Evaluating Upstream Supply Chain Disruptions

with Partial Availability

by

Jennifer J. Yip

Bachelor of Applied Science (Honors) in Management Engineering

University of Waterloo (2013)

Submitted to the Engineering Systems Division

in partial fulfillment of the requirements for the degree of

Master of Science in Engineering Systems

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

© Massachusetts Institute of Technology 2015. All rights reserved.

Author……………………………………………………………………………….

Engineering Systems Division

May 18, 2015

Certified by…………………………………………………………………………..

Yossi Sheffi

Elisha Gray II Professor, Engineering Systems Division

Professor, Civil and Environmental Engineering Department

Director, MIT Center for Transportation and Logistics

Thesis Supervisor

Accepted by………………………………………………………………………….

Munther A. Dahleh

Professor of Electrical Engineering and Computer Science

Acting Director of MIT Engineering Systems Division

2

Evaluating Upstream Supply Chain Disruptions

with Partial Availability

by

Jennifer J. Yip

Submitted to the Engineering Systems Division

on May 18, 2015, in partial fulfillment of the

requirements for the degree of

Master of Science in Engineering Systems

Abstract

Globalization, outsourcing, and the emphasis on lean supply chains continue to shape the supply

chain industry. These trends have increased the prevalence and severity of disruptions to

upstream supply. Disruptions to upstream supply can delay and potentially halt the flow of

necessary materials and/or services to purchasing firms, often resulting in severe operational and

financial losses. This has created a growing need for effective risk assessment techniques to

evaluate the impact of disruptions and inform risk mitigation policies. As a result, many

methodologies have been developed to assess risk by estimating the likelihood and impact of

disruptions. Given the inherent difficulty in estimating the likelihood of disruptions, this thesis

focuses on assessing the risk of supply shortfall independent of the causes and likelihoods of

such disruptions. This thesis presents an optimization-based framework to assess the risk of both

complete and partial supply disruptions and comments on inventory and procurement mitigation

strategies. The framework is used to compare two allocation policies (fair allocation and

preferential product allocation) for the distribution of scarce inventory in times of disruption. The

framework is then applied to data from a food products manufacturer to determine the impacts of

a disruption in the supply of two components feeding dozens of products.

Thesis Advisor: Yossi Sheffi

Title: Elisha Gray II Professor of Engineering Systems and Civil and Environmental Engineering

3

4

Acknowledgements

This thesis is a result of all the support and guidance I have received from the many people I

have met on my journey to and at MIT. I would like to thank the people who have made this

possible.

First and foremost, I must express my deepest gratitude to my advisor, Professor Yossi Sheffi.

Without him, none of this research would be possible and I am so grateful for the opportunity to

work on this research project. This thesis benefited from Professor Sheffi’s invaluable guidance

and wealth of experience. His efforts were instrumental in leading me in the direction of clarity,

improving my academic writing, and encouraging me to think as a researcher and an industry

practitioner. Professor Sheffi, your patience and insights has never failed to improve the quality

of this thesis, and your witty banter on the Boston Bruins has never failed to improve my mood.

I would also like to thank my colleagues and friends. A special thanks to Leisa Kirkaldy, without

your kindheartedness and advice I wouldn’t have made it this far; Hitheam Mohamed, you have

always been the first to encourage me to take risks and bet on myself; and, Nick Rypkema, you

have inspired me with your own research, listened to my endless discussions about this project,

and have provided daily support and understanding for which I am perpetually grateful.

Finally, I would like to thank my family. To my parents and my brother, thank you for your

unparalleled encouragement, strength, and love throughout the years. Thank you for all the

sacrifices you have made to make all that I have achieved possible. To my brother, thank you for

keeping me sane all of these years and encouraging me to keep a positive outlook. To my

parents, you have always been my greatest teachers. My success would not be possible without

all the lessons I have learned from you both. I would not be where I am today without you.

5

6

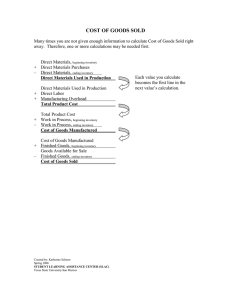

Table of Contents

1

2

3

4

5

Introduction ........................................................................................................................... 13

1.1 Motivation ...................................................................................................................... 15

1.2 Objectives ....................................................................................................................... 15

Literature Review.................................................................................................................. 16

2.1 Risk Background ............................................................................................................ 16

2.2 Sources of Supply Risk .................................................................................................. 17

2.3 Methodologies for Evaluating Supply Risk ................................................................... 18

2.4 Supply Risk Mitigation Strategies ................................................................................. 22

2.4.1 Extra Inventory ....................................................................................................... 23

2.4.2 Strategic Sourcing ................................................................................................... 25

Risk Metrics .......................................................................................................................... 27

3.1 Supplier Time-to-Recovery ............................................................................................ 27

3.1.1 Factors Affecting Supplier Time-to-Recovery ....................................................... 27

3.2 Firm Time-to-Recovery.................................................................................................. 27

3.2.1 Factors Affecting Firm Time-to-Recovery ............................................................. 29

3.3 Customer Impact Time ................................................................................................... 29

3.3.1 CIT with Finished Product Inventory ..................................................................... 31

3.3.2 CIT with Finished Product and Component Inventory ........................................... 33

3.3.3 CIT with all Forms of Inventory ............................................................................. 35

3.4 Value-at-risk ................................................................................................................... 37

Preferential Allocation .......................................................................................................... 41

4.1 Types of Preferential Allocation .................................................................................... 41

4.1.1 Preferential Product Allocation............................................................................... 41

4.1.2 Preferential Customer Allocation ........................................................................... 41

4.1.3 Preferential Product-Customer Allocation .............................................................. 42

4.2 Inventory Allocation ...................................................................................................... 42

4.3 Metrics for Evaluating Risk under Preferential Allocation ............................................ 44

4.3.1

Modified Value-at-Risk .......................................................................................... 44

4.3.1.1

Linear Program ................................................................................................ 45

4.3.1.2

Greedy Algorithm ............................................................................................ 46

4.3.2 Mitigation Factor .................................................................................................... 47

4.3.3 Marginal Financial Return ...................................................................................... 48

4.4 Comparison of Risk under Fair and Preferential Allocation .......................................... 50

4.5 Risk Metric Relationships .............................................................................................. 53

4.5.1 MVAR Relationships ............................................................................................... 54

4.5.2 Mitigation Factor Relationships.............................................................................. 56

4.5.3 Marginal Financial Return Relationships ............................................................... 61

Case Study ............................................................................................................................ 64

5.1 Comp1 ............................................................................................................................ 64

5.1.1 Demand ................................................................................................................... 64

5.1.2 Component Inventory ............................................................................................. 65

5.1.3 Finished Product Days-of-Supply ........................................................................... 66

5.1.4 Usage Rate .............................................................................................................. 67

5.1.5 Financial Value ....................................................................................................... 68

7

5.2 Comp2 ............................................................................................................................ 70

5.2.1 Demand ................................................................................................................... 70

5.2.2 Component Inventory ............................................................................................. 71

5.2.3 Finished Product Days-of-Supply ........................................................................... 72

5.2.4 Usage Rate .............................................................................................................. 73

5.2.5 Financial Value ....................................................................................................... 74

6

Analysis & Results ................................................................................................................ 77

6.1 Analysis with No Inventory ........................................................................................... 77

6.1.1 Financial Loss ......................................................................................................... 78

