Precision Cooling

For Business-Critical Continuity™

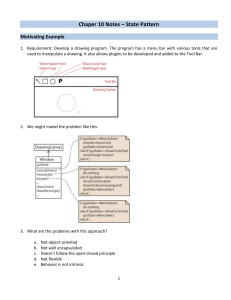

Liebert® DM Series Air Conditioner

Technical Manual

Liebert_DM Series Air Conditioner

Technical Manual

Version

Revision date

BOM

V1.0

Emerson Network Power provides customers with technical support. Users may contact the

nearest Emerson local sales office or service center and company headquarters.

Copyright © 2012 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen

China

Postcode: 518057

Customer Service Hotline: 4008876510

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Contents

Chapter 1 Preface ............................................................................................................................................................... 1

1.1 Special Requirements On The Equipment Room Environment ............................................................................ 1

1.2 Liebert_DM Series AC – Designed For Equipment Room .................................................................................... 1

Chapter 2 Overview ............................................................................................................................................................ 3

2.1 Appearance .......................................................................................................................................................... 3

2.2 Model Description ................................................................................................................................................. 3

2.3 Product Introduction .............................................................................................................................................. 3

2.4 Main Components ................................................................................................................................................. 4

2.4.1 Indoor Unit ................................................................................................................................................. 4

2.4.2 Outdoor Unit .............................................................................................................................................. 4

2.5 Options ................................................................................................................................................................. 5

2.5.1 Humidifier .................................................................................................................................................. 5

2.5.2 Heater ........................................................................................................................................................ 5

2.5.3 Remote Monitor ......................................................................................................................................... 5

2.5.4 Energy-Saving Card .................................................................................................................................. 5

2.5.5 Power SPD ................................................................................................................................................ 5

Chapter 3 Technical Parameter .......................................................................................................................................... 6

3.1 Technical Parameter Of The Indoor Unit .............................................................................................................. 6

3.2 Technical Parameter Of The Outdoor Unit............................................................................................................ 7

3.3 Mechanical Parameter .......................................................................................................................................... 7

3.3.1 Indoor Unit ................................................................................................................................................. 7

3.4 Outdoor Unit.......................................................................................................................................................... 8

3.5 Operation Environment ......................................................................................................................................... 9

Chapter 4 Application Guidline .......................................................................................................................................... 10

4.1 General Arrangement ......................................................................................................................................... 10

4.2 General Principles............................................................................................................................................... 10

4.3 Piping .................................................................................................................................................................. 11

4.4 Model Configuration ............................................................................................................................................ 12

4.5 Cooling Circulation .............................................................................................................................................. 12

Chapter 5 Micro-Processing controller .............................................................................................................................. 13

5.1 Appearance ........................................................................................................................................................ 13

5.2 LCD Screen ........................................................................................................................................................ 13

5.3 Control Buttons ................................................................................................................................................... 13

5.3.1 Function Description ................................................................................................................................ 13

5.3.2 Operation Example .................................................................................................................................. 14

5.4 Control Screen .................................................................................................................................................... 14

5.4.1 ON Screen ............................................................................................................................................... 14

5.4.2 Normal Screen......................................................................................................................................... 14

5.4.3 Password Screen .................................................................................................................................... 15

5.5 Control Logic ....................................................................................................................................................... 15

5.5.1 Cooling logic ............................................................................................................................................ 15

5.5.2 Heating Logic........................................................................................................................................... 16

5.5.3 Dehumidifying Logic ................................................................................................................................ 16

5.5.4 Humidifying Logic .................................................................................................................................... 18

5.5.5 Outdoor Fan Control ................................................................................................................................ 18

5.5.6 Economy Mode Control ........................................................................................................................... 19

5.5.7 Sleep Mode Control ................................................................................................................................. 19

5.5.8 Host/Standby Unit Control ....................................................................................................................... 19

5.6 Alarm Function .................................................................................................................................................... 20

5.6.1 Alarm Category........................................................................................................................................ 20

5.6.2 Alarm State And History .......................................................................................................................... 20

5.6.3 Alarm Prerequisites And Handling Methods ............................................................................................ 20

5.7 Other Functions .................................................................................................................................................. 23

5.7.1 Real-Time Clock ...................................................................................................................................... 23

5.7.2 Operating Record .................................................................................................................................... 23

5.7.3 Parameter Protection ............................................................................................................................... 23

5.7.4 Password Protection ................................................................................................................................ 23

5.7.5 Shutdown Mode ....................................................................................................................................... 23

5.7.6 Diagnosis Output ..................................................................................................................................... 24

5.7.7 Sensor Calibration ................................................................................................................................... 24

5.7.8 Deployment Management........................................................................................................................ 24

Appendix 1 Menu Structure ............................................................................................................................................... 25

Appendix 2 Wiring Diagram............................................................................................................................................... 26

Appendix 3 Glossary ......................................................................................................................................................... 28

Chapter 1

Preface

1

Chapter 1 Preface

This chapter mainly introduces the special requirements on the equipment room environment and the features and

advantages of Liebert_DM series air conditioners (AC for short).

1.1 Special Requirements For The Equipment Room Environment

The precise environment control is very important for the operation of the computers , therefore, the computers have

strict requirements for the equipment room environment, which cannot be achieved by the commercial air conditioners

designed for comfort. The relevant requirements mainly include the following four aspects.

Temperature control: Huge amount of sensible heat is generated when computers and exchanges are operating in

the equipment room, whose density is 6 to 10 times of that of the general offices. To ensure that the computers and the

devices exert their optimal effect, the temperature of the equipment room is best controlled within 24°C±1°C; This

requires that the AC units have sufficient cooling capacity and timely response regulatory capacity to cope with drastic

changes in temperature, which cannot be implemented by the commercial air conditioners.

Humidity control: In computer room, ultra-high or ultra-low humidity will damage the computers. The ultra-high

humidity makes the air moisture condense to form condensation water in the computers, resulting in short-circuit or

damage of the host hardware. The ultra-low humidity will make the static electricity generate in the computer room,

making the computers unable to operate or even crash. The commercial air conditioners cannot control the humidity

within the required range.

Airflow / cleanliness control: Computers and exchanges will produce huge sensible heat during the operation. To

eliminate the heat rapidly, The ACs are required to have large enough large cooling cycle airflow and long blowing

distance. Besides, because of the strict requirement of air cleanliness, the AC should provide an airflow equivalent to

the ventilating rate of 30 times per hour, so as to filter the air. The commercial ACs cannot achieve these.

All-year-round running: The commercial ACs (cooling operation) are only used in summer and they only run for 8 ~

10 hours each day. In the equipment room, however, the ACs are required to work all year round even in winter when

the temperature reached -34°C outdoors.

1.2 Liebert_DM Series AC – Designed For Equipment Room

The Liebert_DM series AC includes units with a cooling capacity of 7.5kW and 12.5kW. You can configure them freely

to meet different requirements of large-, medium-, and small-sized equipment rooms and base stations. Besides, the

AC has precise temperature/ humidity control and reliability design, fully meeting the special use environment

requirement of the equipment rooms.

Special development: As a part of the integration solution to equipment room, the Liebert_DM series ACs are

specially designed for the electrical devices and provides a proper environment for the running of the precise devices,

such as sensitive devices, industry process devices, communication devices and computers.

