Lenntech

info@lenntech.com Tel. +31-152-610-900

www.lenntech.com Fax. +31-152-616-289

INDUSTRIAL MULTI-ROUND

BAG HOUSINGS

Multi-Round Liquid Bag Housings effectively remove dirt, pipe scale, and other substances

from process liquids. Quality construction and design assure clean effluent and protection for

all downstream equipment.

Unfiltered liquid enters the housing above the filter bags or strainer baskets, fills the interior

of the housing and continues through the bag or strainer basket. Solids are trapped inside the

filter bags or strainers and easily removed when the housing is serviced.

FEATURES/BENEFITS

Flow rates up to 3,500 gpm

(13,247.5 Lpm)

150 and 300 PSI (10.3 and 20.7 bar)

ratings

2 basket to 24 basket housing designs,

depending upon the required surface

area and volume of fluid to be filtered

Carbon Steel or Stainless Steel

construction

Each housing is factory hydro-tested

Low pressure drop

Zinc-plated swing bolts with bearingassisted davit closure

Buna-N seals — lid and basket

Differential, drain, and vent ports

304 Stainless Steel strainer basket for

304 Stainless Steel housings and Carbon

Steel housings

316 Stainless Steel strainer basket for

316 Stainless Steel housings

Two-part epoxy finish on carbon steel

housings, inside and outside

Accepts #2-size bag filters

Heavy-duty support legs

APPLICATIONS

OPTIONS

Chemical

Mesh-lined strainer baskets

General Industrial

Alternative O-ring materials

Oil and Gas

Hydraulic lid lift

Water

Positive hold down spring

Higher pressure ratings

FILTRATION & PROCESS

MULTI-ROUND BAG HOUSINGS

SPECIFICATIONS

150 psi @ 300˚F (10.3 bar @ 148.9˚C)

(up to 300 psi (34.5 bar) optional)

2”, 3”, 4”, 6”, 8”, 10”, or 12” RF flange

Zinc-plated swing bolts with bearing assisted davit cover lift

Buna-N

Two differential ports measure pressure across filter bag, 1/4” NPT

Carbon steel w/2-part epoxy finish inside and outside

304 or 316 Stainless steel w/satin finish on outside

304 Stainless Steel strainer basket with 9/64” perforations for 304 Stainless Steel housings

and Carbon Steel housings

316 Stainless Steel strainer basket with 9/64” perforations for 316 Stainless Steel housings

Pressure Rating

Connections

Housing Lid

Lid Seal

Pressure Ports

Construction/Finish

Basket Material

Bag Sizes

Base

#2

Heavy duty support legs

A - BOTTOM OUTLET

STYLE STYLE

A - BOTTOM

OUTLET

DIMENSIONS

G

HOUSING

BASKET

QUANTITY

CONNECTION

SIZE (IN.)

LR2

2

2, 3, 4

LR3

3

2, 3, 4

LR4

4

3, 4, 6

LR6

6

3, 4, 6

LR8

8

4, 6, 8

LR12

12

6, 8, 10

LR17

17

8, 10, 12

LR24

24

8, 10, 12

STRAINING

AREA

FT.2

8.0

0.74

M2

13.2

FT.2

1.23

M2

17.6

FT.2

M2

1.64

26.4

FT.2

2.45

M2

FT.2

35.2

3.27

M2

44.0

FT.2

4.09

M2

74.8

FT.2

6.95

M2

92.4

FT.2

8.58

M2

NOMINAL FLOW

RATE

GPM

400

LPM

1,514

GPM

600

LPM

2,271

GPM

800

LPM

3,028

GPM

1,200

LPM

4,542

GPM

1,600

LPM

6,056

GPM

2,100

LPM

7,949

GPM

3,500

LPM

13,248

GPM

4,300

LPM

16,276

D

A

C

B

E

H

All dimensions are approximate.