6.1.2 Mitigation Factor .................................................................................................... 84

6.1.3 Marginal Financial Return ...................................................................................... 86

6.1.4 Risk Mitigation Recommendations......................................................................... 89

6.2 Analysis with Inventory ................................................................................................. 97

6.2.1 Financial Loss ......................................................................................................... 97

6.2.2 Mitigation Factor .................................................................................................. 100

6.2.3 Marginal Financial Return .................................................................................... 102

7

Conclusions ......................................................................................................................... 105

7.1 Further Research .......................................................................................................... 106

Appendix A ................................................................................................................................. 108

CIT Formulation...................................................................................................................... 108

Critical Time ....................................................................................................................... 112

Accumulation Time ............................................................................................................ 115

VAR Formulation .................................................................................................................... 122

MVAR Formulation ................................................................................................................. 126

Marginal Financial Benefit Formulation ................................................................................ 131

Appendix B ................................................................................................................................. 132

MVAR Formulation for a Single-Component Disruption using Substitution ......................... 132

MVAR Formulation for a Multiple-Component Disruption .................................................... 136

References ................................................................................................................................... 138

8

List of Figures

Figure 3-1: Case of Firm and Supplier Time-to-recovery Equivalence ....................................... 28

Figure 3-2: Case of Differing Firm and Supplier Time-to-recovery ............................................ 28

Figure 3-3: CIT with Finished Product Inventory only ................................................................ 33

Figure 3-4: CIT with Finished Product and Component Inventory .............................................. 35

Figure 3-5: CIT with all Forms of Inventory ................................................................................ 37

Figure 3-6: Unmet Demand after Fair Allocation of Partial Rate of Supply ................................ 40

Figure 4-1: Unmet Demand after Preferential Product Allocation of Partial Rate of Supply ...... 52

Figure 4-2: MVAR vs. Partial Rate of Supply ............................................................................... 55

Figure 4-3: Maximal Effect of Preferential Allocation................................................................. 56

Figure 4-4: Mitigation Factor vs. Partial Rate of Supply.............................................................. 60

Figure 4-5: Mitigation Factor vs. Partial Rate of Supply (at all partial rates of supply) .............. 61

Figure 4-6: Marginal Financial Return vs. Partial Rate of Supply ............................................... 62

Figure 4-7: Marginal Financial Benefit vs. Partial Rate of Supply (at all partial rates of supply) 63

Figure 5-1: Comp1 Monthly Demand........................................................................................... 65

Figure 5-2: Comp1 Monthly Component Inventory and Demand ................................................ 66

Figure 5-3: Comp1 Monthly Percentage of Finished Products by Day-of-Supply ...................... 67

Figure 5-4: Comp1 Percentage of Finished Products by Usage Rate ........................................... 68

Figure 5-5: Comp1 Percentage of Finished Products by Financial Value .................................... 69

Figure 5-6: Comp1 Percentage of Finished Products by Financial Value per Component .......... 70

Figure 5-7: Comp2 Monthly Demand........................................................................................... 71

Figure 5-8: Comp2 Monthly Component Inventory ..................................................................... 72

Figure 5-9: Comp2 Monthly Percentage of Finished Products by Day-of-Supply ...................... 73

Figure 5-10: Comp2 Percentage of Finished Products by Usage Rate ......................................... 74

Figure 5-11: Comp2 Percentage of Finished Products by Financial Value .................................. 75

Figure 5-12: Comp2 Percentage of Finished Products by Financial Value per Component ........ 76

Figure 6-1: Comp1 Financial Loss vs. Partial Rate of Supply ..................................................... 81

Figure 6-2: Comp2 Financial Loss vs. Partial Rate of Supply ..................................................... 82

Figure 6-3: Comp2 First Order Finite Difference of MVAR with respect to Partial Rate of Supply

....................................................................................................................................................... 83

Figure 6-4: Comp1 and Comp2 Mitigation Factor vs. Partial Rate of Supply ............................. 85

Figure 6-5: Comp1 Marginal Financial Return vs. Partial Rate of Supply .................................. 88

Figure 6-6: Comp2 Marginal Financial Return vs. Partial Rate of Supply .................................. 88

Figure 6-7: Comp1 Monthly Safety Stock to Mitigate 25% of Total Financial Loss ................... 91

Figure 6-8: Comp2 Monthly Safety Stock to Mitigate 25% of Total Financial Loss ................... 92

Figure 6-9: Comp1 and Comp2 Percentage of Total Financial Loss vs. Safety Stock ................. 93

Figure 6-10: Comp1 and Comp2 Safety Stock and Partial Rate of Supply to Mitigate 25% of

Total Financial Loss ...................................................................................................................... 97

Figure 6-11: Comp1 and Comp2 Financial Loss vs. Partial Rate of Supply [Analysis with

inventory] .................................................................................................................................... 100

Figure A-1: Allocation of Finished Product Inventory ............................................................... 111

Figure A-2: Critical Time ........................................................................................................... 115

Figure A-3: Accumulation Time ................................................................................................. 122

Figure A-4: Unmet Demand after Fair Allocation of Partial Rate of Supply ............................. 126

Figure A-5: Unmet Demand after Preferential Product Allocation of Partial Rate of Supply ... 129

9

10

List of Tables

Table 3-1: Finished Product Characteristics (CIT Example) ........................................................ 32

Table 4-1: Inventory Allocation Schemes .................................................................................... 43

Table 4-2: Product Characteristics (Marginal Financial Return Example) .................................. 49

Table 4-3: Decreasing Marginal Financial Return under Preferential Product Allocation .......... 50

Table 4-4: Finished Product Characteristics (Preferential Allocation Example).......................... 51

Table 4-5: Product Characteristics (Mitigation Factor Example) ................................................. 58

Table 4-6: Product Set Mean, Variance, CVFC (Mitigation Factor Example) .............................. 58

Table 6-1: Comp1 Financial Loss (in 000s of dollars) ................................................................. 79

Table 6-2: Comp2 Financial Loss (in 000s of dollars) ................................................................. 80

Table 6-3: Comp1 Mitigation Factor ............................................................................................ 84

Table 6-4: Comp2 Mitigation Factor ............................................................................................ 85

Table 6-5: Comp1 Marginal Financial Return (in 000s of dollars) .............................................. 86

Table 6-6: Comp2 Marginal Financial Return (in 000s of dollars) .............................................. 87

Table 6-7: Comp1 Financial Loss (in 000s of dollars) [Analysis with inventory] ....................... 98

Table 6-8: Comp2 Financial Loss (in 000s of dollars) [Analysis with inventory] ....................... 98

Table 6-9: Comp1 Mitigation Factor [Analysis with inventory] ................................................ 100

Table 6-10: Comp2 Mitigation Factor [Analysis with inventory] .............................................. 101

Table 6-11: Comp1 Marginal Financial Return [Analysis with inventory] ................................ 102

Table 6-12: Comp2 Marginal Financial Return [Analysis with inventory] ................................ 103

Table A-1: Finished Product Characteristics (Single Component Disruption with Varied Finished

Product Inventory Example) ....................................................................................................... 110

Table A-2: Time Intervals Considered for Determining Critical Time ...................................... 114

Table A-3: Time Intervals Considered for Determining Accumulation Time ........................... 119

Table A-4: Finished Product Financial Value (Single Component Disruption with Varied

Finished Product Inventory Example) ........................................................................................ 124

Table A-5: Finished Product Financial Value per Component (Single Component Disruption

with Varied Finished Product Inventory Example) .................................................................... 128

11

12

1 Introduction

Disruptions such as Hurricanes Isaac and Sandy in 2012, the Corn Belt drought of 2012, and the

Tōhoku earthquake and tsunami in 2011, have spurred a heightened interest and emphasis on

addressing supply chain risk. Supply chain disruptions, defined as unplanned events affecting the

flow of materials within the supply chain, are becoming increasingly prevalent (Svensson, 2002).