Considerate design: Being concerned about inter-device practical applications, the Liebert_DM series ACs are

designed to keep the overall layout between devices and ensure onsite installation and maintenance.

2

2

Saving space: The Liebert_DM series AC occupies 0.3 m and a total of 1 m area is required plus the maintenance

space.

Precise control: The precise control system of the Liebert_DM series ACs implement precision control over indoor

environment, guaranteeing the safe working and stable running of devices to a maximum degree. For the indoor unit

control panel, see Figure 1-1.

Liebert DM Series Air Conditioner Technical Manual

2

Chapter 1

Preface

J13 Board power

supply input J34 Temp/Hum detection board J23 Pressure sensor

J14 Monitoring

J12 Display board power supply

ON

J39 Display board data line

J18 SCR output

to contactor

J21 Switch input, such as high

pressure switch

J31 DI input power supply

J28 Output, such as J19 Remote switch

electric heater output

Figure 1-1

Control board of the indoor unit

Outstanding man-machine interface: The Liebert_DM series ACs provide a large Chinese/English LCD, a

user-friendly man-machine interface and an expert diagnosis system, as well as implement multi-level password

protection (avoid misoperation) and intelligent display of running states.

High reliability: Relying on the excellent quality and considerate services of Emerson, the Liebert_DM series ACs

ensure 24-hour reliable running all year round.

Strong adaptability to power grid: The Liebert_DM series ACs allow a wide range of voltage and provide the

following distinctive functions: unique phase loss protection, phase-sequence detection and protection, automatic

high-voltage & low-voltage detection and protection, self-recovery upon power failure.

All-weather operation: According to the distinct heating load feature of equipment rooms, the Liebert_DM series ACs

implement 24-hour running all year round in temperature ranging from -15°C to +45°C. If a Lee-Temp outdoor unit is

configured, the allowed running temperature ranges from -34°C to +45°C.

Strong network management: Being configured with a standard RS485 monitor interface, the Liebert_DM series

ACs implement flexible automatic switchover between active and standby devices, work shift, remote turn-off and

turn-on, remote alarm, and fault query and troubleshooting over standard telecommunication protocols.

Easy maintenance: The Liebert_DM series ACs provide a full front maintenance structure, facilitating maintenance.

Table 1-1 describes the differences between the Liebert_DM series ACs and commercial ACs.

Table 1-1 Differences between the Liebert_DM series ACs and commercial ACs

Design focus

Precision

Temperature control

Monitoring

All-rear-round continually operating

Testing before delivery

Control design

Cleanliness

Liebert_DM series AC

±1°C; ±1%RH

Humidifying and dehumidifying control

Local and romote monitoring

All-year-around cooling

Strict requirement

Precise control

High

Commercial AC

Generally ±3°C

None in general

None

No cooling needed in winter

Simple testing

CPU

Low

Liebert DM Series Air Conditioner Technical Manual

Chapter 2

Overview

3

Chapter 2 Overview

This chapter expounds the appearance, model description, product introduction, components and variety of accessory

options.

2.1 Appearance

Taking the indoor unit of the Liebert_DM series air conditioner as an example, the appearance as shown in Figure 2-1.

Figure 2-1 Indoor unit of the air conditioner

2.2 Model Description

The model description of the air conditioner is shown in Figure 2-2.

DM E 07 M C T

1

1: Standard; 2: High efficiency

Version code

C: cooling only; O: with heater; H: with heater and humidifier

Input power supply. M: 380V-3-ph-50Hz

Cooling capacity. 07: 7.5kW ; 12: 12.5kW

E: indoor unit; C: outdoor unit; L: Lee-Temp outdoor unit

Liebert_D series air conditioner

Figure 2-2 Model description

2.3 Product Introduction

The Liebert_DM AC is a small precise environment control system, specially designed for cooling the electrical

devices. It is applicable to environment control in equipement room and computer room. Featuring high reliability, it

can maintain a favorable environment for precise devices such as sensitive devices, industry process devices,

communication devices and computers.

The cooling kit is provided as standard and it can precisely control the ambient temperature. The heater and humidifier

are provided as options and they can precisely control the ambient humidity. If the AC unit is only available for cooling,

the options are not needed.

Liebert DM Series Air Conditioner Technical Manual

4

Chapter 2

Overview

The Liebert_DM AC provides a micro-processing controller that can automatically switch over to the required function

(cooling or heating, dehumidifying or humidifying), based on the programmed setpoints and room ambient conditions.

Each Liebert_DM AC consists of an indoor unit and an outdoor unit. Both units are installed on the floor separately.

Indoor unit

The Liebert_DM AC includes units with a cooling capacity of 7.5kW and 12.5kW, which are applicable to power supply

of 380V, 3-ph. You can select them according to the actual equipment room conditions.

Outdoor unit

The outdoor unit adopts air cooled mode. It is classified into two models: standard model and Lee-Temp model. The

Lee-Temp model can be used at lower temperature (see Table 1-1) than the standard model.

2.4 Main Components

2.4.1 Indoor Unit

The indoor unit consists of evaporator, compressor, fan, micro-processing controller, thermal expansion valve, strainer,

filter, heater (optional), humidifier (optional) and surge protective devices (SPD, optional). For option introduction, refer

to 2.5 Options.

Evaporator

Adopt a fin-tube heat exchanger with high efficiency. The distributor is designed and verified according to individual

model to ensure that the refrigerant is distributed evenly in each loop, improving the efficiency of the heat exchanger to

a great extent.

Compressor

Adopt a compressor with high efficiency ratio. It features low vibration, low noise and high reliability.

Fan

Adopt a centrifugal fan with high efficiency and high reliability. It features large airflow, long blowing distance, direct

driving and easy maintenance.

Micro-processing controller

Provide a simple-operation user interface with multi-level password protection, self-recovery upon power failure,

high-voltage & low-voltage protection, phase loss protection, automatic phase-sequence switching upon anti-phase

and rotate speed control of the outdoor fan. The expert-level fault diagnose system can automatically display current

fault information to facilitate equipment maintenance by maintenance personnel.

Thermal expansion valve

Adopt a thermal expansion valve with external equalizer type. It collects temperature and pressure signals at the same

time to accurately regulate the refrigerant flow.

Strainer

Filtrate the impurities generated during long-term system operation and ensure normal system operation.

Filter

Adopt nylon filter material with big mesh for Liebert_DM AC. The filter features compact structure and easy

maintenance. It can be washed repeatedly.

2.4.2 Outdoor Unit

The outdoor unit consists of fan and condenser. Other than the above components, the Lee-Temp model also includes

a low-temperature unit.

Fan

Adopt axial flow blades with low noise. The single-phase motor with high performance is customized based on the

power grid of base stations, so it can work over a wide voltage range with high reliability.

Liebert DM Series Air Conditioner Technical Manual

Chapter 2

Overview

5

Condenser

Adopt a fin-tube heat exchanger with high heat dissipation and wavy fins. It is free of dust accumulation, and can be

easily cleaned and maintained.

Low-temperature unit

Make the AC unit operate in cooling mode normally at the lowest outdoor temperature of -34°C.

2.5 Options

2.5.1 Humidifier

The humidifier can add pure water vapor (up to 2.5kg/hour) into the room to control the indoor humidity within ranges

required by devices and computer.

