Pump Catalog Lenntech Product Quality, Reliability and Support You Expect www.Lenntech.com

advertisement

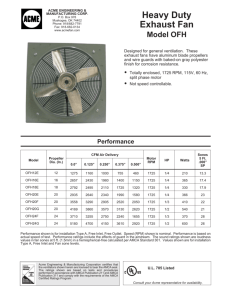

Lenntech info@lenntech.com Tel. +31-152-610-900 www.lenntech.com Fax. +31-152-616-289 Pump Catalog Product Quality, Reliability and Support You Expect www.Lenntech.com World Leader in Triplex Reciprocating High-Pressure Pumps Every design detail of our products is based on our commitment to produce the highest-quality, longest lasting products available to our customers. Building on our superior design, Cat Pumps quality is further enhanced by manufacturing production in ISO 9001 registered facilities, where repeatable process result in reliable product performance. Cat Pumps maintains a rigorous zero defect quality assurance program to guarantee consistently high quality products – every time. Product Performance Range: Nothing outruns, outlasts and outperforms Cat Pumps products. As one of our first customers stated, Cat Pumps produces “The Pumps with Nine Lives.” •M aterials: Brass, Nickel Aluminum Bronze, 304 and 316 Stainless Steel, Duplex Stainless Steel 2 A wide range of pump options are available, including a variety of products that meet various industry certifications and directives. • Flow: 0.13 to 240 gpm (0.49 to 908 lpm) • Pressure: 100 to 10,000 psi (7 to 689 bar) • RPM: 100 to 3450 • Liquid Temperature: -10° to 240°F (-23° to 116°C) • Drives: Electric, Engine, Hydraulic, Pneumatic catpumps.com • (763) 780-5440 Product Ordering Using This Catalog The pump sections are organized by drive type and flow rate by manifold materials; Brass, 316 Stainless Steel, Duplex Stainless Steel and Nickel Aluminum Bronze. The model numbers listed represent standard pump model offering equipped with Buna-N seals and O-rings, except for specialty pumps, like CO2, TEG and Portable Extractor which are fitted with unique seals for the application. Standard Buna-N pump seals and/or O-rings can be changed by adding a suffix to the standard model number that represents the desired new seal material. Optional Seal and O-Ring Configurations MATERIAL CODE DESCRIPTION FPM EPDM Fluorocarbon (Viton®) seals and O-rings Ethylene Propylene Diene Monamer seals and O-rings High-temperature seal for plunger pump high pressure seals High-temperature V-HOT cup for piston pumps, rated to 190˚ F Special Teflon® high temperature low and high pressure seals, rated to 200˚ F Pure Polytetrafluoroethylene (Teflon®) seals and Buna-N O-rings Pure Polytetrafluoroethylene (Teflon®) seals and FPM O-rings Pure Polytetrafluoroethylene (Teflon®) seals and Isolast O-rings Buna-N silicone free seals and O-rings HT STHT PTFE IPFE NBRS PUMP MODEL SUFFIX .0110 .0220 .3000 .3000 .3400 .0700 .0710 .0770 .6000 Viton® and Teflon® are registered trademarks of DuPont Dow Elastomers. Example Pump model 3535 can be changed from Buna-N to either FPM or EPDM. To convert pump model 3535 from Buna-N seals and O-rings to FPM (Viton®), add the suffix (.0110) to the standard pump model number (3535.0110). Use this new number when ordering the pump. Cat Pumps configures a number of pumps for special applications and certifications such as, ATEX, CO2, TEG, Flushed, High-Temp and others. Please contact Cat Pumps directly at (763) 780-5440 for more information. Table of Contents Direct Drive Plunger Pumps Page Specialty Pumps Page Hollow Shaft: Brass Manifold 6–7 Piston Pumps 14 Hollow Shaft: 316 Stainless Steel 7 Flush Manifold Pumps 15 Gearbox: Brass Manifold 7 TEG Pumps 16 Gearbox: 316 Stainless Steel Manifold 8 Liquid CO2 Pumps 17 Bell Housing: Brass Manifold 8 1XP Series Portable Extractor Pumps 18 Bell Housing: 316 Stainless Steel Manifold 8 Bell Housing: 316 Nickel Aluminum Bronze Manifold 9 Centrifugal Pumps 19 Belt Drive Plunger Pumps Brass and 304 Stainless Steel 10 – 11 316 Stainless Steel 12 Duplex Stainless Steel 13 Nickel Aluminum Bronze 13 Custom Pumping Systems 20 - 21 Accessories 22 Investing in Our Products 23 Pump Design Plunger Pumps (0.13 – 240 gpm, 100 – 10,000 psi) 10 4 1 9 8 7 2 Plunger pumps utilize spring-loaded closed and hydraulically opened inlet and discharge valves to direct flow through the pump manifold. At the beginning of the stroke, the plunger displaces the liquid in the manifold chamber, forcing the discharge valve open. When the plunger reaches the end of the stroke, the discharge valve closes. As the plunger rod begins its backward stroke, the inlet valve opens to allow more liquid 3 6 into the manifold chamber, thereby keeping a smooth forward flow of liquid. The spring-reinforced, preset packing design of the plunger pumps tolerates significantly greater pressure than piston pumps. The plunger pumps also offer tremendous versatility with optional direct coupling drives and wet-end material options. XP Series, Plunger Pumps (0.5 – 2 gpm, 100 – 1000 psi) 3 1 11 7 2 6 In XP series pumps, fluid enters the inlet port and flows through the drive-end, lubricating the connecting rods and plunger rods as it passes to the inlet valves. Both inlet and discharge valves are