Real-time Mass Property Estimation Andrew M. Wright

advertisement

Real-time Mass Property Estimation

by

Andrew M. Wright

Submitted to the Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

Master of Science in Mechanical Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

May 2000

@Andrew Wright, 2000. The author hereby grants to M.I.T. and to

Lawrence Livermore National Laboratory permission to reproduce

and to distribute copies of this thesis document in whole or in part.

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

SEP 2 0 2000

Author .....

......................

..........

.L1BRARIF.,..

Department of Mechanical Engineering

May 18, 2000

Certified by...

Kamal Youcef-Toumi

Professor of Mechanical Engineering

Thesis Supervisor

Certified by...

I

U

Dr. Lawrence C. Ng

LLNL supervisor

Thesis Supervisor

-----..-----.

Ain A. Sonin

Chairman, Department Committee on Graduate Students

Accepted by ......

Real-time Mass Property Estimation

by

Andrew M. Wright

Submitted to the Department of Mechanical Engineering

on May 18, 2000, in partial fulfillment of the

requirements for the degree of

Master of Science in Mechanical Engineering

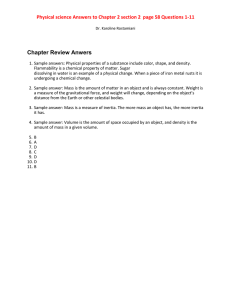

Abstract

In this thesis, we designed and implemented a mass property estimation algorithm to

be executed autonomously by space-borne satellites. Implemented solely in code, the

estimation algorithm uses recursive least squares with a forgetting factor to converge

running mass property estimates to the true values for the satellite alone, or in the

case of a docking mission, the rigidly connected body. A six degree-of-freedom dynamic simulation of the satellite was written to test the algorithm, which was then

corroborated experimentally on a five degree-of-freedom microsatellite test bed. A

method for estimating the mass properties of the docked object alone was demonstrated.

Thesis Supervisor: Kamal Youcef-Toumi

Title: Professor of Mechanical Engineering

Thesis Supervisor: Dr. Lawrence C. Ng

Title: LLNL supervisor

3

4

Acknowledgments

First, I would like to extend my thanks and gratitude to Professor Kamal YoucefToumi for overseeing and guiding my research. His suggestions helped me academically and personally through this thesis. Also, I am indebted to Dr. Larry Ng for his

mentorship and guidance during my internship at the Lawrence Livermore National

Laboratories, without whom this unique research opportunity would not be possible.

I would also like to thank everyone on the Microsat team at LLNL for their

technical, moral, and financial support. Arno Ledebuhr, Microsat program leader,

Joe Kordas, deputy program leader, and Gloria Purpura, administrative specialist

have been instrumental in assuring all the details for allowing me to intern in the

Microsat program were taken care of. I am especially grateful to Eric Breitfeller, for

sharing his expertise and friendship with me. I could not imagine how lost I would be

without his assistance. Special thanks go to those who spent countless hours helping

me with the experimental test runs: Bruce Wilson, the Microsat software guru, Jeff

Robinson, and Don Antelman, the hardware and manufacturing crew, you have my

deepest respect. Their willingness to devote their personal time after-hours allowed a

most critical step in this research to be accomplished. I am grateful and proud to have

worked with all of the extraordinary people on the LLNL Microsat team. Also, special

thanks go to Bob Langland and Ronna Oelrich who oversaw each of my internships

at LLNL and guided me safely through the many inevitable administrative hurdles.

Finally, I would like to thank Fermin Garcia for his assistance in the early phase of

my work with the Microsat group and in the writing of this thesis. Considering his

technical skill and enthusiasm, it is inconceivable that his future could be other than

bright.

I can not thank my parents and sister, Robert, Sanae, and Sharon Wright, enough

for their ceaseless and caring support. Though miles away, they were always ready

to lend an attentive ear, a warm laugh, and a helping hand.

At a time when academics threatened to overwhelm me, she was there to assure

me that life is indeed richer than my rigorous, and engrossing curriculum at MIT.

5

She fed me, helped me with my studies, and nursed me when sick while at the same

time tackling her own studies and inspiring me with her fresh outlook. Emily, I'm all

yours.

6

Contents

1

2

1.1

B ackground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

1.2

O verview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Dynamic Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Overview of Inertia . . . . . . . . . . . . . . . . . . . . . . . .

24

Essential Microsat Hardware . . . . . . . . . . . . . . . . . . . . . . .

27

Overview of Pulse Width Modulation . . . . . . . . . . . . . .

28

Space-based Operational Procedure . . . . . . . . . . . . . . . . . . .

30

2.1.1

2.2

2.2.1

2.3

31

Mass Property Estimation Method

3.1

Recursive Least Squares

. . . . . . . . . . . . . . . . . . . . . . . . .

31

3.2

Estimate Convergence and Observability . . . . . . . . . . . . . . . .

33

. . . . . . . . . . . . . . . . . . . . .

33

3.2.1

4

23

Description of the Microsat

2.1

3

19

Introduction

Observability Condition

37

Single Body Scenario

4.1

Algorithm Structure

. . . . . .

. . . . . . . . . . . . . . . . . . . .

37

4.2

Single Body Simulations . . . .

. . . . . . . . . . . . . . . . . . . .

41

4.3

4.2.1

Simulation Description

.... .... ..... ... ....

41

4.2.2

Preliminary Simulation

... ..... .... .... ....

41

4.2.3

Refined Simulation . . .

.. ..... ..... .... ... .

52

. . . . . . . . . . . . . . . . . . . . 60

Experimental Setup . . . . . . .

7

4.4

Experimental Results . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

4.5

Comparison of Simulation and Experiment . . . . . . . . . . . . . . .

72

5 Multiple Body Scenario

73

5.1

Algorithm Structure

. . . . . . . . . . . . . . . . . . . . . . . .

73

5.2

Multiple Body Simulation . . . . . . . . . . . . . . . . . . . . .

74

5.2.1

Simulation Description . . . . . . . . . . . . . . . . . . .

74

5.2.2

Multiple Body Simulation Results . . . . . . . . . . . . .

77

Experimental Proposal . . . . . . . . . . . . . . . . . . . . . . .

89

5.3

6 Conclusions and Recommendations for Future Work

91

6.1

C onclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91

6.2

Recommendations for Future Work . . . . . . . . . . . . . . . .

92

A Real-time Estimation Code Integration and Raw Trial Data

95

B Initial Covariance Matrix Determination

99

B.1

Covariance Matrices Used in Simulations

. . . . . . . . . . . . . .

