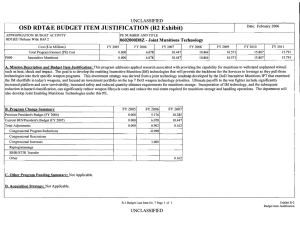

UNCLASSIFIED

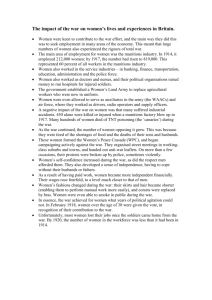

advertisement