spring-loaded closed and hydraulically opened, similar to plunger pumps, however, they utilize a flow- through ceramic plunger design. The continuous forward flow characteristics in conjunction with the packing design of plunger pumps result in improved suction capabilities as well as extended seal life. At the beginning of the stroke, the inlet valve is closed against the ceramic plunger and the flow is forced out through the discharge valve. As the plunger rod begins its backward stroke, the inlet valve opens, moving away from the ceramic plunger, allowing the inlet flow to enter the manifold chamber through the passages in the ceramic plunger. Features 1 Specially formulated, Cat Pumps exclusive high-pressure seals/cups offer unmatched performance and seal life. 4 Chrome-moly crankshaft provides unmatched strength and surface hardness for long life. 2 100% wet cup/seal design adds to service life by allowing pumped fluids to cool and lubricate the elastomers on both sides. 5 T he patented stepped piston rod with hard chrome-plated sleeve provides a durable wear surface and easy wet end servicing. 3 S tainless steel valves, seats and springs provide corrosionresistance, positive seating and long life. 6 Precision-polished, solid ceramic plungers provide maximum resistance to corrosion and abrasion, extending seal life. Piston Pumps (3.0 – 60 gpm, 100 – 1,500 psi) 10 4 5 3 1 2 7 8 9 Flow through the piston pump moves continually in one, smooth forward direction. This allows greater suction capabilities and reduces the risk of cavitation. At the beginning of the stroke, the mechanically actuated inlet valve (and piston) will close. As the piston rod moves forward, the liquid is forced out through the discharge valves. Simultaneously, the liquid enters the pump inlet and flows in behind the inlet valve. As the piston rod begins the backward stroke, the inlet valve mechanically opens, permitting the liquid to continue its flow forward through the piston into the discharge chamber, until the stroke is completed. SF Series, Plunger Pumps (0.5 – 5 gpm, 100 – 3,500 psi) 1 9 4 10 3 6 2 7 In SF series pumps, both the inlet and discharge valves are spring-loaded closed and hydraulically opened, similar to plunger pumps, however, they have a flow-through ceramic plunger design. The continuous forward flow characteristic of piston pumps is utilized in conjunction with the packing design of the plunger pumps. These features give SF pumps both strong suction capabilities and higher-pressure performances. 7 The high-strength stainless steel plunger rods have a 360° supported crosshead providing uncompromising plunger rod alignment. 8 Matched oversized connecting rods are made of high-strength material with exceptional bearing quality. 9 versized ball bearings or tapered roller bearings provide O extended bearing life. At the beginning of the stroke, the inlet valve is closed against the ceramic plungers and the flow is forced out through the discharge valves. As the plunger rod begins its backward stroke, the inlet valve opens, moving away from the ceramic plunger, allowing the inlet flow to enter the manifold chamber through the passages in the ceramic plunger. 10 High-strength, lightweight die cast aluminum crankcase with splash oil design allows operation at speeds as low as 100 rpm. 11 Patented greaseless design uses water from inlet as lubrication, eliminating the maintenance and mess of grease or oil. Plunger Pumps DIRECT DRIVE, HOLLOW SHAFT, BRASS MANIFOLD Electric Motor, 5/8”, 3/4”, and 1”, 56C Face (Except for 1CX Series Pumps) Model 2DX20ES Model 2SF10ES MAXIMUM FLOW MAXIMUM PRESSURE POWER PUMP MODEL gpm lpm psi bar RPM SHAFT hp kW 1CX013ELSPD251 1CX025ELSPD251 1CX05ELSPD501 2DX05ELS.MIST 2SF10ES 2DX15ES.MIST 2DX20ES 2DX20ES.MIST 2SF20ES 2SFX20ES 2SF22ELS 2SF22ES 2SFX22ES 2DX27ES.MIST 2SF29ELS 2DX30ES.MIST 2SF30ES 2SFX30ES 2SF30GES 2SF35ES 2SF35GES 3SPX35GEI 0.13 0.25 0.5 0.5 1 1.5 2 2 2 2 2.2 2.2 2.2 2.7 2.85 3 3 3 3 3.5 3.5 3.5 0.5 1.0 1.9 1.9 3.8 5.7 7.6 7.6 7.6 7.6 8.4 8.4 8.4 10.3 10.8 11.4 11.4 11.4 11.4 13.3 13.3 13.3 1,000 1,000 1,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 1,500 1,500 1,500 1,500 2,000 1,500 2,000 2,500 69 69 69 138 138 138 138 138 138 138 138 138 138 138 103 103 103 103 138 103 138 172 1725 1725 1725 1725 3450 3450 3450 3450 3450 3450 1725 1725 1725 3450 1725 3450 3450 3450 3450 3450 3450 3450 n/a n/a n/a 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 3/4" 5/8" 3/4" 1" 0.1 0.2 0.3 0.7 1.4 2.1 2.7 2.7 2.7 2.7 3.0 3.0 3.0 3.7 2.9 3.1 3.1 3.1 4.1 3.6 4.8 6.0 0.1 0.1 0.3 0.5 1.0 1.5 2.0 2.0 2.0 2.0 2.2 2.2 2.2 2.7 2.2 2.3 2.3 2.3 3.0 2.7 3.5 4.4 DIRECT DRIVE, HOLLOW SHAFT, BRASS MANIFOLD Electric Motor, 1 1/8", 184TC Face Model 4SF45ELS Model 4DNX25GSI MAXIMUM FLOW MAXIMUM PRESSURE POWER PUMP MODEL gpm lpm psi bar RPM SHAFT hp kW 4SF40ELS 4SF45ELS 4SF50ELS 4 4.5 5 15.2 17.1 19.0 3,500 3,000 3,000 241 207 207 1725 1725 1725 1 1/8" 1 1/8" 1 1/8" 9.6 9.2 10.3 7.1 6.8 7.6 DIRECT DRIVE, HOLLOW SHAFT, BRASS MANIFOLD Engine, 3/4" MAXIMUM FLOW MAXIMUM PRESSURE HP