99

B.2 Effects from Variation in Initial P . . . . . . . . . . . . . . . . . . . .

103

B.3 Effects from Variation in Initial

Q

. . . . . . . . . . . . . . . . . . . .

106

B.4 Effects from Variation in Initial R . . . . . . . . . . . . . . . . . . . . 109

C Simulation Code

C.1 Matlab Docking Simulation

113

. . . . . . . . . . . . . . . . . . . . . . .

113

C.1.1

Initialization and Support Functions

. . . . . . . . . . . . . .

113

C.1.2

Docking Code . . . . . . . . . . . . . . . . . . . . . . . . . . .

119

C.1.3

Matlab Plotting Functions . . . . . . . . . . . . . . . . . . . .

128

8

List of Figures

2-1

Diagram illustrating the orientation of the body-fixed axes with respect

to the m icrosat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2

Diagram and equation of combined inertia as a function of the inertia

of the respective objects [7]. . . . . . . . . . . . . . . . . . . . . . . .

2-3

24

26

CAD model of prototype LLNL microsat showing essential hardware

components: Inertial Measurement Unit, Central Processing Unit, and

Propulsion system . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4

27

Approximation of desired force constrained to actual jet thrust value,

. . . . . .

29

4-1

Timeline of the mission showing all control actions. . . . . . . . . . .

42

4-2

Simulation 1: Control torques on each axis resulting from execution

Fjet,

with variable pulse duration, p, over each duty cycle.

of the mission plan. Though all the torque commands are perfectly

balanced with opposite commands during the open loop excitations,

large control torques are evident when attempting to return to initial

orientation, suggesting large deviations in orientation due to inter-axis

torque disturbances. The oscillations at 2, 6, and 10 seconds show the

open loop control roll, pitch, and yaw, respectively to induce parameter

convergence........................................

9

46

4-3

Simulation 1: Three axis moment of inertia (MOI) estimate plot showing the convergence from initial moment estimates of zero to the true

moment represented by the horizontal line. The "precision" boundary

for each plot is the 'true' value ± Pkk with k = 1 for X-axis MOI,

k = 4 for Y-axis MOI, k = 6 for Z-axis MOI. The "precision" remains nearly constant from 12 to 20 seconds because there is no direct

excitation of these modes during that period . . . . . . . . . . . . . .

4-4

47

Simulation 1: Three inter-axis product of inertia (POI) estimate plot

showing the convergence from zero initial values to the true product

represented by the horizontal line. The "precision" boundary for each

plot is the 'true' value ±Pkk with k = 2 for X-Y POI, k = 3 for

X-Z P01, k = 5 for Y-Z POI. Though tapering significantly at the

beginning of the simulation, the "precision" envelopes remain wide at

the end of the simulation from lack of direct excitation, which indicates

the current residual error is more significant than previous residual

error when calculating the current estimate.

4-5

. . . . . . . . . . . . . .

48

Diagram showing uncertainty in CG location based on diverts only in

Y direction. There is no difference in dynamics as the CG location

varies along the Y-axis. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6

49

Simulation 1: Center of gravity (CG) location estimate with respect

to the initial CG location corresponding to the focus of the divert

thrusters on the microsat. The true CG deviation from the focus in

Simulation 1 is 0.1 m in X, Y, and Z directions. The CG location in the

Y direction is unobservable, and thus, there is no change from initial

values. (see Figure 4-5). The "precision" boundary for each plot is the

'true' value ±Pkk with k = 7 for CG along X-axis, k

=

8 for CG

along Y-axis, k = 9 for CG along Z-axis. . . . . . . . . . . . . . . . .

10

50

4-7

Simulation 1: Commanded force plot showing the initial divert away

from the bay, and the divert oscillations at 16 seconds. Simulation

1 contained diverts in the Y (lateral) direction only. Plot (b) shows

the estimated total mass for the microsat in Simulation 1 revealing

correlation between mass convergence and command force excitations.

Since the mass estimate is filtered separately from the other estimates,

the "precision" boundary is only the 'true' value ±/f2. . . . . . . . .

4-8

51

Simulation 2: Open loop control torques about three axes. Periods

of open loop excitation of roll, pitch, and yaw axes start at 2, 6, 10

seconds, respectively. The remaining time was devoted to returning the

microsat to the initial orientation, then holding attitude using closed

loop control. The isolated spikes in each plot are the small torques to

return the microsat to initial orientation which are executed when each

closed loop control period begins. . . . . . . . . . . . . . . . . . . . .

4-9

55

Simulation 2: Time plots of the moment of inertia parameter estimation about the three body-fixed axes. The inertia estimates are initialized at zero, then converge on the true value shown as the horizontal

line. The "precision" boundary for each plot is the 'true' value ±

Pkk

with k = 1 for X-axis MOI, k = 4 for Y-axis MOI, k = 6 for Z-axis MOI. 56

4-10 Simulation 2: Time plots of the product of inertia parameters. The

product of inertia estimates are initialized at zero, then converge on

the true value shown as the horizontal line. The "precision" boundary

for each plot is the 'true' value ±Pkk with k = 2 for X-Y POI, k = 3

for X-Z POI, k = 5 for Y-Z POI.

. . . . . . . . . . . . . . . . . . . .

11

57

4-11 Simulation 2: Time plot of center of gravity location estimation in

the X, Y, Z body-fixed inicrosat axes. The "precision" boundary for

each plot is the 'true' value ±

Pkk with k = 7 for CG along X-axis,

k = 8 for CG along Y-axis, k = 9 for CO along Z-axis. The Y-axis CG

location is unobservable as shown in Figure (4-5), thus the "precision"

bounds do not converge. The "precision" bounds on the X and Z axis

CG location estimates taper initially due to the initial divert away from

the docking bay, then after a period of inactivity in divert excitations,

the bounds taper again at 16 seconds due to the open loop excitations.

58

4-12 Simulation 2: Time plot of open loop Y-axis divert thrusts and time

plot of total mass estimation. The convergence in the first two seconds

and at 16 seconds corresponds to the open loop Y-axis divert thrusts.

The lack of divert thrusts between 2 and 16 seconds lowers the signal

to noise ratio, thereby causing the significant divergence in the mass

estimate. Since the mass estimate is filtered separately from the other

estimates, the "precision" boundary is only the 'true' value ± P2 . . .

