AEROELASTIC PROPERTIES OF STRAIGHT AND by

advertisement

AEROELASTIC PROPERTIES OF STRAIGHT AND

FORWARD SWEPT GRAPHITE/EPOXY WINGS

by

BRIAN JEROME LANDSBERGER

B.S., United States Air Force Academy

(1972)

SUBMITTED TO THE DEPARTMENT OF

AERONAUTICS AND ASTRONAUTICS IN PARTIAL

FULFILLMENT OF THE REQUIREMENTS FOR

THE DEGREE OF

MASTER OF SCIENCE

IN

AERONAUTICS AND ASTRONAUTICS

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

February,

1983

Massachusetts Institute of Technology 1983

Signature of

Author

Department of Aeronautics

nd'Astronautics

December 14, 1982

Certified

by

John 'Duqundji'

Thesis Supervisor

Accepted

by

ArchiveSChairman,

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

MAR 3 0 1983

.

r%

it

Harold Y. Wachman

i i

Departmental Graduate Comittee

AEROELASTIC PROPERTIES OF STRAIGHT AND

FORWARD SWEPT GRAPHITE/EPOXY WINGS

by

BRIAN JEROME LANDSBERGER

Submitted

to the Department of Aeronautics

14,

in

1982,

partial

fulfillment of

the

and Astronautics

requirements

on December

for the degree

of

Master of Science in Aeronautics and Astronautics.

ABSTRACT

The aeroelastic deformation, divergence and flutter behavior of

rectangular, graphite/epoxy, cantilevered plate type wings at zero sweep

and thirty degrees of forward sweep is investigated for incompressible

flow. Since the wings have varying amounts of bending stiffness, torsion

stiffness and bending-torsion stiffness coupling, they each have unique

aeroelastic properties. A five mode Rayleigh-Ritz formulation is used to

calculate the equation of motion. From this equation static deflection,

steady airload deflection, divergence velocities, natural frequencies and

flutter velocities are calculated. Experimental two dimensional lift and

drag curve data and approximations to three dimensional aerodynamics are

used to calculate the aerodynamic forces for the steady airload

analysis.

The Weissinger L-Method for three dimensional aerodynamic

forces is used in the divergence analysis.

The V-g method is used to

make flutter and natural frequency calculations.

Tests on a static

loading apparatus gave static deflections, while wind tunnel tests gave

steady airload deflections for the wings at zero sweep, and divergence

and flutter behavior data for all wings at both zero sweep and thirty

degrees forward sweep.

Wings were tested from zero to twenty degrees

angle of attack for airspeeds up to divergence, flutter or the thirty

meter per second limit of the tunnel.

Static deflection, natural frequencies, steady airload, divergence

and flutter for the straight wing were predicted reasonably well by the

theoretical calculations.

For the swept forward wings, calculated

flutter speeds were beyond the wind tunnel capabilities, while calculated

divergence speeds were reasonable when divergence did occur. When swept

forward, before reaching predicted divergence

speeds some

lightly

bending-torsion stiffness coupled wings went into a torsional flutter,

characterized by a large average bend which caused a high wing tip angle

of attack.

This flutter was not predicted by the theory used.

The

different ' wings

exhibited

markedly

different

stall

flutter

characteristics.

Thesis Supervisor: John Dugundji

Title: Professor of Aeronautics and Astronautics

ACKNOWLEDGEMENTS

I thank Professor John Dugundji for his continuous guidance during

all phases of this project.

I also thank Rob Dare, a fellow student, who

assisted me during all experimental work.

Finally,

to

all

the

staff

of

M.I.T.

who's

instruction

and

assistance made this project possible, and to the United States Air Force

which

funded

my

hearty thank you.

education

and

the

contract

covering

this

project,

a

TABLE OF CONTENTS

Page

List of Figures..................................................6

List of Tables..........................................................7

List of Symbols..........................................................8

Chapter

1. Introduction........................................................

11

2. Theory

2.1

Rayleigh-Ritz Analysis...................................12

2.2

Static Deflection Analysis.................................23

2.3

Steady Airload Analysis...................................25

2.4

Divergence Analysis..................................

2.5

Flutter Analysis.......

....

34

................................... 44

3. Experiments

3.1

Test Wing Selection............

ooooooooo

3.2

Static Deflection Tests .......

ooooooooo

..

0

.

3.3

Wind Tunnel Test Setup.........

ooooooooe

.. 0

.

3.4

Natural Frequency Tests*........

3.5

................ 60

.

................ 61

.

.

................ 63

..ooooooooo

0

.

.

.

................ 66

Steady Airload Tests...........

ooooooooo

.. 0

.

.

................ 66

3.6

Flutter Boundary Tests........

ooooooooo

3.7

Flutter Tests..................

.

.

...........

.....

... 67

.. .. ... 67

4. Results

4.1

Static Deflection..........................................70

4.2

Steady Airload Deflection...................................73

4.3

Divergence Velocities.....................................76

4.4

Natural Frequencies........................................78

4.5

Flutter Velocities.......................................79

5. Conclusions and Recommendations.....................................86

6. References and Bibliography.......

.....................

88

Appendices

A. Mode Shape Integrals and Their Numerical Values..................... 90

B. Static Deflection Investigation Results.............................97

C. Steady Airload Investigation Results...............................105

D. Flutter Investigation Results.........................

.............

119

About the Author ............................................................................ 158

LIST OF FIGURES

Page

Figure

2.1

Wing coordinate system............................................12

2.2

Graph of knT vs.

2.3

Flexible wing twist feedback system diagram.......................25

2.4

Lift and drag curves for a flat plate...............................26

2.5

Components of force for a wing at angle of attack.................27

2.6

Approximation to the C

2.7

Approximation for the C curve ....................................

p

2.8

Center of pressure movement with changes in angle of attack.......30

2.9

Spanwise lift distribution for varius twist conditions for

22

................................................

curve.....................................28

29

a straight wing...................................32

2.10

Changes in force due to drag with changes in angle of attack.....33

2.11

Lift distribution in the spanwise x direction using the

Weissinger L-Method..............................................39

2.12

40

Swept forward wing coordinate system..........................

3.1

Static deflection test appartus...................................61

3.2

Static test stand with a moment being applied...................62

3.3

M.I.T. wind tunnel setup..........................................63

3.4

Looking down on a test wing by using a mirror......................64

3.5

Equipment used to illuminate and record test data.................65

3.6

Double exposure showing extreems of flutterr motion...............69

4.1

Static deflection test results for [±15/0]s layup wing............71

4.2

Initial camber (exagerated) in the [±15/0]s layup wing............72

4.3

Steady airload analysis on the four wings with a 15 degree

ply fiber angle...................................................73

4.4

Flutter analysis diagrams for the four wings with a 15 degree

ply fiber angle...................................

4.5

...............

82

Effects of ply fiber angle on flutter and divergence speeds ....... 84

B.1 - B.7

Static deflection theoretical analysis and experimental

data.................. .................

C.1 - C.13

..................... 98

Steady airload theoretical analysis and

experimental data.........................................106

D.1 - D.8

D.9 - D.34

Flutter boundary curves.....................................124

V-g method flutter analysis diagrams......................132

LIST OF TABLES

Page

Table

2.1

Assumed modes used in the Rayleigh-Ritz analysis..................19

3.1

Different laminate layups used for the test wings .................