The increase in frequency and intensity of both human and man-made disasters has prompted

companies to address the risks associated with supply chain disruptions.

Several trends have increased the susceptibility of supply chains to disruptions. Increased

competition has forced supply chains to be leaner, holding low inventory levels and relying

heavily on just-in-time deliveries. Leaner supply chains and logistics operations, coupled with

outsourcing and globalization of supply chains, have not only increased the likelihood of supply

chain disruptions but also the severity of their consequences. Furthermore, the increased

complexity and length of supply chains cause supply chains to be slower to respond to changes,

resulting in greater vulnerability (Tang and Tomlin, 2008).

While disruptions can impact any part of the supply chain, it has become especially

important to apply risk evaluation and mitigation strategies to procurement functions and

suppliers. Suppliers impact all downstream operations. Any disruption which prevents firms

from obtaining certain materials, parts, and/or services may result in production delays, stockouts, and delayed product launches at downstream organizations. The prominence of off-shore

sourcing and the increased connectedness of supply networks make supply chains vulnerable to

the risks imposed by suppliers’ disruptions.

13

The operational and financial losses from such disruptions can be substantial. Ericsson

reported a loss of $400 million in 2000 and subsequently exited from the mobile phone business

after its sub-supplier plant caught fire (Norrman and Jansson, 2004). In 2001, Ford was forced to

shut down five of its plants because they were unable to receive engine parts from Canada due to

border crossing restrictions after the 9/11 terrorist attacks (Martha, 2002). Disruptions caused

from natural disasters have had equally destructive effects. The 2007 earthquake in Tokyo

severely damaged major production facilities of Riken Corporation which led to ceased

production in twelve Toyota plants; three days of suspended production at Mitsubishi Motors

Corporation; and, a temporary shutdown of five of Suzuki Motor Company’s domestic plants

(Hayashi, Smith and Chozick, 2007). Disruptions caused by natural disasters alone, resulted in

losses of $380 billion dollars in 2011 (Munich Reinsurance America, Inc., 2012).

Although the immediate operational and financial losses caused by disruptions are

significant, non-financial consequences such as loss of reputation among customers and

suppliers, loss of market share, and loss of brand value have further increased the importance of

addressing supply chain risk. Hendriks and Signhal (2005) found that companies that suffered

from supply chain disruptions experienced 33-40% lower stock returns relative to their

respective industry benchmarks.

Current supply chain trends and the increase in the number and severity of disruptions

have led companies to focus on risk identification, evaluation, and mitigation strategies. This has

created a growing need for metrics that quantify supply chain risk, thereby allowing management

to prioritize and focus.

14

1.1 Motivation

Traditional risk assessment methods typically consist of “expected value” analyses based on a

combination of the likelihood of a disruption and its impacts (Zsidsin, 2004). However, due to

the difficulty of estimating likelihoods, alternative approaches use a “worst-case” or “what if?”

scenario, focusing the analysis on the consequences of a supplier ceasing to operate and the

unavailability of a part (or material) for a period. Following examination of many actual

disruptions, the latter “what if?” approach is too conservative and may lead to over-investment in

resilience and inventories. In reality, it is very rare that a supplier is completely down (most have

multiple plants where they can increase production through overtime and delayed maintenance)

or that no alternate supplier is available. Usually, a fraction of the volume is available during the

“down time”. This gap motivates the need for metrics that quantify supply chain risk

independent of estimating disruption likelihood and also model realistic scenarios, where a

fraction of supply is available during a supplier’s downtown.

1.2 Objectives

The objective of this thesis is to provide a framework for evaluating risk imposed on a

manufacturer when one of its suppliers fails. The research aims to combine and extend current

risk metrics, such as time-to-recovery and value-at-risk, and develop new risk metrics that can

determine the risk associated with a supplier failure without quantifying the likelihood of such

events. The framework will be used to estimate the disruption-minimizing strategy following a

partial supply disruption. These metrics can be used to assess and prioritize a manufacturer’s

vulnerability to a supplier failure or disruption. The results can be used to facilitate supplier

selection and the allocation of resources for monitoring and auditing suppliers.

15

2 Literature Review

This chapter establishes a basis for understanding supply risk and risk management. The chapter

provides an overview of the research conducted in this domain, focusing on literature addressing

supply chain risk evaluation methods and mitigation strategies.

2.1 Risk Background

The two common terms used in the discussion of risk management are uncertainty and risk.

There is a distinction between risk and uncertainty, although they are closely related. Knight

(1964) defines risk as being quantifiable whereas uncertainty is not. Risk is identified as

quantifiable since the probability distribution of outcomes is measurable although the outcomes

are unknown. On the other hand, uncertainty is characterized by unquantifiable probability

distributions and unknown outcomes.

Zsidisin (2004) extends the meaning of risk to define supply risk within the context of

supply chains. He defines supply risk as “the potential occurrence of an incident associated with

inbound supply from individual supplier failures or the supply market, in which its outcomes

result in the inability of the purchasing firm to meet customer demand…”. Another suggested

definition of supplier risk is “…an abnormal operational state that might occur in an upstream

supplier, spread downstream through the supply chain, and harm the purchasing firm” (Jung,

Lim and Oh, 2011). An abnormal operational state is considered, by the authors, as an event,

such as a bankruptcy or a strike, which affects the working process of the supply chain (Jung,

Lim and Oh, 2011). For the purpose of this research, supply disruption will be defined as the

financial loss that may be incurred from an inbound supply interruption causing an inability to

meet customer demand.

16

Supply chain management, as defined by Norrman and Lindroth (2002), is the

collaboration of supply chain partners to handle risk and uncertainties impacting or caused by

logistics-related activities and resources. Tang (2006) suggests a slightly different meaning of

supply chain risk management, defining it as the collaboration and coordination of supply chain

partners to manage supply chain risks in order to ensure continuity and profitability of all

partners.

2.2 Sources of Supply Risk

Purchasing firms can be impacted by any of the disruptions that their upstream suppliers may

experience. While there are multiple and diverse sources of supplier risk, each of which can be

studied at length, the following literature review describes some of the more recent supplierrelated risks firms have encountered.

Finances have always been a prevalent source of risk to suppliers, in particular,

insolvency and bankruptcy. In 2008, Chrysler was forced to temporarily shut down four of its

plants due to the cash-flow and liquidity problems experienced by its supplier Plastech (Revilla

and Sáenz, 2013). In a similar situation, Land Rover had to make a multi-million pound

“goodwill” payment to its only supplier of chassis frames, UPF-Thompson, to prevent a ninemonth production halt of its products and a potential loss of 1,500 Land Rover jobs (Sheffi and

Rice, 2005).

Natural disasters, ranging from tsunamis, earthquakes, and hurricanes, to fires and floods,

have been the source of disruption in supply chains. Hurricane Katrina prevented inbound supply

of products to stores within the affected areas (Oke and Gopalakrishnan, 2009). In 1999, an

earthquake in Taiwan hit factories that were responsible for over half of global semiconductor

contract manufacturing (Sherin and Bartoletti, 1999). This led to a shortage of semiconductors,

17

which impacted revenue and earnings of major electronic product producers, such as HewlettPackard and Dell Inc.