PUMP MODEL gpm lpm psi bar RPM SHAFT Typical Gas Engine 4DNX25GSI 4DNX27GSI 3DX29GSI 2SF30GS 2SFX30GS 2SFX30GZ 3DX30GSI 2SF35GS 2.5 2.7 2.9 3 3 3 3 3.5 9.5 10.3 11.0 11.4 11.4 11.4 11.4 13.3 2,850 2,850 2,500 2,000 2,000 2,500 2,500 2,000 197 197 172 138 138 172 172 138 3450 3450 3450 3450 3450 3450 3450 3450 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 6.5 8 6.5 6.5 6.5 8 8 8 DIRECT DRIVE, HOLLOW SHAFT, BRASS MANIFOLD Engine, 1" MAXIMUM FLOW MAXIMUM PRESSURE HP PUMP MODEL gpm lpm psi bar RPM SHAFT Typical Gas Engine 66DX30G1I 4SPX32G1I 4SF35GS1 66DX35G1I 4SF40GS1 66DX40G1I 4SF45GSI 4SF50GSI 3 3.2 3.5 3.5 4 4 4.5 5 11.4 12.2 13.3 13.3 15.2 15.2 17.1 19.0 4,000 3,000 3,500 4,000 3,500 4,000 3,000 3,000 276 207 241 276 241 276 207 207 3450 3450 3450 3450 3450 3450 3450 3450 1" 1" 1" 1" 1" 1" 1" 1" 13 9 13 13 13 16 13 16 Model 66DX40G1I DIRECT DRIVE, HOLLOW SHAFT, 316 STAINLESS STEEL MANIFOLD Electric Motor, 5/8", 56C Face MAXIMUM FLOW MAXIMUM PRESSURE POWER PUMP MODEL gpm lpm psi bar RPM SHAFT hp kW 2SF05SEEL 2SF10SEEL 2SF15SEEL 2SF22SEEL 2SF25SEEL 2SF29SEEL 2SF35SEEL 2SF42SEEL 0.5 1 1.5 2.2 2.5 2.85 3.5 4.2 1.9 3.8 5.7 8.4 9.5 10.8 13.3 16.0 1,200 1,200 1,200 1,200 1,200 1,200 1,200 1,000 83 83 83 83 83 83 83 69 1725 1725 1725 1725 1725 1725 1725 1725 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 0.4 0.8 1.2 1.8 2.1 2.3 2.9 2.9 0.3 0.6 0.9 1.3 1.5 1.7 2.1 2.1 Model 2SF29SEEL DIRECT DRIVE, HOLLOW SHAFT GEARBOX, BRASS MANIFOLD Engine, 3/4" and 1" PUMP MODEL 740G1 3CP1120G 5CP3160CSSG1 60G1 5CP3120CSSG1 45G1 700G1 5CP5140CSSG1 5CP6120CSSG1 56G1 5CP6190G1 7CP6110G1 7CP6170G1 MAXIMUM FLOW MAXIMUM PRESSURE RPM gpm lpm psi bar Pump Engine 2.8 3.5 4 4.2 4.5 4.5 4.5 5.5 6.7 8 8.7 10 12 10.6 13.3 15.2 16.0 17.1 17.1 17.1 20.9 25.5 30.4 33.1 38.0 45.6 5000 2,200 3,500 4,000 3,500 3,500 5,000 3,500 1,600 2,500 1,200 2,000 1,800 345 152 241 276 241 241 345 241 110 172 83 138 124 1700 1420 1627 1570 1645 1645 1700 1500 1570 1760 1570 1667 1600 3465 3600 3320 3200 3353 3353 3465 3060 3200 3600 3200 3400 3264 SHAFT 1" 3/4" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" HP Typical Gas Engine 13 8 13 18 16 16 20 18 8 16 11 18 16 Model 56G1 Note: All 1" Gearboxes are also available in 1 1/8" size (G118) Model 5CP3120CSSG1 Plunger Pumps DIRECT DRIVE, HOLLOW SHAFT GEARBOX, 316 STAINLESS STEEL MANIFOLD Engine, 1" PUMP MODEL 341G1 781G1 351G1 7CP6111G1 Model 7CP6111G1 MAXIMUM PRESSURE RPM SHAFT lpm psi bar Pump Engine 4 4.5 5 10 15.2 17.1 19 38 2000 5,000 1,500 2,000 138 345 103 138 1725 1700 1725 1667 3515 3465 3515 3400 1" 1" 1" 1" RPM SHAFT 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 16.5 mm 16.5 mm 20 mm 20 mm 16.5 mm 16.5 mm 20 mm 20 mm 16.5 mm 16.5 mm 20 mm 20 mm 24 mm 24 mm 20 mm 20 mm 20 mm 20 mm 20 mm 24 mm 20 mm 24 mm RPM SHAFT 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 16.5 mm 16.5 mm 16.5 mm 16.5 mm 20 mm 20 mm 16.5 mm 20 mm 20 mm 24 mm HP Typical Gas Engine 8 20 8 18 DIRECT DRIVE, SOLID SHAFT, BRASS MANIFOLD Electric Motor - Bell Housing PUMP MODEL Model 3CP1120 MAXIMUM FLOW gpm 230 3CP1130 5CP3105CSS 5CP3110CSS 240 3CP1140 340 5CP2140WCS 270 3CP1120 5CP3160CSS 5CP4120CSS 60 700 5CP3120CSS 350 5CP2150W 5CP5120 5CP6120 56 5CP6190 7CP6110 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 2.4 2.5 3.6 3.6 3.6 4 4 4.2 4.2 4.3 4.5 4.7 4.7 4.8 5 5 6 7.4 8 9.7 10.5 8.7 9.1 9.5 13.7 13.7 13.7 15.2 15.2 16.0 16.0 16.3 17.1 17.9 17.9 18.2 19.0 19.0 22.8 28.1 30.4 36.9 39.9 1,500 2,000 3,500 3,500 1,200 2,200 1,800 2,500 1,000 2,200 3,500 4,000 4,000 5,000 3,000 1,500 2,000 2,500 1,200 2,500 1,200 2,000 103 138 241 241 83 152 124 172 69 152 241 276 276 345 207 103 138 172 83 172 83 138 POWER hp kW 2.4 3.3 6.0 8.6 3.0 5.4 4.9 6.8 2.9 6.3 10.3 12.3 12.9 16.1 9.9 5.1 6.8 10.3 6.1 13.7 8.0 14.4 1.7 2.4 4.4 6.4 2.2 4.0 3.6 5.1 2.1 4.7 7.6 9.1 9.5 11.9 7.3 3.8 5.1 7.6 4.5 10.1 5.9 10.6 Model 5CP3160CSS DIRECT DRIVE, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD Electric Motor - Bell Housing PUMP MODEL Model 3CP1231 231 3CP1231 241 3CP1241 341 5CP6241CS 3CP1221 351 5CP6251 7CP6111 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 2.3 3.6 3.6 4 4 4.2 5 5 10.5 8.7 8.7 13.7 13.7 15.2 15.2 16.0 19.0 19.0 39.9 1,500 2,000 1,200 2,000 1,800 2,000 2,000 1,500 2,000 2,000 103 138 83 138 124 138 138 103 138 138 POWER hp kW 2.4 3.2 3.0 4.9 4.9 5.5 5.8 5.1 6.8 14.4 1.7 2.3 2.2 3.6 3.6 4.1 4.3 3.8 5.1 10.6 DIRECT DRIVE, SOLID SHAFT, NICKEL ALUMINUM BRONZE MANIFOLD Electric Motor - Bell Housing PUMP MODEL 237 247 347 357 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 3.6 4 5 8.7 13.7 15.2 19.0 1,500 1,200 1,800 1,500 103 83 124 103 RPM SHAFT 1725 1725 1725 1725 16.5 mm 16.5 mm 20 mm 20 mm POWER hp kW 2.4 3.0 4.9 5.1 1.7 2.2 3.6 3.8 Model 277 Direct-Drive Mounting Components BELL HOUSING ASSEMBLY PUMP SERIES MODELS 3CP Series 3CP1120 - 40, 3CP1231 - 41 3FR Series 230 - 270, 231 - 241, 237 - 247 5CP Series 5CP3110CSS - 5CP6190, 5CP6221 - 5CP6251 5FR Series 340 -350, 341 - 351, 347 - 357 7CP Series 7CP6110, 7CP6111 7FR/8FR Series 56, 60, 700, 781, 781K MOTOR FRAME