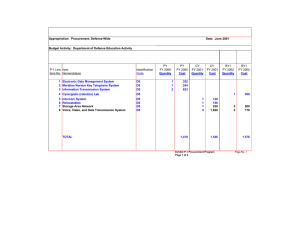

DEPARTMENT OF THE ARMY Procurement Programs

advertisement