Finally, the terrorist attacks on September 11, 2011 have caused security threats and

terrorism to be viewed as significant sources of supplier risk. Even when suppliers are not

directly affected, government actions, taken in response to terrorist threats, have greatly

impacted international suppliers and purchasing firms (Sheffi, 2002). During the attacks of 9/11,

US borders were sealed, preventing the flow of inbound parts. Following this attack, Ford and

Toyota halted production in U.S. manufacturing plants due to delivery delays of parts sourced

internationally (). However, security threats are not limited to terrorist attacks; they also include

vandalism, sabotage, theft, cyber-attacks, and attacks on infrastructure or information systems.

2.3 Methodologies for Evaluating Supply Risk

The following section provides a survey of both qualitative and quantitative supply chain risk

evaluation methodologies.

Ericsson developed a supplier risk assessment approach following the fire in a subcontractor plant in Albuquerque, New Mexico, which caused Ericsson to exit the handset

manufacturing business (Norrman and Jansson, 2004). Ericsson evaluates its sourced

components through their first, second, and third tier suppliers. Each component is evaluated in

terms of a business interruption value metric, similar to what is commonly known as value-atrisk. The business interruption value metric represents the financial consequences of a disruption,

calculated by multiplying gross margin and business recovery time. Business recovery time is the

estimated length of time Ericsson’s deliveries may be affected by a specific incident disrupting a

component’s supply. For Ericsson, the key factors affecting business recovery time are the

number of suppliers available in the marketplace and the current sourcing strategy of the firm

18

(whether the component is single-sourced or multi-sourced). Ericsson also qualitatively defines

the probability of each supplier facing disruptions. The probability and consequences (business

interruption value metric) are mapped into a standard likelihood/consequence matrix to help

prioritize risks.

Jung et al. (2011) developed a binary logit model to assess whether suppliers pose low or

medium levels of risk firm. The dependent variable was based on a Korean vehicle

manufacturer’s classification of its first-tier suppliers as posing low or medium levels of risk.

Data about the suppliers was collected from both the manufacturer and the suppliers and used to

determine independent variables for the model. The model’s independent variables were

operational and financial capability indicators, measured objectively, and variables

characterizing the market for sourced parts, measured subjectively. Each independent variable

category has a number of sub-characteristics, each with its own scale for measurement. The

independent variables act as proxies to estimate the likelihood of a supplier encountering a

disruption and the impact of a disruption. The authors suggest the logit model use five key

independent variables (switching cost, operating profit margin, asset turnover ratio, quality

capability, and technological capability). Switching cost, operating profit margin, and quality

capability variables are negatively correlated with supplier risk. Asset turnover ratio and

operation technology variables are positively correlated with supplier risk.

Another risk evaluation approach uses Bayesian networks to develop supplier risk

profiles. The methodology analyzes relationships between supplier attributes and the purchasing

firm to determine an expected value-at-risk, representing the supplier’s impact on the purchasing

firm’s revenues (Lockamy and McCormack, 2012). The expected value-at-risk is the product of

the probability of revenue impact and monthly revenue impact. The purchasing firm’s subjective

19

assessment of the likelihood of its suppliers encountering each of three types of risks (network,

operational, and external risks), are used as a basis for the probability of revenue impact. The

average value of the probabilities assigned to each of the three risk categories represents the

supplier’s overall likelihood of encountering a disruptive event. The monthly gross revenue of all

finished assemblies using parts sourced from the supplier represents the impact of the disruption

on the purchasing firm. The single value-at-risk metric can be used to assess and compare the

risk that each supplier poses to the purchasing firm. The framework can also be used to evaluate

how changes in the probabilities of risk categories can affect the supplier’s overall risk profile

and value-at-risk (Lockamy and McCormack, 2012).

Wu et al. (2006) developed an analytical hierarchy process (AHP)-based method to

evaluate supplier risk in single-tier supply chains. The model is based on a set of risk factors

derived from literature and interviews with managers from various industries, including

electronics and food service manufacturers. Each risk factor is classified within a hierarchy; the

first tier categorizes risks as internal or external and the second tier categorizes risks as

controllable, partially controllable, or uncontrollable. AHP is used to determine the relative

importance of the set of risk factors. Then, each risk factor is assigned a subjective probability

of impacting each supplier. A single risk index is computed using the weights and probabilities

of each risk factor for each supplier. Wu et al. (2006) define this metric as the integrated

uncertainty factor, representing the level-of-risk a supplier poses to the purchasing firm. The

integrated uncertainty factor ranges from 0 to 1; the greater the value, the greater the risk posed

by the supplier. The integrated uncertainty factor is a subjective measure of risk, based upon a

firm’s perception of the importance of a set of risk factors and their probability of occurrence.

20

Blackhurst et al. (2008) produced a similar multi-criteria risk assessment model to

evaluate components. The model was developed through analysis of suppliers to an automotive

manufacturer. Nine risk categories, each with individual risk subcategories, are defined. Each

risk category is classified as internal, where the supplier has control over the risk factor, or

external, where the supplier has limited or no control over the risk factor. Each risk category is

assigned a weighing based upon the probability of each category of disruption occurring or the

relative impact of the disruption of each category on supply. These weights are subjective, based

on what is important to the automotive manufacturer. Sourced components are then graded on a

100-point scale in each risk category; a higher score is indicative of poorer supplier performance.

Component risk scores are based upon the weights and grade in each risk category. The model

also computes supplier risk scores, based upon component scores, weighted by the percentage of

volume the supplier provides of the given component. This methodology does not account for

the criticality of the part but rather the volume of the part supplied by the supplier. Blackhurst et

al. (2008) suggest using their model to evaluate risk over time; this enables the firm to assess the

movement of part of supplier risk toward unacceptable levels, aiding in the prediction of

potential supply problems in the future.

The aforementioned inbound risk assessment models are “expected value” analyses,

involving techniques that enumerate risk sources; assign probabilities to risk factors; and,

evaluate the consequences of disruptions to the purchasing firm. The assignment of probabilities

to risk factors is largely subjective, while consequences are evaluated based on financial impact.

Most models compute a single risk score to characterize suppliers’ or components’ risk. The

underlying logic to compute these risk scores varies among these methodologies.

21

Another branch of supply risk assessment research focuses on evaluating the “worstcase” or “what if?” scenario, where supplier operations are completely ceased. Simchi-Levi et al.

(2014) use linear optimization to quantify the financial and operational impacts of an inoperative

supplier facility for a specified time period. The impacts of removing a supply node from the

purchasing firm’s network are calculated under the assumption that total loss (of revenues,

profits, or production) is minimized. The model accounts for inventory and production

dependencies. The approach assigns each node a risk exposure index, which is a normalization of

the impact of each node relative to the node with the greatest impact. The risk exposure index

provides a prioritization of the risk to the various supply nodes in a firm’s network.

Berger et al. (2004) use decision trees to assess single- and multi-sourcing strategies in

the presence of risk. The methodology combines risk assessment with the evaluation of risk

mitigation sourcing strategies. Decision trees are used to compare the expected cost of sourcing

strategies where either one or several suppliers are simultaneously out of commission. The

financial loss of disrupted suppliers and the operating costs of working with multiple suppliers

are integrated in the model.

Most inbound supply risk assessment models revolve around “expected value” analyses,

which have limited use given the difficulties in estimating disruption likelihood. A small number

of researchers have focused on quantifying supply risks under the “what if?” scenario – evaluate

the consequences in case a part or material cannot be supplied for a period.

