Safe Water Storage in Kenya's Modified ... Standardization, Tap Design, and Cost Recovery

advertisement

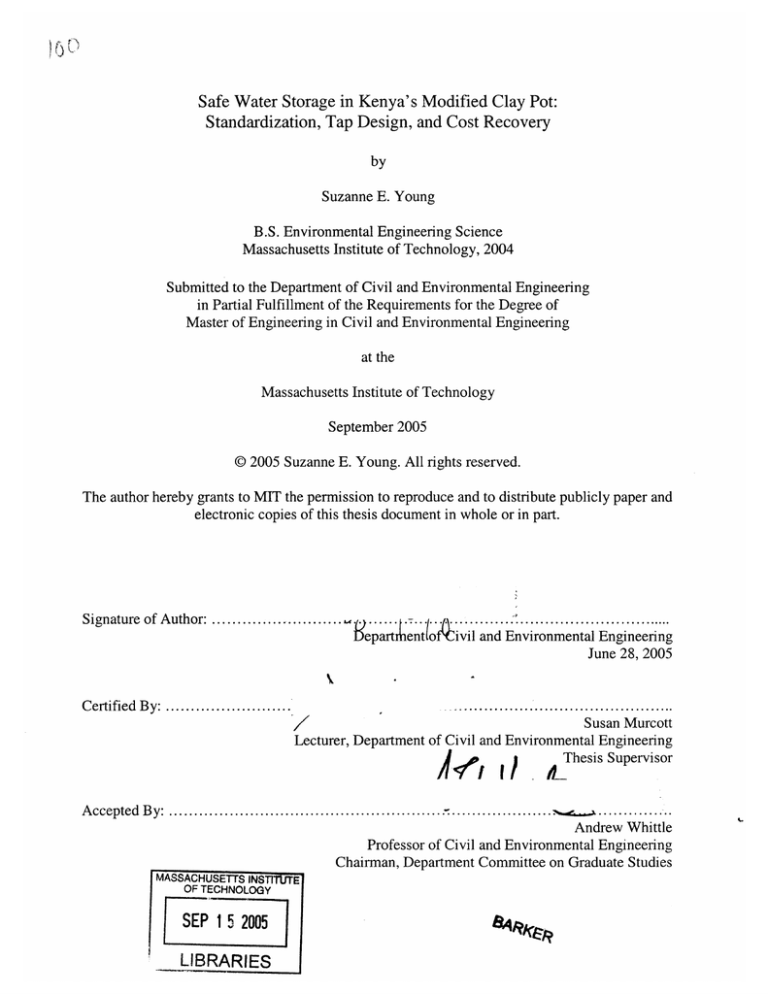

Safe Water Storage in Kenya's Modified Clay Pot:

Standardization, Tap Design, and Cost Recovery

by

Suzanne E. Young

B.S. Environmental Engineering Science

Massachusetts Institute of Technology, 2004

Submitted to the Department of Civil and Environmental Engineering

in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Civil and Environmental Engineering

at the

Massachusetts Institute of Technology

September 2005

©2005 Suzanne E. Young. All rights reserved.

The author hereby grants to MIT the permission to reproduce and to distribute publicly paper and

electronic copies of this thesis document in whole or in part.

Signature of A uthor: ...........................

. . . . . . .

....... ...............................

epart ent o:.ivi. and Environmental Engineering

June 28, 2005

C ertified B y: ....................

.........................................

Susan Murcott

Lecturer, Department of Civil and Environmental Engineering

Thesis Supervisor

Accepted B y: ......................................................-

:....................

Andrew Whittle

Professor of Civil and Environmental Engineering

Chairman, Department Committee on Graduate Studies

MASSACHUJSETTS INSTITUE

OF TECHNOLOGY

SEP 15 2005

LIBRARIES

Safe Water Storage in Kenya's Modified Clay Pot:

Standardization, Tap Design, and Cost Recovery

by

Suzanne E. Young

Submitted to the Department of Civil and Environmental Engineering

on June 30, 2005 in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Civil and Environmental Engineering

ABSTRACT

One of the main components necessary for providing safe drinking water for users who lack

piped water in the home is the ability to safely store it in the home. Users in the Nyanza Province

of Kenya frequently carry water from some distance or purchase vended water and traditionally

store this water in their homes in clay pots. CARE/Kenya, a non-governmental organization

working in conjunction with local women potters and the Centers for Disease Control and

Prevention, modified these clay pots so that they fit the definition of designated safe storage

water containers, which contain the following three characteristics: a narrow mouth, a lid, and a

tap to prevent recontamination. Three pottery production sites were visited in order to document,

analyze, and suggest improvements for the design of the modified clay pots, specifically with

regards to the standardization of the size and shape of the pots, so as to allow simple and

convenient standardized household chlorine dosing, and the tap design and attachment, because

the current tap design is expensive and prone to leaking. The modified clay pots displayed little

variability in pot dimensions, and the 20 liter modified clay pots from the Amilo location showed

a less than or equal to 10% volume variability that is acceptable according to the Centers for

Disease Control and Prevention household chlorine dosing procedure. A reference rope tool

developed to help standardize the size of modified clay pots can be used to train new potters but

is not necessary for experienced potters. The spring-operated plastic tap was found to be the most

promising design to replace the current metal tap design. The material cost of the modified clay

pots at the three sites was determined with some certainty to range from 202-370 KSH

(US$2.70-US$4.90). However, labor costs, transportation costs, profit margins and the role of

subsidies, if they exist, were unable to be accurately determined. Therefore, cost recovery of the

modified clay pot is unclear at all three pottery sites due to insufficient data.

Thesis Supervisor: Susan Murcott

Title: Lecturer in Civil and Environmental Engineering

Acknowledgements

"Do you not know? Have you not heard? The Everlasting God, the Lord, the Creator of the ends

of the earth does not become weary or tired. His understanding is inscrutable. He gives strength

to the weary, and to him who lacks might He increases power. Though youths grow weary and

tired, and vigorous young men stumble badly, yet those who wait for the Lord will gain new

strength; they will mount with wings like eagles, they will run and not get tired, they will walk

and not become weary." (Isaiah 40: 28-3 1)

To God, thank you for your strength, thank you that your power is made perfect in my weakness,

thank you that your grace is sufficient for me.

To Susan Murcott, thank you for finding this project and for your careful reading of this thesis.

To Daniele Lantagne, thank you for your help in kick-starting this project in Kenya, careful

reading of this thesis, quick replies to emails and encouragement throughout.

To CARE Kenya, thank you for hosting me in Homa Bay and making this project possible.

To Eric Adams, Cynthia Stewart, and Blanche Staton, thank you for your administrative help

regarding finishing this thesis during the summer. Dr. Adams, thank you also for the last minute

calculus help!

To AC, EC, and CR, thank you for your help with taking pictures, giving me access to a digital

camera, and giving me access to a scanner.

To my M.Eng classmates, thank you for a fun year.

To my friends, AP, PH, JT, AC, AF, RB, KL, MC, JZ, RW, EH, CBCGB girls group and Charis

home group, thank you for listening to my thesis woes, encouraging me in hard times and

supporting me throughout.

To my family, Mommy, Daddy, SM, KL, and BN, thank you for loving and supporting me 100%,

and for constantly reminding me not to give up and that in the end I will always be okay.

Contents

Chapter 1 General Introduction.....................................................................................

1.1

1.2

1.3

1.4

1.5

Introduction .....................................................................................................

W ater in Kenya..............................................................................................

Safe W ater System ..........................................................................................

M odified clay pot............................................................................................