59

4-13 Microsat experimental test bed at Lawrence Livermore National Laboratories. The microsat shown above is moving freely in five degrees of

freedom. The spherical air bearing at the top of the support structure

allows all three rotational degrees of freedom and the support structure

itself slides freely in two degrees of freedom on the plane of the glass

tab le. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

4-14 Combined Linear and Spherical Air Bearing. . . . . . . . . . . . . . .

61

4-15 Spherical Air Bearing location at CG of vehicle. . . . . . . . . . . . .

61

4-16 Timing Schematic for Microsat Prototype.

63

4-17 Experimental Trial:

. . . . . . . . . . . . . . .

Control torques requested by the microsat con-

troller. As in the simulations, the isolated spikes are caused by small

attitude corrections when each closed loop attitude control period begins. 66

12

4-18 Experimental Trial: Moment of inertia estimates: the "precision" boundary for each plot is the current estimate ± Pkkwith k = 1 for X-axis

MOI, k = 4 for Y-axis MOI, k = 6 for Z-axis MOI.

4-19 Experimental Trial: Product of inertia estimates:

. . . . . . . . . .

67

The "precision"

boundary for each plot is the current estimate ± Pkk with k = 2

for X-Y POI, k = 3 for X-Z POI, k = 5 for Y-Z POI. . . . . . . . . .

68

4-20 Experimental Trial: Center of gravity deviation estimates: The "precision" boundary for each plot is the current estimate t

Pkkwith k = 7

for CG along X-axis, k = 8 for CG along Y-axis, k = 9 for CG along

Z -ax is. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

4-21 Experimental Trial: Command force plot showing the initial divert

away from the docking station and the divert excitations at 16 seconds. The second plot shows the corresponding mass estimate. The

mass estimate is filtered separately from the other estimates, thus, the

"precision" boundary is only the 'true' value ±fI.

. . . . . . . . . .

70

4-22 Experimental Trial: Observed Accelerations by the IMU on-board the

Microsat. The acceleration due to gravity is filtered from the Z acceleration plot, as are the centripetal, and Euler accelerations because

the IMU is located at a fixed distance from the axes of rotation. . . .

5-1

71

Diagram illustrating the three main control phases during the docking

mission. First, the Microsat executes a series of open loop rotations

and diverts (a), then docks with the space-borne object (b) and again,

executes a series of open loop rotations and diverts (c) to identify the

combined body mass parameters.

5-2

. . . . . . . . . . . . . . . . . . . .

75

Timeline of the multiple body docking mission detailing all control

actions.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

76

5-3

Docking Simulation: Control torques on each axis resulting from execution of the docking mission plan. The closed loop control torques

to return the microsat to initial attitude occur at 8 seconds.

At 9

seconds, the mass properties of the microsat immediately change to

the combined body mass properties (docking), inducing large control

torque com m ands.

5-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

78

Docking Simulation (0-9 Seconds): Three axis moment of inertia estimate plot showing the convergence from initial moment estimates of

zero to the true moment represented by the horizontal line. The "precision" boundary for each plot is the 'true' value ± Pkkwith k =1

for X-axis MOI, k = 4 for Y-axis MOI, k

5-5

=

6 for Z-axis MOI ... . . .

80

Docking Simulation (0-9 Seconds): Three inter-axis product of inertia estimate plot showing the convergence from zero initial values to

the true product represented by the horizontal line. The "precision"

boundary for each plot is the 'true' value ± Pkkwith k = 2 for X-Y

POI, k = 3 for X-Z POI, k = 5 for Y-Z POI. . . . . . . . . . . . . . .

5-6

81

Docking Simulation (0-9 Seconds): Center of gravity (CG) location

estimate with respect to the initial CG location corresponding to the

focus of the divert thrusters on the microsat. The "precision" boundary

for each plot is the 'true' value ± Pkkwith k = 7 for CG along X-axis,

k = 8 for CG along Y-axis, k = 9 for CO along Z-axis.

5-7

. . . . . . . .

82

Docking Simulation (0-9 Seconds): Commanded force plot showing no

activity until the divert oscillations at 6 seconds. The docking simulation contains diverts only in the Y (lateral) direction. The mass plot

shows the estimated total mass for the microsat alone before docking. Interestingly, the precision envelope begins to converge before

any divert activity due to noisy inputs from the accelerometer. Since

the mass estimate is filtered separately from the other estimates, the

"precision" boundary is only the 'true' value ±/I2. . . . . . . . . . .

14

83

5-8

Docking Simulation (9-36 Seconds): Three axis moment of inertia estimate plot showing the convergence from initial moment estimates of

zero to the true moment represented by the horizontal line. The Y

and Z axis MOI estimates are not within the precision bounds for two

reasons: the covariance matrix was not reinitialized at a high enough

value to account for the large estimate error, and until directly excited,

the low signal to noise ratio prevented the estimates from converging.

However, once excited, both the Y and Z axis MOI estimates converged

near the true values.

5-9

. . . . . . . . . . . . . . . . . . . . . . . . . . .

85

Docking Simulation (9-36 Seconds): Three inter-axis product of inertia

estimate plot showing the convergence from zero initial values to the

true product represented by the horizontal line.

. . . . . . . . . . . .

86

5-10 Docking Simulation (9-36 Seconds): Center of gravity location estimate

with respect to the initial CO location corresponding to the focus of

the divert thrusters on the microsat.

At 9 seconds, the overall CO

shifted along the X-axis toward the docked body. At 12 seconds, the

estimation precision was reinitialized and does not reconverge for the X

and Z CO location until the open loop Y-axis diverts for the combined

body at 24 seconds; the Y CO location precision never converges (See

F igure 4-5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

87

5-11 Docking Simulation (9-36 Seconds): Commanded force plot showing

the Y-axis divert oscillations at 24 seconds. Plot (b) shows the estimated total mass for the combined body. The mass estimate actually

diverges initially since there are no excitations other than accelerometer

noise (which actually converge the precision envelope). At 24 seconds,

the divert oscillations induce good convergence of the mass estimate.

15

88

5-12 Proposed experimental setup: the CG location is external to both

bodies, thus allowing the ball which is fixed to the rigid connecting

bracket to be located between the two bodies. This experimental setup

allows full rotational freedom and translational freedom in the plane

of the glass table (5 degrees of freedom). . . . . . . . . . . . . . . . .

90

A-i Real-time moment of inertia estimate plots for previously untested microsat. ........

...................................

96

A-2 Real-time attitude plot for previously untested microsat. The three

plots, qPitch, qRoll, and qYaw are the first three terms of the microsat

quaternion which represents the axis of rotation at that time . . . . .