4.1

Wing divergence speeds............................................77

4.2

Wing natural frequencies..........................................78

D.1

Flutter data, unswept wing.......................................120

D.2

Flutter data, swept wing..........................................122

60

LIST OF SYMBOLS

Symbol

A

stress-strain modulus matrix; aerodynamic matrix

B

stress-bending modulus matrix

b

semi-chord of the wing

C

compliance matrix

c

chord of the wing

Cd

Cf

coefficient of drag

coefficient of force

C

coefficient of lift

Cm

coefficient of moment about the quarter chord

Cp

coefficient of pressure

cp

center of pressure

D

moment-bending modulus matrix

EL

logitudinal Young's modulus

ET

transverse Young's modulus

GLT

shear modulus

g

structural damping

h

vertical deflection

K

stiffness matrix

kiT

non-dimentional torsional stiffness

L

lift

P

length of wing from root to tip

LA

lift associated with bending displacement

LB

lift associated with torsional displacement

LC

lift associated with chordwise displacement

M

moment per unit length; mass matrix

m

mass per unit area

MA

moment associated with bending displacement

MB

MC

moment associated with torsional displacement

moment associated with chordwise displacement

N

force per unit length; chordwise force

NA

NB

chordwise body force associated with bending displacement

NC

chordwise body force associated with chordwise displacement

P

distributed force per unit length

p

distributed force per unt area

Qi

q

generalized enternal force

qi

R

generalized coordinate

S

matrix used to transform K

T

kenetic energy

V

potential (strain) energy; velocity

V,

W

free stream velocity

weighting matrix

w

deflection in the z direction

chordwise body force associated with torsional displacement

dynamic pressure

matrix used to transform K

x

y

cartesian coordinates

z

x

spanwise axis

y

chordwise axis

a

angle of attack

ai

beam bending mode constant

0

warping stiffness parameter

Yxy °

shear strain tensor at midplane

Yi

Rayleigh-Ritz mode

6ij

EXo

delta function

SYo

Ei

strain tensor in the y direction at midplane

beam bending mode constant

strain tensor in the x direction at midplane

9

ply fiber angle; twist angle

Kx

Ky

KXy

A

LT

(

curvature strain tensors

wing sweep angle

Poisson's ratio

chordwise deflection

air density

Rayleigh-Ritz mode shape part that is a function of x

Rayleigh-Ritz mode shape part that is a function of y

CHAPTER 1.

INTRODUCTION

of composite materials in aircraft structures has added

The use

Useful not only for

another design dimension to the aircraft designer.

their

high

strength

vary

ability

to

scheme,

they

the

have

In

attractive.

to

weight

but

certain

particular,

by

previously

forward

giving

by

behavior

deflection

force

made

ratio

the

designer

layup

the

varying

impractical design

options

gained

renewed

wings

swept

the

have

interest because their major drawback, low wing divergence speeds, can be

by

tailored

using

material

composite

in

wing

significantly

improved

construction.

A good discussion of this is contained in reference 1.

This project will draw on the work of four previous experimenters

at M.I.T.;

5).

Jensen,

Hollowell,

Selby and Dugundji

(references

2,3,4 and

Those men worked with some of the same wings that were used in

project.

They made

calculations

and ran experiments

this

the

to determine

wing stiffness and bending-torsion stiffness coupling, the steady airload

deflection behavior and the flutter and divergence speeds at low and high

angles of attack.

range

by

Using their work as a foundation,

investigating

investigating

several

aeroelastic

new

ply

at

properties

its

we will extend

angle

layup

30

degrees

patterns

and

forward

by

sweep.

Primary interest is in the investigation of divergence and flutter speeds

and the wing shapes during those conditions at both low and high angle of

attack.

Low angle of attack

flutter is

investigated both theoretically

flutter

and experimentally while high angle of attack

experimental

airload

only.

deflection

We

also

analysis

extend

by

the work

including

a

of

investigation

Hollowell

realistic

on

non-linear

curve, drag and approximations to three dimentional aerodynamics.

is

steady

lift

CHAPTER 2. THEORY

2.1 Rayleigh-Ritz Analysis

In this research both static and dynamic analysis are done using

We therefore need to formulate an

the Rayleigh-Ritz analysis technique.

equation of motion for the dynamic analysis and then by setting the time

derivatives

equal to zero,

analysis.

Because

of

we can use

the

the same

equation for the static

complicated nature of anisotropic material,

exact analysis is difficult and often impossible.

Therefore I chose an

approximate

mode

method

Rayleigh-Ritz method.

of

This is

and Selby (references 2,

and in

analysis,

the

assumed

or

so

the same method used by Hollowell,

3 and 4)

who were mentioned in

called

Jensen

the introduction

fact, due to the amount of work already done on these wings with

this method I decided to use the same assumed modes im my analysis.

analysis

The

is

perpendicular to the wing in

linear

and

assumes

all

the z direction as shown in

deflections

figure 2.1.

G = PLY FIBER ANGLE

V.

Figure 2.1 Wing coordinate system.

are

Note that the ply fiber angle is

measured

in

the opposite

direction as

compared to the standard composite material direction.

The basic equation.for the assumed modes is:

n

Yi (x,y) q (t)

w(x,y,t) =

(2.1)

i=1

Where Yi(x,y) are the modes.

In our case we have five modes so n=5.

To get the equation of motion we start with Lagrange's equation.

d

dt

ST

K 4 r

av

aT

qr

3q

-

(2.2)

at

Where Q represents the applied loads.

Now we need expressions

for the kinetic

and

potential

energies.

For the kinetic energy of a plate we have:

T =

ff

m (w2

dA

(2.3)

Where m = mass/unit area.

Using equation (2.1) for w we get:

i

S=f f m I iAi

TJ

j

jyj dA

(2.4)

Moving summations and grouping terms:

=

T

i j

(2.6)

=f f Y.my.dA

M.

where

(2.5)

Mqq

The variational potential energy for a plate is:

6v = ff

( N

Se

x

+ N

x

oo

+ M

xy

6

yo

+ M 6K + M 6K

y

y

x

x

Y

+ N

xy

xy

(2.7)

6K xy ) dx dy

where using conventional displacement notation:

*

au

ax

x

= av

ay

Yo

K

y

xo

2

a2w

ax 2

2

au

XY

ay +

aw

2

- 2(2.8)

9v

x

xy

axay

To apply this to anisotropic plates we start with the modulus equations

for the general laminate.

{]

M

B

D

i

K

(2.9)

N = Force/length vector

M = Moment/length vector

= strain vector

K = curvature strain vector

A,B,D are the appropiate modulus matrices

Since this

direction.

is for a plate we assume no strain or shear in the z

For a symmetric

strain, only bending so

direction so

Mx

Y

yxy

laminate,

B = 0.

moments about x any y do not cause

In our analysis all loads are in the z

N = 0, leaving us with, in expanded form:

D11

D 12

D 16

Kx

D2

D2 2

D 26

Ky

1

(2.10)

D6

1

D6 6

xy

Using equation (2.10) for M, integrating with respect to the variational

terms and using equations (2.8) for the curvatures we get:

D1 1

D 12

D 16

S-W,

V = 1/2

ff [-w,xx -w,yy -2w,xy

D2 1

D2 2

D26

XX

yy

(2.11)

D6 1

D6 2

D6 6

-2w,xy

where:

2

w,

=

xx

w

, etc.