CARE/Kenya ...... s....

......................................

..........................................

9

9

12

13

14

15

Chapter 2 Research Objectives .................................................................

18

2.1 Research objectives..........................................................................................

18

2.1.1 Standardization ................................................................................

2.1.2 Tap design and attachm ent...............................................................

2.1.3 Cost recovery analysis .....................................................................

Chapter 3 Literature Review ..........................................................................................

3.1 M aster of Engineering theses..........................................................................

3.2 Organization-based reports............................................................................

3.3 Other works.....................................................................................................

Chapter 4 Methodology.................................................................................................

4.1

4.2

4.3

4.4

Observation .....................................................................................................

Interviews............................................................................................................29

Trial-and-error problem solving .........................................................................

Focus groups..................................................................................................

4.4.1 Definition and motivation..............................................................

4.4.2 Form at of discussions .....................................................................

18

19

20

21

21

23

24

28

29

31

31

31

33

Chapter 5 Focus Group Results......................................................................................35

5.1

5.2

5.3

5.4

5.5

Background on shapes of clay pots.......................................................

Preparation for focus groups..........................................................................

Am ilo focus group .........................................................................................

Oriang focus group .........................................................................................

Summ ary

.....................................................................................

.35

38

39

43

46

Chapter 6 Standardization.............................................................................................

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

Background and m otivation............................................................................

Construction of m odified clay pots.................................................................

Pre-existing techniques ...................................................................................

Shrinkage .......................................................................................................

Variability in pot dim ensions and volumes ...................................................

Techniques and tools to standardize pottery ...................................................

Reference ropes...............................................................................................

Summ ary of results ..........................................................................................

Chapter 7 Tap Design and Attachment ........................................................................

7.1

7.2

7.3

7.4

7.5

Current design and attachment ........................................................................

Leakiness from current tap ..................................................................................

Alternative designs..........................................................................................

Plastic tap ............................................................................................................

Summ ary of results .........................................................................................

48

48

50

53

54

61

74

75

79

81

82

88

90

92

99

Chapter 8 Cost Recovery Analysis..................................................................................101

8.1

8.2

8.3

8.4

8.5

Cost breakdown of Am ilo m odified clay pot....................................................102

Cost breakdown of Oriang modified clay pot...................................................107

Cost breakdown of Kinda E Teko (Asembo) modified clay pot ...................... 110

Limitations of analysis......................................................................................112

Summ ary of results ...........................................................................................

113

Chapter 9 Conclusions......................................................................................................114

9.1

9.2

9.3

9.4

Standardization .................................................................................................

Tap design and attachm ent................................................................................115

Cost recovery ....................................................................................................

Overall conclusions...........................................................................................116

References...........................................................................................................................117

114

116

List of Figures

Figure

Figure

Figure

Figure

1-1.

1-2.

1-3.

1-4.

A provincial m ap of Kenya............................................................................

10

W ide-m outh clay pot.....................................................................................

10

The m odified clay pot .....................................................................................

12

Map of Kenya showing administrative boundaries........................................17

Figure 4-1. Map of Kenya's Nyanza Province and field site locations .............................

Figure

Figure

Figure

Figure

28

5-1. Examples of different traditional forms of Kenyan pottery...........................37

5-2. Various shapes of clay pots............................................................................

38

5-3. The author's drawings of pot shapes..............................................................39

5-4. Examples of Amilo Potters' individual drawings of clay pots ...................... 41

Figure 5-5. Examples of Oriang Potters' individual drawings of clay pots .....................

44

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

6-1. Dimensions of the modified clay pot ............................................................

50

6-2. Forming base by pounding clay into a flat disk ............................................

51

6-3. Extending vessel w alls ..................................................................................

52

6-4. Continued vessel wall extension ...................................................................

52

6-5. Before and after sm oothing............................................................................

53

6-6. Rate of water loss in drying moist clay ..........................................................

59

6-7. Stages in drying moist clay ............................................................................

59

6-8. Measuring pots with a seamstress tape at Amilo ..........................................

61

6-9. Graphical representation of the dimensions of 20 L modified clay pots .....

64

6-10. Graphical representation of the dimensions of 40 L modified clay pots ......... 65

6-11. Variability in 20 L modified clay pots made by Amilo Potter No. 7...........67

6-12. Variability in 40 L modified clay pots made by Amilo Potter No. 2...........67

6-13. Symbols used in equations to convert dimensions to volumes .................... 69

6-14. Varying shapes of modified clay pots..........................................................72

6-15. Hardwood calipers and aluminum calipers used to standardize pottery .......... 75

6-16. Pictorial drawing of 20 L modified clay pot reference rope ........................ 77

6-17. Photograph of 20 L modified clay pot reference rope. ...............................

77

6-18. A potter using the 20 L modified clay pot reference rope at Amilo ........... 78

6-19. Teaching the potters to use the reference rope tool .....................................

78

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

7-1.

7-2.

7-3.

7-4.

7-5.

7-6.

7-7.

7-8.

7-9.

Exam ple of a m etal tap...................................................................................

82

Cutting PVC pile to proper length with a hacksaw blade .............................

83

Heating PVC pipe to thermally press fit it to the metal tap threads...............84

The PVC pipe fits snugly over the metal tap threads.....................................84

Close-up of split PVC pipe used to fit tap to PVC pipe..................................84

Tap attachm ent in parallel .............................................................................

85

Tap w edged in vessel .....................................................................................

86

Tap is fixed in place using nill on inside and outside of vessel.....................86

Nill is applied to the base, forming an outer layer .........................................

86

Figure 7-10.

Figure 7-11.

Figure 7-12.

Figure 7-13.

Figure 7-14.

Figure 7-15.

Figure 7-16.

Figure 7-17.

Figure

Figure

Figure

Figure

Figure

8-1.

8-2.

8-3.

8-4.

8-5.

Nill is extended up to the tap and around the base of the vessel..................87

Using rocks and pottery shards to stabilize tap............................................87

Alternative designs to current metal tap design ..........................................

90

Potters for Peace Filtr6n System.................................................................93

Schematic drawing of the spring-operated plastic tap .................................

94

The plastic tap attached to a small flower pot at Oriang..............................95

Close-up of jam nut used to secure the plastic tap .......................................

96

A 20 L modified clay pot at Oriang with plastic tap attached .................... 97

Interviewing Amilo CBO members .................................................................

103

Pie chart showing material cost breakdown at Amilo (Amilo CBO)...............104

Pie chart showing material cost breakdown at Amilo (Mwaki, 2005).............106

Pie chart showing material cost breakdown at Oriang.....................................109

Pie chart showing material cost breakdown at Kinda E Teko ......................... 111

List of Tables

Table 6-1. Shrinkage line tests performed at Oriang ........................................................

55

Table 6-2. Dimensions of modified clay pots freshly made and after drying...................56

Table 6-3. Percent shrinkage of modified clay pots at Oriang .........................................

57

Table 6-4. Dimensions of 20 L modified clay pots ........................................................

62

Table 6-5. Dimensions of 40 L modified clay pots .........................................................

63

Table 6-6. Variability in modified clay pot dimensions by location ................................

66

Table 6-7. Measured volumes and dimensions of four 20 L pots.....................................68

Table 6-8. Comparison of measured volumes to calculated volumes ..............................

70

Table 6-9. Calculated volumes of Amilo 20 L modified clay pots...................................72

Table 6-10. Calculated volumes of modified clay pots by location and size ................... 73

Table 6-11. Dimensions calculated for the 20 L modified clay pot reference rope..........76

Table 7-1. Leakiness experiment at Oriang .....................................................................