BELL HOUSING ASSY 56C - 145TC 182/184TC 213/215TC 56C - 145TC 182/184TC 213/215TC 56C - 145TC 182/184TC 213/215TC 254/256TC 182/184TC 213/215TC 182/184TC 213/215TC 254/256TC 213/215TC 254/256TC 76056.3CP 34423 76215.3CP 34121 34126 76215.3FR 76056.5CP 76184.5CP 76215.5CP 76256.5CP 76184.5FR 76215.5FR 76184.7CP 76215.7CP 76256.7CP 76215.7FR 76256.7FR 5CP6190BH73 Bell Housing Series FLEXIBLE COUPLER ASSEMBLY PUMP SERIES 3CP & 3FR Series 5CP & 5FR Series 7CP & 7FR Series MOTOR FRAME FLEX COUPLER ASSY HP RATING 56C 145TC 182/184TC 182/184TC 213/215TC 145TC 182/184TC 213/215TC 254/256TC 182/184TC 213/215TC 254/256TC 8215 8210 8220 8225 8270 8260 8230 8275 8217 8370 8375 8380 3 3 3 10 20 10 10 20 20 10 10 20 Flex Coupler Series Plunger Pumps BELT DRIVE, SOLID SHAFT, BRASS AND 304 STAINLESS STEEL MANIFOLD PUMP MODEL Model 1810 Model 310 Model 700 230 3CP1130 5CP3105CSS 1810 270 240 3CP1140 5CP3110CSS 340 310 5CP2120W 5CP2140WCS 270 3CP1120 5CP3160CSS 45 5CP3120 57 5CP4120CSS 60 700 5CP3120CSS 310 350 5CP2150W 530 5CP5120 550 56 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 2.4 2.5 3 3.5 3.6 3.6 3.6 4 4 4 4 4.2 4.2 4.3 4.5 4.5 4.5 4.5 4.7 4.7 4.8 5 5 5 5 5 5 5.5 8.7 9.1 9.5 11.4 13.3 13.7 13.7 13.7 15.2 15.2 15.2 15.2 16.0 16.0 16.3 17.1 17.1 17.1 17.1 17.9 17.9 18.2 19.0 19.0 19.0 19.0 19.0 19.0 20.9 1,500 2,000 3,500 10,000 1,500 1,200 2,200 3,500 1,800 2,200 2,500 2,500 1,000 2,200 3,500 3,500 3,500 4,000 4,000 4,000 5,000 3,000 1,500 1,500 2,000 2,500 3,000 3,000 3,500 103 138 241 690 103 83 152 241 124 152 172 172 69 152 241 241 241 276 276 276 345 207 103 103 138 172 207 207 241 RPM SHAFT 1725 1725 1725 1500 1420 1725 1725 1725 1725 950 950 1725 1725 1725 1725 1645 1645 1285 1725 1725 1725 1725 1190 1725 1725 1100 1415 1415 1210 16.5 mm 16.5 mm 20 mm 30 mm 16.5 mm 16.5 mm 16.5 mm 20 mm 20 mm 20 mm 20 mm 20 mm 16.5 mm 16.5 mm 20 mm 20 mm 20 mm 24 mm 20 mm 24 mm 24 mm 20 mm 20 mm 20 mm 20 mm 24 mm 20 mm 24 mm 24 mm POWER hp kW 2.4 3.3 6.0 20.5 3.6 3.0 5.4 8.6 4.9 6.0 6.8 6.8 2.9 6.3 10.3 10.8 10.8 12.3 12.3 12.9 16.1 9.9 5.1 5.1 6.8 8.6 10.3 10.3 13.2 1.7 2.4 4.4 15.2 2.7 2.2 4.0 6.4 3.6 4.5 5.1 5.1 2.1 4.7 7.6 8.0 8.0 9.1 9.1 9.5 11.9 7.3 3.8 3.8 5.1 6.3 7.6 7.6 9.8 Selecting a Power Source Positive displacement pumps can utilize a variety of different power sources, including electric motors, gas or diesel engines, hydraulic and pneumatic motors. Note: System power sources must be sized with adequate horsepower to handle the maximum system flow and pressure required. Handy Formulas Required Electric = Brake HP* gpm x psi 1460 *Standard 85% Overall Efficiency Model 5CP2120W Hydraulic Torque (ft. lbs.) gpm x psi = 3.6 x Required rpm BELT DRIVE, SOLID SHAFT, BRASS AND 304 STAINLESS STEEL MANIFOLD PUMP MODEL 5CP6120 5CP5120 1570 650 5CP6120 56 1560 5CP6190 1050 660 6810 7CP6170 7CP6110 1050 1530 1540E 2510 3560 2530 3520 2530 3560 3535 6835 3545 3545HS 6760 6775 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 6 6 6 7 7.4 8 8 9.7 10 10 10 10.5 10.5 12 15.6 18 20 20 21 23 25 25 36 40 45 50 60 75 22.8 22.8 22.8 26.6 28.1 30.4 30.4 36.9 38.0 38.0 38.0 39.9 39.9 45.6 59.3 68.4 76.0 76.0 79.8 87.4 95.0 95.0 136.8 152.0 171.0 190.0 228.0 285.0 1,600 2,500 6,000 3,000 1,200 2,500 4,000 1,200 2,200 3,000 10,000 2,000 2,000 1,800 1,500 1,200 2,000 4,000 1,200 2,000 1,000 3,000 1,200 3,000 1,000 1,500 1,200 1,200 110 172 414 207 83 172 276 83 152 207 690 138 138 124 103 83 138 276 83 138 69 207 83 207 69 103 83 83 RPM SHAFT 1450 1725 1350 1000 1725 1725 1140 1725 958 1429 600 1450 1725 1150 1450 1100 1450 1160 860 800 1025 1450 800 625 765 850 520 650 20 mm 20 mm 30 mm 30 mm 20 mm 24 mm 30 mm 20 mm 30 mm 30 mm 45 mm 24 mm 24 mm 30 mm 30 mm 30 mm 30 mm 35 mm 30 mm 35 mm 30 mm 35 mm 35 mm 45 mm 35 mm 35 mm 45 mm 45 mm POWER hp kW 6.6 10.3 24.7 14.4 6.1 13.7 21.9 8.0 15.1 20.5 68.5 14.4 14.4 14.8 16.0 14.8 27.4 54.8 17.3 31.5 17.1 51.4 29.6 82.2 30.8 51.4 49.3 61.6 4.9 7.6 18.2 10.6 4.5 10.1 16.2 5.9 11.2 15.2 50.7 10.6 10.6 10.9 11.9 10.9 20.3 40.5 12.8 23.3 12.7 38.0 21.9 60.8 22.8 38.0 36.5 45.6 Model 1570 Model 660 Model 1540E Selecting a Drive A variety of different drive options are offered by Cat Pumps. Most systems are belt-driven by a pulley or clutch, but there are also some direct-drive options such as direct coupled, gearbox or hollow shaft direct drive. Handy Formulas Desired Desired x = gpm rpm Rated rpm Rated gpm Pump Pump rpm Motor Pulley* x Motor/Engine rpm = Pulley* *Pitch Diameter Model 3535 Plunger Pumps BELT DRIVE, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD PUMP MODEL Model 311 Model 1051 Model 2531 Model 6811 231 3CP1231 271 241 3CP1241 341 5CP6241CS 311 3CP1221 781 351 5CP6251 5CP6221 1051 1861 3801 7CP6171 7CP6111 1051 3811 6811 6801 1531 1541 2511 2531 2831 3521 3821 2531 6821 3531 3831 3531HS 6831 3541 3841 6841 6761 6861 6771 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 2.3 3.5 3.6 3.6 4 4 4 4.2 4.5 5 5 6 10 10 10 10.5 10.5 12 14 15 15 15.6 18 20 21 21 23 23 25 25 36 36 40 40 45 45 48 60 60 75 8.7 8.7 13.3 13.7 13.7 15.2 15.2 15.2 16.0 17.1 19.0 19.0 