97

B-i Simulation 1: Three axis moment of inertia estimate plot showing good

convergence from initial moment estimates of zero to the true moment

represented by the horizontal line. The "precision" boundary for each

plot is the 'true' value ±Pkk with k = 1 for X-axis MOI, k = 4 for

Y-axis MOI, k = 6 for Z-axis MOI. The "precision" remains nearly

constant from 12 to 20 seconds because there is no direct excitation of

these modes during that period. . . . . . . . . . . . . . . . . . . . . .

102

B-2 Simulation 1: Three axis moment of inertia estimate plot with lower

initial P values (diagonal of 0.01's). . . . . . . . . . . . . . . . . . . .

104

B-3 Simulation 1: Three axis moment of inertia estimate plot with higher

initial P values (diagonal of 1000's). . . . . . . . . . . . . . . . . . . .

105

B-4 Simulation 1: Three axis moment of inertia estimate plot with lower

initial

Q values

(zero matrix).

. . . . . . . . . . . . . . . . . . . . . .

107

B-5 Simulation 1: Three axis moment of inertia estimate plot with higher

initial

Q values

(diagonal of I X 10-2S).

. . . . . . . . . . . . . . . .

108

B-6 Simulation 1: Three axis moment of inertia estimate plot with lower

initial R values (diagonal of 5 x 10- 6's).

. . . . . . . . . . . . . . . .

B-7 Simulation 1: Three axis moment of inertia estimate plot with higher

. . . . . . . . . . . . . . . . . . . .

initial R values (diagonal of 5's).

16

110

List of Tables

4.1

Microsat parameters for first simulation showing reasonable mass properties including cross coupling inertia terms, center of gravity offset in

all axes and no noise. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2

Microsat parameters for second simulation showing the approximate

mass properties and sensor noise values of the experimental vehicle.

5.1

43

.

53

Non-mass related microsat parameters for the multiple body docking

simulation. These properties remain the same after docking with the

............................

space-borne object. ........

5.2

Overall 'true' and estimated mass parameters for the microsat alone

before docking at 9 seconds.

5.3

. . . . . . . . . . . . . . . . . . . . . . .

79

Overall 'true' and estimated mass parameters for the multiple body

docking simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4

77

84

Mass properties of docked object calculated at 36 seconds and the 'true'

docked object mass properties showing reasonable estimation. ....

17

89

18

Chapter 1

Introduction

Space missions in the future will require autonomous manipulation and control of

space-borne objects. To this end, Lawrence Livermore National Laboratories has

developed technology for a new generation of small, highly maneuverable satellites:

Microsats. Potential missions for the microsat include performing inspection maneuvers, and docking with other satellites. Attaining accurate knowledge of the mass

properties of the microsat and the docked objects is highly desirable not only for

precise motion control, but also as an in depth inspection of the docked object. Many

accurate methods for determining the mass properties exist; however, they often require a ground based test facility, or provide only the initial mass properties calculated

from the CAD model. In reality, the microsat will experience change in mass and

mass distribution due to fuel consumption and docking operations. Ideally, satellites

would autonomously determine the current mass properties in real-time during a mission. In this thesis, we develop an algorithm that a satellite such as the microsat can

use during a mission to calculate the complete set of mass parameters to enhance the

microsat operation during pre and post docking precision maneuvers.

1.1

Background

The field of system identification with respect to control of space objects is historically

rich; indeed, some of the first practical Kalman filter applications were developed

19

for orbital guidance and navigation problems in the Apollo space program

[4].

In

particular, there exists a wealth of information on estimation schemes used for attitude

prediction and control of satellites

[6].

Generally, satellites are intended to hold

attitude and orbit and thus are equipped with minimal propulsion capability. As a

result, most satellites do not experience large changes in mass properties; little or no

fuel is consumed. In this case, the mass properties calculated through ground based

testing remain suitable estimations for the operational life of the satellite. The extent

of mission based estimation of satellite mass properties consists of applying constant

torques or accelerations then calculating the mass or moment of inertia about one

axis from the resulting accelerations. These mass properties could then be used in

any number of simple control techniques designed for known mass parameters. Cristi

proposed an indirect adaptive control algorithm to estimate the inertia matrix for the

sole purpose of attitude control [1]. The estimation scheme presented in this paper

also produces the mass properties directly; however, it represents a deviation from the

traditional motivation for system identification. In the field of system identification,

complex physical phenomena often forces designers to construct models based on

data taken from experiments which are directly conducted to excite the plant and

measure its response. The final objective in system identification is to stabilize the

plant dynamics and give good performance which usually results in the identification

of a scrambled combination of system parameters, thus obscuring the physical nature

of the system in order to better represent the system in a control sense [2]. In this

thesis, we seek to aid in the control of the microsat while preserving the physical

representation of the system as an investigative tool.

1.2

Overview

Methods to recursively determine the inertia parameters of a satellite during a space

mission exist, at least in theory [1]. In this report we extend the estimated state to

include the ten essential mass parameters of a satellite: six inertia matrix parameters,

three center of gravity location parameters, and the total mass. Furthermore, given

20

accurate estimation of the ten mass parameters before and after rigidly docking with

space-borne objects, we demonstrate a method of determining mass properties of

the docked object and the combined body. We then present computer simulation

and experimental verification of the proposed estimation scheme on the Lawrence

Livermore National Laboratory's ground-based Microsat testbed.

21

22

Chapter 2

Description of the Microsat

2.1

Dynamic Model

The microsat is a compact, roughly cylindrical object capable of controlling attitude

and position via jet propulsion. In this study, we assume the satellite to have a rigid

body. For rigid bodies in general, the Newtonian equation:

F

(2.1)

P = mV

(2.2)

dt

where p is the momentum, F is force, m is mass, and v is velocity, describes the

motion of the center of mass, or translation of the satellite. The attitude dynamics

of a rigid spacecraft are given by Euler's equation:

dL

d

dt

=

mist

+ Tcontrol - W x L

(2.3)

L =W

10(2.4)

where L is the angular momentum vector and Tdist,

Tcontrol

are the disturbance and

control torques respectively. The second term in Equation (2.3), W x L, accounts for

the induced torque when the spacecraft angular velocity vector, W, is not aligned with

23

Yaw

Z An'is

Y Ais

Pitch

Roll

Figure 2-1: Diagram illustrating the orientation of the body-fixed axes with respect

to the microsat.

the angular momentum vector, L, or 10, where I is the inertia tensor.

