Document 10901167

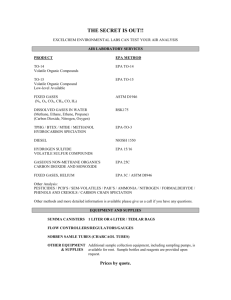

advertisement