22.8 38 38 38 39.9 39.9 45.6 53.2 57 57 59.28 68.4 76 79.8 79.8 87.4 87.4 95 95 136.8 136.8 152 152 171 171 182.4 228 228 285 1,500 2,000 1,500 1,200 2,000 1,800 2,000 2,200 2,000 5,000 1,500 2,000 2,000 2,200 2,200 5,000 2,000 2,000 1,800 3,000 5,000 7,000 1,500 1,200 1,500 1,200 1,200 2,000 2,000 1,000 3,000 1,200 1,200 2,000 2,300 1,000 1,000 2,000 1,200 1,200 1,200 103 138 103 83 138 124 138 152 138 345 103 138 138 152 152 345 138 138 124 207 345 483 103 83 103 83 83 138 138 69 207 83 83 138 159 69 69 138 83 83 83 RPM SHAFT 1725 1725 1420 1725 1725 1725 1725 950 1725 1700 1725 1725 1400 958 958 915 1450 1725 1150 800 600 600 1450 1100 1450 860 860 800 800 1025 615 800 800 888 625 765 765 615 520 520 650 16.5 mm 16.5 mm 16.5 mm 16.5 mm 16.5 mm 20 mm 20 mm 20 mm 16.5 mm 24 mm 20 mm 20 mm 20 mm 30 mm 30 mm 35 mm 24 mm 24 mm 30 mm 35 mm 45 mm 45 mm 30 mm 30 mm 30 mm 30 mm 30 mm 35 mm 35 mm 30 mm 45 mm 35 mm 35 mm 35 mm 45 mm 35 mm 35 mm 45 mm 45 mm 45 mm 45 mm POWER hp kW 2.4 3.2 3.6 3.0 4.9 4.9 5.5 6.0 5.8 15.4 5.1 6.8 8.2 15.1 15.1 34.2 14.4 14.4 14.8 28.8 51.4 71.9 16.0 14.8 20.5 17.3 17.3 31.5 31.5 17.1 51.4 29.6 29.6 54.8 63.0 30.8 30.8 65.8 49.3 49.3 61.6 1.7 2.3 2.7 2.2 3.6 3.6 4.1 4.5 4.3 11.4 3.8 5.1 6.1 11.2 11.2 25.3 10.6 10.6 10.9 21.3 38.0 53.2 11.9 10.9 15.2 12.8 12.8 23.3 23.3 12.7 38.0 21.9 21.9 40.5 46.6 22.8 22.8 48.7 36.5 36.5 45.6 BELT DRIVE, SOLID SHAFT, DUPLEX STAINLESS STEEL MANIFOLD PUMP MODEL 1051D 661D 3501 3511 3822 3832 6762 6862 157R060 152R060 152R080 157R080 152R100 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 10 10 10 14 23 36 60 60 100 115 200 200 240 38 38 38 53.2 87.4 136.8 228 228 380 437 760 760 912 2,200 3,000 5,000 3,000 2,000 1,200 1,200 1,200 2,700 1,200 1,200 1,560 1,000 152 207 345 207 138 83 83 83 186 83 83 108 69 RPM SHAFT 958 1429 915 800 800 800 520 520 310 360 355 355 270 30 mm 30 mm 35 mm 35 mm 35 mm 35 mm 45 mm 45 mm 100 mm 100 mm 100 mm 100 mm 100 mm RPM SHAFT 1725 1420 1725 1725 950 1725 958 915 1150 800 700 860 800 800 888 615 520 650 16.5 mm 16.5 mm 16.5 mm 20 mm 20 mm 20 mm 30 mm 35 mm 30 mm 35 mm 35 mm 30 mm 35 mm 35 mm 35 mm 45 mm 45 mm 45 mm POWER hp kW 15.1 20.5 34.2 28.8 31.5 29.6 49.3 49.3 184.9 94.5 164.4 213.7 164.4 11.2 15.2 25.3 21.3 23.3 21.9 36.5 36.5 136.8 69.9 121.6 158.1 121.6 Model 6762 BELT DRIVE, SOLID SHAFT, NICKEL ALUMINUM BRONZE MANIFOLD PUMP MODEL 237 277 247 347 317 357 1057 3507 1057 3517 3527HS 2537 3527 3537 3537HS 6747 6767 6777 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 3.5 3.6 4 4 5 10 10 12 14 20 21 23 36 40 48 60 75 8.7 13.3 13.7 15.2 15.2 19.0 38 38 45.6 53.2 76 79.8 87.4 136.8 152 182.4 228 285 1,500 1,500 1,200 1,800 2,200 1,500 2,200 5,000 1,800 3,000 2,300 1,200 2,000 1,200 2,000 2,000 1,200 1,200 103 103 83 124 152 103 152 345 124 207 159 83 138 83 138 138 83 83 POWER hp kW 2.4 3.6 3.0 4.9 6.0 5.1 15.1 34.2 14.8 28.8 31.5 17.3 31.5 29.6 54.8 65.8 49.3 61.6 1.7 2.7 2.2 3.6 4.5 3.8 11.2 25.3 10.9 21.3 23.3 12.8 23.3 21.9 40.5 48.7 36.5 45.6 Model 152R100 Model 277 Model 3517 Piston Pumps PISTON PUMPS, SOLID SHAFT, BRASS MANIFOLD Belt Drive PUMP MODEL Model 280 280 290 333 430 323 623 820 390 1010 2520 6040 6020 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 3 3.5 4 5 5 6 10 12 13 25 40 60 11.4 13.3 15.2 19 19 22.8 38 45.6 49.4 95 152 228 1,000 1,200 1,200 1,000 1,500 1,200 1,000 600 700 800 1,500 1,000 69 83 83 69 103 83 69 41 48 55 103 69 RPM SHAFT 1330 1200 1070 1040 1000 850 940 1200 900 772 500 500 16.5 mm 16.5 mm 16.5 mm 16.5 mm 20 mm 25 mm 25 mm 20 mm 25 mm 30 mm 45 mm 45 mm RPM SHAFT 1330 1200 1070 1040 850 940 900 772 500 500 16.5 mm 16.5 mm 16.5 mm 16.5 mm 25 mm 25 mm 25 mm 30 mm 45 mm 45 mm POWER hp kW 2.1 2.9 3.3 3.4 5.1 4.9 6.8 4.9 6.2 13.7 41.1 41.1 1.5 2.1 2.4 2.5 3.8 3.6 5.1 3.6 4.6 10.1 30.4 30.4 PISTON PUMPS, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD Belt Drive PUMP MODEL Model 820 Model 2520 281 291 331 431 621 821 1011 2521 6041 6021 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 3 3.5 4 5 6 10 13 25 40 60 11.4 13.3 15.2 19 22.8 38 49.4 95 152 228 1,000 1,200 1,200 1,000 1,200 1,000 700 800 1,500 1,000 69 83 83 69 83 69 48 55 103 69 POWER hp kW 2.1 2.9 3.3 3.4 4.9 6.8 6.2 13.7 41.1 41.1 1.5 2.1 2.4 2.5 3.6 5.1 4.6 10.1 30.4 30.4 TECH TIP Pump Rotation Model 6020 Forward rotation (towards the manifold) is recommended for optimum lubrication of the crosshead area, increasing drive-end life. If the installation does not allow for forward rotation, reverse rotation is acceptable if the crankcase oil is above the red dot in the oil gauge. This assures adequate lubrication. Forward Rotation Reverse Rotation Flush Manifold Pumps FLUSHED MANIFOLD PUMPS, SOLID SHAFT, BRASS AND 304 STAINLESS STEEL MANIFOLD Belt Drive PUMP MODEL 1810K 1540EC 3520C 3535C MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 3 18 23 36 11.4 68.4 87.4 136.8 10,000 1,200 2,000 1,200 690 83 138 83 RPM SHAFT 1500 1100 800 800 30 mm 30 mm 35 mm 35 mm POWER hp kW 20.5 14.8 31.5 29.6 15.2 10.9 23.3 21.9 Model 3520C FLUSHED MANIFOLD PUMPS, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD Belt Drive PUMP MODEL 311C 781K 1051C 1861K 3801K 7CP6171C 7CP6111C 3811K 6811K 6801K 2831K 3521C 3821K 6821K 3531C 3831K 6831K 3541C 3841K 6841K 6861K MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 4 4.5 10 10 10 10.5 10.5 14 15 15 21 23 23 25 36 36 40 45 45 48 60 15.2 17.1 38 38 38 39.9 39.9 53.2 57 57 79.8 87.4 87.4 95 136.8 136.8 152 171 171 182.4 228 2,200 5,000 2,200 3,000 5,000 2,000 2,000 3,000 5,000 7,000 1,200 2,000 2,000 3,000 1,200 1,200 2,300 1,000 1,000 2,000 1,200 152 345 152 207 345 138 138 207 345 483 83 138 138 207 83 83 159 69 69 138 83 RPM SHAFT 950 1700 958 1429 915 1450 1750 800 600 600 860 800 800 615 800 800 625 765 765 615 52 20 mm 24 mm 30 mm 30 mm 35 mm 24 mm 24 mm 35 mm 45 mm 45 mm 30 mm 35 mm 35 mm 45 mm 35 mm 35 mm 45 mm 35 mm 35 mm 45 mm 45 mm POWER hp kW 6.0 15.4 15.1 20.5 34.2 14.4 14.4 28.8 51.4 71.9 17.3 31.5 31.5 51.4 29.6 29.6 63.0 30.8 30.8 65.8 49.3 4.5 11.4 11.2 15.2 25.3 10.6 10.6 21.3 38.0 53.2 12.8 23.3 23.3 38.0 21.9 21.9 46.6 22.8 22.8 48.7 36.5 Model 1051C FLUSHED MANIFOLD PUMPS, SOLID SHAFT, DUPLEX STAINLESS STEEL MANIFOLD Belt Drive PUMP MODEL 3501C 661C 3511C 152R060C 152R080C 152R100C MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 10 10 14 115 200 240 38 38 53.2 437 760 912 5,000 3,000 3,000 1,200 1,200 1,000 345 207 207 83 83 69 RPM SHAFT 915 1429 800 360 355 270 35 mm 30 mm 35 mm 100 mm 100 mm 100 mm Model 781K POWER hp kW 34.2 20.5 28.8 94.5 164.4 164.4 25.3 15.2 21.3 69.9 121.6 121.6 Model 3841K Triethylene Glycol (TEG) Pumps TRIETHYLENE GLYCOL PUMPS, SOLID SHAFT, BRASS MANIFOLD Belt and Bell Housing Drive PUMP MODEL Model 3CP1120.44101 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.4 2.5 3.6 4 4 4.2 6 10 12 18 21 25 9.1 9.5 13.7 15.2 15.2 16.0 22.8 38.0 45.6 68.4 79.8 95.0 2,200 3,500 2,200 2,500 2,500 2,200 1,600 2,200 1,800 1,200 1,200 1,000 152 241 152 172 172 152 110 152 124 83 83 69 3CP1130.44101 5CP3105CS.44101 3CP1140.44101 5CP2120W.44101 5CP21040WCS.44101 3CP1120.44101 5CP6120.44101 1050.44101 1050.44101 1540E.44101 2530.44101 2530.44101 RPM SHAFT 1725 1725 1725 950 1725 1725 1400 958 1150 1100 860 1025 16.5 mm 20 mm 16.5 mm 20 mm 20 mm 16.5 mm 20 mm 30 mm 30 mm 30 mm 30 mm 30 mm POWER hp kW 3.6 6.0 5.4 6.8 6.8 6.3 6.6 15.1 14.8 14.8 17.3 17.1 2.7 4.4 4.0 5.1 5.1 4.7 4.9 11.2 10.9 10.9 12.8 12.7 TRIETHYLENE GLYCOL PUMPS, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD Belt and Bell Housing Drive PUMP MODEL Model 5CP2120W.44101 Model 1050.44101 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 2.3 3.6 4 4.2 5 6 10 12 18 21 25 8.7 13.7 15.2 16.0 19.0 22.8 38.0 45.6 68.4 79.8 95.0 2,000 2,000 2,000 2,000 2,000 2,000 2,200 1,800 1,200 1,200 1,000 138 138 138 138 138 138 152 124 83 83 69 3CP1231.44101 3CP1241.44101 5CP6241CS.44101 3CP1221.44101 5CP6251.44101 5CP6221.44101 1051.44101 1051.44101 1541.44101 2531.44101 2531.44101 TEG Pump Reliability and Performance you expect from Cat Pumps •P erformance Range 0.14 to 25 gpm 100 to 3500 psi • Consistent Flow Rate • Leak-Free Design • L owest Cost of Ownership – Longest Lasting Seals – Less Maintenance – Less Downtime – High Overall Efficiency Model 2530.44101 RPM SHAFT 1725 1725 1725 1725 1725 1400 958 1150 1100 860 1025 16.5 mm 16.5 mm 20 mm 16.5 mm 20 mm 20 mm 30 mm 30 mm 30 mm 30 mm 30 mm POWER hp kW 3.2 4.9 5.5 5.8 6.8 8.2 15.1 14.8 14.8 17.3 17.1 2.3 3.6 4.1 4.3 5.1 6.1 11.2 10.9 10.9 12.8 12.7 Liquid CO2 Pumps LIQUID CO2 PUMPS, SOLID SHAFT, BRASS MANIFOLD Belt Drive PUMP MODEL 30.CO2 310.CO2 1560M.CO2 1050M.CO2 1530RSCM.CO2 1540ECM.CO2 3520CM.CO2 3535CM.CO2 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 0.68 1.75 2.5 4 5 7 11.4 19.4 2.6 6.7 9.5 15.2 19.0 26.6 43.3 73.7 2200 2200 4000 2200 1800 1200 2000 1200 152 152 276 152 124 83 138 83 RPM SHAFT 450 450 450 450 450 450 450 450 20 mm 20 mm 30 mm 30 mm 30 mm 30 mm 35 mm 35 mm RPM SHAFT 450 450 450 450 450 450 450 450 450 450 450 24 mm 20 mm 24 mm 20 mm 30 mm 35 mm 30 mm 30 mm 45 mm 35 mm 45 mm POWER hp kW 1 3 7 6 6 6 16 16 0.8 2.0 5.1 4.5 4.6 4.3 11.7 12.0 Model 30RS.CO2 LIQUID CO2 PUMPS, SOLID SHAFT, 316 STAINLESS STEEL MANIFOLD Belt Drive PUMP MODEL 784KM.CO2 301.CO2 781KM.CO2 351.CO2 1861KM.CO2 3801KM.CO2 1051CM.CO2 2831KM.CO2 6811KM.CO2 3831KM.CO2 6841KM.CO2 MAXIMUM FLOW MAXIMUM PRESSURE gpm lpm psi bar 0.34 0.68 0.82 1.22 2.5 3.5 4 10 7.2 19.4 30 1.3 2.6 3.1 4.6 9.5 13.3 15.2 38.0 27.4 73.7 114.0 5000 2150 5000 1500 3000 5000 2200 1200 5000 1200 2000 345 148 345 103 207 345 152 83 345 83 138 POWER hp kW 1.2 1.0 2.8 1.3 5.1 12.0 6.0 8.2 24.7 15.9 41.1 0.9 0.8 2.1 0.9 3.9 9.0 4.5 6.2 18.5 12.0 30.8 For over 20 years, Cat Pumps has been working closely with research facilities, universities, equipment manufacturers and site locations to provide dependable and reliable pumping solutions for the challenging CO2 market. Model 1530RSCM.CO2 Model 781KM.CO2 Model 1051CM.CO2 Portable Extractor Pumps PORTABLE EXTRACTOR PUMPS, DIRECT DRIVE, ALUMINUM MANIFOLD Electric Motor (Induction) Included MAXIMUM FLOW PUMP MODEL Model 1XP150.031 1XP050.031 1XP075.031 1XP085.031 1XP100.031 