Roll, pitch, and yaw are dynamic terms referring to rotations about the body-

fixed X, Y, and Z axes, respectively. Figure (2-1) illustrates the axis orientation with

respect to the microsat.

2.1.1

Overview of Inertia

A significant portion of this paper is devoted to the investigation of the inertia matrix parameters of the microsat and objects the microsat may encounter in space.

The lack of restoring forces in space prevents the use of the significantly simplified

planar dynamics often used to model ground based phenomena. Therefore, the iner-

24

tia representation in this paper must remain in three dimensional, symmetric matrix

form:

I

/Iz

IXY

Izz

IXY

IvY

IYZ

Izz

lyz

Izz

\

(2.5)

where the diagonal terms are the moments of inertia:

N

=

my

z)

(2.6)

i=1

N

I

=Zmi(Xi + zy)

(2.7)

i=1

N

izz =

mi(Xi + y)

(2.8)

i=1

and the off-diagonal terms are the products of inertia:

N

I

= -

>y mixzyi

(2.9)

N

Izz = - EMixizi

(2.10)

i=1

N

z = - >miyizi

(2.11)

Intuitively, the moments of inertia of an object, dependent on the amount and distance

of mass from the axis of rotation, describes the resistance the object has to torque

along each axis of a body-fixed frame. The products of inertia describe the inter-axis

correlation and indicate the degree of symmetry in the mass distribution of the object

with respect to the chosen body-fixed frame.

The inertia of two rigidly fixed bodies, such as a microsat docked with a spaceborne object, can be derived from the individual inertia matrices, center of gravity

locations, and masses of both the microsat and the object.

The combined inertia

of the two-body system, derived from the three dimensional parallel axis theorem is

presented in Figure (2-2):

25

CG2

Y~

z

b

a2

Z

0

G

x

1

0G 1

combined

S

(bO

Icombined =

ICGl +

M

1

I + M 2x

(MiX

+ c

-alb 1

-al cl

M1y1 + M2Y2

lvi combined

2

combined

-aibi

-aici

c2

a2 +

±

- b11

1

1

1i + b

MIz 1 + M 2 z 2

+ ICG2 + M2

combined

b2 + c2

-a 2 b2

-a2C2

)

-a2c2

a2 + c2

-b2C2

-

b2 C2

2i + b2

where:

X1, y1, zi = distance from origin, 0, to first object

Z2 = distance from origin, 0, to second object

is the inertia matrix with respect to the center of gravity of the first object and with frame orientation parallel

to the combined Inertia frame,

M 1 is the mass of the first object,

al, bi, ci are the x, y, z components of the distance from the combined CG to the CG of the first object

ICG2 is the inertia matrix with respect to the center of gravity of the second object and with frame orientation

parallel to the combined Inertia frame,

M 2 is the mass of the first object,

a2, b2 , C2 are the x, y, z components of the distance from the combined CG to the CG of the second object.

X2, Y2,

ICGI

Figure 2-2: Diagram and equation of combined inertia as a function of the inertia of

the respective objects [7].

26

Divert Jets (2)

Fuel Tanks (4)

CPU

Attitude Control Jets (16)

Inertial Measurement Unit (Internal)

Figure 2-3: CAD model of prototype LLNL microsat showing essential hardware

components: Inertial Measurement Unit, Central Processing Unit, and Propulsion

system.

2.2

Essential Microsat Hardware

Three essential hardware components that allow the microsat to recognize and respond to it's environment are the on-board sensor array, CPU, and propulsion system. The CAD drawing in Figure (2-3) shows these major hardware components on

a microsat prototype.

One of the key elements necessary for mass property estimation in the microsat

sensor array is the Inertial Measurement Unit (IMU). The IMU is a combined rate

integrating gyro and accelerometer often found on strap-down navigation systems. In

a strap-down navigation system, the sensors are physically attached to the satellite

thus giving the orientation and acceleration data with respect to the satellite axes.

The microsat prototype uses a Litton IMU which supplies the rate of change of

orientation of the microsat to well within t5 prad/s and the linear acceleration to

27

within ±3 cm/s 2. The gyro operates at 400Hz; however in order to synchronize with

the overall control loop rate of 20Hz, the IMU temporarily stores and sums every

batch of 20 samples.

The prototype Microsat contains a Motorola MV 1603 Power PC 603e microprocessor running the VxWorks 5.3.1 real-time operating system. The processor cycles

the overall control loop at 20Hz, during which it reads data from the sensor array,

interprets the data, implements the control law, and operates the solenoid valves for

the attitude control system jets and divert jets.

In this investigation, the microsat uses cold gas propulsion system, which means

the gas does not rely on chemical reaction to produce thrust.

In particular, the

microsat uses compressed nitrogen to produce attitude control system (ACS) thrusts

on the order of 0.25 lb and up to 5 lb divert thrusts. These thrust ratings are the

steady state values for the jets; however, there also exists transient rise and fall times

associated with jet actuation. The jet thrust on the Microsat is assumed to have a

3 ms rise and fall time due to the mechanical response time of the valves and the

propulsion dynamics of the gas. This is a conservative estimation given the solenoid

valve maximum rise and fall times of 1.5 ms.

2.2.1

Overview of Pulse Width Modulation

Pulse width modulation as applied to gas thrusters is a method of compensating for

the full on, full off nature of the thrusters. Though the thrust force is constrained

to either being on or off, the duration of the burn is constrained in the lower bound

only by the bandwidth of the solenoid gas valves and the rise and fall time of the gas

propulsion dynamics and in the upper bound by the width of the total duty cycle. In

other words, the gas thruster is capable of mimicking the desired force over a time

interval by matching the area under the desired force curve and the area under the

thruster force curve within a duty cycle. Thus, the gas thruster attempts to match

the average desired impulse over the duty cycle with a constant steady state thrust

28

F

Flet

(k-1

(k-1)T

(k+1)T

kT

O

(k+2)T

Desired force calculated for each time step

Desired force profile for each time step

Pulse width modulated jet approximation of desired force

Figure 2-4: Approximation of desired force constrained to actual jet thrust value,

Fet, with variable pulse duration, p, over each duty cycle.

for the appropriate duration, p:

I/(k+1)T

kT

Fdes(t)dt G- Fet -P

(2.12)

where the left hand side of the equation is the area under the desired force curve over

the interval, k, Fjet is the steady state thrust of the jet, and p is the duration the

thrust is held on. The diagram in Figure (2-4) illustrates the pulse width modulation

of the jet thrust which approximates the desired force calculated at each duty cycle.