2

equation and using

expanding

this

D21Dx

expanding this equation and using

+ 4D

16

w,

xx

w,

We now substitute in

xy

and D2 6=D

62

2

x

+ 4D w,

+ 2 D 1 2 w, x1xyy

,

+ D 22yy

2 2 w, y

66 xy

f f{ D 11 w,

=1

V

D2 1 =D1 2 , D 16 =D61

+ 4D

26

w,

yy

w,

equation (2.1)

xy

j dA

(2.12)

for w bring sumations and q's out of

the integral to get:

i j

V

=I1

qq

i

2

+ D

22

+ 4D

j

ff

y.,

1 xxY., yy

I

D Y

Y ,

xx j

11

+ 4D

66

Y.,

xx

1 xy y,j xy

+ 2D

Yxx

Y.

12 1'xx j'yy

+ 4D

,

y.,

16 i xx 3 xy

} dA

Y.,

Y.,

26 1 yy ] xy

(2.13)

Finally it is rewritten in the compact form:

=-1

i j

Kij qq

(2.14)

where

= ff

K

D

11

Yi,

Y.,

+ D Yi'

22

xx ] xx

+ D1 2

i'xx'

+ 2D

y,

Y.(

j'+

Y.,

1 xx j xy

16

yy

y.,

yy

+4D

y,

,

66 i xy j xy

xxj'yy

+ y,.

Y.,

j xxI xy

+ 2D26 ( Yi'yyj xy

)

(2.15)

Yyyixy

symmetric.

Note that Kij is

Now we can put our expressions for

T and V

in equation

(2.2).

First

for kinetic energy:

Tq r

M..

13

Mij

2

i.

q

qr

a4

q'-

using

qi =

;q

aqr

M

3T

aq

is

+

arq.

r

r

i )

j

and expanding

ir

1 i

;T

-r = - IM

q. + 2

rj i

r 2

since

qi

Mir qi

ir i

(2.17)

symmetric we can sum the two parts:

= IMr

rj

q.

(2.18)

]

similarly for potential energy:

S

Krjq.

(2.19)

finally

3T

d3T

q=

dt

Mrj qj

r

We note that:

aT

these into Lagranges

put

and

equation, using0

and put these into Lagranges equation, using

M

1]

q. +

K.,. q. = Q.

J

13

J

1

r=i:

( j = 1,2,...N)

(2.21)

in matrix form:

M q+

rre

Kq =Q

me

(2.22)

r

This equation will be used to derive all the displacements and motion of

the wings.

The five mode shapes used are

listed on table

the variables have been separated in the form:

Yi(x,y) = 'i(x)

*i(Y)

(2.1)

where

Mode

i.

i (x)

cosh ( -

-

- a

cos ( -EX

- )

{ sinh

Ex

cosh (

2.

-)

)

Ex

- sin

3.

sin (-)

4.

3ix

sin ( --

)

Ex

-cos ( -

Sx

- a2

( -

sinh

sin (

(2

ex

22-

4y

5x

A

A

c

1

2

3

where:

El

= 1.8785104

al = 0.734096

a2 = 1.018466

C2 = 4.694091

Table 2.1 Assumed modes used in the Rayleigh-Ritz analysis.

The first two are cantilever beam bending modes the second two are

beam torsion modes and the fifth is

notice

that

modes

3 & 4 do

cantilevered

plate

at the

You may

a chordwise bending mode.

not meet the

root where

w,

x

boundary

is

zero.

conditions

But the

for a

error

small away from the root and an aspect ratio correction for this is

is

made

3 goes

Jensen in reference

terms.

matrix

in the stiffness

through in

detail the algebra for working out the mass and stiffness matrix terms

In this

correction factor.

torsion stiffness

and he also derives the

report only the results are stated.

Mass Coefficients

M

22

= mc£I

mct

I

12 3

M55

44

mc£

12

12

M..

13 =0

M

2

4mc£

I

45 I5

33

M

=mctI

M

4

i

j

Stiffness Coefficients

D

D

c

11

K

=-I

11

£3

K

I6

22

=

2D

26

K

=-I

2

23

K 12 =0

16

22

2D

K

14

=-

K3 4 = 0

10

4D 16

K

11

-

35

32

4D

16

2.2

24

7

K

25

=-

66

c2

33

4D

K

55

=

c

11

452. 3

22

c

3

20

64D66

I

5

+

3ck

c

2T

37/2

2

16D 2 6

iw/2

64D 22

+

19

2

1T

26

I

17

2

+

k

66

32

32.

45

k

15

16

2

4D 16

16

I

13

ci

4D

12

ct I9

16D

I

c£

44

12

8D

16

I

8

2

8D

15

I

2D

2D

13

c

11

3

I

23

2

21

Where the original values for K33 and K44 were changed using the aspect

ratio

correction

worked

out

by

and

Crawley

Dugundji

(contained

in

reference 4).

where:

D11c

8 =

2

48D 66

2

8 in figure 2.2.

And the values of knT ( n = 1,2 ) are plotted vs.

The integrals and their values are listed in table 2.1.

using

the

The engineering constants are for Hercules ASI/3501-6 graphite/epoxy

for

For

our

particular

wings,

values

of

Dij

calculated

were

material constants listed below.

EL = 98 x 109 N/m2

2

ET = 7.9 x 109 N/m

VLT = 0.28

2

GLT = 5.6 x 109 N/m

wing thickness = .804 mm

density of wing = 1520 kg/m 3

loading

out-of-plane

differences

loading).

in

(see

reference

the engineering

constants

5

for

for in

an

explanation

on

the

plane and out of plane

2.05

2.00

1.95

1.90

1.85

1.80

1.75

1.70

1.65

1.60

1.55

0

E-3

5

0

E-3

5

10

15

20

25

30

35

40

45

50

E-3

30

35

40

45

50

E-3

BETA

7.5

7.0

65

S6.0

5.5

5.0

4.5

10

15

20

25

BETA

Figure 2.2 Graph of knT vs.8.

2.2 Static Deflection Analysis

For static loading, all inertia terms in equation (2.22) are zero

so we have left:

(2.23)

Kq = Q

Q is the modal force where:

Qr =ff py rdA

Qr

(2.24)

r dA

where p is a distributed load per unit area.

For our tests the load was applied at

c/2

Qr =

-c/2

so we have:

£

I

f

x = £

p(x,y)

6

(x-£) Yr(x,y) dA

0

c/2

= f P(£,y) Yr(£,y) dy

(2.25)

-c/2

where P is the load per unit length.

For the bending

load

the apparatus used was assumed to apply a

the y direction so we can take P out of the integral.

load constant in

c/2

Q = P

r

f

Y (a,y) dy

r

(2.26)

-c/2

Now we

need only

insert the

five modes

to get the five values

of Qr.

They are listed below.

Q1

= 2Pc

Q2

=

-2Pc

Q3 = Q4 = Q5 = 0

For

the

torsional

load

the

test apparatus

was

assumed

to apply

load

linear to y such that:

p = ay

where a is a constant.

Our equation becomes:

c/2

Q = af y y (,y)

r

r-c/2

-c/2

dy

(2.27)

Again,

putting in

the five modes we get:

Q1 = Q2 = Q5 = 0

ac

12

Q3

2

2

ac

12

4

The values for Q were calculated

solved

for

the

vector q.

The values

to get the analytical

(2.1)

equation

column

(2.23)

and put into equation

of q were

which was

then put into

The results are shown

deflection.

together with the experimental data on figure B.1 to B7.

2.3 Steady Airload Analysis.

When

put

in

airforces,

generates

an

airstream

indeed this

at

is

a

given

angle

its purpose.

of

attack

a wing

These airforces

not

only support the weight of the airplane but they also bend and twist the

wing itself.