The humidifier consists of a steam canister with automatic flushing control function, inlet tube, drain tube, solenoid

valve and steam distributor.

Note

1. The electrode humidifier should be installed and tested in factory.

2. The Liebert_DM AC can control the ambient humidity only after a humidifier is installed.

2.5.2 Heater

A ceramic heater with positive temperature coefficient can be selected. It is safe and reliable. When the surface

temperature is too high, it will reduce the heating power to avoid danger caused by over-temperature. A temperature

switch is provided on the surface of the heater, and it will cut off the power of the heater when the surface temperature

is too high. When the surface temperature decreases to normal, the temperature switch will restore the operation of

the heater automatically.

2.5.3 Remote Monitor

The Liebert_DM AC communicates with the host computer through a configured RS485 port and receives the control

of the host software. You can also select and configure a monitoring card to realize different monitoring functions. For

the descriptions of the host monitoring software SiteMonitor developed by Emerson, refer to

Appendix 3 SiteMonitor Software Introduction.

2.5.4 Energy-Saving Card

The Liebert_DM AC can monitor the maximum room temperature with the energy-saving card located outside the unit

cabinet. The card is placed in position with high heat load and temperature. Up to four cards can be used for an AC

unit. When the temperatures measured by all energy-saving cards are lower than the setpoint in ‘Sleep Mod’ and only

indoor fan is running, if the ‘Sleep Mod’ is set to ‘ENAB’, the AC unit will turn off the indoor fan and enter the sleep

mode for saving the energy.

2.5.5 Power SPD

The power SPD is used for second level (C level) lightning over-voltage protection of the AC power. It can be

maintained easily and provides status indicating and alarm function.

Note

The power SPD should be installed in factory.

Liebert DM Series Air Conditioner Technical Manual

6

Chapter 3

Technical Parameter

Chapter 3 Technical Parameter

This chapter expounds the technical parameter, mechanical parameter and operating environment of the

indoor/outdoor unit of the Liebert_DM series AC.

3.1 Technical Parameter Of The Indoor Unit

Table 3-1 Technical parameter of DME07 series indoor unit

Model

Type

DME07

MCT1

DME07

MOT1

DME07

MHT1

DME07

MCP1

DME07

MOP1

DME07

MHP1

7500

7500

7500

7500

7500

7500

6500

6500

6500

6500

6500

6500

1800

1

1800

1

1800

1

1800

1

1800

1

1800

1

0

0

0

0

0

0

1

0.25

2

-

1

0.25

2

3.2

1

0.25

2

3.2

1

0.25

2

-

1

0.25

2

3.2

1

0.25

2

3.2

-

-

1.5

-

-

1.5

485 × 845

×8

312 × 317

×8

3

485 × 845

×8

312 × 317

×8

3

485 × 845

×8

312 × 317

×8

3

485 × 845

×8

312 × 317

×8

3

485 × 845

×8

312 × 317

×8

3

485 × 845

×8

312 × 317

×8

3

9.52

9.52

9.52

9.52

9.52

9.52

12.7

12.7

12.7

12.7

12.7

12.7

-

-

19

-

-

19

20

20

20

20

20

20

Net weight (kg)

90

92

95

Max. current (A)

6

8

20

Electrical

parameter

Air breaker

32

32

32

Note: all the cooling capacity is nominal, ±5% error exists in the actual capacity

90

6

32

92

8

32

95

20

32

Cooling

capacity and

sensible

cooling

capacity (kW)

Fan

Compressor

Evaporator coil

Electric heater

Electrode

humidifier

Filter

Port size

Cooling

capacity

Sensible

50%RH

cooling

capacity

Standard airflow (m3/h)

Number

Static pressure outside

the fan (Pa)

Number

Front face area (m2)

Face air velocity (m/s)

Power (kW)

Humidifier water rate

(kg/h)

Front filter size (mm, 1

pcs)

Side filter size (mm, 1

pcs)

Number

Liquid return pipe ID

(mm)

Discharge pipe ID (mm)

Humidifier

Charging pipe OD (mm)

Condensed water drain

pipe OD (mm)

24°CdB

Table 3-2 Technical parameter of DME12 series indoor unit

Model

Type

Cooling

capacity and

sensible

cooling

capacity (kW)

Fan

Cooling

capacity

Sensible

50%RH

cooling

capacity

Standard airflow (m3/h)

Number

Static pressure outside

the fan (Pa)

24°CdB

DME12

MCT1

DME12

MOT1

DME12

MHT1

DME12

MCP1

DME12

MOP1

DME12

MHP1

12500

12500

12500

12500

12500

12500

10200

10200

10200

10200

10200

10200

2800

1

2800

1

2800

1

2800

1

2800

1

2800

1

0

0

0

0

0

0

Liebert DM Series Air Conditioner Technical Manual

Chapter 3

Compressor

Evaporator coil

Electric heater

Electrode

humidifier

Filter

Port size

Number

Front face area (m2)

Face air velocity (m/s)

Power (kW)

Humidifier water rate

(kg/h)

Front filter size (mm, 1

pcs)

Side filter size (mm, 1

pcs)

Number

Liquid return pipe ID

(mm)

Discharge pipe ID (mm)

Humidifier

Charging pipe OD (mm)

Condensed water drain

pipe OD (mm)

Technical Parameter

1

0.37

2.1

-

1

0.37

2.1

3.2

1

0.37

2.1

3.2

1

0.37

21

-

1

0.37

2.1

3.2

1

0.37

2.1

3.2

-

-

2.5

-

-

2.5

578 × 914

×8

376 × 427

×8

3

578 × 914

×8

376 × 427

×8

3

578 × 914

×8

376 × 427

×8

3

578 × 914

×8

376 × 427

×8

3

578 × 914

×8

376 × 427

×8

3

578 × 914

×8

376 × 427

×8

3

12.7

12.7

12.7

12.7

12.7

12.7

16

16

16

16

16

16

-

-

19

-

-

19

20

20

20

20

20

20

140

10.5

32

142

10.5

32

145

22

32

Net weight (kg)

140

142

145

Max. current (A)

10.5

10.5

22

Electrical

parameter

Air breaker

32

32

32

Note: all the cooling capacity is nominal, ±5% error exists in the actual capacity

3.2 Technical Parameter Of The Outdoor Unit

Table 3-3 Technical parameter of the standard outdoor unit

Model

Item

Airflow (CMH)

Condenser coil CSA (m2)

Number of the condenser coil row

Motor power (W)

Operating temperature range (°C)

Refrigerant charge quantity (g)

Size of the liquid pipe (mm)

Size of the discharge pipe (mm)

DMC07WT1

3800

0.73

2

170

-15°C ~ +45°C

500

9.52

12.7

DMC12WT1

7300

1.1

2

340

-15°C ~ +45°C

1000

12.7

16

Table 3-4 Technical parameter of the Lee-Temp outdoor unit

Model

Item

Airflow (CMH)

Condenser coil CSA (m2)

Number of the condenser coil row

Motor power (W)

Operating temperature range (°C)

Refrigerant charge quantity (g)

Size of the liquid pipe (mm)

Size of the discharge pipe (mm)

7

DML07W1

3800

0.49

2

150

-34°C ~ +45°C

4870

9.52

12.7

3.3 Mechanical Parameter

3.3.1 Indoor Unit

The mechanical parameters of the indoor unit are listed in Figure 3-1 and Table 3-6.