1XP125.031 1XP150.031 1XP200.031 1XP050.051 1XP075.051 1XP085.051 1XP100.051 1XP125.051 1XP150.051 1XP200.051 1XP150.071 1XP200.071 MAXIMUM PRESSURE POWER gpm lpm psi bar RPM hp kW 0.5 0.75 0.85 1 1.25 1.5 2 0.4 0.7 0.8 0.9 1.2 1.5 2 1.4 2 1.9 2.9 3.2 3.8 4.8 5.7 7.6 1.5 2.7 3.0 3.4 4.6 5.7 7.6 5.3 7.6 800 600 600 500 400 325 250 1000 1000 1000 800 800 600 450 800 550 54.4 40.8 40.8 34.0 27.2 22.1 17.0 68.0 68.0 68.0 54.4 54.4 40.8 30.6 54.4 37.4 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4 0.24 0.24 0.24 0.24 0.24 0.24 0.24 0.37 0.37 0.37 0.37 0.37 0.37 0.37 0.55 0.55 PORTABLE EXTRACTOR PUMPS, DIRECT DRIVE, ALUMINUM MANIFOLD Electric Motor (Permanent Magnet) Included Model 1XP150.03DC MAXIMUM FLOW PUMP MODEL 1XP050.03DC 1XP075.03DC 1XP085.03DC 1XP100.03DC 1XP125.03DC 1XP150.03DC 1XP200.03DC MAXIMUM PRESSURE POWER gpm lpm psi bar RPM hp kW 0.5 0.75 0.85 1 1.25 1.5 2.3 1.9 2.9 3.2 3.8 4.8 5.7 8.7 600 500 400 350 300 250 150 40.8 34.0 27.2 23.8 20.4 17.0 10.2 1725 1725 1725 1725 1725 1725 1725 1/3 1/3 1/3 1/3 1/3 1/3 1/3 0.24 0.24 0.24 0.24 0.24 0.24 0.24 Cat Pumps 1XP Series Pumps Head to Head Comparative Testing 1.5 gpm at 500 psi Pump Flow at 500 PSI Cat Pumps 1XP150.051 Competitor 1.7 1.5 GPM For over 45 years, Cat Pumps has been providing the longest-lasting pumps available. The durability of the 1XP Series pumps make it a great fit for the portable extractors that users depend on. Head-to-head testing against competitors shows once again: when it comes to long life and durability, nothing beats Cat Pumps. 1.3 1.1 0.9 0.7 0.5 Run Hours 0 200 400 600 800 1000 Centrifugal Pumps 304 STAINLESS STEEL CASING Centrifugal pumps offer solutions for high-flow, low-pressure industrial pumping needs. Typical fluids pumped include fresh water, semi-dirty water or liquids with some suspended solids. Below is a sampling of popular centrifugal models that include the pump, seal and motor. Most of the pumps listed are rated at 3450 rpm, but many models are available at 1725 rpm. SUBMERSIBLE PUMPS WITH INTEGRAL MOTOR AND SEAL* 45 to 100 gpm (170 to 379 lpm) PUMP MODEL 1K100 1K201 1K203 1K205 1K301 1K303 1K305 2K102 2K103 2K200 2K202 MAXIMUM FLOW MAXIMUM PRESSURE HORSEPOWER gpm lpm psi bar hp kW PHASE/VOLTAGE 45 73 73 73 74 74 74 88 88 100 100 170 276 276 276 280 280 280 333 333 379 379 10 17 17 17 21 21 21 9 9 11 11 0.69 1.17 1.17 1.17 1.45 1.45 1.45 0.62 0.62 0.76 0.76 0.3 0.5 0.5 0.5 0.8 0.8 0.8 0.5 0.5 1.0 1.0 0.2 0.4 0.4 0.4 0.6 0.6 0.6 0.4 0.4 0.7 0.7 1PH / 115V** 1PH / 115V** 1PH / 115V*** 3PH / 460V*** 1PH / 115V** 1PH / 115V*** 3PH / 460V*** 1PH / 230V*** 1PH / 230V** 1PH / 115V** 1PH / 230V** 4.3 4.3 0.9 2.2 2.2 3.0 3.0 4.3 2.0 2.0 0.5 1.0 1.0 1.5 1.5 3.0 1.5 1.5 0.4 0.7 0.7 1.1 1.1 2.2 1PH / 115/208-230V 3PH / 208-230/460V 3PH / 208-230/460V 1PH / 115/208-230V 3PH / 208-230/460V 1PH / 115/208-230V 3PH / 208-230/460V 3PH / 208-230/460V *Motor side seal is NBR fitted Carbon/Ceramic and impeller side seal is Viton® fitted Silicon Carbide/Silicone Carbide. **Supplied with automatic float switch ***Manual models, no float switch END-SUCTION MOTORIZED UNITS WITH TEFC 56J NEMA MOTOR 38 to 63 gpm (144 to 238 lpm) 3K132WT0 38 144 62 3K132WT3 38 144 62 3K392BT3 52 197 13 3K142WT0 63 238 32 3K142WT3 63 238 32 3K152WT0 63 238 44 3K152WT3 63 238 44 3K162WT3 63 238 63 Note: All motors are rated at 3450 rpm except model 3K392BT3 which is rated at 1725. All models listed are equipped with a Viton®/Carbon/Ceramic chemical resistant seal. Buna-N and high temperature seals are also available. END-SUCTION MOTORIZED UNITS WITH TEFC 213/215JM NEMA MOTOR 153 to 380 gpm (579 to 1,438 lpm) 4K142WT3 153 579 90 6.2 4K192WT3 250 946 82 5.7 4K252WT3 380 1,438 84 5.8 0.5 1.0 1.0 0.4 0.7 0.7 3PH / 208-230/460V 3PH / 208-230/460V 3PH / 208-230/460V Note: All motors are rated at 3450 rpm. All models listed are equipped with a Viton®/Carbon/Ceramic chemical resistant seal. Buna-N and high temperature seals are also available. SELF-PRIMING MOTORIZED UNITS WITH TEFC 56J NEMA MOTOR 18.5 gpm (70 lpm) 5K112WT0 5K112WT3 5K122WT0 5K122WT3 18.5 18.5 18.5 18.5 70 70 70 70 56 56 82 82 3.9 3.9 5.7 5.7 1.0 1.0 1.0 2.0 0.7 0.7 0.7 1.5 Note: All motors are rated at 3450 rpm. All models listed are equipped with a Viton®/Carbon/Ceramic chemical resistant seal. Buna-N and high temperature seals are also available. 