2.4 Supply Risk Mitigation Strategies

Upon evaluating and assessing risks, various strategies can be implemented to mitigate these

risks. Some mitigation strategies specifically aimed at supply risk include holding additional

inventory, dual or multi-sourcing, increasing flexibility, and increasing capacity (Chopra and

22

Sodhi, 2004). This section focuses on literature regarding the mitigation of risk through holding

additional inventory and multiple sourcing. While the literature for each strategy will be

considered separately, it is important to note that use of a single strategy is unlikely to mitigate

all supply risk. Multiple mitigation approaches can be used in concert to provide a robust

mitigation strategy.

2.4.1 Extra Inventory

Holding inventory is an established strategy for mitigating many types of risk. The 2002 West

Coast port lockout provides an illustrative example of the significance of inventory during times

of disruption. This 10-day strike of unionized West Coast port workers was estimated to have

impacted the United States economy at a rate of $934 million per day (Wolk, 2002) in the first

week. The impact rose quickly thereafter. Many firms were unable to bring in parts to their

manufacturing plants. However, not everyone was affected in the same way. The New United

Motor Manufacturing Inc. was affected within less than a week because it had almost no

inventory. The company operated a just-in-time system that only allowed them to continue

operations for five to seven days (Isidore, 2002). At the other end of the spectrum was Playmates

Toys, who invested in inventory before the disruption and thus were largely unaffected by the

disruption (Tomlin, 2006).

Inventory, however, is expensive to hold so a firm should analyze how much inventory to

hold, when to hold additional inventory, what policies to use for managing additional inventory,

and where within the supply chain to hold the inventory. The following section summarizes

some of the relevant literature addressing these questions.

A number of factors play a role in determining the applicability of holding inventory as a

risk mitigation strategy. When disruptions are frequent but their length is short, holding

23

additional inventory may be better than dual sourcing and contingent rerouting tactics (Tomlin,

2006). In this case, inventory is not being held for long periods of time between disruptions and

since the disruptions are not large, the amount of extra inventory needed is limited. The function

of additional inventory to hedge against frequent but short disruptions is similar to that of safety

stock. Although not mentioned by the authors, if these frequent and short disruptions are of a

similar order of magnitude to demand fluctuations, it is possible to combine inventory held for

these disruptions with safety stock. Then, safety stock could be used to mitigate both demand

and supply fluctuations.

Inventory can be helpful when there are advanced warnings of disruptions. For example,

labor negotiations going badly may be indicative of imminent labor strikes. Weather alerts and

terrorism threats also offer advance warning of potential disruptions. In such cases, inventory

reserves can be built ahead of the disruption instead of holding additional inventory

continuously. A system that periodically reviews threat levels can help determine the need to

adjust inventory levels, prior to an anticipated disruption.

Another proposed strategy is to use a dual inventory system, which applies to large

anticipated threats (Sheffi, 2002). A dual inventory system involves holding strategic emergency

stock that is to be used only in times of extreme disruption. To ensure this stock is not used in

normal times, its use requires senior management or board approval.

In a multi-echelon supply chain, additional inventory is recommended to be held

downstream in a variety of sites for diversification (Snyder and Shen, 2006). This contrasts with

the strategy of holding additional inventory in an upstream, centralized location, which is

appropriate under demand uncertainty since it provides risk pooling. Schmitt et al. (2015)

maintain that decentralized inventory models are optimal when both demand uncertainty and

24

supply disruptions are prevalent in the system since risk-diversification benefits outweigh risk

pooling benefits.

An alternative classification, based on the value of products, can be used to determine

whether inventory should be held centrally or across multiple sites (Chopra and Sodhi, 2004). A

decentralized inventory model is suggested for lower value products with predictable demand

patterns. Higher value products that have less predictable demand patterns may require a more

centralized inventory model.

In industries characterized by high value products with uncertain demand and short

lifecycles, the cost of holding inventory is significant. Often, using inventory to mitigate risk is

more appropriate for products with low risks of obsolescence; these products have lower holding

costs, which increases the economic feasibility of holding inventory of these products (Chopra

and Sodhi, 2004). However, for higher value products or those with high rates of obsolescence,

using a redundant supplier is considered more appropriate (Chopra and Sodhi, 2004). The

following section examines how strategic sourcing decisions can mitigate supply risk.

2.4.2 Strategic Sourcing

Single sourcing is always more effective in terms of leveraging pricing and building

relationships with the supplier. However, single sourcing is risky even without a disruption. For

example, a single supplier may not have the capacity to meet surges in demand. While multisourcing can mitigate procurement risks, in some situations sole sourcing is the only option

because no alternative suppliers exist. A variety of conditions impact sourcing decisions that

determine which strategy is most appropriate to mitigate risk. These conditions include, but are

not limited to, current relationships with suppliers, the depth of supplier reliability information, a

purchasing firm’s perception of their suppliers’ vulnerability, and product characteristics.

25

The relationship between a purchasing firm and supplier can often govern which sourcing

strategy is best for the purchasing firm. A firm may choose to have a single supplier to have

greater access to innovation or greater influence upon the supplier. To make a single-sourcing

strategy effective, the relationship between the firm and supplier must be deep; significant

investment must be placed into developing a strong relationship with the supplier. In this

situation, it is important for the purchasing firm to keep a watchful eye on the supplier’s financial

indicators and its operations. A firm may also choose to source from multiple suppliers to foster

competition, decrease prices, or any other business reason. In that case, it may be too expensive

to maintain deep relationships with all suppliers, relying instead on the flexibility to switch

between suppliers during times of disruption.

While multi-sourcing provides flexibility to move between suppliers, it does not

guarantee full supply continuity. Sheffi (2005) provides three reasons that multiple suppliers

cannot offer continuous supply: regional disruptions that affect multiple suppliers, lack of

capacity by alternative suppliers, and the interconnection of commodity markets. Alternate

suppliers may not have the capacity or may be unwilling to ramp up to help a company that only

uses them in times of disruption. Moreover, disasters have the potential to impact multiple

suppliers. To make the multi-sourcing strategy more effective, the suppliers should be spread

geographically.

26

3 Risk Metrics

This chapter introduces established metrics that are typically used for risk evaluation, including

time-to-recovery, customer impact time, and value-at-risk. Factors affecting these metrics are

also discussed.

3.1 Supplier Time-to-Recovery

Time-to-recovery, TTR, is defined as the time it takes to fully recover after the occurrence of a

disruption. TTR can characterize the firm and/or the supplier. Supplier TTR is the duration of

time, starting at the time of the disruption, and ending at the point in time when the supplier can

once again provide the firm with the component at the same rate that the component was

supplied before the disruption.

3.1.1 Factors Affecting Supplier Time-to-Recovery

A supplier’s TTR is largely influenced by the characteristics of the disruption, specifically the

location and the type of disruption. Some disruptions, such as bankruptcy, do not affect an actual

location whereas natural disasters may affect a site or a small group of sites. The type of

disruption also determines a supplier’s TTR; different types of disruptions will affect the supplier

to different extents and may affect the entire business or just a portion of it.

3.2 Firm Time-to-Recovery

A firm’s TTR is the time it takes for the firm to fully recover from a disruption affecting its

supplier, not accounting for inventory available to the firm. This duration of time begins at the

time of the disruption to its supplier and ends when the firm can fulfill all its customers’

demands.

