DEPARTMENT OF THE ARMY Procurement Programs Committee Staff Procurement Backup Book

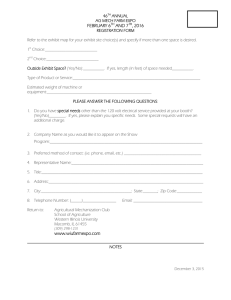

advertisement