Table 7-2. Leakiness experiment at Amilo .......................................................................

Table 7-3. Pugh chart used to evaluate tap design alternatives .......................................

89

89

92

Table 8-1. Material cost breakdown of Amilo modified clay pot (Amilo CBO) ............... 104

Table 8-2. Material cost breakdown of Amilo modified clay pot (Mwaki, 2005)..............106

Table 8-3. Summary of costs and sale prices for Amilo modified clay pots ..................... 107

Table 8-4. Material cost breakdown of Oriang modified clay pot......................................108

Table 8-5. Summary of costs and sale prices for Oriang modified clay pots .................... 109

Table 8-6. Material cost breakdown of Kinda E Teko modified clay pot .......................... 110

Table 8-7. Summary of costs and sale prices for Kinda E Teko modified clay pots ......... 111

Table 8-8. Summary of cost of metal tap and total material costs......................................113

Chapter 1

General Introduction

1.1

Introduction

One of the main components necessary for providing safe drinking water is the ability to

safely store it in homes of users that do not have a piped water supply at all times. Whether the

water is obtained from an improved source, such as a protected well; cleaned, such as by using

filters or a coagulant; or disinfected through SODIS, household chlorination, or some other

method, the potential for contamination in transport and storage undermines and can negate the

resources spent ensuring the water is safe to drink at the improved source.

People in the Nyanza Province of Kenya (Figure 1-1), located along the shores of Lake

Victoria, have a tradition of storing their water in wide-mouth clay pots (Figure 1-2). Users

prefer using clay pots because of the evaporative cooling effect such vessels have on water and

because the clay makes the water palatable (Bovin and Morohashi, 2004). However, the wide

mouths encourage the drawing of water with cups, and often, the hands holding the cups are

contaminated. So, even pristine water stored improperly can be easily contaminated, leading to

incidences of diarrheal disease, mainly in children under the age of five.

9

Figure 1-1. A provincial map of Kenya showing the location of Nyanza Province on the shores of

Lake Victoria (western border).

(Source: United Nations Development Programme-Kenya/ GEF-SGP, 2004)

Figure 1-2. Wide-mouth clay pot.

(Source: CARE Kenya, 2003)

10

One approach to minimizing potential contamination routes in storage is the use of a

designated safe water storage container. Safe Water System (SWS) containers are designed to

eliminate potential routes of contamination when used properly, by providing a fully enclosed

container with a tap that enables safe access to water. The Centers for Disease Control and

Prevention (CDC) defines a safe storage container as having the three following characteristics:

1) narrow mouth; 2) lid; and 3) a tap to prevent recontamination (CDC, 2005).

This study focuses on a safe water storage container called the "modified clay pot"

(Figure 1-3), which was developed by the non-governmental organization (NGO) CARE/Kenya,

working in conjunction with local women potters and the CDC. Despite their improvements to

the wide-mouth clay pot to make it into a safe storage container (narrowing the mouth, adding a

lid, and attaching a tap), the design of the modified clay pot needs further improvement (Quick,

2004). The metal tap leaks, and is very expensive, costing nearly the same amount as all of the

other materials combined. In addition, the size and shape are non-standard. A standard size is

essential for proper chlorine dosing, and a standard shape is ideal to ease tap attachment.

This thesis begins in Chapter 1 with a brief introduction to water in Kenya, the Safe

Water System (SWS), the modified clay pot, and the role of CARE/Kenya regarding the

modified clay pot. The research objectives are stated in Chapter 2, followed by a literature

review in Chapter 3, the methodology in Chapter 4, a spotlight on the focus group results in

Chapter 5, a discussion and results of standardization in Chapter 6, a discussion and results of the

tap design and attachment in Chapter 7, a cost recovery analysis in Chapter 8, and conclusions in

Chapter 9.

11

own

Lid

Narrow mouth

Sediment pouch

Metal tap to access wa

Flat base

Figure 1-3. The modified clay pot.

(Source: Murcott, 2004)

1.2

Water in Kenya

Kenya is a country struggling to meet the water demand of its 31.5 million people. Only

57% of the population has access to an improved water supply (e.g. piped household connection,

public standpipe, borehole, protected dug well, protected spring, or rainwater collection), and

31% of the population has to travel over half an hour to fetch water (Gordon, 2004).

Two thirds of Kenya is arid or semi-arid; therefore, access to water in many areas is very

limited. Women spend several hours daily collecting water, a resource that is shared with

animals that drink from it and contaminate it.

In Nyanza Province, only 14% of people receive their drinking water from a piped supply.

The percentage of people using unimproved open water sources such as springs, streams, and

12

rivers amounts to nearly 58% (Central Bureau of Statistics, 2003). In such open water systems,

the likelihood of contamination is significantly higher than for piped and treated water systems.

One simple and cost effective solution to treating contaminated drinking water and

storing it safely is the Safe Water System (SWS) intervention.

1.3

Safe Water System

According to the Centers for Disease Control and Prevention's (CDC) Safe Water System

web site (2005), "Safe Water System (SWS) is a water quality intervention that employs simple,

inexpensive and robust technologies appropriate for the developing world. The objective is to

make water safe through disinfection and safe storage at the point of use. The intervention

consists of three steps:

1) Point-of-use treatment of contaminated water using sodium hypochlorite solution

purchased by a local manufacturer or in the community;

2) Safe water storage in plastic containers with a narrow mouth, lid, and a tap to

prevent recontamination; and,

3) Behavior change techniques, including social marketing, community mobilization,

motivational interviewing, communication and education. These activities

increase awareness of the link between contaminated water and disease, the

benefits of safe water, and hygiene behaviors, including the purchase and proper

use of the water storage vessel and disinfectant."

Quick et al. (2002) field tested a Safe Water System intervention that consisted of water

treatment, safe storage, and community education in Kitwe, Zambia. They tested a random

selection of 166 intervention households and 94 control households and found that diarrheal

13

disease risk for individuals in intervention households was 48% lower than for controls. Semenza

et al. (1998) also found that the use of SWS reduced diarrheal disease incidence by 85% in

Uzbekistan. For this particular thesis, the focus is safe water storage not in plastic containers as

in Zambia and Uzbekistan, but in clay containers, also with a narrow mouth, lid, and a tap to

prevent recontamination. This container is known as the "modified clay pot".

1.4

Modified clay pot

The modified clay pot (Figure 1-3) includes the following features recommended by the

CDC: a narrow mouth, a lid, and a tap to access water. In addition, the modified clay pot has the

benefits of a flat base for easy water extraction and a space at the bottom (below the tap) to retain

sediment. The form, color, and function of the traditional clay pot are essentially retained.

However, there are several weaknesses associated with the modified clay pot's design. These

include fragility of the structure, leakage around the metal tap, and a non-standard size as a result

of manual molding. Because CARE/Kenya is promoting treatment of water with a 1% sodium

hypochlorite solution at the household level, a standard size is essential to choose the proper dose.

Moreover, from an affordability standpoint, there is interest to replace the metal tap with a

different type of tap because the metal tap itself costs about the same as the entire clay pot.

A brief history of CARE/Kenya's role in conceptualizing and disseminating the modified

clay pot is found in the next section.