Liebert DM Series Air Conditioner Technical Manual

DML12W1

7300

0.98

2

300

-34°C ~ +45°C

7150

12.7

16

8

Chapter 3

Technical Parameter

600

510

50

0

38

5

1850

1750

600

510

510

600

DME07kW

DME12kW

Figure 3-1

Dimensions of the indoor unit (unit: mm)

The shadows in Figure 3-1 indicate a reasonable installation and service space. For 7.5kW units, 510mm must be

reserved to facilitate maintenance; For 12.5kW unit, 600mm must be reserved to facilitate maintenance.

The AC unit equipped with a heater should be kept a distance of minimum 150mm from combustible substance. When

testing the AC unit, keep the external static pressure below 150Pa lest the air volume becomes too low and the heater

becomes too hot.

3.4 Outdoor Unit

The mechanical parameters of the outdoor unit are shown in Figure 3-2, Figure 3-3 and Table 3-6.

352

787

829

1240

352

787

Figure 3-2

Dimensions of standard outdoor unit (unit: mm)

Liebert DM Series Air Conditioner Technical Manual

Chapter 3

352

352

Technical Parameter

103

7

103

Figure 3-3

575

575

829

1240

7

Dimensions of Lee-Temp outdoor unit (unit: mm)

Table 3-5 Mechanical parameters of indoor unit and outdoor unit

Model

Cooling capacity (kW)

7.5

12.5

-

DME07***

DME12***

DMC07WT1

DMC12WT1

DML07W1

DML12W1

Indoor unit

Outdoor unit

Dimensions (W × D × H, mm)

510 × 385 × 1750

600 × 500 × 1850

787 × 352 × 829

787 × 352 × 1240

1037 × 352 × 829

1037 × 352 × 1240

Net weight (kg)

90

145

40

60

53

95

3.5 Operation Environment

The operation environment requirements are listed in Table 3-7.

Table 3-6 Operation environment requirements

Item

Installation position

Installation mode

Ambient temperature

Requirements

The maximum equivalent horizontal distance between the indoor unit and outdoor unit[1]: 50m;

Vertical distance ΔH[2]: -5m ≤ ΔH ≤ 20m

Indoor unit: vertical mode; mounting base ≥ 150mm;

outdoor unit: horizontal airflow mode

Indoor: 0°C ~ 40°C

Outdoor: standard model, -15°C ~ +45°C; Lee-Temp model, -34°C ~ +45°C

30%RH ~ 80%RH

Outdoor unit: IPX4

< 1000m. Derating is required when the altitude exceeds 1000m

380V (-15% ~ +15%), settable according to different environments, the error is 3%

Ambient humidity

Protection level

Altitude

Operation voltage range

Note:

[1]: The value is positive if the outdoor unit is installed above the indoor unit; negative if the indoor unit is installed above the

outdoor unit.

[2]: ΔH = Altitude of the outdoor unit - Altitude of the indoor unit

[3]:Total transportation and storage time should not exceed six months. Otherwise, the performance needs to be re-calibrated

Liebert DM Series Air Conditioner Technical Manual

9

10

Chapter 4

Application Guidline

Chapter 4 Application Guidline

This chapter mainly introduces the general arrangement, general principle, piping, model configuration and cooling

cycle.

4.1 General Arrangement

The general system arrangement diagram is shown in Figure 4-1. The standard pipe sizes are shown in Table 4-1.

Figure 4-1

General arrangement diagram

Note

1.

: Factory piping.

2.

: Field piping (by technicians).

3. *: Check valve and traps are optional and not supplied by Emerson. But they are recommended for normal system operation

and easy maintenance. They should be installed on site by technicians.

4. +: Solenoid valve is a part of extended piping kit.

Table 4-1 Standard pipe sizes

Actual cooling capacity

7.5kW unit

12.5kW unit

Liebert_DM series

Pipe length (m)

5

5

Discharge pipe OD

1/2” (12mm)

5/8” (16mm)

Liquid pipe OD

3/8” (10mm)

1/2” (12mm)

4.2 General Principles

1. Use copper pipes with quick thread connector to connect the indoor unit and the outdoor unit. If the pipe length

exceeds the standard pipe length (see Table 4-1) and straight copper pipe is used, piping joints must be brazed.

2. Follow standard industry procedures in selection and placement of pipe, system evacuation and charging with

refrigerant (only when pipeline is too long). The standard refrigerant of the AC unit is R22.

3. Give considerations to pipeline pressure drop, oil return to the compressor, to avoid oil leakage and clogging in parts

of the system and minimize noise and vibration to the greatest extend.

4. Consult Emerson before installation on whether measures such as using extended piping kit are needed, if the

equivalent length exceeds 50m, or if the vertical distance between the indoor unit and the outdoor unit exceeds the

values in Table 4-2.

Liebert DM Series Air Conditioner Technical Manual

Chapter 4

Application Guidline

11

Table 4-2 Vertical distance between indoor unit and outdoor unit

Relative position

Outdoor unit installed higher than indoor unit

Outdoor unit installed lower than indoor unit

Value

Maximum: 20m

Maximum: 5m

5. The equivalent length of each part is given in Table 4-3. The resistance loss caused by elbows and valves has been

taken into consideration. The installer should confirm if these values are appropriate for site conditions.

Table 4-3 Equivalent length of each part

Liquid pipe OD (inch)

Equivalent length (m)

45° elbow

0.10

0.12

0.15

0.18

0.24

0.3

90° elbow

0.21

0.24

0.27

0.3

0.44

0.56

3/8

1/2

5/8

3/4

7/8

1-1/8

T-type three way

0.76

0.76

0.76

0.76

1.1

1.4

4.3 Piping

All equipment must be installed vertically. The Liebert_DM AC is available in two installation modes: outdoor unit

installed higher than indoor unit and indoor unit installed higher than outdoor unit. See Figure 4-2 and Figure 4-3 for

details.

Outdoor unit

Liquid pipe (not be exposed to sun)

Max. 20m

Indoor unit

Trap

7.5m

Protection

tube

Sealed

Figure 4-2

Humidifier canister water

supply pipe (to water tap)

Isolataion

floor

Discharge pipe (slope)

1:200

Insulation

material

Outdoor unit above indoor unit

Liebert DM Series Air Conditioner Technical Manual

Floor Condensation water

drain pipe (to outdoor)

1:200

12

Chapter 4

Application Guidline

Indoor unit

Protection tube

Discharge pipe (slope)

1:200

Sealed

Humidifier canister water

supply pipe (to water tap)

Isolation floor

Min. 5m

Liquid pipe (not be

exposed to sun)

Outdoor unit

Insulation

material

Floor Condensation water

drain pipe (to outdoor)

1:200

Figure 4-3 Indoor unit above outdoor unit

4.4 Model Configuration

Table 4-4 Configuration of the indoor unit and the outdoor unit

Main power

Cooling

capacity

Single cooling

380V/3P/50Hz

7.5kW

12.5kW

DME07MCT(P)1

DME12MCT(P)1

Indoor unit

With electric

heating

DME07MOT(P)1

DME12MOT(P)1

With humidifying

and heating

DME07MHT(P)1

DME12MHT(P)1

Outdoor unit

Standard

Lee-Temp

model

model

DMC07WT1

DML07W1

DMC12WT1

DML12W1

4.5 Cooling Circulation

As shown in Figure 4-4, the compressor (1) presses the high-temperature gaseous refrigerant into the air-cooled

condenser (2). The refrigerant is condensed as fluid in the condenser and sent to the evaporator (4) after being

throttled by the thermostatic expansion valve (3). In the evaporator (4), the refrigerant performs heat exchange with

the indoor air that is driven and circulated by the indoor fan (5) and then evaporates. The refrigerant is sent back to the

compressor (1) to start a new circulation. The system adjusts the rotation speed of the outdoor fan (6) to retain the

discharge pressure normal.