Assuming the desired force over the duty cycle to be a constant, u, and that the

desired force is less than the steady state thrust, the following equation resolves the

proper duration, p, for an equivalent pulse:

uT

P

Fjet

29

(2.13)

2.3

Space-based Operational Procedure

Ideally, the microsat would be able to continuously update an estimate of the mass

properties based on information from sensors already in place.

During a mission,

the microsat compares the command thrust from pulse width modulated jets to the

motion information from the on-board control sensors. Using this approach requires

only extra computation and no additional hardware and thus introduces minimal

interference to the space mission.

30

Chapter 3

Mass Property Estimation Method

3.1

Recursive Least Squares

The well-known recursive least squares (RLS) approach was chosen because of its

effective and easily implemented estimation scheme. The following RLS equations

adapted from common discrete Kalman filter

[3]

and recursive least squares [1] equa-

tions are used in this study:

0

k+1 =

0

k

+ Pk+1H T (tk)Rk

Pk+1 = Pk - PkHT (tk)

1[U(tk) - H(tk)k]

[Rk + H(tk)PH T (tk)

1H(tk)Pk + Q

(3.1)

(3.2)

where 0 is the nx1 vector of unknown paramaters, P is the nxn error covariance

matrix, H is the lxn observation or regressor matrix, R is the lxi measurement noise

Q is

covariance matrix, ulx1 the input vector, and

the nxn model noise covariance

matrix.

The initial value of the covariance matrix, P, is given by the expectation of the

outer product of the parameter estimate error vector squared

PO

E[00 T ]

0

31

[31:

(3.3)

-(3.4)

where the error in the parameter estimates, 0, is the difference between the estimated

(0) and actual(0) values. Similarly, the measurement noise covariance matrix, R, is

given by the following equation:

Ro = E[vilT]

(3.5)

where v is the vector of measurement error or "noise" [3]. The addition of

Q in

the

update equation (3.2) yields a recursive structure equivalent to a discrete Kalman

filter with no state propagation i.e. the estimated state is assumed constant. A true

Kalman filter accounts for time-varying paramaters by "postulating that the true

parameter vector, [0], is not constant, but varies like a random walk" [5]:

k+1 - Ok + Wk

(3.6)

Qk= E[wkwi]

(3.7)

0

where w is white Gaussian. In essence, the added

Q term

acts as a 'forgetting ma-

trix' by preventing the covariance matrix, P, from tending to zero, thereby ensuring

effective parameter estimate corrections based on the residual error.

In reality, two events significantly change the mass properties over time. The first

is fuel consumption, and the second is docking with other space-borne objects. In

the former case, the change in mass properties is assumed to be much slower than

the convergence of the estimation to the true values. Thus, the filter is capable of

following the migrating mass parameters due to fuel consumption. On the other hand,

during the docking procedure the microsat undergoes a large, instantaneous change

in mass properties. In this case, the filter covariance matrix, P, is reset to initial

values and the mass property estimates are recalculated.

32

3.2

Estimate Convergence and Observability

Though the recursive least squares approach is widely used, the RLS estimates do

not necessarily converge on the true values. In order for the limit of the estimates,

lim

k-+oo

Ok

--

:)

(3.8)

to equal the true values, the measurements in the observation matrix, H, must be

persistently exciting; i.e.

N

H (t,)H T (tk)

lim Amin[

N -+oo

= O

(3.9)

k=O

where Amin is the minimum eigenvalue of the outer product of the regressor matrices,

H, and HT

[1].

Through simulation, Cristi shows that transient signals during regu-

lation provide enough excitation for convergence of only the inertia matrix estimates.

By providing open loop command thrusts to the microsat, we seek to provide

sufficiently exciting input to drive the inertia matrix as well as the center of gravity

location, and total mass estimates to their true values. Though all measurements

may be exciting, the system may remain unobservable if the observation matrix, H,

is sparse. The practical result, in this case, is the convergence of only some of the

estimates. Satisfying the following observability condition guarantees convergence of

all the parameter estimates.

3.2.1

Observability Condition

If we take the lx vector z which is linearly related to the estimated nxl state, 0, by

Hglxn),i

z = HO,

(3.10)

then assuming the measurements to be contained in the observation matrix, H, the

residual,

U(tk) - Z(tk),

33

(3.11)

is the error between the input, u, and the vector, z. In Equation (3.1) this error

is weighted by the sensor covariance matrix, R, re-transformed to the state, via the

observation matrix, then weighted once more by the system covariance matrix, P.

The resultant vector is added to the previous estimate of the state to produce the

new state estimate. In other words the comparison between the input vector, u, and

the vector, z, drives the current estimates toward the true state values.

A sparse observation matrix, H, produces a vector, z, which is not dependent on

all previous state estimates, thus, a sparse H indicates a lack of feedback in producing

the current state estimates.

Gelb defines the observability condition for a discrete, deterministic, constant

nth-order system

[31:

(3.12)

Xk+1 = (Xk

where x is the nxi state, and b is the nxn state transition matrix. In this system,

there are n scalar noise-free measurements taken over time, zk:

Zk = HXk,

k = 0, 1, 2, ... ,n - 1

(3.13)

so that H is a constant, n-dimensional row vector (lxn). We may write

zo=

HxO

Z

Hx1 = H?xo

=

Zn_1=

(3.14)

Hx,- 1

= H4n-IXO

Therefore,

zi

.

\ zn_1

HG

=

.

h Hn

xo =

TXO

(3.15)

mIxs

If xO is to be determined uniquely, the nxn matrix , E, must be nonsingular. Thus,

34

the observability condition is that the matrix

(HT

THT

...

( T)n-1HT)

(3.16)

be of rank n.

The extension of this observability condition to accommodate an 1 vector z, i.e.

1 measurements instead of a scalar z at each time step, k, produces a (l-n)xn matrix,

7T. Thus, the new observability condition is that an nxn window centered on the

current time, k, must be of rank n.