14

1.5

CARE/Kenya

CARE/Kenya has been one of the non-governmental organizations (NGOs)

implementing the SWS program in Kenya. CARE is an international NGO that has contributed

to poverty reduction in Kenya for the past 32 years. After conducting a baseline survey in

February 2000 that revealed that 99% of the target population stored their drinking water in

traditional wide-mouth clay pots, CARE/Kenya started a unique adaptation of the SWS

intervention (Mwaki, 2005). Although the second step of the SWS intervention calls for the use

of safe water storage in plastic containers with a narrow mouth, lid, and a tap, CARE/Kenya

found that the target community preferred clay pots because of their cooling effect on water, a

key point considering the hot climate of the region. Common 20-liter plastic jerry cans are used,

however, to collect and transport water from the sources in the target region of Nyanza Province.

In response to the community's preference, CARE/Kenya's SWS team designed a

modified clay pot with features similar to the improved plastic container. This proved a rigorous

exercise, especially the molding of the pot to both incorporate the SWS features and keep a

similar design to the wide-mouth clay pot. During the re-designing of the pot in August 2000, the

SWS team contacted a local pottery group known as the Oriang Women's Pottery Group to make

the modified clay pots on behalf of CARE/Kenya.

When the first batch of pots were ready to be sold at the market, the demand was already

much greater than the limited supply. The features of the improved pots, including the metal taps

and lids, appealed to the local community, increasing demand. At this point, the CARE/Kenya

SWS team recognized the need to scale up the production by identifying additional pottery

groups across the region, thereby decentralizing the production.

15

In 2003, the SWS team identified a local pottery group known as the Amilo Community

Based Organization (CBO) to be trained in the SWS intervention. This group eventually started

manufacturing the modified clay pots in addition to supplying the chlorine for water treatment.

At this same time, the SWS intervention greatly expanded to other districts across the

Lake Victoria region. When CARE/Kenya held training sessions about SWS, one of the

implementing partners, Society for Women and AIDS in Kenya (SWAK), identified a pottery

group named Bar chando Women's Group to make the modified clay pots. The CARE/Kenya

team trained this group and ultimately distributed the pots to the support groups working under

the umbrella of SWAK. The Bar chando Women's Group has made pots that are sold 100 km

away in Kisumu City (Figure 1-4).

Beginning in February 2005, CARE/Kenya's SWS intervention began to expand to fifty

schools in three districts of Nyanza Province: Homa Bay, Suba, and Rachuonyo (Figure 1-4). In

each school, the SWS team earmarked a minimum of five modified clay pots for the storage of

treated drinking water. In addition, the team is making available hand-washing facilities such as

plastic vessels with taps in these schools. In March 2005, the team expanded the SWS

intervention to the Siaya District (Figure 1-4) through the training of all health workers in the

health facilities that provide Prevention of Mother to Child Transmission (PMTCT) of HIV

services. SWS has also been integrated into the existing Water Sanitation and Education for

Health (WASEH) project that is currently implementing activities in two districts as of April

2004. CARE/Kenya has high hopes that the SWS intervention will be further scaled up to

include all of Kenya's Ministry of Health facilities.

16

TE R

KA

SIA

G

VAHIGA

Isum

BONDO

YAI

KE

RACH UONY-

HO

BA

WS.YAMIFGUC

MIGORI

TRANSM/

RUR IA

Figure

1-4. Map of Kenya showing administrative boundaries.

(Source: FAO, 2005)

17

Chapter 2

Research Objectives

2.1

Research objectives

The goals of this thesis are to document, analyze and suggest improvements for the design

and cost of modified clay pots in Kenya's Nyanza Province, specifically with regards to the

standardization of the pots, design of a new tap and cost recovery.

In parallel with the work of this thesis, in the Master of Engineering thesis of teammate

Michael Pihulic, the entire production and manufacture process of modified clay pots, from start

to finish, was documented using a combination of photography, videotape, and interviews

conducted with the potters (Pihulic, 2005a).

2.1.1

Standardization

The first goal of this thesis is to address standardization of the modified clay pot. In order

to implement a disinfection protocol that is simple and easy to use, either a versatile dosing

system based on volume of household water storage container is required (which is complicated

for users to implement) or much preferably, a standardized container should be utilized or

introduced. Given the variation in the size of non-jerry can household water storage containers, it

is not always feasible to design a simple disinfection dosing procedure for different volumes.

The current method used in Kenya is to use a pre-measured dose of a 1% sodium hypochlorite

solution for a known volume of water. The typical jerry can used to collect water in Kenya is a

20 liter volume; thus, a standard size of the pot, either 20 L or 40 L, is critical to ensure that

people do not fill the pots with e.g. 1

jerry cans. A 20 L or 40 L standard size means the

18

chlorine dosing remains effective. A standard pot size also eases transport of the pots to local

markets and to homes. Various methods for standardizing the size of the clay pot during

production have been investigated and field tested in this thesis.

2.1.2

Tap design and attachment

A second goal of this thesis is to suggest an alternative to the modified clay pot's current

metal tap design and attachment. The tap usually costs more than all the other materials required

to make the modified clay pot (e.g. the tap costs 200 KSH out of a total material cost of 370 KSH

at one pottery production site). In addition, however, the technique for attaching the tap also has

not been perfected and often creates leaks that reduce the effectiveness of the containers. The

goal is to design a replacement tap using locally available resources that will significantly reduce

the cost of the safe water storage container and at the same time reduce leaks.

Several alternatives to the current tap design were developed and evaluated using the

following criteria: cost, leakiness, local availability of materials and potential for distribution in

the Lake Victoria region, ease-of-use for young children, ease of construction, social

acceptability, likelihood of contamination, and maintenance. Each design alternative was

evaluated against the current design using a tool called a Pugh chart.

Ensuring that the local populace is comfortable with any new tap design and attachment

technique used is also a high priority.

19

2.1.3

Cost recovery analysis

Cost recovery of all of the materials used to make the modified clay pot is a key

component, because one of the goals of designing a new tap is to address affordability. Cost data

at Amilo was obtained via interviews and later updated with numbers provided via email

correspondence with CARE/Kenya staff Alex Mwaki (2005), while cost data at Kinda E Teko

was obtained by Gibney (2005) via interview. Cost data for Oriang was incomplete at the time of

field work; however, unknown data was estimated using the Amilo data. The goal of the cost

recovery analysis is to create the best product at the cheapest price, which is integral to creating a

financially viable enterprise.

20

Chapter 3

Literature Review

The modified clay pot has been produced for only five years. Except for the work

documenting the production process of the modified clay pot by teammate Michael Pihulic

(2005a), the Best Practicespublication from Nuffic and UNESCO/MOST (2002), A Manual on

the Safe Water System from CARE Kenya (2003) and an unpublished presentation entitled "Safe

Water System as a Home Care Intervention for People Living with HIV/AIDS" given by Alie

Eleveld at the 2004 International Symposium "Household Technologies for Safe Water" in

Nairobi, Kenya, it has never been studied before. Therefore, this literature review examines the

work of previous Master of Engineering (M.Eng) students in the MIT Department of Civil and

Environmental Engineering (CEE) and others on the related topics of ceramic water filter

manufacture and performance and safe water storage.

3.1

Master of Engineering theses

Three students in the CEE M.Eng program at MIT have previously completed theses

relevant to this study. Their work is summarized below, along with brief explanations as to how

it relates to this study.

Chian Siong Low's (2002) thesis documents the production process of the terra cotta disk

filter in Thimi's Potter Square. Low references the Potter's For Peace (PFP, 2001) web site,

which encourages the use of a press mould for consistency in pot size and shape. Like Nepal,

Kenya also has a long and established tradition in ceramic pottery making. It is therefore ideal

21

for the SWS intervention to build on this tradition. Low also touches upon the issue of

standardizing pot size and shape by use of a press mold.