The compressor (1) is configured with a crankcase heating strip to prevent the refrigerant from flowing back from the

condenser in summer. This can protect the compressor from liquid strike during startup.

Figure 4-4 Schematic diagram of the system

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

Micro-Processing Controller

13

Chapter 5 Micro-Processing controller

This chapter gives a detailed description on appearance, LCD screen, control buttons, control screen, control logic,

alarm function of the micro-processing controller of the Liebert_DM AC.

5.1 Appearance

The micro-processing controller panel is shown in Figure 5-1.

Figure 5-1 Micro-processing controller panel

5.2 LCD Screen

The LCD screen displays English menus with white backlight. When the system is operating normally, it displays the

current temperature & humidity (whether to display humidity is optional. Only the unit configured with a humidifier can

display humidity), unit output status (cooling, heating, dehumidifying and humidifying), unit status (single, host,

standby), unit operation status (running, standby, locked), alarm information and current date & time, as shown in

Figure 5-2.

21°

C

Heat SIG

50%rh

Hum RUN

High Hum

1/4

2012/01/01

00:00

Figure 5-2

LCD screen

More detailed operating status of certain component and alarm information are available from the Main Menu screen.

The selected menu item will be highlighted while browsing. The digit to be changed will be highlighted while you are

changing setting.

5.3 Control Buttons

5.3.1 Function Description

The micro-processing controller provides five control buttons, as shown in Figure 5-3.

ON/OFF button

Up button

Enter button

Down button

Esc button

Figure 5-3 Control keypad

The functions of the control buttons are described in Table 5-1.

Table 5-1 Function descriptions of control buttons

Control button

Function descriptions

Liebert DM Series Air Conditioner Technical Manual

14

Chapter 5

Micro-Processing Controller

ON/OFF button

Enter button (ENT)

Esc button (ESC)

Up button

Down button

Press this button for 3s to turn on or off the unit

Enter the selected menu screen. Validate the parameter setting value

Exit the current menu and return to the Normal screen or previous menu screen. Abort parameter change;

silence the audible alarm

Move the cursor up or increase the parameter value. For a toggle selection: scroll through the options. For a

multi-screen menu: scroll up the screen

Move the cursor down or decrease the parameter value. For a toggle selection: scroll through the options.

For a multi-screen menu: scroll down the screen

5.3.2 Operation Example

Example 1: Inputting password to enter the Main Menu

After the unit is started up, you can enter the Main Menu through conducting the following operations on the Normal

screen.

1. Press the Enter button to enter the Password screen.

2. Press the Enter button to highlight the input data field in the Password screen.

3. Press the Up or Down button to change the current password number.

4. Press the Enter button to confirm the password and enter the Main Menu screen.

Example 2: changing parameters

Taking Hi Temp in Alarm Output screen as an example, the procedures are as follows:

1. Press the Up or Down button to move the cursor on the Alarm Menu in the Main Menu screen.

2. Press the Enter button to enter the Alarm Menu.

3. Press the Up or Down button to move the cursor on Alarm Output in the Alarm Menu screen.

4. Press the Enter button to enter the Alarm Output screen.

5. Press the Up or Down button to move the cursor on Hi Temp.

6. Press the Enter button to highlight the parameter field of Hi Temp.

7. Press the Up or Down button to select the parameter option.

8. After selecting, press the Enter button to confirm. The parameter will take effect.

9. Press the Esc button to return to the previous menu screen.

Note

After changing the parameter, if you do not press the Enter button to validate the changed parameter, the change will be invalid.

5.4 Control Screen

5.4.1 ON Screen

After the AC unit is powered on, the LCD screen will display the ON screen, as shown in Figure 5-4.

Connecting

Please wait...

Figure 5-4

ON screen

5.4.2 Normal Screen

After the AC unit is powered on, the Normal screen will be displayed after 10 seconds (default) for heat startup delay or

through pressing the Enter button directly, as shown in Figure 5-5. The Normal screen displays the following

information: the current temperature and humidity, unit operation state (cooling, heating, dehumidifying, humidifying),

unit mode (single, host, standby), unit operation status (running, standby, locked, off, sleep), alarm information and

current date & time.

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

Micro-Processing Controller

15

21°

C

Heat SIG

50%rh

Hum RUN

No alarm

0

2012/01/01

00:00

Figure 5-5

Normal screen

5.4.3 Password Screen

Press the Enter button on the Normal screen, and the Password screen will appear, as shown in Figure 5-6.

Password: 1***

Figure 5-6 Password screen

Three levels of passwords are provided for accessing the menus. The detailed descriptions are listed in Table 5-2.

Table 5-2 Password level

Password level

User

Initial password

Level 1

General operator

0001

Level 2

Level 3

Maintenance personnel

Factory technician

-

Remark

Browse all menu information. Only set temperature and

humidity setpoints (see Figure 5-12) and cannot change any

values and settings

Set all parameters

-

For detailed operation on entering the password, refer to 5.3.2 Operation Example. If entering a wrong password, you

can only view the menu, but cannot change the settings. In this case, you can press the Esc button to return to the

Normal screen, and then press the Enter button to enter the Password screen again.

Note

If pressing the Enter button in the Password screen instead of inputting any password, you can only view the menu settings but

cannot change any parameters.

5.5 Control Logic

5.5.1 Cooling logic

When the actual temperature = set temperature + temperature precision value, the cooling requirement reaches

100%.

When the actual temperature = set temperature, the cooling requirement is 0%.

When the actual temperature rises to the degree corresponding to the 100% cooling requirement, cooling starts; when

the actual temperature drops to the degree corresponding to the 0% cooling requirement, cooling stops (the

compressor is turned off).

Figure 5-7 shows the cooling logic diagram.

Liebert DM Series Air Conditioner Technical Manual

16

Chapter 5

Micro-Processing Controller

The compressor is

turned off

Indoor temperature

0%

Set point

Figure 5-7

The compressor

is turned on

+100%

Cooling logic

5.5.2 Heating Logic

When the actual temperature = set temperature - temperature precision value, the heating requirement reaches 100%.

When the actual temperature = set temperature, the heating requirement is 0%.

When the actual temperature drops to the degree corresponding to the 100% heating requirement, heating starts;

when the actual temperature rises to the degree corresponding to the 0% heating requirement, heating stops (the

electronic heater is turned off).

Figure 5-8 shows the heating logic diagram.

Electric heater

is turned on

Electric heater

is turned off

-100%

Indoor temperature

0%

Set point

Figure 5-8

Heating logic

5.5.3 Dehumidifying Logic

1. Relative humidity control logic

Dehumidifying is activated when the cooling requirement is smaller than 125% and the dehumidifying requirement is

larger than 100%.