Because we assume the mass properties to remain constant, the state transition

matrix, <D, is the identity matrix, and drops from 7. Thus, with each time step, H is

appended by the current observation matrix,

7 = (HT

H[

HT:

... HT),

(3.17)

and the observability condition requires the latest nxn elements of 7 to be of rank,

n. Depending on the structure of H, there exists a chance the observability condition

may never be satisfied. This occurs when elements in H which must necessarily be

non-zero to prevent singularity are not dependent on any parameter estimates, and are

therefore constrained to be zero. In other words, no amount of commanded excitation

would produce a non-singular rxn window in E, thus, never satisfying the observability

condition. A method employed in this thesis to prevent this case is to split the single

large filter which estimates all the mass parameters into smaller simultaneous filters,

thereby reducing the number of elements in H which are constrained to zero. In

practice, each parameter might not be excited simultaneously, and thus, the rank

of E may not be full; however, if each parameter is sufficiently excited over a short

enough time period, one can be confident that all the parameters converged near the

true values by the end of the time period.

35

36

Chapter 4

Single Body Scenario

During a space mission, when accurate mass property estimates are especially necessary, the proposed LLNL Microsat executes a series of open loop thrust commands to

excite and estimate all the mass parameters. This section presents two simulations

and experimental results for the estimation of the mass properties of the microsat

alone.

The preliminary simulation establishes the viability of the estimation algorithm

given suitably large values to be estimated and no noise. The second, refined simulation closely matches the experimental setup in hopes of accurately emulating the true

dynamics of the experiment. In the experimental trial, a control plan identical to that

in the second simulation was executed. Data concerning the dynamics of the satellite

were recorded in real time, thus producing a synchronized set of control actions and

dynamic reactions. Once the experimental trial was recorded, the resulting data was

processed incrementally through the estimation filter.

4.1

Algorithm Structure

In order to prevent producing a sparse observation matrix, H, two simultaneous

Kalman filters are used. In the single body case, the mass parameter vectors to be

estimated apply to the microsat by itself:

37

01

=(1

112

'13

CGx

133

123

'22

CGY

CG2)T

(4.1)

(4.2)

02 = (m)

where Ijj is the corresponding inertia matrix value with respect to the center of gravity, CG

is the current three dimensional center of gravity location with respect to

the initial CG location, and m is the total mass of the object. The following equations relate the state vectors to the resultant torque and force through the observed

accelerations and velocities contained in the regressor matrices, Hi:

Ti

T2

=H1O1

(4.3)

=H2

(4.4)

T3

Fi

F2

F3

where -rj is the resultant torque component, and F is the resultant force component.

The regressor matrix, H 1 , is a combination of the dynamic torque equation (2.3)

added with the torque component from firing divert jets which do not pass through

the center of gravity. The torque equations are rewritten below for convenience:

Ttotal = idnamics

cdivert

-

Tdynamics =Iw±WXIW

Tdivert = rX

F

(4.5)

(4.6)

(4.7)

where W- is the angular acceleration vector in three dimensions:

W

W2J,

38

(4.8)

'

is the angular velocity vector:

(4.9)

L02

W3

r is the vector from the initial center of gravity location, on which the divert jets are

focused, to the current center of gravity:

CG\

CGY

(4.10)

,

CGz;

and F is the force vector from those divert jets:

Fcmd

F=

(4.11)

F2cmd

F3cmd /

where F cmd is the component commanded force. Expanding, then summing

and

7c'iert

'cynamics

in Equations (4.6) and (4.7), then collecting terms into an expression linear

in the mass parameters to be estimated (Equation 4.1) gives the explicit form of the

regressor matrix, H 1 :

LD1

1W3

W

I

I

W 1A 32

LD2 -Wl103

-W2WW3

~

)2

_2-

L;)3 - L)1 W2

W2W-W2

-U)2W3

WW

02

32

W

C;4 -W2W3

W102

22W

W 22-o

3-UW

2

-W1W3

W2W3

0

F3cmd

-W1W3

-F3cmd

0

Fcmd

-Flcmd

0

W3

F2cmd

-F2cmd

(4.12)

The second regressor matrix in Equation (4.4) multiplied by the state vector in Equation (4.2) is simply the Newtonian equation, (2.1), rewritten below:

F = md

(4.13)

where F is the applied divert force vector, m is the total mass of the satellite, and

39

a is the satellite acceleration vector. The explicit form of H 2 given in the following

equation:

a,

H2 =

(4.14)

a2

ka3

where aj is the observed component acceleration.

At each iteration, the covariance matrix, P is updated, and the elements of the

covariance matrix along the diagonal indicate the second moment of the error, 0, as

seen in Equation (4.15)

[3].

/

P = E[O]

E[02]

E[ 10 2]

SE[0 1 02]

E[02]

E[16n]

-

E[ 1On]

...

(4.15)

... E[6n]

The "precision" bounds in all the figures are the square roots of the covariance terms,

or the root-mean-squared (rms) values of the error, 0, found on the diagonal of the P

matrix. The off-diagonal terms indicate the cross-correlation between the elements in

0. In all simulations in this thesis, the initial error covariance matrix, P, measurement

noise matrix, R, and model noise covariance matrix,

Q,

are diagonal, meaning no

initial cross correlation exists between the parameter estimate errors/noise.

The

magnitude of each element is chosen based on a best educated guess; though defined

theoretically, the initial covariance matrices often need to be redefined to produce a

stable, and converging filter. Appendix B presents examples of the iteration process

required for the simulations in this thesis to find suitable covariance matrix values.

The resultant torque and force vector from the left sides of equations 4.3 and 4.4

subtracted from the commanded torque and force produces the residual error. This

error is then multiplied by the Kalman gain, then added to the current estimation as

seen in the update equation, 3.1. Assuming the inputs in H are persistently exciting,

the state estimate, 0 , will eventually converge on the true mass property values.

40

4.2

Single Body Simulations

This section presents six degree-of-freedom simulations of the microsat in space. The

objective of these simulations is to show the estimation algorithm capable of determining the correct mass properties of the microsat. In order to accurately simulate the

estimation algorithm, we reproduced both the microsat plant and controller dynamics

in a variable step differential equation solver.

4.2.1

Simulation Description

The six degree-of-freedom (DOF) simulation executed in Matlab takes advantage of

the pulse width modulated control action of the microsat. Depending on the desired

control action, the resultant jet thrust durations could vary between a minimum of 3

ms and a maximum equal to the duration of the control cycle, 50 ms. Each step of the

differential equation solver corresponds to the duration of constant thrust. Thus, this

six DOF simulation provides accurate dynamics data while minimizing computation.

(See Appendix C for Simulation code)

The controller parameters in the simulation match those downloaded to a physical

microsat; however, physical parameters must be specified within the simulation as

truth. These variables include the mass parameters to be estimated. Though specified

in the simulation, the inertia, CG location, and mass only manifest themselves in the

dynamic reactions to the control thrusts. Random processes normally encountered in

reality can also be reproduced within the simulation as sensor noise. The simulated

trials indicate the ability of the estimation algorithm to converge on the specified true

parameters.