27

A firm’s TTR can differ from its supplier’s TTR. Before the supplier recovers, the firm

may be able to find and qualify an alternative supplier or component; it may also use dilution

solutions to reduce the amount of the disrupted component required in finished products; or, it

may implement other engineering solutions, such as qualifying other materials or creating new

processes, thereby eliminating the need for the component. In all these cases the firm’s TTR will

be less than the supplier’s TTR. When a firm’s supplier faces a disruption, the firm’s TTR is the

minimum amount of time among the aforementioned various activities and the time to wait for

its current supplier to recover. In the case that the supplier’s TTR is shorter than the time it takes

to find an alternate supplier or another engineering solution, the firm’s TTR is equivalent to the

supplier’s TTR (see Figure 3-1). In cases where the time to find an alternate supplier or another

engineering solution are shorter, the firm’s TTR is less than the supplier’s TTR (see Figure 3-2).

Figure 3-1: Case of Firm and Supplier Time-to-recovery Equivalence

Figure 3-2: Case of Differing Firm and Supplier Time-to-recovery

28

3.2.1 Factors Affecting Firm Time-to-Recovery

A firm’s TTR is mainly affected by its sourcing strategy; the speed at which the firm can conduct

contingency activities; the specific component whose supply has been disrupted; and, whether

the disruption is industry-wide. A firm that sources its disrupted component from a single

supplier will likely have a different TTR than a firm with multiple suppliers. In a multi-sourcing

situation, the firm has the potential to procure the component from another supplier who has not

been disrupted, as long as the other supplier has enough capacity.

The speed at which the firm can conduct contingency activities, such as qualifying an

alternate supplier or finding engineering solutions, can also affect a firm’s TTR. The speed at

which the firm can conduct these activities is a function of its pre-planning. For example, if a

firm has identified alternate suppliers and qualified them before a disruption, the firm must only

wait for the alternate supplier to ramp-up its production.

The specific component whose supply has been disrupted also affects the firm’s TTR. If

the component is unique, the firm may have no choice but to wait for its supplier to recover.

However, a common component may be easily procured by an alternate supplier, thereby

reducing the firm’s TTR.

An industry-wide disruption can significantly affect a firm’s TTR. In an industry-wide

disruption, competitors of the firm are also disrupted. In this situation, not only may the

component be in limited supply, but many firms may be competing for this limited resource.

This can affect how long it will take for a firm to obtain the required supply of components.

3.3 Customer Impact Time

Customer impact time, CIT, measured in the same units of time as TTR, represents the interval of

time during which a firm’s customers will be affected. The period begins when a firm can no

29

longer satisfy 100% of its expected demand and ends at the firm’s recovery time. In the model

described here and subsequent analysis CIT does not account for transit times, such as the

inbound transportation of components from the supplier to the firm or outbound transportation of

the finished goods to customers. This is a simplifying assumption that can be easily relaxed.

CIT is determined by accounting for inventory available to the firm. This includes

finished product inventory, component inventory at the firm, and components accumulated from

the on-going partial rate of supply while these inventories are expended. The calculation of CIT

depends on an assumption for allocating these inventories. Two potential assumptions are

described below.

1. Continued allocation of inventory among affected finished products according to demand

for as long as finished inventory and parts are available.

2. Continued allocation of inventory for the duration of the firm’s TTR.

Under the first assumption, original demand for all affected products is sustained until all

inventories are exhausted. This assumption allows the firm time to determine its allocation policy

during the CIT period, communicate its intended actions to customers, and provide its customers

some buffer time to make contingency plans and mitigate their own losses. Under the second

assumption, this inventory is added to incoming components from the on-going partial rate of

supply and spread throughout the firm’s TTR. For now, assume CIT is calculated based on the

first assumption.

CIT can be derived using the following variables:

𝑡𝑑 – time of the disruption.

𝑡𝑟 – time of recovery.

𝐹. 𝑇𝑇𝑅 – firm time-to-recovery, equivalent to the difference between the time of recovery

and the time of the disruption (𝑡𝑟 − 𝑡𝑑 ).

30

𝐶. 𝐼𝑛𝑣 – component inventory-on-hand at the time of disruption (units: components).

𝑃. 𝐼𝑛𝑣𝑖 – inventory-on-hand of finished product 𝑖 at the time of disruption (units: finished

products).

𝐷𝑖 – average demand of finished product 𝑖 by all customers per day, from the date of the

disruption (𝑡𝑑 ) until the firm recovers (𝑡𝑟 ). Where 𝑖 is from 1 to n.

𝑢𝑖 – usage rate of components in finished products; the number of components required

to produce a single unit of finished product 𝑖 (units: components per single unit of

finished product).

𝑅 – the percentage of the normal rate of supply of the disrupted component available

during the firm’s TTR (units: percentage).

Calculations of CIT given varying availability of different types of inventories are detailed in

the following subsections. In all calculations, if total demand can be fulfilled throughout the

firm’s recovery period, the firm’s customers are unaffected and CIT = 0.

3.3.1 CIT with Finished Product Inventory

Given availability of only finished product inventory, CIT is defined in equation (3-1). When

only finished product inventory is available, CIT has will vary between products, depending on

the days of supply represented by this inventory. In equation (3-1), 𝑃. 𝐷𝑂𝑆𝑖 represents finished

product inventory days-of-supply, available to meet total demand.

𝐶𝐼𝑇𝑖 = max [(𝐹. 𝑇𝑇𝑅 − 𝑃.

𝐼𝑛𝑣𝑖

) , 0] = max[(𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆𝑖 ), 0]

𝐷𝑖

(3-1)

In the rest of this section, finished product days-of-supply will be assumed to be the same

for all affected products.

31

Example

The following example will be used throughout the chapter to illustrate the allocation of

inventory and how CIT changes with available inventory. Assume there are three products with

the following characteristics:

Total Daily Product Demand 𝑫𝒊

Usage Rate 𝒖𝒊

Finished Product Inventory on Hand

𝑷. 𝑰𝒏𝒗𝒊

Product 1

5,000

4

Product 2

2,000

8

Product 3

1,000

4

3,750

1,500

750

Table 3-1: Finished Product Characteristics (CIT Example)

The disruption is assumed to occur at time 0, and the firm recovers 6 days afterward.

𝑡𝑑 = 0, 𝑡𝑟 = 6

𝐹. 𝑇𝑇𝑅 = 𝑡𝑟 − 𝑡𝑑 = 6 − 0 = 6

Although the amount of finished product inventory differs between products, each

sustains average daily demand for three-quarters of a day. Thus, the CIT for each product is the

same, as depicted in Figure 3-3. The components usage rate is not relevant in the calculation of

CIT when only finished product inventory is considered.

𝐶𝐼𝑇1 = max (0, [𝐹. 𝑇𝑇𝑅 −

𝐶𝐼𝑇2 = max (0, [𝐹. 𝑇𝑇𝑅 −

𝐶𝐼𝑇3 = max (0, [𝐹. 𝑇𝑇𝑅 −

𝑃.𝐼𝑛𝑣1

𝐷1

𝑃.𝐼𝑛𝑣2

𝐷2

𝑃.𝐼𝑛𝑣3

𝐷3

3,750

]) = max (0, [6 − 5,000]) = max(0, [6 − 0.75]) = 5.25

1,500

]) = max (0, [6 − 2,000]) = max(0, [6 − 0.75]) = 5.25

750

]) = max (0, [6 − 1,000]) = max(0, [6 − 0.75]) = 5.25

32

Figure 3-3: CIT with Finished Product Inventory only

3.3.2 CIT with Finished Product and Component Inventory

Given the availability of both finished product inventory and component inventory, CIT is

defined in equation (3-2). Under the assumption that component inventory is fairly allocated

across all affected finished products and all affected products have the same days-of-supply,

component inventory days-of-supply is the same for all finished product.