This deformation of the wing,

angle of attack,

in

return,

changes the airforces on the wing.

by changing

The result,

shown in

figure (2.3) is a simple feedback system.

a

0

c fopressure

curve

Figure 2.3

dynamic

ressure

force(a)

wing

stiffness

stiffness

Flexible wing twist feedback system diagram.

the

When

the

loop

In

deflection.

increased

beyond

airforces

and

divergence.

converges

certain

a

to a

deflection

value

increase

the

loop

without

we

does

have

the

when

theory analysis

linear

critical

certain value

not

limit.

the

final

airspeed

converge

This

is

is

and

called

In the real world there are limits to the actual increase in

deflection and airforces.

come

They

to distruction

about due

of

the

wing, non-linear stiffness of the wing or non-linear increase of airload

with increases in the angle of attack.

non-linearity,

especially

at

With our wings the most important

airspeeds

at

and

below

the

divergence

airspeed, is the non-linear increase of airload with angle of attack.

For the steady airload analysis we put in this non-linearity by

using the lift and drag curves for a flat plate from reference 10 shown

in figure 2.4.

reference 10 data

0.8

C

0.6

CD, C

L

0.4

CD

0.2

0

4

8

12

16

20

angle of attack

Figure 2.4

Lift ands drag curves for a flat plate.

The force that deflects the wing is the force perpendicular to the

wing (in the z direction).

This force has a component from lift and drag

dependent on angle of attack as shown in figure 2.5.

Lift

Resultant

Force

Vs

Drag

Figure 2.5

Components of force for a wing at angle of attack a.

From figure 2.5 we get:

Cf = CY cosa + Cd sin a

For the lift component of force, I made a Cf(lift) vs.

(2.28)

a curve.

This

curve was approximated by a polynomial of the form:

n

Cf(lift)

[

i=1 A

a

(2.29)

For our purposes

gave a sufficiently accurate curve.

n = 4

Both the

coefficient of force curve and the polynomial approximation are shown in

figure 2.6.

4

C

= -37.7072a

f(2.30)

3

+ 42.472a

- 23.167a

2

{a

+ 6.6746a

in radians}

(2.30)

0.6r

Cf(lift)

reference 10 data

approximation

-

0.2

U

I

20

16

12

8

4

0

angle of attack

Figure 2.6

This

gives

the

Cf curve.

Approximation for the

section

coefficient

of

force

from

lift

as

a

function of angle of attack but we also need to know the dependance on x

and y, or in other words, force distribution on the wing. In reference 4

Selby showed the lift distribution of a rigid wing.

guide

for

modeling

the

force

distribution

polynomial approximation was used.

on

our

This.was used as a

wing.

Again

a

The distribution in the chordwise y

direction and the approximation are shown in figure 2.7 as coefficients

of pressure versus chord.

equation

Approximation

in

distribution

force

for

the

chordwise

y

direction:

C

0

= C

3( 0.5

-

y

2

(2.31)

p avg

p

reference 4 data

approximation

0.2

0

0.4

0.6

0.8

1.0

(y + 0.5)/cord

Figure 2.7

Approximation for the Cp curve.

Both the approximation and the theory give 25%

chord as

the center of

pressure in the y direction. Reference 10 shows the coefficient of moment

about the quarter chord vs. angle of attack. From this we can calculate

the center of pressure movement with changing angle of attack by using:

C

=(py cp -y

m

.25c

Cit

where ycp is the center of pressure location.

(2.32)

To approximate

center of

a modification was made

this,

approximation are shown in

pressure movement and its

The

(2.31).

to equation

figure

2.8.

Approximation

for

equation

distribution

force

in

chordwise

the

y

direction with a correction for cp movement:

( 3.5 - 5.71a )*( 0.5 - y

C = C

p avg

p

2.5

(2.33)

+ 1.63a

reference 10 data

0.4

-

-

approximation

8

12

16

20

angle of attack

Figure 2.8

Center of pressure movement with changes in angle of attack.

In the spanwise x direction, the lift distribution was calculated

using lifting line theory.

I used the matrix equation given in reference

7.

rsinro

i

S 81 sin1+F

N

sinro l

c I

(2.34)

a

where:

0

= 2w

c = chord

£ = semi-span

x

m

=

cos

-

( 2n

r =

(

-

m

1

)

n = column number

m = row number

The lift

at

2 degrees

distribution was calculated for three cases, a rigid wing

angle of attack,

a wing with positive

twist of 4 degrees

with the root angle of attack at 2 degrees and a wing with negative twist

of 4 degrees with the root angle of attack at 6 degrees.

These three

cases span a good part of the low angle of attack deformation conditions

for our wings.

The

three cases along with the approximation used are

plotted in figure 2.9.

The

same approximation was

used in

all

cases.

Note that C£a(root) = C/a(root)

Approximation

equation

for

force

distribution

in

the

spanwise

direction:

C

f

= C

f avg

1.111 1 -(

x

R

)

9(2.35)

}

(2.35)

x

= 2 deg. constant

lifting line

- - approximation

(

-

8

C (root)

4

0

0

0.2

0.6

0.4

0.8

1.0

x/length

S

C

= 6 deg. root to 2 deg. tip

lifting line

approximation

(root)

0.2

0.4

0.6

0.8

1.0

0.8

1.0

x/length

C t(root)

0

0.2

0.4

0.6

x/length

Figure 2.9 Spanwise lift distribution for various twist conditions for a

straight wing (A = 0).

for

Finally,

drag I used

the

figure 2.10 with its approximation.

curve

from reference

10 shown in

Drag was assumed to be a function of

angle of attack only and not of x and y .

Approximation equation for force due to drag:

Cd sina = 3.5a 3

d

Cf. (drag)

(2.36)

0.20

reference

10 data

approximation

0.15

Cf (drag)

0.10

0.05

0

8

4

12

16

20

angle of attack

Figure 2.10

Putting

Change in force due to drag with changes in angle of attack

all the approximations

distribution on the wing where:

p=Cp

p

p

.Axy

Z'c

together we get a two dimentional

force

C

4

A

=

+ A 3a

3

(

*1.11[ 1 -

+ A 2a

2

+ A1 a

] { (3.5

+ 1.63a

25

[ 0.5 - (

- 5.71a

}

3

(2.37)

+ 3.5a

For

a,

vast

the

majority

the

of

twist

()

is

the

from

first

assumed

torsion mode so I used equation (2.38) for a = aO + 0 *

q3

) sin(

+ sin- ( -

a(x) = a

'

)

(2.38)

This completes the distributed force coefficient term.

Multiply this by

This

dynamic pressure and we get the distributed force per unit area.

was put in the Rayleigh-Ritz analysis to get the modal force Q.

c/2

X

Qr =f

0

f

(2.40)

f(x,y) y(x,y) dx dy

-c/2

The equation was solved on a digital computer by numerical integration.

Then equation

(2.23) was solved for q.

Solutions were calculated

for

three airspeeds 5, 11.5 and 16 meters per second at angles of attack from

2 to 20 degrees

at 2 degree increments.

If

16 m/s was higher than the

wing divergence speed, I omitted the calculation at that speed.

m/s three iterations were sufficient,

for 11.5 m/s five iterations were

sufficient and for 16 m/s up to seven iterations were used.

for a straight wing (A = 0)

For 5

The results

are plotted along with experimental data in

figures C.1 through C.13.

2.4 Wing Divergence Analysis.

Basically

a

wing

diverges

when

the

aerodynamic

forces

from

increased angle of attack due to twist are stronger than the resisting

forces

from

the

wing's

bending also causes

torsional

stiffness.