Rob Dies (2003) documents in detail the ceramic water filter production process of

Madhyapur Clay Crafts in Thimi, Nepal, which includes material selection, processing, shaping

and pressing the filter element into a mold, firing, drying and quality control. He found that

materials include clay, water, combustible material (used to increase the porosity of the material

since combustible material will burn off during the firing, leaving behind pores or voids through

which the water will travel, e.g. sawdust, flour), temper, known colloquially as "grog" (nonplastic material used to reduce shrinking/warping and to control porosity to some extent, e.g.

ground bricks), and colloidal silver (used to reduce microbial contamination). Dies also notes

that equipment is a major capital investment for the potter, and sources of energy in developing

countries are usually unreliable or expensive, if at all available. Therefore, Dies found it

preferable to use non-electricity powered equipment. When mixing clay, Dies reports the goal is

to find the optimal combination of clay, water, combustibles and/or grog, which depends on the

properties of materials, the equipment used, and methods of production. He discovered these

optimal clay recipes depend on both experience and trial and error, and that mixing by hand,

which is common in developing countries, is very labor intensive. This detailed documentation

of ceramic water filter production was valuable for teammate Michael Pihulic's M.Eng thesis

(2005a), which focused solely on the production and manufacture of the modified clay pot. In

addition, Kenyan potters experience similar bottlenecks to production, including limited

equipment due to high capital costs and time- and labor-intensive steps such as mixing clay by

hand.

22

Rebecca Hwang (2003) performed extensive field monitoring of the Potter's for Peace

(PFP) ceramic water filter in Nicaragua. Hwang points out several of the manufacturing and

transporting difficulties related to ceramics, which include inconsistent product standardization

and quality control due to variability in the composition of clay in different geographic locations,

and fragility of the ceramics, which causes easy breakage during transport and inhibits efficient

shipping and delivery to distant rural areas. Hwang suggested improving the filter design to

include increasing durability to reduce breakage by changing materials or adding steps to the

manufacturing process, and standardizing the quality of raw materials to guarantee consistency

of quality in the production. The modified clay pot has similar impediments to those of the PFP

ceramic water filter, including lack of standardization and quality control, and breakage during

transport.

3.2

Organization-based reports

Best practices using indigenous knowledge - Africa, a joint publication from Nuffic and

UNESCO/MOST co-edited by Bovin and Morohashi (2002), contains a report entitled, "The use

of locally produced clay pots modified for safe storage of drinking water in the home-a

component of CARE Kenya's Nyanza Health Water Project." This is one of the only reports

exclusively on the Kenyan modified clay pot. Nuffic and UNESCO/MOST indicate that the

purpose of the modified clay pot is to reduce both the recontamination of treated water during

storage and the incidence of water borne disease transmission. These two organizations state that

the modified clay pots serve this purpose in addition to retaining an aspect of traditional culture,

i.e. storing water in clay pots. Moreover, because the practice of making modified clay pots is

based on indigenous knowledge, Nuffic and UNESCO/MOST consider the modified clay pot

23

cost-effective. For these reasons, Nuffic and UNESCO/MOST deem the modified clay pot a

"Best Practice". This report is valuable because it is the first written work documenting the

modified clay pot. It introduces the practice, defines its purpose, details the role of indigenous

knowledge, and describes the achievements, results and concerns to date.

A Manual on the Safe Water System Based on CARE Kenya's Experience in Rural

Western Kenya by CARE Kenya (2003) is a case study based on CARE Kenya's experiences

while conducting a scientific study and implementing SWS in areas where diarrhea prevalence is

high, due to inaccessibility of safe water. CARE completed an entire study on home-based water

chlorination in the Lake Victoria region. SWS intervention is a household-based point-of-use

water treatment system whose component includes three strategies: 1) Water treatment using a

1% sodium hypochlorite solution branded Klorin (renamed Water Guard); 2) Safe water storage

vessels; and 3) Behavior change. CARE Kenya describes the features of the modified clay pot, as

well as its advantages and disadvantages. This report is relevant because modified clay pots are a

specific example of a local adaptation of the SWS intervention.

Safe Water Systems for the Developing World: A Handbook for Implementing

Household-Based Water Treatment and Safe Storage Projects by The Centers for Disease

Control and Prevention (CDC, 2005) is a detailed and comprehensive reference guide for

implementing household-based water treatment and safe storage projects. It serves to better

clarify the definition of SWS and gives many examples of safe storage containers.

3.3

Other works

Daniele Lantagne (2001a, 2001b) reiterates the PFP mission statement, which includes

the "stability and improvement of ceramic production" and the "preservation of cultural

24

inheritance." Lantagne was contacted to provide an assessment of the Potter's for Peace filter to

USAID/Nicaragua, including information on the intrinsic effectiveness in the laboratory and

field performance in rural communities. Lantagne produced two reports, one on the intrinsic

effectiveness of the filter (including studies on colloidal silver, flow rates, sliver concentration in

water, and the health effects of ingesting silver), and the other on the performance of the PFP

filter under field conditions in six rural communities. Lantagne's survey of 24 families indicated

that the most common problems were the breakage of the filter and recontamination of the stored

water after filtration, and that there currently exists a lack of education about safe water sources

and correct filter cleaning and maintenance in the families using the filter. Lantagne's

recommendations include dedicating a PFP staff member or a local community leader to the role

of following up on filter use in the families, educating families about proper filter use and

maintenance, and developing and selling a cleaning kit with the filters. This study is useful

because it gives an example of the methodology, results, and recommendations of field-testing a

ceramic product. The recommendations may also be relevant to the modified clay pot, i.e.

following up on modified clay pot use in households, educating families about proper chlorine

dosing, and developing and selling cleaning kits with the pots.

Stuart Cheeseman (2003) documented Reid Harvey's methods for producing ceramic

candle filters and ceramic disk filters. Cheeseman catalogs the requisite tools and techniques for

producing these filters. He includes schematics of the presses and molds used to create the filters,

as well as the methods used to produce them. Cheeseman examines the variables inherent in each

stage of the production process and how the local manufacturer, Hari Govinda, has altered and

adapted the production process to produce ceramic filters according to the Reid Harvey method.

These variables include production difficulties found at each stage and how they influence the

25

final product. Cheeseman identified six design issues that were not addressed in the design

specifications provided by Harvey. Cheeseman noted a smearing effect during extrusion that

reduces filter porosity, the necessity of oil or paper to aid in mold extraction, the importance of

obtaining a reliable silver source, the importance of drying following colloidal silver application,

the parameters necessary for achieving good seals, and problems associated with carbon trapping

when firing the ceramics. This study, in common with the theses of Low (2002) and Dies (2003),

provides valuable information on ceramic water filter production methods and tools.

Alie Eleveld, a representative of the CDC/Kenya's Global AIDS Program, presented

"Safe Water Systems as a Home Care Intervention for People Living with HIV/AIDS" at the

2004 International Symposium "Household Technologies for Safe Water," hosted by the Kenya

Ministry of Health, Nursing Council of Kenya, Emory University, Population Services

International (PSI), the Centers for Disease Control and Prevention (CDC) and CARE/Kenya in

Nairobi, Kenya on June 16-17, 2004. Eleveld, working with the Society of Women and AIDS in

Kenya (SWAK) helped to identify local potters in two areas in Asembo to be trained on

manufacturing modified clay pots for safe water storage. Eleveld reported that the first modified

clay pots from the Asembo pottery sites would be available in June 2003.

Teresa Yamana (2004) performed a paper survey of safe storage vessel types in the

Dominican Republic. She found the most likely reason for contamination of stored water is

contact with contaminated human hands or utensils used to scoop water from the storage vessel.