𝐶. 𝐼𝑛𝑣

) , 0]

∑𝑛𝑖=1 𝐷𝑖 𝑢𝑖

= max[(𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆𝑖 − 𝐶. 𝐷𝑂𝑆𝑖 ), 0]

𝐶𝐼𝑇𝑖 = max [(𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆𝑖 −

(3-2)

Where:

∑𝑛𝑖=1 𝐷𝑖 𝑢𝑖 represents the total number of components required per day to fulfill total

demand of all affected products.

𝐶. 𝐷𝑂𝑆 represents the component inventory days-of-supply, the number of days that

component inventory can meet average demand of all products.

33

Example

Assume that at the time of disruption there are 30,000 components of inventory available

(𝐶. 𝐼𝑛𝑣 = 30,000). The average daily demand of components is (5,000 ∙ 4 + 2,000 ∙ 8 + 1,000 ∙

4 =) 40,000, so component inventory can meet average total demand for 0.75 days. This results

in finished product 1 being allocated 15,000 components, used to produce 3,750 finished

products. Finished product 2 is allocated 12,000 components, used to produce 1,500 finished

products. Finished product 3 is allocated 3,000 components, used to produce 750 finished

products. Figure 3-4 shows the CIT of each product given the allocation of component and

finished product inventory.

𝐶. 𝐷𝑂𝑆 =

𝐶. 𝐼𝑛𝑣

30,000

30,000

=

=

= 0.75

3

∑𝑖=1 𝐷𝑖 𝑢𝑖 5,000 ∙ 4 + 2,000 ∙ 8 + 1,000 ∙ 4 40,000

𝐶𝐼𝑇1 = max(0, [𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆1 − 𝐶. 𝐷𝑂𝑆]) = max(0, [6 − 0.75 − 0.75]) = 4.5

𝐶𝐼𝑇2 = max(0, [𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆2 − 𝐶. 𝐷𝑂𝑆]) = max(0, [6 − 0.75 − 0.75]) = 4.5

𝐶𝐼𝑇3 = max(0, [𝐹. 𝑇𝑇𝑅 − 𝑃. 𝐷𝑂𝑆3 − 𝐶. 𝐷𝑂𝑆]) = max(0, [6 − 0.75 − 0.75]) = 4.5

34

Figure 3-4: CIT with Finished Product and Component Inventory

3.3.3 CIT with all Forms of Inventory

During a disruption, it is common for some inbound supply to be available during a disruption.

This can be the result of the supplier having some ability to produce or a dual source having

capacity to meet a fraction of the firm’s demand. The available inbound supply, henceforth

referred to as the partial rate of supply (denoted by 𝑅), represents the fraction of the normal rate

of supply of the disrupted component that is available from the time of the disruption until the

purchasing firm recovers from the disruption. The available partial rate of supply is assumed to

be constant and available throughout the firm’s time-to-recovery. This, naturally, is a simplifying

assumption, as in most cases the partial rate of supply increases over time. The constant partial

rate of supply can be interpreted as the average availability over the disruption.

35

While finished product and component inventories are expended, components from the

partial rate of supply accumulate and extend the time over which total demand can be met. CIT,

given the availability of finished product inventory-on-hand, component inventory-on-hand, and

accumulated parts from the partial rate of supply, is defined in equation (3-3). Under the

assumption that the components accumulated from the partial rate of supply are allocated fairly

across all finished products, the CIT of each product will be extended by the same amount of

time. This equation is valid under the assumption that all finished products inventory is the same

in terms of days-of-supply, across all products.

𝐶𝐼𝑇 = max [(𝐹. 𝑇𝑇𝑅 −

𝑃. 𝐷𝑂𝑆 + 𝐶. 𝐷𝑂𝑆

) , 0]

1−𝑅

(3-3)

Where:

𝑅 represents the partial rate of supply; the percentage of the normal rate of supply of the

disrupted component available during the firm’s TTR.

𝑃. 𝐷𝑂𝑆 + 𝐶. 𝐷𝑂𝑆 represents the number of days that available finished product and

component inventories can fulfill total demand.

𝑃.𝐷𝑂𝑆+𝐶.𝐷𝑂𝑆

represents the total number of days, from the time of the disruption, that total

demand can be fulfilled with all forms of inventory.

1−𝑅

Example

Using the same example, now assume there is a partial incoming rate of supply of 40%. Each

day, 40% of the total required number of components per day is available for use in production.

Over the time that component and finished product inventory-on-hand are being expended, 1.5

days in total, 24,000 components accumulate. While these 24,000 components are being

expended, another 9,600 components have accumulated. The amount of components

accumulating continues to decrement until no more components accumulate from the partial rate

of supply. This accumulation enables another full day of demand to be met. Recall that initially

36

CIT was 4.5 days. After considering the accumulated components from the partial rate of supply,

CIT is 3.5 days.

𝐶𝐼𝑇 = max (0, [𝐹. 𝑇𝑇𝑅 −

= 3.5

𝐶. 𝐷𝑂𝑆 + 𝑃. 𝐷𝑂𝑆

1.5

]) = max (0, [6 −

]) = max(0, [6 − 2.5])

1−𝑅

1 − 0.4

Figure 3-5 shows the CIT of each product after allocation of three types of inventory:

component

inventory-on-hand;

finished

product

inventory-on-hand;

and,

components

accumulated from the partial rate of supply.

Figure 3-5: CIT with all Forms of Inventory

3.4 Value-at-risk

During the CIT period, financial losses accumulate as a result of unmet customer demand, where

unmet customer demand is assumed to be lost. During this time, the partial rate of supply is

37

allocated to fulfill demand to the extent possible and reduce financial loss. Value-at-risk, VAR,

represents the financial loss during the CIT period under a fair allocation policy. A fair allocation

policy allocates the partial rate of supply to affected products such that each product will receive

the same percentage of its demand during the shortage period.

VAR is based on the financial value, 𝐹𝑖 , of each affected product, representing the worth

of a single unit of the product to the firm. It can be based on revenue, profit, contribution margin,

or any other related metric. VAR is also based on the demand of each affected product.

Calculations of demand are assumed to be based on historical data. In actual disruption cases and

other short supply situations, many customers inflate their orders assuming that the firm will

allocate a set percentage under a fair allocation policy. The assumption is the firm is aware of

this inflation and any allocation will be based on the firm’s best estimate of actual customer

demand of affected products.

When there is no partial rate of supply, the value lost for each finished product is the

length of time where no customer demand is fulfilled, CIT, multiplied by the product’s demand

and its financial value. VAR is the summation of the values lost for all affected products. When a

partial rate of supply is available, it can be used during the CIT period to partially fulfill demand.

Once all available inventories have been expended (assuming that the firm continues to serve all

its customers’ demand as long as inventories are available), the firm can continue to make

products at a reduced rate, based on the partial rate of supply. The value lost is now dependent

upon the partially unmet demand for a product throughout the product’s CIT period. Given that

the partial rate of supply will be allocated fairly across all affected products, each affected

product will meet the same percentage of demand, which is equivalent to the percentage of

available components – the partial rate of supply. VAR is defined in equation (3-4).