Dehumidifying is deactivated when the dehumidification requirement is no larger than 50%.

Figure 5-9 shows the dehumidifying activation and deactivation requirements.

Exit

dehumidifying mode

Enter dehumidifying

mode

Indoor humidity

Set point

Figure 5-9

+50%

+100%

Dehumidifying activation and deactivation requirements

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

Micro-Processing Controller

17

In the dehumidifying mode, the fan switches to high gear immediately when the cooling requirement is larger than

125%. The fan switches back to low gear when the temperature drops normal.

Figure 5-10 shows the high/low gear switch diagram of the fan in the dehumidifying mode.

Switch to

high gear

Switch to low gear

+125%

Set point

Figure 5-10

Indoor

temperature

High/low gear switch diagram of the fan in the dehumidifying mode

In the temperature compensation mode, the compressor is turned on when the cooling requirement is larger than 0%

and it is turned off when the cooling requirement is smaller than -100%; the electronic heater is turned on when the

cooling requirement is smaller than 0% and it is turned off when the cooling requirement is larger than 25%.

Figure 5-11 shows the control logic of the compressor in a) and the control logic of the electronic heater in b).

The

compressor

is turned off

-100%

Indoor

temperature

Set point

Set point

a) Control logic of the compressor

Figure 5-11

The electric heater

is turned off

The electric heater

is turned on

The compressor

is turned on

+25%

Indoor

temperature

b) Control logic of the electronic heater

Dehumidification logic in the temperature compensation mode

In the non-temperature compensation mode, the compressor is turned on and the electronic heater is turned off when

the cooling requirement is no smaller than 0%; the compressor is turned off and the electronic heater is turned on

when the cooling requirement is smaller than -100%.

Figure 5-12 shows the control logic of the compressor in a) and the control logic of the electronic heater in b).

The

compressor

is turned off

-100%

Set point

a) Control logic of the compressor

Figure 5-12

The electric

heater is

turned off

The electric

heater is

turned on

The

compressor

is turned on

Indoor

temperature

-100%

Set point

Indoor

temperature

b) Control logic of the electronic heater

Dehumidifying logic in the non-temperature compensation mode

2. Absolute Humidity Control Logic

If absolute humidity control logic is used, users should calculate the absolute humidity based on the actual

temperature and humidity and perform humidity control by referring to 1. Relative humidity control logic in this section.

Liebert DM Series Air Conditioner Technical Manual

18

Chapter 5

Micro-Processing Controller

5.5.4 Humidifying Logic

1. Relative humidity control logic

When the actual humidity = set humidity - humidity precision value, the humidification requirement reaches 100%.

When the actual humidity = set humidity, the humidification requirement is 00%.

When the actual humidity drops to the value corresponding to the 100% humidification requirement, humidification

starts; when the actual humidity rises to the value corresponding to the 0% humidification requirement, humidification

stops.

Figure 5-13 shows the humidification logic diagram.

The

humidifier is

turned off

The

humidifier is

turned on

0%

Set point

-100%

Figure 5-13

Indoor

temperature

Humidification logic

2. Absolute humidity control logic

If absolute humidity control logic is used, users should calculate the absolute humidity based on the actual

temperature and humidity and perform humidity control by referring to 1. Relative humidity control logic in this section.

5.5.5 Outdoor Fan Control

1. If the pressure sensor is faulty, the fan operates at full speed.

2. If frequency deviation happens, the fan stops operating.

3. If the compressor is supplied with power and the pressure in the condenser meets requirements for starting the fan,

the fan starts.

4. If the compressor is supplied with power and the pressure in the condenser meets requirements for stopping the fan,

the fan stops. Alternatively, if the compressor is stopped for more than one minute, the fan stops.

5. Figure 5-14 shows the voltage control curve during fan operating, which is on the basis of FSC1P control curve.

V

100%

Vin

F

E

L2

B

MaxV

C

D

A

Vx

L1

H

MinV

100% output

Condensation pressure point

G

Pband

Pv100 = (Pset + Pband + 5)

I

Poff

Pset

Px

Pmaxv Pv100

P

Figure 5-14 FSC1P control curve

During fan startup, the voltage is obtained based on the pressure-voltage curve if the pressure is kept within the set

range and the voltage is the value of MaxV if the pressure exceeds the set range. During fan operating, the power

system stops supplying power to the fan if the condensation pressure is smaller than (Pset - 1), namely Poff. The

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

Micro-Processing Controller

19

control process is A -> B -> C -> D -> E -> F -> C -> B -> A -> G -> H -> I (point A corresponds to the pressure ranging

from B to G). In the case of 100% voltage output, the voltage restores to MaxV after the pressure drops by 2 bars to

the point of Pmaxv. Table 5-3 lists the voltage and pressure parameters.

Table 5-3 Voltage and pressure setting table

Parameter

Min. power supply voltage (%)

Max. power supply voltage (%)

Start pressure (Bar)

Pressure bandwidth (Bar)

Lower limit

30

60

11

4

Upper limit

50

100

15

6

Default

30

100

13

5

5.5.6 Economy Mode Control

1. The AC units enter the Economy mode after this mode is enabled.

2. When the system starts to operate in this mode, the temperature control precision is added with the precision

amplification value. When the system exits this mode, the normal precision value recovers.

Table 5-4 lists the parameter setting in the Economy mode.

Table 5-4 Parameter setting in the Economy mode

Parameter

Economy mode

Start At

Start At

Zoom (°C)

Default value

OFF (0)

22: 00

7: 00

2

Lower limit

OFF (0)

18: 00

5: 00

2

Upper limit

ON (1)

3: 00

10: 00

10

5.5.7 Sleep Mode Control

1. The AC units enter the Sleep mode when there is one energy-saving card or more.

2. In this mode, the fan stops operating when the following conditions are met:

1) All the other moving parts do not need to operate except for the indoor fan.

2) The temperature of all energy-saving cards (four at most) is lower than the sleep temperature.

3) The energy-saving cards are kept in the temperature for 600 seconds.

3. The AC units exit the Sleep mode when either of the following conditions is met:

1) The temperature of an energy-saving card exceeds the value of sleep temperature plus 2 and the energy-saving

card is kept in the temperature for 30 seconds.

2) No energy-saving card is available.

Table 5-5 lists the parameter setting in the Sleep mode.

Table 5-5 Parameter setting in the Sleep mode

Parameter

EngySave Cd Num

Sleep At

Default value

0

27°C

Lower limit

0

15

Upper limit

4

40

5.5.8 Host/Standby Unit Control

1. The host unit automatically switches as a standby unit after a rotate cycle ends.

2. The host unit switches as a standby unit and the standby unit switches as an host unit after a fault occurs in the host

unit or standby unit, such as high pressure locking, low pressure locking, or discharge locking.

3. The standby unit works as a host unit after a high temperature alarm is generated by the host unit.

Table 5-6 lists the parameter setting for host/standby unit control.

Table 5-6 Parameter setting for host/standby unit control

Parameter

Unit Status

Switch Mod

Rt Time

Lower limit

0

0

Upper limit

2

1

By day (1, 2, 3, 4, 5, 6, and 7)

Default

0

0

1

Remark

0: SIG; 1: HST; 2: Standby

0: Standby; 1: Rotate

The number indicates the interval days

between two polling cycles.

