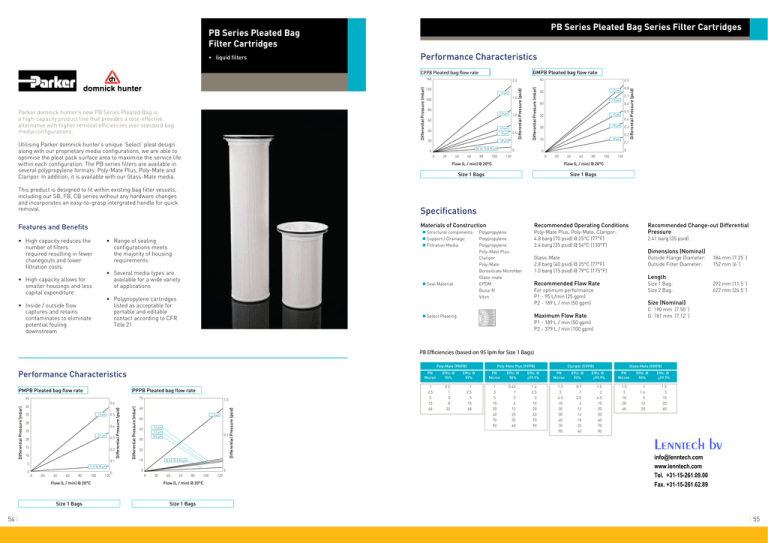

PB Series Pleated Bag Filter Cartridges

advertisement

PB Series Pleated Bag Series Filter Cartridges PB Series Pleated Bag Filter Cartridges Performance Characteristics GMPB Pleated bag flow rate Parker domnick hutner’s new PB Series Pleated Bag is a high-capacity product line that provides a cost-effective alternative with higher removal efficiencies over standard bag media configurations. Utilising Parker domnick hunter’s unique ‘Select’ pleat design along with our proprietary media configurations, we are able to optimise the pleat pack surface area to maximise the service life within each configuration. The PB series filters are available in several polypropylene formats: Poly-Mate Plus, Poly-Mate and Claripor. In addition, it is available with our Glass-Mate media. 120 1.5 µm 1.5 100 80 3.0 µm 1.0 60 4.5 µm 40 0.5 10 µm 20 20 µm 30, 40, 70 & 90 µm 0 0 This product is designed to fit within existing bag filter vessels, including our SB, FB, CB series without any hardware changes and incorporates an easy-to-grasp intergrated handle for quick removal. 60 2.0 Differential Pressure (psid) Differential Pressure (mbar) 140 20 40 60 80 0 100 30 10 µm 20 20 µm 10 40 µm 0.6 0.5 0.4 0.3 0.2 0.1 0 0 20 40 60 80 100 Flow (L / min) @ 20°C Flow (L / min) @ 20°C Size 1 Bags Size 1 Bags Structural components: Support / Drainage: Filtration Media: Seal Material: • Range of sealing configurations meets the majority of housing requirements • Several media types are available for a wide variety of applications • Polypropylene cartridges listed as acceptable for portable and editable contact according to CFR Title 21 • Inside / outside flow captures and retains contaminates to eliminate potential fouling downstream 0.7 3.0 µm 40 0 120 Materials of Construction • High capacity allows for smaller housings and less capital expenditure 0.8 1.5 µm 50 120 Specifications Features and Benefits • High capacity reduces the number of filters required resulting in fewer chanegouts and lower filtration costs. 0.9 Differential Pressure (psid) CPPB Pleated bag flow rate Differential Pressure (mbar) • liquid filters Recommended Operating Conditions Recommended Change-out Differential Pressure Poly-Mate Plus, Poly-Mate, Claripor: 4.8 barg (70 psid) @ 25°C (77°F) 2.4 barg (35 psid) @ 54°C (130°F) Polypropylene Polypropylene Polypropylene Poly-Mate Plus Claripor Poly-Mate Borosilicate Microfiber Glass-mate EPDM Buna-N Viton 2.41 barg (35 psid) Dimensions (Nominal) Glass-Mate 2.8 barg (40 psid) @ 25°C (77°F) 1.0 barg (15 psid) @ 79°C (175°F) Outside Flange Diameter: 184 mm (7.25¨) Outside Filter Diameter: 152 mm (6¨) Recommended Flow Rate Size 1 Bag: Size 2 Bag: Length For optimum performance P1 - 95 L/min (25 gpm) P2 - 189 L / min (50 gpm) Size (Nominal) C: 190 mm (7.50¨) G: 181 mm (7.12¨) Maximum Flow Rate Select Pleating: 292 mm (11.5¨) 622 mm (24.5¨) P1 - 189 L / min (50 gpm) P2 - 379 L / min (100 gpm) PB Efficiencies (based on 95 lpm for Size 1 Bags) Poly-Mate (PMPB) Performance Characteristics 70 35 1.0 µm 30 0.5 0.4 25 2.5 µm 20 15 0.3 0.2 10 0.1 Differential Pressure (mbar) 40 5 60 1.0 µm 50 3.0 µm 40 5.0 µm 0.5 10.0 µm 30 20 10 20, 40, 70 & 90 µm 5, 15 & 48 µm 0 20 40 60 80 100 Flow (L / min) @ 20°C Size 1 Bags 54 | 1.0 0.6 Differential Pressure (psid) Differential Pressure (mbar) 45 0 PPPB Pleated bag flow rate 0 120 0 0 0 20 40 60 80 100 Flow (L / min) @ 20°C 120 Differential Pressure (psid) PMPB Pleated bag flow rate PN Micron 1 2.5 5 15 48 Effic. @ 95% Effic. @ 99% 0.2 1 3 8 32 1 2.5 5 15 48 Poly-Mate Plus (PPPB) PN Micron 1 3 5 10 20 40 70 90 Effic. @ 90% Effic. @ >99.9% 0.45 1 2 4 12 20 35 60 1.4 2.5 5 10 20 40 70 90 Claripor (CPPB) PN Micron 1.5 3 4.5 10 20 30 40 70 90 Effic. @ 90% 0.7 1 3.5 4 12 16 18 25 40 Glass-Mate (GMPB) Effic. @ >99.9% 1.5 3 4.5 10 20 30 40 70 90 PN Micron 1.5 3 10 20 40 Effic. @ 90% Effic. @ >99.9% 1 1.6 5 12 20 1.5 3 10 20 40 Lenntech bv info@lenntech.com www.lenntech.com Tel. +31-15-261.09.00 Fax. +31-15-261.62.89 Size 1 Bags | 55