38

𝑛

𝑉𝐴𝑅 = (1 − 𝑅) ∑(𝐶𝐼𝑇𝑖 ∙ 𝐷𝑖 ∙ 𝐹𝑖 )

(3-4)

𝑖=1

Example

Using the same example, now assume that the financial value of products 1, 2 and 3 are 5, 8 and

6 respectively. The VAR of this example is 98,700 financial units. This is based upon a partial

rate of supply of 40% and a CIT value of 3.5 days for all products.

𝑛

𝑉𝐴𝑅 = (1 − 𝑅) ∙ 𝐶𝐼𝑇 ∙ ∑ 𝐷𝑖 𝐹𝑖 = (1 − 0.4) ∙ (3.5) ∙ (5,000 ∙ 5 + 2,000 ∙ 8 + 1,000 ∙ 6)

𝑖=1

𝑉𝐴𝑅 = 0.6 ∙ 3.5 ∙ 47,000 = 98,700

The allocation of all types of inventory and the partial rate of supply is shown in Figure

3-6. Each affected product has been allocated 40% of the total number of components it requires

to meet customer demand. 60% of daily customer demand is unmet for each finished product.

39

Figure 3-6: Unmet Demand after Fair Allocation of Partial Rate of Supply

40

4 Preferential Allocation

In the previous section, risk metrics were established under the assumption of fair allocation,

where each product, affected by a component whose supply has been disrupted, receives

available components proportionate to the demand of the product. However, components can

also be allocated preferentially. Preferential allocation refers to allocating components to those

products or customers that have the highest financial contribution first. This chapter introduces

different preferential allocation policies, but focuses on one scheme (preferential product

allocation) and the methodologies to evaluate this policy.

4.1 Types of Preferential Allocation

Product, customer, and product-customer preferential allocation are different policies that can be

used to govern the distribution of inventory during a disruption.

4.1.1 Preferential Product Allocation

Under a preferential product allocation policy, components are allocated to those products with

the highest financial contribution per component first. Taking into account the number of

components used to make each product, the allocation should be based on the financial

contribution per component of the finished product.

The preferential product allocation policy is applicable when all customers are valued the

same. In this case, there is no benefit in allocating a given product to one customer over another.

4.1.2 Preferential Customer Allocation

A preferential customer allocation policy uses the value of customers to govern the allocation of

inventory during a disruption. Customers possessing the greatest value to the firm are allocated

41

components first. The value of the customer to the firm may be based on a number of factors

such as the depth of the relationship; potential for future business; customer vulnerability; etc.

The preferential customer allocation policy is applicable when all products are valued the

same. In this case, there is no benefit in allocating a given customer to one product over another.

4.1.3 Preferential Product-Customer Allocation

The preferential product-customer allocation policy is a hybrid of the preferential product

allocation and preferential customer allocation policies. Under a preferential product-customer

allocation policy, inventory is allocated to those product-customer pairs that have the greatest

value to the firm first. A product-customer pair represents a certain customer’s demand for a

specific finished product. The value of a product-customer can be the product of the financial

contribution per component of the product and the value of the customer.

The product-customer allocation policy is relevant when there is variation in the values of

products and customers. This indicates that providing a certain product to a certain customer can

be much more beneficial than producing the same product for a different customer or providing

the same customer a different product.

4.2 Inventory Allocation

Preferential allocation policies use the value of products, customers, and product-customer pairs

to specify which customers or products should be allocated available inventory and supplies first.

However, not all forms of inventory and supply must be allocated preferentially; some inventory

may still be allocated fairly, such that demand for all products or customers is sustained for the

same amount of time.

The three types of inventory considered for allocation are: component inventory-on-hand;

finished product inventory-on-hand; and, components accumulated from the incoming partial

42

rate of supply while other inventories are expended. The allocation of the partial rate of supply is

also considered.

Table 4-1 shows various combinations of allocating the three types of inventory and the

partial rate of supply fairly or preferentially. Inventory allocation scheme #1 specifies allocation

of all inventory and supply fairly, where demand of each customer or product is sustained for the

same amount of time. Inventory allocation scheme #16 lies at the other end of the spectrum,

where all types of inventory and the partial rate of supply are allocated preferentially. Firms may

opt for a hybrid inventory allocation scheme (#2 through #15), where some types of inventory

and the partial rate of supply are allocated fairly and other types allocated preferentially. These

hybrid schemes ensure that demand of every affected customer or product is fulfilled to some

degree.

Inventory Allocation Scheme #

Component

Inventory-onhand

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Fair

Fair

Fair

Fair

Preferential

Fair

Fair

Preferential

Fair

Preferential

Preferential

Fair

Preferential

Preferential

Preferential

Preferential

Type of Inventory

Finished

Accumulated

Product

Components

Inventory-onfrom Partial Rate

hand

of Supply

Fair

Fair

Fair

Fair

Fair

Preferential

Preferential

Fair

Fair

Fair

Fair

Preferential

Preferential

Fair

Fair

Fair

Preferential

Preferential

Fair

Preferential

Preferential

Fair

Preferential

Preferential

Fair

Preferential

Preferential

Fair

Preferential

Preferential

Preferential

Preferential

Table 4-1: Inventory Allocation Schemes

43

Partial Rate of

Supply

Fair

Preferential

Fair

Fair

Fair

Preferential

Preferential

Preferential

Fair

Fair

Fair

Preferential

Preferential

Preferential

Fair

Preferential

Inventory allocation scheme #2 will be the scheme studied henceforth. As mentioned

above, this allows the firm time to determine its allocation policy during the CIT period;

communicate its intended actions to customers; and, provide its customers some buffer time to

make contingency plans and mitigate their own losses. Only the partial rate of supply, used to

reduce the amount of unmet demand during the CIT period, will be allocated preferentially.

Since CIT is dependent only upon component inventory-on-hand, finished product

inventory-on-hand and accumulated components from the partial rate of supply, there is no

difference between the CIT used in the calculation of VAR (see Equation (3-4)), and the CIT

under a preferential allocation policy.

4.3 Metrics for Evaluating Risk under Preferential Allocation

Three metrics will be used to evaluate risk under preferential allocation. The first metric is

modified value-at-risk, MVAR, which measures financial loss as the result of unmet customer

demand under preferential allocation. The second metric is a mitigation factor, which measures

the relative benefit of allocating the partial rate of supply preferentially instead of fairly. The

third metric is marginal financial return, measuring the change in the firm’s financial results with

respect to a change in the partial rate of supply over the firm’s CIT period. These metrics and the

methodologies to determine are defined in this section. In addition, the example from section 3 is

used to evaluate the preferential product allocation policy and compare it with the results under

fair allocation.

4.3.1 Modified Value-at-Risk

Modified value-at-risk, MVAR, represents the financial loss during the CIT period, under a

preferential product allocation scheme. Under preferential product allocation, the partial rate of

44

supply is allocated to affected products so as to minimize the total financial impact to the firm.

This policy takes into account the financial value of each product, 𝐹𝑖 , and the numbers of

components used to make each product, 𝑢𝑖 . MVAR will always be less than VAR; only when all

affected products have the same financial contribution per component, or the partial rate of

supply is 0 or 100%, will the two values be the same.

MVAR is contingent upon the set of variables 𝑋𝑖 , representing the number of affected

products 𝑖, produced per day, given the allocation of components from the partial rate of supply

to each respective product.

MVAR, defined in equation (4-1), is the summation of the product of the amount of time

that total demand is unfulfilled, CIT; the average unmet demand during this period; and, the