Liebert DM Series Air Conditioner Technical Manual

20

Chapter 5

Micro-Processing Controller

Rt At

0: 00

23: 00

12: 00

-

5.6 Alarm Function

5.6.1 Alarm Category

Alarms fall into the following categories: high pressure alarm, low pressure alarm, discharge temperature alarm, high

temperature alarm, low temperature alarm, high humidity alarm, low humidity alarm, humidifier fault, fault of return air

temperature sensor, high pressure locking, low pressure locking, discharge temperature locking, floor wetting, power

loss, over-voltage alarm, under-voltage alarm, frequency deviation, loss phase alarm, negative phase alarm, custom

alarm 1 (lightning protection), energy-saving card fault, air flow loss, pressure sensor fault, humidity sensor fault, air

flow sensor fault, and custom alarm 2.

5.6.2 Alarm State And History

1. Alarm state recording

1) Alarms are recorded based on alarm occurrence time.

2) Both the alarm category and alarm time are recorded.

3) Alarm states are cleared upon power failure.

2. Alarm history recording

1) Historical alarms are recorded based on alarm occurrence time.

2) A maximum of 200 historical alarms are recorded.

3) A historical alarm includes the alarm SN., alarm category, alarm time, and alarm clearance time.

4) Historical alarms are saved upon power failure.

5) Historical alarms can be manually cleared.

6) Two-level password protection is enabled for historical alarms.

5.6.3 Alarm Prerequisites And Handling Methods

Table 5-7 Alarm prerequisites and handling methods

No.

Alarm

Alarm Prerequisite

Alarm Mode

Clearance Method

Alarm

reporting

delay (unit:

second)

Alarm Output

High

pressure

alarm

The high pressure switch is

kept open-circuited for a

duration of alarm reporting

delay

The alarm is

triggered and

the

compressor is

forcibly closed

Keep the high

pressure switch turned

off for a duration of

alarm reporting delay

3

Enabled/

disabled

2

Low

pressure

alarm

The low pressure switch is

kept open-circuited for a

duration of alarm reporting

delay in the case of

compressor operating. The

state of the low pressure

switch is ignored for 180

seconds. The duration is

configurable, ranging from

30 seconds to 600 seconds

The alarm is

triggered and

the

compressor is

forcibly closed

Keep the low pressure

switch turned off for a

duration of alarm

reporting delay

30

Enabled/

disabled

3

Discharge

temperature

alarm

The discharge temperature

switch is kept turned off for a

duration of alarm reporting

delay in the case of

compressor operating

The alarm is

triggered and

the

compressor is

forcibly closed

Keep the discharge

temperature switch

turned off for a

duration of alarm

reporting delay

3

Enabled/

disabled

4

High

temperature

alarm

The fan is enabled for 10

minutes and the return air

temperature is kept higher

The alarm is

triggered and

the electronic

Keep the return air

temperature lower

than the value (current

30

Enabled/

disabled/

closed

1

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

No.

Alarm

Alarm Prerequisite

than the high temperature

threshold for a duration of

alarm reporting delay while

the return air temperature

sensor operates normally

Alarm Mode

heater is

closed

Micro-Processing Controller

Clearance Method

Alarm

reporting

delay (unit:

second)

Alarm Output

high temperature

threshold - 2°C) for a

duration of alarm

reporting delay

Low

temperature

alarm

The fan is enabled for 10

minutes and the return air

temperature is kept lower

than the low temperature

threshold for a duration of

alarm reporting delay while

the return air temperature

sensor operates normally

The alarm is

triggered and

the cooling

system is

closed

Keep the return air

temperature higher

than the value (current

low temperature

threshold + 2°C) for a

duration of alarm

reporting delay

30

Enabled/d

isabled/

closed

High

humidity

alarm

The fan is enabled for 10

minutes and the return air

humidity is kept higher than

the high humidity threshold

for a duration of alarm

reporting delay while the

return air humidity sensor

operates normally

The alarm is

triggered and

humidification

stops

Keep the return air

humidity lower than

the value (current high

humidity threshold 2%) for a duration of

alarm reporting delay

30

Enabled/

disabled/

closed

7

Low

humidity

alarm

The fan is enabled for 10

minutes and the return air

humidity is kept lower than

the low humidity threshold

for a duration of alarm

reporting delay while the

return air humidity sensor

operates normally

The alarm is

triggered and

dehumidificati

on stops

Keep the return air

humidity higher than

the value (current low

humidity threshold +

2%) for a duration of

alarm reporting delay

30

Enabled/

disabled/

closed

8

Humidifier

fault

The humidifier switch is kept

turned off for a duration of

alarm reporting delay

The alarm is

triggered

Keep the humidifier

switch turned off for a

duration of alarm

reporting delay

10

Enabled/

disabled/

closed

9

Fault of the

return air

temperature

sensor

The return air temperature is

kept out of the allowed range

for a duration of alarm

reporting delay

The alarm is

triggered and

the cooling

system is

forcibly started

Keep the return air

temperature within the

allowed range for a

duration of alarm

reporting delay

10

Enabled/

disabled/

closed

10

High

pressure

locking

The high pressure alarm is

reported for three times

within an hour or the alarm is

kept uncleared within 10

minutes

The alarm is

triggered and

the

compressor is

locked

Manually clear the

alarm

/

Enabled/

disabled

11

Low

pressure

locking

The low pressure alarm is

reported for three times

within an hour or the alarm is

kept uncleared within 10

minutes

The alarm is

triggered and

the

compressor is

locked

Manually clear the

alarm

/

Enabled/

disabled

12

Discharge

temperature

locking

The discharge temperature

alarm is reported for three

times within an hour or the

alarm is kept uncleared for

20 minutes

The alarm is

triggered and

the

compressor is

locked

Manually clear the

alarm

/

Enabled/

disabled

13

Floor

wetting

alarm

The floor wetting switch is

kept turned off for a duration

of alarm reporting delay

The alarm is

triggered and

humidification

stops

Keep the floor wetting

switch turned off for a

duration of alarm

reporting delay

10

Enabled/

disabled/

closed

5

6

Liebert DM Series Air Conditioner Technical Manual

21

22

Chapter 5

No.

Micro-Processing Controller

Alarm

Alarm Prerequisite

Alarm Mode

Clearance Method

Alarm

reporting

delay (unit:

second)

Alarm Output

14

Power loss

Power loss occurs when the

AC units are in operation

The alarm is

triggered

The alarm is

automatically cleared

one second later

/

Enabled/

disabled/

closed

15

Over-voltag

e alarm

The input voltage increases

by 15%

The alarm is

triggered and

the system is

locked

Restore the input

voltage

3

Enabled/

disabled/

closed

16

Under-volta

ge alarm

The input voltage decreases

by 15%

The alarm is

triggered and

the system is

locked

Restore the input

voltage

3

Enabled/

disabled/

closed

17

Frequency

deviation

The input frequency is

deviated by 5Hz

The alarm is

triggered and

the system is

locked

Restore the frequency

3

Enabled/

disabled/

closed

18

Open phase

alarm

Open phase occurs

The alarm is

triggered and

the system is

locked

Manual restoration

3

Enabled/

disabled/

closed

19

Negative

phase alarm

Negative phase occurs

The alarm is

triggered and

the system is

locked

Manual restoration

/

Enabled/

disabled/

closed

20

Custom

alarm 1

(lightning

protection)

The set polarities are kept

inconsistent with those input

for a duration of alarm

reporting delay

The alarm is

triggered

Keep the set polarities

consistent with those

input for a duration of

alarm reporting delay

30

Enabled/

disabled/

closed

Energy

saving card

fault

The number of normally

online energy-saving cards

is less than the set number

or more than one

energy-saving card exceed

the allowed temperature

range

The alarm is

triggered and

the dormancy

mode cannot

be activated if

all

energy-saving

cards are

faulty

Keep the number of

the cards consistent

with the set number

and keep the cards in

normal temperature

30

Enabled/

disabled/

closed

22

Air flow loss

The value (temperature

measured by using the

sensor NTC0 - return air

temperature) is kept larger

than the set temperature for

a duration of alarm reporting

delay when the fan is in

normal operation. The air

flow detection thermal

resistor output is closed

when the fan is shut down.