HOUSING

CONNECTION

SIZE

2

LR2

3

4

2

LR3

3

4

FILTRATION & PROCESS

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

A

16.0

406

16.0

406

16.0

406

18.0

457

18.0

457

18.0

457

B

2.0

51

3.0

76

4.0

102

2.0

51

3.0

76

4.0

102

C

43.1

1,096

45.2

1,148

47.2

1,199

46.3

1,176

45.0

1,143

47.4

1,203

DIMENSIONS

D

E

61.3

5.0

1,556

127

63.3

5.8

1,608

146

65.3

6.5

1,659

165

65.3

5.3

1,657

133

64.0

5.8

1,624

146

66.3

6.5

1,684

165

MULTI-ROUND BAG HOUSINGS

F

8.7

220

10.0

253

11.5

293

9.3

237

10.9

278

12.3

311

G

11.1

281

11.1

281

11.1

281

12.1

308

12.1

308

12.1

308

H

11.1

281

11.1

281

11.1

281

12.4

314

12.4

314

12.4

314

F

WEIGHT

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

335

152

360

163

385

175

410

186

435

197

460

209

DIMENSIONS (CONTINUED)

HOUSING

CONNECTION

SIZE

2

LR4

3

4

3

LR6

4

6

3

4

LR8

6

8

4

6

LR12

8

10

6

8

LR17

10

12

8

LR24

10

12

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

IN

MM

A

B

C

22.0

559

22.0

559

22.0

559

26.0

660

26.0

660

26.0

660

30.0

762

30.0

762

30.0

762

30.0

762

36.0

914

36.0

914

36.0

914

36.0

914

42.0

1,067

42.0

1,067

42.0

1,067

42.0

1,067

48.0

1,219

48.0

1,219

48.0

1,219

2.0

51

3.0

76

4.0

102

3.0

76

4.0

102

6.0

152

3.0

76

4.0

102

6.0

152

8.0

203

4.0

102

6.0

152

8.0

203

10.0

254

6.0

152

8.0

203

10.0

254

12.0

305

8.0

203

10.0

254

12.0

305

46.3

1,175

49.2

1,249

51.4

1,307

46.1

1,170

48.3

1,227

46.0

1,168

50.7

1,288

52.9

1,343

50.8

1,291

55.9

1,421

52.8

1,341

50.9

1,294

57.3

1,456

59.8

1,518

52.5

1,334

59.3

1,505

61.7

1,567

62.8

1,595

59.7

1,516

62.2

1,580

65.1

1,653

DIMENSIONS

D

E

66.0

1,676

68.9

1,751

71.2

1,808

66.1

1,678

68.3

1,735

66.9

1,699

72.6

1,843

74.8

1,899

72.7

1,846

77.8

1,976

77.8

1,975

75.9

1,927

82.3

2,089

84.7

2,151

79.4

2,018

86.1

2,188

88.6

2,251

89.8

2,280

88.1

2,239

90.7

2,304

93.6

2,376

5.0

127

5.8

146

6.5

165

5.8

146

6.5

165

7.0

178

5.8

146

6.5

165

7.0

178

10.8

273

6.5

165

7.0

178

10.8

273

11.0

279

7.0

178

10.8

273

11.0

279

11.0

279

10.8

273

11.0

279

11.0

279

F

G

H

10.2

259

11.2

284

12.3

311

13.2

336

14.3

363

14.5

369

14.2

361

15.1

383

18.1

460

22.3

568

18.2

463

21.1

536

23.7

602

26.8

679

23.3

591

25.3

642

28.3

720

32.2

818

28.3

718

31.4

797

33.4

848

14.1

359

14.1

359

14.1

359

16.2

411

16.2

411

16.2

411

18.2

462

18.2

462

18.2

462

18.2

462

24.5

622

24.5

622

24.5

622

24.5

622

27.6

702

27.6

702

27.6

702

27.6

702

30.6

776

30.6

776

30.6

776

15.3

387

15.3

387

15.3

387

18.1

461

18.1

461

18.1

461

20.9

532

20.9

532

20.9

532

20.9

532

25.3

641

25.3

641

25.3

641

25.3

641

29.5

749

29.5

749

29.5

749

29.5

749

33.2

843

33.2

843

33.2

843

WEIGHT

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

LBS

KG

535

243

555

252

590

268

535

243

555

252

590

268

665

302

705

320

850

385

960

435

870

395

1,010

458

1,150

522

1,210

548

1,960

889

2,070

939

2,200

998

2,380

1,079

2,200

998

2,350

1,066

2,530

1,147

All dimensions are approximate.

