Baled Silage Costs Plastic Cost: $5.00 - $15.00/ton DM Wrapper cost: $2.00 - $5.00/ton DM Fuel & Repairs: $0.50 - $5.00/ton DM Labor: $0.75 - $2.00/ton DM Total: $12 - $25/ton DM Wrapping System Determines Through-Put The Unseen Cost of Hay Storage • Cut mid-afternoon on one day, bale & wrap the next day. Cost of ProducFon ($/ton) Expected $100 $120 $140 Losses $80 • Amount cut = how much can be baled and wrapped the next day. Value of Losses in the System ($/ton) Hay, no cover/on ground 50% $40 $50 $60 $70 Hay, under roof 25% $20 $25 $30 $35 Baleage 15% $12 $15 $18 $21 • Bales should be wrapped w/in 12 hrs of baling. Dr. Dennis Hancock Extension Forage Specialist 5 2011 Southeast Hay Convention Hay Preservatives and Baled Silage Choose an Appropriate Site for Wrapping Make Good Bales • Wrap at the storage site • Optimize bale size reduces handling reduces risk of spoilage match to tractor dense bales 4’x 5’ bale is most popular 900-1300 lbs, dep. on %M square edges • Use plastic twine or net sisal twine degrades plastic Apply enough plastic but no more. Bale at the Right Moisture Ideal Range, 50-65% Moisture Toxic Potential (Clostridial, Listeriosis) 70% 40% Moisture Poor Fermentation 6-10 layers (+ double on joints) 4-6 layers Rule of thumb: bale when the forage is no longer wet enough to wring juice out of a handful. Resources Questions? Dr. Dennis Hancock Extension Forage Specialist 6 www.georgiaforages.com 1-800-ASK-UGA1