When

wings

are

swept,

changes in angle of attack while bending stiffness

resists these changes.

To calculate divergence, therefore we need to relate the stiffness

forces to the aerodynamic forces.

In matrix form the torsional stiffness

equation is :

If

(

= [ c zE

{ 0

[ C

I

M

(2.41)

the forces and moments can be combined to make a force at a specific

chordwise point we get:

S) =

[C

( F )

(2.42)

The aerodynamic forces for a station along the span are:

a

q = dynamic pressure

= cC ,q

)

(2.43)

In matrix form we have:

L } =q

Where

the

[

W

]

is

appropiate

cC

}

(2.44)

a weighting matrix for the stations chosen and contains

amount of spanwise

length to make the running

lift for the area covered by the station.

in equation (2.42) so we have:

lift

.the

In this case lift is the force

So } = [

[

c ]q

]

}

cC

(2.45)

By use of an aerodynamic scheme we will get:

(2.46)

)

a =A(cC

In matrix form:

Where A is the aerodynamic operator.

Sa

=

[ A]

(2.47)

cC

or:

(2.48)

a

C,}=[A]

putting this into equation (2.45) we get:

)

=

Where

a0

q[c[

a

We note that

[

a

{a

(2.49)

+0

is the rigid or root angle of attack.

To calculate divergence,

Sa

-1

[A]

=

{e }

we set

a0

=

0,

so we get:

(2.50)

and

-1

1

[

o }=[ C

-{

q

[

]

-1

(2.51)

{}A

This we recognize as a characteristic

value equation where for the first

characteristic value, say X, we have:

= --

(2.52)

(divergence)

This is the form of the solution to the divergence problem.

only determine the three matricies

[ C ],

[ W ] and [ A ].

We need

Because the

compliance matrix will be made to match the aerodynamic matrix we will

determine the aerodynamic matrix first.

To derive the aerodynamic matrix I used the Weissinger L-Method.

This method and its theoretical

foundation are outlined

in

reference

7.

The final matrix form for lift symmetric about the fuselage is:

a{

=[ A ]

{

}

cCS

(2.53)

DeYoung and Harper is reference 11 write this equation in the form:

(m-1)/2

a

The

avn

v

=

a

n=1

terms

vn

are

G

(2.54)

n

the

form of the chord times

terms

the

lift

of

the

aerodynamic

coefficient.

matrix

and

Gn

is

a

They have graphed values

for

the

aerodynamic matrix terms

versus wing geometry giving a 4 x 4

Although the swept wing was of primary interest in

aerodynamic matrix.

the divergence analysis, I constructed an aerodynamic matrix for both the

straight wing and a 30 degree swept forward wing ( A = 0, -30 ). With the

aerodynamic

matrix

and

known

angle

of

solution of the four equations gives

attack,

a

simple

simultaneous

the section coefficient of

lift.

The results are shown for constant angle of attack for both straight and

sweep forward wings in figure

2.11.

The lifting

line results

for the

straight wing are coplotted for comparison.

The

four

stations

used by Harper

and

DeYoung

are

the

four

so

called Multhopp stations and are at:

x

= .9239, .7071,

for the stations

vortex

.3827, 0.0

1, 2, 3 and 4 respectively.

chord while

at the quarter

This method puts the bound

meeting boundary conditions

at the

This is equivalent to saying the force is at the

three quarter chord.

quarter chord while the angle of attack is measured at the three quarter

chord position.

This gives

us the

necessary information to match the

compliance matrix to the aerodynamic matrix.

Also reference

7 gives the terms

in [E] when using the Multhopp

stations.

To

calculate

the

system in figure 2.12.

compliance

matrix we will use

the

coordinate

x (root)

0.6

0.4

0.2

0.8

x/length

= constant

m(root)

i/length

Figure

2.11

Lift distribution

Weissinqer L-method

in

the

spanwise

x

direction using

the

V,

A

---

y

y

Figure 2.12 Swept forward wing coordinate system.

In our case all

loads

can be

considered point loads applied at

quarter chord in the y-axis and at the Multhopp stations in the x-axis.

This reduces equation (2.24) to:

4

j=1 F.x.,y.

expanding this:

(2.55)

\

1

1(x ,

1(x2

2 ).

Y1( x4'

4)

2(x4

4)

F

Q2

2 x2' 2 "")

75(Yx2 2 ..

5

{

Q} =[R]

Now putting

angle 0.

e

w

5 x4'y 4

{F},

[R],

F

so in

4

short form:

F

(2.57)

that aside for

the moment,

get a

let's

relation

for

twist

Using small twist angle assumptions we can say:

= -

(2.58)

-

= -

For

that premultiplies

call the matrix

Let's

F2

cosA - a

(2.59)

sinA

we substitute in equation (2.1)

5

yi (x,y)

ai (x,y)

a(

0=-

- cosA +

sinA ) qi

(2.60)

i-=1

To get the twist at the four Multhopp stations we use the x-axis position

of the station for

3j

and three quarter chord for

index for the Multhopp station.

This gives us:

j where j

is the

e

5

j

= -

ay

yi (x.,y

++cosA

x.,y

sinA)q.

-

(2.61)

i=

i=1

in expanded form

a1(Xl,

ay2(x1

)

I

01

ay 5 (x 2 ,y 2 )

ay2 (x2 f

)

ay1x 1

x2

ay

2)

ay

2

1xy 4)

a2(x4

4

a5(x4,y

....

cosA

4)

ay

e4

a 2(x IYl

....

a5s(x11Y)

ql

ax

a

ay 2 (x

2 ,'

2)

....

ax

sinA

a7 1a.

(x2'Y

2)

ay 1 (x 4 'y

4)

ay 2 (x4'Y 4 )

a3E

Calling the matrix

....

Dy5(x4

93F

37'

that premultiplies

{q}

in

4)

equation

92

q5

(2.62),

[S],

we

have in short form:

S)

=[ s] {q}

(2.63)

Now using equation

(2.23) where we premultiply by the inverse of [K].

q}= [K

(2.64)

Q}

SK

putting this in equation (2.63) we have:

{

}= [s]]

K

{Q

(2.65)

putting equation (2.57) into equation (2.65)

{

}=[s][K]

[R ]{F

(2.66)

We can now see that our compliance matrix is of the form:

[c] =[s][K]

[R]

(2.67)

Finally, we put equation (2.67) in equation (2.51) giving us:

1

){

-1

[s][K]

-1

[R][W][A]

{}

(2.68)

q

This

equation

characteristic

was

solved

in

a digital

computer

value gives the divergence velocity.

and

the

first

With some of the

wings with negative bending torsion coupling, for the straight wing case,

the divergence velocity was imaginary.

This indicates that according to

linear theory .the wing will not diverge. The results of the analysis are

shown together with experimental data in table 4.1.

2.5 Flutter Analysis.

For flutter analysis,

this method,

structural

V - g

I used the well known

damping

(g)

is

introduced into

method.

In

the equation of

motion. since solutions of the equation of motion represent the neutral

When

g

solution,

condition

stability

is

positive

we

see

when

that

Flutter occurs when g is

stability.

g is

the

negative

damping

is

is

wing

required

for

stable.

neutral

equal to the actual damping of the

structure.

Assuming

motion

harmonic

q(t)

= q

eiLt

),

the

equation

of

motion is:

2

-

SK

ist

itQ

)

M

(2.69)

First we need to derive the unsteady aerodynamic forces in terms

of Q in equation

work (W)

(2.22).