As mentioned previously, contaminated hands are also the main reason for contamination of

water stored in wide-mouth clay pots.

26

Significant research has been completed by MIT CEE M.Eng students, organizations, and

others that is relevant to this thesis. A number of these authors identify some of the same issues

with ceramics as they relate to "safe water" and as seen in Kenya, such as bottlenecks to

production, the role of indigenous knowledge, standardization, breakage, and lack of quality

control. The background literature also places the modified clay pot into the larger context of the

household drinking water treatment and safe storage' intervention. This review of literature

informed the development of the thesis plan and was valuable in fitting this one thesis into a

larger picture.

1http://www.who.int/householdwater

27

Chapter 4

Methodology

Each of the following organizations (with extent of visit in parentheses) was visited by

the author Suzanne Young and teammate Michael Pihulic, with assistance also provided by

Centers for Disease Control and Prevention (CDC) staff and former MIT Master of Engineering

student ('01) Daniele Lantagne: Oriang Women's Pottery Group in Oriang (5 days); Amilo

Community Based Organization (CBO) Pottery Group in Rangwe (5 days); and Kinda E Teko

Pottery Group in Asembo (1 day). These locations are shown on Figure 4-1. While both the

Oriang Women's Pottery Group and the Amilo CBO Pottery Group are supported by

CARE/Kenya, the Kinda E Teko group is supported by the Society of Women and AIDS in

Kenya (SWAK).

Figure 4-1. Map of Kenya's Nyanza Province and field site locations.

(Source: Kenya Web, 2001; United Nations Development Programme-Kenya/ GEF-SGP, 2004)

28

Methodology in the field during January 2005 included observing potters at work,

interviewing potters and project partners, trial-and-error problem-solving with the women

potters, and conducting focus groups. These methods are described in detail in sections 4.1-4.4.

An essential part of the field methodology was working with the women potters to try new

techniques and designs and to think outside of the box.

4.1

Observation

The first day at each site was spent jointly with teammate Michael Pihulic observing

potters at work and visually documenting the current production and manufacturing processes.

Since little was known about the exact processes, it was important to fully understand how the

pots are made, step by step, and to begin to identify potential areas for improvement. This time

was also spent becoming familiar with the potters' skill levels and willingness to try out new

ideas. Observation and visual documentation continued during the remainder of the days spent at

each site. (See Pihulic, 2005a for this complete process documentation.)

4.2

Interviews

The author carried a field notebook and pen at all times in order to record answers to any

questions that came to mind as she observed the potters working. Because the potters only speak

the local dialect of Luo, it was necessary to interview and ask them questions via a hired

translator. (See sections in the next chapter, 5.3 and 5.4, for more detailed information regarding

the translators.) Information on the subject of cost recovery was obtained by interviewing not

only the potters, but CARE/Kenya staff and members of the Amilo Community Based

Organization (CBO) as well. Answers to questions were carefully recorded in field notebooks

29

and reviewed daily to ensure complete understanding of the responses. Any vagueness was

clarified the next day with follow-up questions.

Here is a sampling of some of the questions asked and answers gathered during

interviews of the potters (via a translator) and other members at the Amilo CBO:

Q: How long have the potters been making pottery,

and specifically, modified clay pots?

A: The potters have each been making pottery for about ten years; they have made

modified clay pots since 2003.

Q: How did the potters

learn how to make pottery, and specifically, modified clay pots?

A: Each potter learned how to make pottery from her mother or mother-in-law. Two

Amilo potters were sent to Oriang to learn how to make the modified clay pots and

subsequently passed on this knowledge to other Amilo potters.

Q: What is the production rate of modified clay pots?

A: The average potter can make up to three pots per day; however, production rates are

limited by potters having to share equipment and tools.

Q: What techniques have the potters tried to standardize

the modified clay pot?

A: Potters rely on the length of their arms and the width of their hands as well as

experience to shape modified clay pots into 20 L and 40 L sizes.

Q: For what price

are the modified clay pots sold at the market?

A: 20 L modified clay pots are sold for 380 KSH; 40 L modified clay pots are sold for

500 KSH.

Q: Do the potters test the

pots for leakage before selling them?

A: No, no attempt is made to test the pots before selling them.

30

4.3

Trial-and-error problem solving

After observing and interviewing potters at the field sites, and identifying potential areas

of improvement to the modified clay pot production process, the author engaged daily in

brainstorming sessions with teammate Michael Pihulic to formulate new ideas and decide which

of these ideas to test in the field with the potters. Brainstorming sessions were conducted by

discussing ideas aloud, posing possible solutions to problems identified, and evaluating each idea

in terms of available time, access to materials, feasibility, and potters' willingness to participate

in trying any new ideas developed. Reference books on ceramics properties and fabrication

processes were also consulted to flesh out ideas in Kenya. If necessary, calculations were worked

out and tools were constructed in preparation for the next day in the field. This approach of trialand-error problem solving proved very effective and was used to address both the issue of

standardizing the pots and designing a new tap.

4.4

Focus groups

In order to garner the local women potters' thoughts about the origins of the shape of the

modified clay pot, and to have them develop ideas for pot shapes that would better ease the

insertion of a tap, i.e. a pot that has at least one flat area large enough to accommodate a tap will

create a fit between tap and pot that is less prone to leaking, focus groups were conducted at both

Amilo and Oriang.

4.4.1

Definition and motivation

Focus groups consist of about 6 to 10 people that are part of a relevant target market or

political entity gathered in the same room and guided through a moderator-led discussion that

31

investigates attitudes about a specific client's services, products, or political persuasions. While

often used in market research or political analysis, focus groups can also simply be a small group

representative of a wider population and guided though open discussion for its members'

opinions about or emotional response to a specific area or subject.

Focus groups typically have six features, according to Focus Groups: A Practical Guide

for Applied Research by Richard A. Krueger (1994): "(1) people, (2) assembled in a series of

groups, (3) possess certain characteristics, and (4) provide data (5) of a qualitative nature (6) in a

focused discussion." Krueger (1994) further elaborates on each of these six features:

(1)

Focus groups are typically composed of 6 to 10 people, but the size can

range from as few as 4 to as many as 12. The size is conditioned by two

factors: It must be small enough for everyone to have opportunity to share

insights and yet large enough to provide diversity of perceptions.

(2)

The focus group interview is conducted in a series. Multiple groups with

similar participants are needed to detect patterns and trends across groups.

(3)

Focus groups are composed of people who are similar to each other [and]

who do not know each other.. .More recently, however, researchers are

questioning the necessity and practicality of this [latter] guideline,

especially in community-based studies.

(4)

Focus groups produce data of interest to researchers. In this respect the

purpose differs from other group interactions in which the goal is to reach

consensus, provide recommendations, or make decisions among

alternatives.

(5)

Focus groups produce qualitative data that provide insights into the

attitudes, perceptions, and opinions of participants. These results are

solicited through open-ended questions and a procedure in which

respondents are able to choose the manner in which they respond and also

from observations of those respondents in a group discussion. The

researcher serves several functions in the focus group: listening, observing,

and eventually analyzing, using an inductive process.

(6)

The topics of discussion in a focus group are carefully predetermined and

sequenced.

32

Focus groups were included in the methodology because it was ideal to ask questions and

encourage discussion in a group setting. Focus groups provided a dynamic atmosphere for

participants to share ideas. Because the potters have the first-hand experience in producing and

manufacturing the modified clay pots, it is their attitudes, beliefs and perceptions that are of

interest. Discussions in a group setting were also more time efficient than one-on-one interviews.