FILTRATION & PROCESS

MULTI-ROUND BAG HOUSINGS

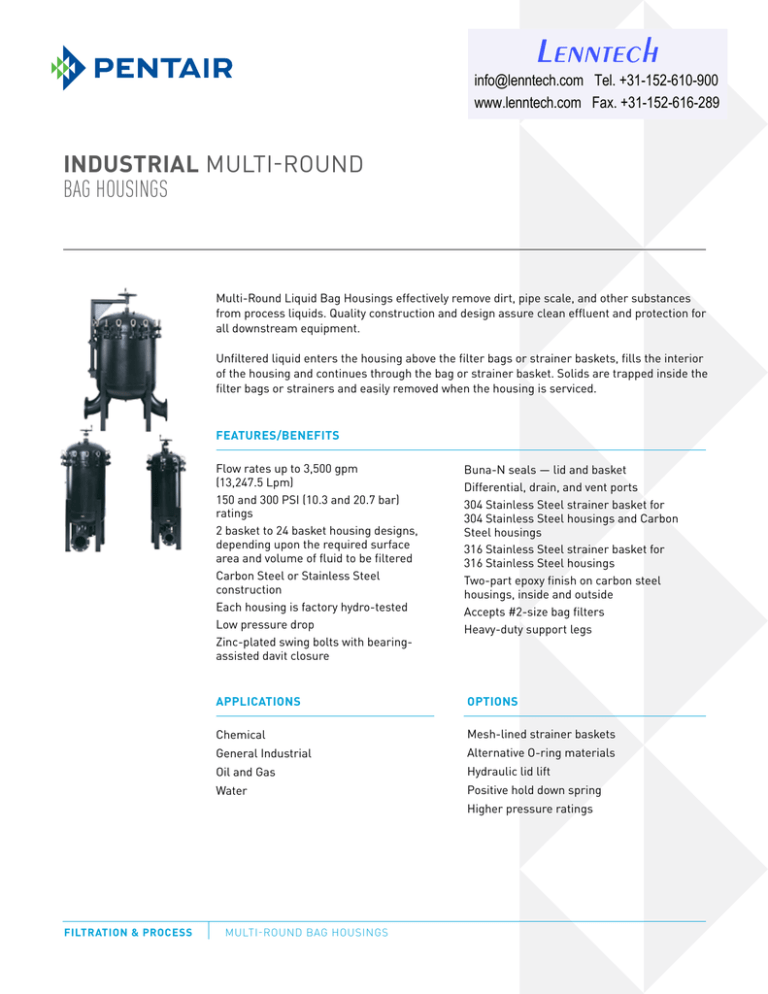

PRESSURE DROP VS FLOW RATE

12

(0.83)

2”

3”

4”

6”

8”

10”

Differential Pressure

psi (Bar)

10

(0.69)

8

(0.56)

6

(0.41)

4

(0.26)

2

(0.14)

12”

1

(0.07)

0

500

(132)

1,000

(264)

1,500

(396)

2,000

(528)

2,500

(660)

3,000

(792)

3,500

(925)

4,000

(1,056)

Flow Rate – gpm (Lpm)

ORDERING INFORMATION

To create your ordering part number, use the part number configurator below.

Custom configurations available. Please contact customer service.

Carbon steel not recommended for water use as the epoxy coating is not designed as a corrosion inhibitor.

HOUSING EXAMPLE: LR2302FAC15

LR2 Housing (LR2), 30” basket (30), 2” (2), Flange connection (F)

Carbon steel (C), 150 psi (15)

LR2 30 2

HOUSING

LR2

LR3

LR4

LR6

LR8

LR12

LR17

LR24

F

A

BASKET

(IN.)

CONNECTION

(IN.)

CONNECTION

TYPE

OUTLET

LOCATION

30 = #2

REFER TO

DIMENSION

CHARTS

F = Flange

A = Bottom

C

15

MATERIAL

PSI

ASME

CODE

C = Carbon Steel

4 = 304 SS

4L= 304L SS

6 = 316 SS

6L = 316L SS

15 = 150

30 = 300

U = (U) Stamp

Blank = No Stamp

Lenntech

FILTRATION & PROCESS

info@lenntech.com Tel. +31-152-610-900

www.lenntech.com Fax. +31-152-616-289

All Pentair trademarks and logos are owned by Pentair, Inc. or its affiliates. All other registered and unregistered trademarks and logos are the property of their

respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

4003037 Rev D DE14 © 2014 Pentair Residential Filtration, LLC. All rights reserved.