We will do this by deriving the variational

and put that in terms of Q by using equation (2.70).

5

I

Q q

n-1

r

6W =

(2.70)

r

The general form for 6W is:

1

6w = f

0

The

term

respective

c/2

(2.71)

f p 6w dydx

-c/2

p6w

can

be

displacements;

separated

lift,

into

moment

three

and

components

camber

force

and

about

their

the

midchord (L6h, M60 and N6).

where:

c/2

L =

p dy

f

-c/2

c/2

yp dy

M = - f

-c/2

c/2

N =

I

-c/2

5 p dy

(2.72)

~PI

V

+1

4-91?'

Figure

2.13

convention.

Swept wing

coordinate

system and

the

displacement

sign

Using

figure

figure

2.13

2.12

for

(reproduced here)

the

h

(x) q1 +

=

1

=-

55(x)

sign

displacement

assumed modes to the different

2 (x)

3(x)3

for

the

swept

convention,

wing geometry

and

then

the

displacements we can write:

q2

+

relating

(2.73)

4(

)

q4

dh

cosA + d sinA

}

(2.74)

(2.75)

q5

Using equation (2.73) we can write equation (2.74) as:

8e

-

{

[ 03(x) q3 +

4 (x)

q4

+ - q1 + -

cosA

q2

sinA

}

(2.76)

Putting equation (2.72) in equation (2.71) we get:

W = f L Sh dx + f M 6e dx + f N 6~ dx

0

0

Now putting equation (2.73),

rearranging terms we get:

(2.77)

0

(2,75), and (2.76) into equation (2.77) and

d1(x)

6W =

{

fL

1

(X) dx

sinA

-

fM

d

f

1

dx

6qi

d

1

0

+

f L

2

-

(x) dx

sd#

2 (x)

sinAI M

d

dx

}

6

q2

0

cosA

f M43(x) dx

6q3

0

f M

C

0

f

+

0

4

(x) dx

Sq4

(2.78)

N t5 (x) dx 6q

5

Now, taking the relations worked out by Spielberg for 2-D incompressible

aerodynamic theory

in

12, and adapting them to our swept wing

reference

case, we get equations for lift, moment and camber force.

B

Ab

M = wp2be

N =

Where p is

wrp

2 3 it

be

( M h + MB

(N

h

Ab

+ N

B

the air density, a is

Cb

+ MC

) cosA

+ N

) cosA

Cb

the

(2.79)

oscillating frequency, b is

the

functions

the

and

semichord

LA,

LB ,

LC ,

non-dimentional complex functions of reduced frequency

are

etc

MA ,

k = Wb/V, given

by:

L

A

L

L

i

+

k

B

C

2C (k)

-i

=1

k

2C(k)

SC(k)

X

+

k

k2

i

1

12

=

-i

2C(k)

2

C(k)

3k

k

C(k)

k

M

M

B

NA

N

1

i

8

2k

C

N

N

=---

B

C

+i

C(k)

C(k)

2

2k +

k

i

-1

2k

C(k)

+

6k

1

12

C(k)

3k

i

3k

C(k)

6k

=----

=-+i

1

=--i

36

j C(k)

+

1 8k

k

C(k)

1

2

k

C(k)

2

3k

+

1

2k

2

C(k)

2

3k

(2.80)

where C(k) is the Theodorsen function.

49

These equations assume harmonic motion such that:

h(x,y,t)

h(x,y) e

=

iwt

(2.79),

Putting equations

, etc.

(2.73),

(2.76)

(2.81)

and

(2.75)

in

(2.78),

equation

using equation (2.70) and rearranging terms we get for Qi:

Q =

pw 2b

I [ cosA

3

iwt

LA

- f

*

2

(

)

(X)

(x)

d

d

- cosA sinA M

dx

A

dx

dx (x)

1(x)

d

- cosa sinA L B

f 1 ((X)

0

(

)

i

q1

0

#2(x) dx - cosA sinA LB f

1

(x)

d#2 (x)

d

dx

0

da 1 (x)

d 1(

- cosA sinA M

2

dO (x)

2

l (x) dx + b cosA sin A M

L

+ [ cosA

dx

2(x) dx

0

Sd

2

+ b cosA sin A M

B

0

(x)

d2 (x)

d

dx

dx ] q 22

cos 2 A

c

LB f

2

cos ALB

c

L

+ [ cosA

=

Q2

I

L

b

-

(x)

(x)

1 x)

3

)

f

(x)

4

1

(x) dx -

dx

2

-bcos

4

B

dx

d1

A sinA

5

(x)

(x)

B

c

f(x)

d

4

dx

(x)

dx - cosA sinA Mc I

d)

C

dx

05

dx

]

q

5

2 3 iwt

wpw b e

d

LA

{

(x) dx ] q 3

3

1

d

(x)

(x)

d

b cos A sinA

c

cosA - f

2(x)

- cosA sinA MA

W1(X)

dx - cosA sinA LB

d2(x)

d02 Wd

dx

/

I

2 (x)

(x)

dx

dx

1(x) dx

0

d

+ b cosA sin 2 A M

2

L

+

[

cosA

b

-

2 (x)

2

- cosA sinA MA f

B

d2

dx - cosA sinA LB /

LB J

dx

2x

2

2

(x) d

0 (x) dx + bcosA sin 2 A %

(x)

x ] q

1

d rx

d

d

d(x)

dx

(x)

dx

dx

1

dx

( d

2

(dx)

] q2

2

2

(x)

x)

A L

LBB

cos A L

(x)

dx

2(b

b cos A sinA

cos

A sinAM

0

LC f

f

d(x)

2)

f

3(x) dx

.q

2

0

+[ cosA

+

MB

2(x)

5(X)

d

W

do 22 (x)

dx - cosA sinA MC f

di

5 (x) dx ] q5

2 3 iwt

- wPW

Q3

b e

2

cA s

E A

S[

3 x)

(x) dx1 x)x

2

b cos A sinA

£

dl (x)

MB f

4)3(X)

b cos A sinA

MBB f

c

0

X

c1

(x)

d

+

cos A M

c

3 (x)

A

2(x)

2 dx-

0

_ [ b cosAA

-

2

M f 03(x)

0

dx ] q3

£

-

b

MB

c

f

0

3

(x)

4 (x ) dx ] q 4

3

)x)

dx ] q1

d

2

d2

)

dx ] q2

+

cos

A

c

M f

3

(x)

(x) dx

]

q5

0

Q4= p2 3 iwt

*

Q 4 =-- Wpbe

cos 2A

1BJ

(x

A MA f4

2

a

(x)

dx

d

(

4

]

0

2,

2

+ cos A

+

MA f

0

(x) dx

2

t4(X)

b cos A sinA

c

MB f

0

4

(x)

_ 2(x)

d

dx ] q2

3

b cos A

-2

B

f

*4()

3

b cos A

--2

MB

f

(

03(x) dx ] q 3

c

2

)

dx ] q4

c

cos 2 A

S

MC f

0

+

4

()

5 (x)dx

q

5

2 3 iwt

5

= WpW b e

S cosA

d

NA

5 x)

1()

I

dx - cosA sin

N

5

x

x

r

d

x

i

dx]q

Sd2~(x)

+[

sA

f

A

5

0

-

[oL

2

NB

(x) 4 2 (x) dx - cosA sinA NB f

0

5

3 (x)

(x)

5)

d

dx

]

q2

dx] q 3

(2.82)

0

2

[ cos A

B

5 x) *4(x) dx

] q4

0

+

Nc f

5 (x)

dx] q5

0

to

Inorder

with

integrate

respect

to

the

variable

we

x

use

the

substitution;

(2.83)

x = E cosA

This makes the limits of integration: 0 to X/cosA or 0 to

original distance in the unswept case.

