Document 10886018

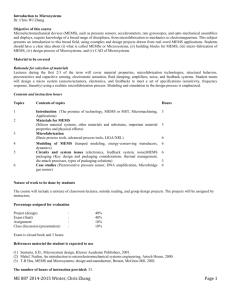

advertisement