4.4.2

Format of discussions

The author's objectives of the focus group discussions at each site included the following:

-

Discover the potters' thoughts on the origins of the rounded shape typical of the

wide-mouthed and modified clay pots;

-

Obtain the potters' opinions about a cylindrical shaped pot (an example of which

was made the previous day according to the author's specifications at the Amilo

CBO);

-

Have the potters each come up with her own drawings of pot shapes after being

told that the goal is to ease insertion of the tap (i.e. because the tap is currently

inserted on the rounded surfaces of the pots, the "fit" is not very good-a flat

surface is ideal); and,

-

Determine preferences of several different sketches of pot shapes drawn by the

author, also keeping with the condition that the aim is to ease insertion of the tap.

33

The only deviation from the objectives sought during the Amilo focus group versus those sought

during the Oriang focus group is that the researchers did not ask the Oriang potters to make a

cylindrical shaped pot at all, so the question of whether they preferred the rounded shaped pot or

the cylindrical pot (i.e. their opinions about a cylindrical shaped pot) was not asked.

The results of observation, interviews and trial-and-error problem solving are found

throughout Chapters 6, 7, and 8, while the results of the focus group discussions are found in

Chapter 5.

34

Chapter 5

Focus Group Results

Before the results of the focus groups conducted at Amilo and Oriang are discussed, it is

important to understand the variations in the shapes of clay pots in traditional Kenyan pottery

and how the skills and knowledge of pottery making are passed down.

5.1

Background on shapes of clay pots

In western Kenya, pottery has almost exclusively been in the woman's domain

(Mutagaywa, 1995). However, only a small proportion of the women in any potting community

are involved in the trade, and those women who do make pottery usually undertake this craft

part-time in combination or alternating with other household tasks (Wandibba 2003).

Women produce various types of clay pots and pans mainly for household use in food

processing, preparation, and storage and for water carriage and storage. Mutagaywa (1995)

classifies traditional Kenyan pottery into three forms (with Luo terminology in parentheses):

1) Simple open form: Smaller sizes for processing and serving meat and vegetables, or

larger sizes for brewing and serving beer or fermenting and serving porridge of

millet/maize (nyalora);

2) Simple restricted form: For cooking and preparing fish (haiga),or for cooking and

storing grains and starchy foods (kabange or dakuon);

3) Forms with a neck: For brewing and storing beer (mbiru), for carrying and storing

water (dapi), or for odd jobs (agulu).

35

Figure 5-1 shows examples of some of these different traditional forms of pottery. Those

in the foreground (haiga)are for cooking fish, while those with a neck (dapi) are for carrying

and storing water. Examination of different pottery forms produced suggests that variation in size

within form classes relates to differential function, such that potters distinguish these differences

with terminological distinctions (Wandibba 2003). However, sometimes distinct forms have the

same terminology. One specific example of this is described by Wandibba (2003):

The Okiek [tribe of west central Kenya] traditionally made three different forms

of the honey pot, depending on whether the honey pot was to be stored in the

forest or at home. Although the three forms were ingrained in the potter's mental

template, she had no separate names for them and simply referred to all three as

"honey pots." Although all three forms had necks, the pots varied in size and body

form. The vessel for storing the honey in the forest was elongated in form and had

a narrow mouth to accommodate a stopper to facilitate sealing before the pot was

buried in the ground for safekeeping. The shape designed for storage in a cave

was much bigger and had a rounded body to enable it to stand unsupported on a

shelf or the floor. Finally, the house honey pot (the only one of the honey pots still

being made today) has a rounded body and a short cylindrical neck, with a tightfitting leather cover and leather carrying handle. It would thus appear that unique

functions produce subtle differences in vessel forms.

This example explains that one function of the rounded body is to enable a pot to stand

unsupported on a shelf or floor, and that rounded bodies can be much bigger than

elongated forms. This suggests why pots used for water transport and storage

traditionally have rounded bodies, i.e. rounded pots are bigger and can hold more water.

36

Figure 5-1. Examples of different traditional forms of Kenyan pottery with different uses; those in

the foreground (haiga)are for cooking fish, while those with a neck (dapi)are for carrying and

storing water.

(Source: Mutagaywa, 1995)

The wide-mouth clay pot (Figure 5-2a), the traditional shape of pots used to store

water in the Nyanza Province, has a rounded body, a wide mouth, and a rounded base.

The method for drawing water from such shaped pots typically involves dipping in cups

or calabashes with one's hands. The modified clay pot (Figure 5-2b), a variation of the

traditional shape, has a more prominent base so that sediment can settle below the tap, a

rounded body, a narrow neck opening to a narrow mouth, and a lid, also made of clay.

This shape, which is a designated safe water storage container, was developed by CAREKenya's SWS team in 2000. Water is dispensed by turning the tap handle. An alternate

pot shape, the cylindrical pot (Figure 5-2c), was suggested by the author and built by one

of the potters at the Amilo Community Based Organization (CBO). The idea behind this

shape is that a flat, not round, surface would ease insertion of the tap and reduce leakiness

around the tap caused by an imperfect fit between the clay pot and tap.

37

a

b

c

Figure 5-2. Various shapes of clay pots: wide-mouth clay pot (a), modified clay pot (b), and

cylindrical pot (c).

(Source: CARE Kenya, 2003; Murcott, 2004; Pihulic, 2005b)

Skills and knowledge of pottery making are passed through generations (mother to

daughter, mother-in-law to daughter-in-law, aunt to niece, and so on) as well as between the

different regions and tribes via intermarriage, through informal channels of communication such

as observation, imitation and working together (Wandibba, 2003; Mutagaywa,1995).

5.2

Preparation for focus groups

In preparation for the focus group discussions, during a brainstorming session, the author

drew several additional pot shapes (Figure 5-3), keeping in mind that having at least one flat

surface on the pot would aid in tap attachment and reduce leakiness. One of the drawings is a

modified clay pot with an even more prominent cylindrical base (Figure 5-3a), such that the tap

could be attached to this cylindrical portion while still leaving room below the tap for sediment

to settle out. The other drawings included a cylindrical shape with a wider base (Figure 5-3b),

making the height shorter than the cylindrical pot shown in Figure 5-2c; a cylindrical pot with a

38

base that flares out like a salt-shaker (Figure 5-3c); an asymmetrical pot with one rounded side

and one flat side (Figure 5-3d); and a hexagonal pot (Figure 5-3e). Once the author was prepared

for the focus groups with the necessary background research and materials, focus groups were

conducted at Amilo and Oriang.

a

b

c

d

e

Figure 5-3. The author's drawings of pot shapes: rounded pot with extended cylindrical base (a),

cylindrical pot (b), cylindrical pot with flared base (c), asymmetrical pot with one rounded side and

one flat side (d), and hexagonal pot (e).

5.3

Amilo focus group

The first of two focus group meetings was conducted on the third day of field research,

January 8, 2005, at the Amilo CBO. Members of the group included four local women potters

(Amilo Potter #1-4), a translator, a listener from the Centers for Disease Control (CDC), and the

author, who served as the moderator for the discussion. All of the women are of Luo ethnicity

and are mothers. Most of the women learned how to make clay pots from their mothers or their

husband's mothers after they were married, and have roughly ten years experience each (the

range of experience is unknown, as each woman stated they had ten years experience making

pots). However, only two of the women potters traveled to Oriang to receive training in making

39

the modified clay pots. They subsequently taught the other potters at the Amilo CBO the new

design and techniques they learned. It is noteworthy that the translator is an elderly man who is

the General Chairman of the Amilo Community Learning Resources Centre (CLRC), one

component of the Amilo CBO. This position is the most senior position of the Amilo CBO's

Executive Committee. It was originally suggested by the CARE/Kenya representatives upon the

initial meeting between the Amilo group and the researchers that perhaps a young local woman

would be most appropriate to serve as translator. The listener from the CDC, Ms. Daniele

Lantagne, served as an advisor and friend to the research project.