1, which is the

Now we write Q in the form:

5

q

=

wp2b3e

i

t

I Aij q

j=1

(2.84)

where the terms of [A] are:

2

cos A

b

LA

b

A

A11

11

I

2

- cos A sinA L

1

B

I

2

- cos A sinA M I

A 24

24

2

2

1

I

+ b cos A sin A M

Bt 25

A

A

=

=

12

- cos 2AsinA L I

- cos 2 AsinA M I

+

B 26

A 27

13

3

cos A

c

14

3

cosA

c

LB

+

2 -9

B

A22

22

2

- cos A sinA MC 134

34

33

I

I

27

-cos

2

2

sinAM I

+ b cos A sin A

A 26

MB

X

2

2

- cos A sinA L

2

3

A

3

24

=

=

cos A

--

5

LLB

B

cos A

-A

L

c

B

28

30

B

I

35

- cos

1

2

2

+ b cos A sin2A M - I

B

36

A2

MB

32

31

A2 1 = - cos 2A sinA L

21B

2

cos A

b

LA

b

A

a

3

b cos A sinA

2

cos A

b

C

15

3

b cos A sinA

M

c

B

2

2

b cos A sin A

I37

37

I

3

b cos A sinA

MB 138

3

+ b cos A sinA M

39

c

B 140

2

sinA M I

A 35

28

I

-I

N VUTS V SOO

N

LSv

q

V SOD

0

-

=

sv0

V soo

so

V

q

0

I

W

VUT

s

+

6£

V

LE

w

0

V£S o o

V

=

0

V

W VI

V Soo q

V IOW

=

V soo

0

=

VT

V soo q

=

V~

0

EI '6W

8EI HN ~

o

S VuTs V soo q

£

LEI

0£ I

6Z

gW V u T s

o

+

V soo q

IVI3

vu

'6vW

V£ Soo

0f

V soo

Z V

LE

VSo£

ZI DN VUTS V ,soo

LI

DDq

v

q

s O

r

_ Sq

A5 2 =

52

2

cos A

N

b

A

b

I

2

- cos A sinA N I24

B 42

41

53

cos A

c

B

43

54

cos 3 A

N

B

c

14I

44

A

A5 5

55

2

cos A

bos NC

C

b

I1

(2.85)

5

The integrals and their values are listed in table A.1.

From this point on, the flutter analysis for the swept wing is the

same as the analysis for the straight wing as give by Hollowell and

Dugundji in reference 5.

Equation

is

(2.84)

put in

(2.69)

equation

and both sides are devided by

eiwt.

K q - w

In

the

damping

normal

2

2 3

M q = wpw b A q

fashion

for

the

(2.86)

V

- g

(g) is introduced by multipling

flutter analysis,

K by

(1 + ig).

structural

We define a

complex eigenvalue Z as:

1 + ig

2

(2.87)

2.7

we define a new matrix B as:

B = M + rpb

3

A

(2.88)

Finally putting equations (2.87) and (2.88) in equation (2.86) we have, a

standard form, complex eigenvalue problem:

{

-Z K I q = 0

(2.89)

This equation was solved on a digital computer.

of

The

Selected values

reduced frequency k were used to calculate the aerodynamic matrix.

eigenvalues

Z were

used

structural damping required g,

to get

the

frequency

oscillating

w,

the

and the velocity V, according to equations

(2.90).

W

1

Re(Z)

g -

Im(Z)

(Z)

Re(Z)

(2.90)

The flutter velocity was chosen as the velocity at which the structural

damping required to maintain neutral stability became zero on any of the

five modes.

The associated

simplify calculation of

value of w is

the flutter frequency.

the Theodorsen function C(k),

I used the R. T.

Jones approximation given in equation (2.91).

C

2

0.5 p + 0.2808 p + 0.01365

p + 0.3455 p + 0.01365

( p = ik

To

}

(2.91)

Note that by using large values of k the output frequency will be

the natural vibration frequency of the wing in an atmosphere of density

p.

This technique was used to get the theoretical natural frequencies.

This analysis was done for all thirteen wings.

plotted in figure D.9 through D.34.

The results

are

CHAPTER 3. EXPERIMENTS

3.1 Test Wing Selection

The criteria defining desireable characteristics of the test wings

are the same criteria used by Hollowell in reference 2.

they are:

a) The wings should have a wide range of bending-torsion stiffness

coupling.

b) The wings should have constant chord, thickness, sweep and zero

camber.

c)The wings

should flutter or diverge within the

0-30 m/s speed

range of the available wind tunnel.

d)

The wings should be small enough to be made with the available

equipment for manufacturing graphite/epoxy plates at M.I.T..

e) The wings should not sustain any damage under repeated large

static and dynamic deflections.

To

bending-torsion

give

a

coupling

good

and

cross

stiffness,

section

both

of

balanced

laminates were made at three different ply angles.

the

range

of

and

unbalanced

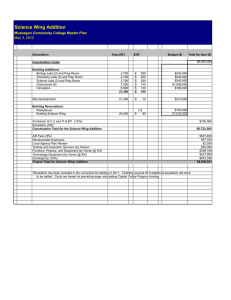

In table 3.1 we can

see the range covered.

[ 02/90] s

[+15 2 /0]s

[±15/0]s

[T15/0]s

[-152/0]

[+302/0]s

[±30/0]s

[T30/0]s

[-302 /0

[+452/01s

[±45/0]s

[T45/0]s

(-45 2 /01s

increased

negative

bending-torsion

Table 3.1

coupling

s

increased

positive

bending-torsion

coupling

Different laminate layups used for the test wings.

--i.--

- .

~-------*--X--~X-l --..

~-3~-C--C_-

The

[02/90]s

- -~----

serves

as

I-

the

only

uncoupled

bending-torsion coupling means when the wing is

direction

the

wing will

twist

is

in

the

the

same

positive

twist

direction

as

twist direction

attack.

Because of the layup convention shown in

on

outside

plies

result

in

negative

example.

bent in

positive

the

---

Positive

the positive

direction.

positive

z

The

angle

of

figure 2.1,

+0 fibers

bending-torsion

stiffness

coupling and vice versa.

3.2 Static Deflection Tests

The goal for the static deflection tests was

wings under static loads of pure force and pure moment.

to test the

Also the loads

should be large enough to cause large deformations, inorder to identify

any non-linearities in

the stress-strain relations and thus identify the

limitations of our linear analysis.

The

static

deflection

Figure 3.1

setup

is

shown

in

fig

3.1.

Static deflection test apparatus.

It

is

I

constructed

of

sturdy

wood

with

beams

insides of the top horizontal beams.

horizontal

deflection

vertical deflection.

while

a

metal

rulers

to

attached

the

These rulers were used to measure

carpenters

square

was

used

to measure

To minimize measuring error we extended pins from a

balsa wood clamp at the wing tip.

threads ran from

two eyelets

on the

balsa wood clamp around pulleys clamped to the side of the test apparatus

Figure 3.2

Static test stand with a moment being applied.

and down to weight holders.