This alarm is not reported if

the fan is closed and the

temperature sensor is faulty

The alarm is

triggered and

shut down all

the devices

except for the

fan

Keep the value

(temperature

measured by using the

sensor NTC0 - return

air temperature)

smaller than the value

(set temperature - 2°C)

10

Enabled/

disabled

23

Fault of

pressure

sensor 1

The condensing pressure is

kept out of the allowed range

for a duration of alarm

reporting delay

The alarm is

triggered

Keep the condensing

pressure within the

allowed range for a

duration of alarm

reporting delay

3

Enabled/

disabled

The return air humidity is

The alarm is

Keep the return air

10

Enabled/

21

(lightning

protection)

24

Humidity

Liebert DM Series Air Conditioner Technical Manual

Chapter 5

No.

25

Alarm

Alarm Prerequisite

sensor fault

kept out of the allowed range

for a duration of alarm

reporting delay

Air flow

sensor fault

The temperature measured

by using the air flow loss

sensor (NTC0) is kept out of

the allowed range for a

duration of alarm reporting

delay

Alarm Mode

triggered

The alarm is

triggered

Micro-Processing Controller

Clearance Method

Alarm

reporting

delay (unit:

second)

humidity within the

allowed range for a

duration of alarm

reporting delay

Keep the temperature

measured by using the

air flow loss sensor

(NTC0) within the

allowed range for a

duration of alarm

reporting delay

23

Alarm Output

disabled/

closed

10

Enabled/

disabled/

closed

Note:

1. Alarm reporting delay is a fixed configuration.

2. In the case of system locking, the compressor, heater, humidifier, and outdoor fan are locked.

5.7 Other Functions

5.7.1 Real-Time Clock

1. Set and display the system date and time.

2. This function provides the accurate time of data recording.

5.7.2 Operating Record

1. Device startup and stop record

A maximum of 50 records about device startup and stop are recorded, including the fan, compressor, electronic heater,

and humidifier.

2. Operating time record

The operating time of the fan, compressor, electronic heater, and humidifier is recorded by hour.

5.7.3 Parameter Protection

1. All parameters that need to be protected are saved in the internal EEPROM.

2. Default parameter settings can be restored.

3. Two-level password protection is enabled.

5.7.4 Password Protection

1. A password consists of four digits, ranging from 0000 to 9999. Password protection is classified into three levels.

2. Level 1 password is available for ordinary users. They can modify password protection parameters and level 1

password.

3. Level 2 password is available for operators. They can modify password protection parameters and level 1 and level

2 password.

4. Level 3 password is available for maintenance personnel. Except for level 3 password, they can modify password

parameters and level 1 and level 2 password.

5.7.5 Shutdown Mode

1. Shutdown modes fall into local shutdown, monitor shutdown, and remote shutdown.

2. Local shutdown is implemented by pressing the on/off button on the display panel.

3. Monitor shutdown is implemented through the background monitor RS485-1.

4. Remote shutdown has the highest priority and is in serial relationship with the other shutdown modes.

Liebert DM Series Air Conditioner Technical Manual

24

Chapter 5

Micro-Processing Controller

5.7.6 Diagnosis Output

1. In the diagnosis mode, devices such as the primary fan, compressor, electronic heater, and humidifier can be

tested.

2. A tested device can be automatically or manually shut down when it diagnoses another load.

3. If a device is not manually shut down within an hour, the device automatically exits the manual shutdown mode.

4. The fan must be always in operation. If the fan stops operating, the other devices are forcibly shut down. The

system must be protected in the case of major alarms, such as air flow loss, high pressure alarm, low pressure alarm,

discharge alarm and locking, and power fault.

5.7.7 Sensor Calibration

1. The temperature calibration range is ±5°C.

2. The humidity calibration range is ±10%.

5.7.8 Deployment Management

Deployment management is required during initial system operating.

Liebert DM Series Air Conditioner Technical Manual

Appendix 1

Menu Structure

Appendix 1 Menu Structure

Main Menu

Alarm Menu

Set Points

System Status

Temp Calib

Help Menu

System Menu

Temp Stpt

Analog

Hum Calib

Mntr Prtcl

Temp Sens

Time/Date

NTC0 Calib

Mntr Addr

Hum Stpt

Language

Run Time

Comp SS Record

Heat SS Record

Under Press

Pwr Freq Devia

Hi Temp

Hum SS Record

Alarm

Setpoint

Lo Temp

Out Fan SS

Record

Lo Hum

Enab Open

SS Record

Hum Sens

Air Loss

Contrast

In Fan SS Record

Alarm

Status

Alarm

History

Hi Hum

Version Info

In/Out Status

Setup

System

Baut Rate

Over Press

Min. Volt

Max. Volt

Outdoor

Unit

Out Volt

Start Press

Press BdWdth

Heat Num

Hum Num

Select

Options

CostSave Mod

EngySave Cd Num

Unit Mode

Switch Mod

Change Password

Factory Reset

Figure 1 Menu structure

Liebert DM Series Air Conditioner Technical Manual

LCD Setting

25

Appendix 2 Wiring Diagram

Appendix 2 Wiring Diagram

Black

Yellow Fuse

Yellow

Red

Transformer T2

Indoor connection

terminal TB1

Black

TB1-N

TB2-21

TB2-22

J2-2

J2-1

Black

Black

A2

J1-N

J1-L

Filter

board

KM2

J18

KM2-A1

J28-4

Black

Black

J01-7

1 2 3 4 5 6 7 8

1 2

J01

J02

Black

Black

J02

2

1

J14 2

Power

board

1

GND

J12 2 12V

Yellow-green

J03

2

1

J39 2

1

J29

J3-4

White

Black

J30

Grounding point

of the electrical

control box

SPD-NC

SPD-COM

Remote turn on/off

Grounding point

Standby unit request

of the electrical Start capacitor

control box

J19-1

J19-2

J19-5

J19-6

J19-7

J19-8

1

2

3

4

5

6

7

8

GND

4

12V

3

A

2

B

Gray

A

B

J4

1

Gray

J34

Control board

Indoor

fan

Brown

Yellow-green

KM1-A2 N1 L1

Monitoring

card

DB9

Display

board

1 2 3 4 5 6 7 8

5 4 3 2 1

Brown

Brown

J14-2

J14-1

1

J03

1 2 3 4 5 6 7 8

Electric

heater

1 2

J13 J31

J3

2 4 6 14

Brown

Electric heater belt

of the compressor