The potters could not say much about the origins of the rounded shape typical of both the

wide-mouth and modified clay pots. (Studies have suggested that shapes are dictated by function,

and that rounded pots used for water transport and storage are shaped so they can hold more

water. See Section 5.1.) The shape is just the way that they were taught to make clay pots by

their mothers or other relatives when they first started. As for whether they preferred the rounded

shape or a cylindrical shape, the women collectively agreed (as summarized by the translator)

that they prefer the cylindrical shape because it is more easily carried, it uses less clay, and

attaching the tap is easier. While the potters themselves support the cylindrical shape, since the

idea is new and people are free to make their own choices, they do not know if the local

population will as readily welcome the differently shaped pot. Therefore, they said they will

make both the modified clay pot and the cylindrical pot and see which one sells better in the

market.

Examples of the potters' individual drawings of clay pots are shown in Figure 5-4. All of

the women's drawings included at least one clearly cylindrical shaped pot (Figures 5-4a, g, h, 1,

40

n), and one or more rounded shaped pots. The women at first were hesitant to start drawing and

needed encouragement from the author and translator. However, it was later evident by their

facial expressions and comments after completing the exercise that they found it enjoyable.

Amilo

Potter #1

a

b

c

d

Amilo

Potter #2

e

f

g

Amilo

Potter #3

h

Amilo

Potter #4

k

I

M

n

Figure 5-4. Examples of Amilo Potters' individual drawings of clay pots.

41

When next asked which of the author's drawings (Figure 5-3) they liked the best, keeping

in mind that they should choose the drawing that would best ease insertion of the tap, two of the

potters, Amilo Potter #1 and Amilo Potter #4, chose the rounded pot with the extended

cylindrical base (Figure 5-3a) because it is easy to attach a tap and particles in the water can

settle out and be retained in the base, below the tap. Amilo Potter #2 originally picked the

cylindrical pot with the flared base (Figure 5-3c) but seemed to be convinced by the group and

translator otherwise. She eventually also chose the rounded pot with the extended base (Figure 53a). Amilo Potter #3 chose the cylindrical pot (Figure 5-3b) because she said making that shape

is easier and that it uses less clay.

After voting on which of the researcher's drawings they preferred most, Amilo Potter #1

proceeded to make the rounded pot with the extended cylindrical base and Amilo Potter #3 a

cylindrical pot with a wider base than was made the previous day. Amilo Potter #1 did not make

the extended base envisioned by the researcher; instead, she just made it less slanted and more

gradual than the base of the modified clay pot (similar to the shape of a clay flower pot). Both a

lack of sufficient communication and translation and the potter's misunderstanding contributed

to this outcome.

There were several limitations of the January 8, 2005 Amilo focus group. One important

thing to note is that a cylindrical shaped pot was made the day before the focus group took place,

as per request by the author. The timing may have been poor because it may have influenced the

potters' preference for the cylindrical shaped pot over the rounded shaped pot. The potters may

also have chosen it because they thought it was the author's own preference. In addition, one of

the reasons they preferred the cylindrical pot is because it uses less clay; however, the amount of

clay was never formally quantified, so whether or not this assumption is true is unknown. Also,

42

whether the women carry through with actually making both the modified clay pot and the

cylindrical pot and selling them at the market remains to be seen. Furthermore, it is believed that

the male translator added bias to the all women's group's responses because he seemed to

dominate their discussion and not merely translate but add his own ideas and convince the

women of certain responses. To what extent this bias contributed is unknown.

5.4

Oriang focus group

A second focus group was conducted at the Oriang Women's Pottery Group on the fourth

day of field research at that site, January 12, 2005. Members of the group included seven local

women potters (Oriang Potter #1-7), a translator, the author (who served as the moderator for the

discussion) and teammate Michael Pihulic. All of the women potters in this group are of Luo

ethnicity and are mothers, each with more than ten years of experience doing pottery work. The

translator was a 25-year old woman who works at a local elementary school teaching

kindergarten-aged children. She was asked to serve as the translator because of her fluency in

both Luo and English, and because she lives nearby and is acquainted with one of the woman

potters.

When asked why pots that store water are molded into the traditional rounded shapes, the

potters said the rounded pots are so shaped in order to better fetch water, i.e. pots with rounded

bodies can hold more water. Historically, rounded ceramic pots were used to both fetch and store

water. They also said that different pot shapes serve different purposes, which is consistent with

background research. Each potter drew shapes of pots, taking into account that a flat spot is

needed to better accommodate tap attachment. Examples of the potters' individual drawings are

shown in Figure 5-5.

43

Oriang

Potter #1

15

a

b

C

d

e

Oriang

Potter #2

-A,

Oriang

Potter #3

't

L'

,

~

h

i

g

Oriang

Potter #4

V

~-

L

I

-

Oriang

Potter #5

m

Oriang

Potter #6

Oriang

Potter #7

p

n&

O

q

a

r

U

Figure 5-5. Examples of Oriang Potters' individual drawings of clay pots.

44

All of the drawings were of rounded pots, except for two single sketches of pots with

flatter surfaces, one drawn by Oriang Potter #1 (Figure 5-5b) and the other by Oriang Pottery #6

(Figure 5-5p). The lack of cylindrical shaped pots is perhaps expected. Recall that at Amilo, the

idea of a cylindrical pot was introduced by the author prior to the focus group discussion;

however, this was not the case at Oriang. It is noteworthy that Oriang Potter #7 labeled her pot

drawings (Figures 5-5r, s, t, u) with their Luo names. Figure 5-5r is a drawing of an ohigla,

which by its shape may be another name for a haiga, a pot used for cooking and preparing fish.

Figure 5-5s is a drawing of a dapi, historically used for water carriage and storage, while Figure

5-5u is a drawing of a dapi tap, which is the name given for a water storage container with a tap,

i.e. the modified clay pot. Figure 5-5t is a drawing of a kabange, used for cooking and storing

grains and starchy foods.

Finally, potters were shown the researcher's drawings of various pot shapes (Figure 5-3)

and asked to choose which they liked best by raising their hands. Six potters chose the rounded

pot with the extended cylindrical base (Figure 5-3a), while two voted for the asymmetrical pot

with one rounded side and one flat side (Figure 5-3d). (Note that an eighth potter joined the

group late and participated in this activity). The potters who chose the rounded pot with the

extended cylindrical base (Figure 5-3a) said they liked it because they have tried that idea before,

and that they liked the rounded, symmetrical shape because it is aesthetically pleasing. The two

potters that chose the asymmetrical pot (Figure 5-3d) said they liked it because they think they

are capable of making it. Furthermore, the potters all said that the shape of the pot does not

matter so much as the cooling effect the clay has on the water and the taste of the water from the

pot.

45

One limitation of this focus group discussion is that the moderator did not have the

complete attention of the members because they were engaged in other activities (e.g. molding

pots, mixing clay) while answering questions. However, unlike at Amilo, the translator at Oriang

was a woman and a teacher (and not an "official"). It is believed that the translation at this site

was more accurate and more effective than at Amilo, and that the translator added little if any