One eyelet was at the wing leading edge

while the other was at the trailing edge.

and weights were put on

the same

side of

To apply a force the pulleys

the

test apparatus

while

to

apply a moment the pulleys and weights for the leading edge were put on

one side and those for the trailing edge were put on the other side. (see

figure 3.2)

We applied force in

then in

cm.

double increments

increments of approximately 0.2 N up to 1.0 N

till

a bending deflection of approximately

12

Moment was applied in a similar manner with initial increments of

.0075 NM till approximately 0.2 NM.

This caused a twist of from 8 to 22

degrees depending upon the torsional stiffness of the wing.

3.3 Wind Tunnel Test Setup.

We did the wind tunnel tests in

This

the M.I.T.

tunnel has continuous flow with a 1.5 by

Figure 3.2

acoustic wind tunnel.

2.3 meter

free-jet test

M.I.T. wind tunnel test setup.

section 2.3 meter long, located inside a large anechoic chamber.

tunnel speed range is

continuously variable up to approximately

Velocity was sensed by a pitot tube in

The

30 m/s.

the throat immediately before the

test section and registered on a electrical baratron.

The test setup is

shown in

figure 3.2.

The wing mount consists of

a turntable machined from alluminum and mounted on a rigid pedestal.

mount for

the

wing

is

attached

to

the

turntable allows rotation of the wing to

top

of

the

turntable.

of 15 degrees from -45 to +45 degrees of sweep.

sweep

positions

mounted

increments

The photo shows the wing

In our testing only the -30 and 0 degrees of

were used.

Figure 3.4

Slightly

below

the

base

of

the wing we

Looking down on a test wing by using a mirror.

a flat disk

to provide

smooth airflow

background for the vertical photos,

past the model,

rod and also a place to mount a terminal

wires.

The disk was also labeled for each test to identify the still

pictures.

A

typical

photo

a good

a place to mount the angle of attack

control

video

The

angles of attack from -4 to 20

degrees while the top of the wing mount allows wing sweep in

in -30 degrees of sweep.

The

taken

during

for the strain gauge

a

test

is

shown

and

in

;-- -- - -rr---- -- ~--r

,-----~--

~--'i -- I;

We hung a mirror over the wing to get the pictures looking

figure 3.4.

down on the wing.

still camera,

down" the

-----r~rr -

strobe

motion

were

floodlights

the location of the

Figure 3.5 shows

and floodlight.

during a

used.

flutter

By

checking

necessary to

When it was

test we

the

strobe,

used a

strobe

video camera,

frequency

"slow

otherwise

we

could

determine the wing flutter frequency.

The scale on the disk was used to measure wing tip bending and

twisting.

It is graduated in 1 cm increments.

Since viewing angle and

position affect the picture you see when looking at the test wing through

the

mirror,

tests

and calculations

were made

displacement to the actual displacement.

These

to

adjust the apparent

adjustments

were

then

applied to the data readings off the pictures.

Fig.3.5

Equipment used to illuminate and record test wing movement.

- - I--------

-

3.4 Natural Frequency Tests.

Hollowell,

Jensen,

and

Selby

(references

2,3

and

theoretical analysis using the

gives

results

accurate

torsional

natural

test.

natural

frequency

the

for

tests

we

and

Therefore

frequencies.

simple

did a

wing mounted

With the

first

five Rayleigh-Ritz

modes

and

first

second

instead

initial

the wind

for

already

Also they have

tested many of these wings for their natural frequencies.

shown that the

4),

tunnel

bending

of

doing

extensive

deflection

vibration

test we gave

it

an

initial deflection in twist and bending, released the wing and recorded

the oscillations on the strip chart recorder.

The resulting oscillations

contained strong first bending with weak second bending and first torsion

oscillations.

3.5 Steady Airload Test.

The steady airload tests were to be run at zero sweep and wind

However after investigating the results and

speeds of 5, 10 and 15 m/s.

repeating selected tests we determined that the baratron on the original

than the actual

tests was indicating a lower airspeed

Using

a different

tests

we determined

tests were 5,

and accurately

that

the

tunnel airspeed.

calibrated baratron during the

actual

tunnel

airspeeds

on

the

repeat

original

11.5 and 16 m/s within a tolerance of 0.5 m/s.

To run the test,

first

we set the

then using

tunnel speed,

the

strain gauge readings we zeroed the angle of attack by setting it so that

the average bending and torsion gauge readings were zero.

(The tunnel,

especially

cause

at

higher

irregular deflections

speeds

has

enough

in the wing causing

even at zero degrees angle of attack.)

turbulence

to

temporary non

The wing was

small

zero readings

then run through

angles of attack from 0 to 20 degrees at two degree increments.

We made

records of each incremental stop by strip chart records of the strain

gauge

readings,

still

photos

and

video

recordings.

Following

the

completion of tests at one airspeed we repeated the procedure at the next

higher airspeed.

Once a wing showed moderate

flutter,

angle of attack

was

Some of the wings will flutter at 16

not increased at that speed.

m/s at any angle of attack so that portion of the test for those wings

was omitted.

3.6 Flutter Boundary Tests.

A flutter boundary is

graph

attack

invariably

for

the

lower

a flutter

other is

a

a curve plotted on a airspeed vs. angle of

particular

airspeed

Previous

area.

boundaries of many of the wings in

experimenters

had

the

of

area

sweep.

flutter.

run

through

the

different

found the flutter

forward

zero the angle of attack

of

angles

When we encountered any flutter,

the

Our goal was to complete

our tests.

Our procedure was to set the airspeed,

then

graph,

while

tests for all the wings at both no sweep and 30 degrees

these

and

side

flutter free

a

is

side,

one

where

wing

attack

checking

for

either bending or torsion, we

made strip chart recordings and checked the

frequency with the strobe.

After finishing tests at that airspeed the angle of attack was reduced,

the airspeed was increased by 1 m/s and the test procedure was repeated.

When airspeed is increased to the point where the wing flutters at all

angles of attack or the maximum tunnel speed is

are taken and the test for that wing is

reached final readings

complete.

3.7 Flutter Test.

Our goal was to observe the actual shapes of the wing during both

In particular we wanted to

low and high angle of attack flutter.

concentrate on observing the wing tip, getting not only qualitative data

but actual measurements of the bending and twisting seen at the tip. We

chose 1 degrees AOA for the low angle of attack flutter and 10 degrees

AOA for the high angle of attack flutter.

Using data from the previously

run flutter boundary tests, we set the airspeed at the flutter speed and

then set the angle of attack.

small amplitude

we

increased

If

the flutter was intermittent or of very

the airspeed by as

much as one

meter per

second inorder to get a flutter motion visible on the video pictures.

Of

all the

with the various wings,

flutter cases

the wings fell into two

ones that had flutter dominated by torsion oscillations

main categories;

and ones that had flutter dominated by bending oscillations.

The torsion

flutter frequencies were in the area of 30 to 60 hz.

is much to

This

fast to see clearly with the eye and even using a video camera the motion

However since the motion is

will come out blurred on each frame.

in a periodic sense it can be captured by use of a strobe.

steady

The strobe

flash frequency is set near the flutter frequency by visual observation,

resulting in flutter motion that can be viewed at apparent slow motion.

The strobe has

The images also record relatively well on a video camera.

a very fast flash during which the wing moves very little, giving a sharp

elements,

camera

video

the

but brief image.

have a

however,

certain

amount of persistency, holding the image after the flash has stopped.

when the

video camera

scans

it

an image

has

nearly all

though the flash lasts less than 1/1000th of a second.

the

So

time even

For this reason

the video pictures made using the strobe provided all the quantitative