1PH / 115/208-230V 3PH / 208-230/460V 1PH / 115/208-230V 3PH / 208-230/460V Custom Pumping Systems YOU DEFINE. WE DESIGN AND DELIVER. Custom Engineered to Meet Your Application Demands For over 25 years, Cat Pumps has been the industry leader in providing customers with quality custom-engineered pumping systems to meet a wider range of application needs. By selecting Cat Pumps for your next pumping system, customers eliminate the hassle and expense of designing, multiple source buying, fabrication and testing. The knowledgeable and helpful technical sales team assists with proper component selection, as well as installation, operation and maintenance support. All systems are designed, built and pressure tested in the Cat Pumps Minneapolis location. To begin the quoting process, call the main office at (763) 780-5440 or submit the custom system quote form at catpumps.com. With thousands of installations running around the world, Cat Pumps is the supplier of choice for custom pumping systems. Call or go online to start your quote today. System Configuration With extensive experience building thousands of systems, Cat Pumps can help determine the best configuration for any application. Cat Pumps Advanced Control Options Base System design starts with choosing the base that best fits the application. Numerous base configurations are available to meet space, portability, sound and material demands. • Standard • Vertically Stacked • Portable • Enclosed • Multiple Pump Power Source A qualified technical staff with extensive experience can assist in recommending the correct product for any power source available. A wide variety of drive packages are available to complement any power source of choice. Drive Package Ask about the wide variety of advanced control options designed to provide maximum system performance as well as maximum system protection. Options include: • Belt • Direct Drive • Gearbox • Flex Coupling/Bell Housing • Clutch • Variable Frequency Drives (VFD) Accessories •P ID Loop (varies speed of pump to maintain system pressure) • Electric • Gas • Diesel • Hydraulic • Pneumatic Choose from hundreds of high-quality genuine Cat Pumps accessories for optimum system performance and life. • Regulator • Unloader • Relief / Pop-off Valve • Pressure Gauge • Pulsation Dampener • Captive Acceleration Tube (C.A.T.) • Inlet Filter / Strainer • Guns • Oil • Multiple Pump Systems • Low-Pressure Seal Monitors •A uto Shutdowns (Temperature and Low Inlet Pressure) Other control options are available upon request. Accessories MAXIMUM PUMP PERFORMANCE Demand Genuine Cat Pumps Accessories Cat Pumps offers a wide range of accessories that meet the same exacting standards as its pumps. A pumping system’s performance is as good as its weakest component, which is why accessory components are rigorously tested and evaluated. The goal is to provide the best system value by offering pumps and accessories that exceed performance and reliability expectations. Cat Pumps products offers the lowest possible life cycle cost. Check out our complete line of accessories online at lenntech.com Investing In Our Products Cat Pumps built its reputation on the dependability and reliability of its products. A comprehensive distributor network locally stocks pumps, repair kits and accessories, and is available to assist with pump selection and system design requirements. Manifold Design •P recision-machined high-strength forged manifolds provide a superior sealing surface for consistently longer seal life when compared to competitive designs. •P roprietary seal materials and designs offer unmatched performance, often providing two to three times longer seal life than competitors’ pumps. • A variety of optional seals/elastomers are available to handle special applications. •M anifolds are available in different materials, meeting the requirements needed for various liquids. • S tainless steel valves, seats and springs provide corrosive-resistant performance and extended service life. Drive Design •D rive components are designed to meet continuous-duty industrial applications, consistently outperforming competitor’s designs. •P roprietary ceramic plungers provide maximum resistance to corrosion and abrasion, maximizing seal life and outperforming the competition. • Heavy-duty ball and roller bearings provide long service life. •H ardened crankshafts and connecting rods are sized to minimize surface speed at the journal, contributing to lower temperature operation and longer drive life. Industry Leading Customer Service Cat Pumps employs a knowledgeable and experienced customer service team that provides assistance with order information, as well as technical assistance in product selection, installation, maintenance support, pump repair and general system troubleshooting. Live support is available M – F, 8:00 a.m. to 5:00 p.m. CST at (763) 780-5440. Email: techsupport@catpumps.com Cat Pumps occupies over 145,000 sq. ft. at its world headquarters in Minneapolis, MN. Cat Pumps Locations SALES, DISTRIBUTION, SERVICE Call today for product and application assistance. +31-152-610-900 or visit us at www.lenntech.com Lenntech info@lenntech.com Tel. +31-152-610-900 www.lenntech.com Fax. +31-152-616-289 For International inquiries go to www.catpumps.com and navigate to the “Contact Us” link. ©2014 Cat Pumps Inc. All rights reserved. All written and visual data contained in this document are based on the latest product information available at the time of publication. Cat Pumps reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. For more information, contact us at (+31-152 610 900 • Lenntech.com PN 993320 Rev C 2/14

![Leader_Analysis_Sheet_Peter_the_Great[1]](http://s3.studylib.net/store/data/009220992_1-b864ff548a7d360a25262ba94c316f4a-300x300.png)