4.2.2

Preliminary Simulation

The indirect adaptive control simulations presented by Cristi show a fast convergence

of the six 3x3 inertia matrix parameters. The algorithm presented in this paper

shows similar convergence for the center of gravity location and total mass as well

as the inertia matrix parameters. However, rather than immediately substituting the

41

Divert Away

From Initial

Docking Port

Open Loop

Roll Oscillations

0

2

4

Open Loop

Pitch Oscillations

6

Open Loop

Y-Axis Diverts

Open Loop

Yaw Oscillations

10

8

12

14

16

18

20

Time (s)

Indicates Control Action To

Return To Initial Attitude

And Hold

Figure 4-1: Timeline of the mission showing all control actions.

estimated mass properties into the controller, the controller executes a series of open

loop command torques and diverts to excite the estimated states. Specifically, each

moment of inertia is excited directly with alternating 100 ms pulses for approximately

two seconds. Each two second excitation is followed by the command to return to

the initial orientation and hold attitude for an additional two seconds. After the

roll, pitch, and yaw motions are executed, the microsat diverts along the Y axis with

alternating 200 ms pulses for two seconds. Figure (4-1) shows the overall mission

profile used in the following simulations.

The first simulation, demonstrates the ability of the estimation algorithm to converge on the true values with perfect information from the sensors. The true mass

properties correspond to a reasonable estimate of a physical microsat. (See Table 4.1)

In the first simulation trial, we show the convergence of reasonable mass parameter

estimates in a perfect world with no random variations. The truth parameters are

not perfect in a design sense; satellites are often physically symmetric and produced

at extremely tight tolerances which practically eliminates the center of gravity offset

from the divert thrusters. Because symmetric design represents a desire to produce

42

Microsat Mass Property

(Calculated at end of first trial)

'True' 'Estimated'

Value Value

Moment of Inertia Ixx [kgm2]

0.7

0.70

Moment of Inertia Iyy [kgm2]

4

4.00

Moment of Inertia Izz [kgm2]

4

4.00

Product of Inertia Ixy [kgm2]

0.1

0.10

Product of Inertia Ixz [kgm2]

0.1

0.09

Product of Inertia Iyz [kgm2]

0.1

0.10

0.1

0.10

0.1

0.00

through which all divert jets fire [m]

0.1

0.10

Total Mass [kg]

20

19.99

Moment arm about X-axis from zero deviation CG to ACS Jet [m]

0.1475

Not estimated

Moment arm about Y-axis from zero deviation CG to ACS Jet [m]

0.2575

Not estimated

Moment arm about Z-axis from zero deviation CG to ACS Jet [m]

0.2575

Not estimated

ACS jet thrust [lbf]

0.25

Not estimated

Divert jet thrust [lbf]

0.50

Not estimated

0

Not estimated

0

Not estimated

Center of Gravity X-axis deviation from point

through which all divert jets fire [m]

Center of Gravity Y-axis deviation from point

through which all divert jets fire [m]

Center of Gravity Z-axis deviation from point

Gyro noise 6

o- magnitude

Accelerometer noise 6 u- magnitude

Table 4.1: Microsat parameters for first simulation showing reasonable mass properties including cross coupling inertia terms, center of gravity offset in all axes and no

noise.

43

a dynamically intuitive vehicle, many of the mass property terms which are of vital

interest on a space mission because of their interference in control are assumed to

be zero or near zero. These parameters include the products of inertia, or inter-axis

coupling terms, and the center of gravity location. One can imagine that a deviation

in the center of gravity of a space vehicle could result in unpredicted torques caused by

divert jets that were assumed to have focused on the center of gravity. Therefore, in

order to predict these interferences, this simulation assumes reasonably large center

of gravity offsets from the divert thrusters as well as dynamically significant cross

coupling as seen in the product of inertia values in the true mass parameters in

Table (4.1). These mass parameter truth values may very well closely represent the

parameters encountered as a combined body of a microsat docked with another spaceborne object. We investigate this trial to assure the estimation algorithm does not

depend on the significantly simplified dynamics of a symmetric vehicle.

The control torques shown in Figure (4-2) indicate large control efforts to regain

the initial attitude after the excitations. Because this simulation reproduces a perfect

world with no random variations, these deviations are not a result of unaccounted

jet misalignments or sensor noise. Rather, the deviations are indications of the high

degree of cross correlation in this system. Though each roll, pitch, and yaw motion is

executed independently, rotation still occurs in the remaining two axes because of the

off-diagonal inertia matrix terms, or products of inertia. Also, the command torque

oscillations at 16 seconds represent the controller effort to reduce the additional torque

produced by the Y-divert oscillations through a point that is 0.1 m away from the

center of gravity.

The control actions in this trial were exciting enough in the first 2 seconds to significantly converge both the X-axis and Z-axis moments of inertia. As each rotation

axis is excited, the corresponding moment of inertia estimate shows further convergence on the true value (See Figure 4-3). This is also true of the "precision" of the

filtering algorithm; as a specific mode is excited, the corresponding covariance term

decreases. The inter-axis correlations induce compensation in the form of immediate

control torques in all axes. Thus all the moment estimations begin to show excitation

44

and convergence though not specifically excited. Even before any specific rotational

axis is excited, the roll moment of inertia estimate nearly converged. The product of

inertia estimates (See Figure 4-4) show convergence as a direct result of cross coupling of axis rotations. Despite initially diverging, the products of inertia estimates

eventually converge on the true values as indicated by the tapering precision envelope.

The center of gravity location estimations are calculated based on the comparison

between the control actions and the resultant angular velocities. The X and Z components of the CG location estimation converge quickly and in a similar fashion to the

inertia parameters; however, the Y component does not deviate from the initial value

of zero. Though the estimation algorithm attempts to converge on all ten parameters

simultaneously, observability of the parameters is not guaranteed. In this case, the

Y component of the CG location depends on linear excitation of the vehicle in any

direction other than along the body-fixed Y-axis. Intuitively, since the vehicle was

given only diverts along the Y-axis, no degree of deviation of the center of gravity

along this axis would induce a rotation on the vehicle (see Figure 4-5); thus, the Y

component can never converge to the true value of 0.1 m with forces applied only in

the Y-axis direction.

Analogous to the relationship between torque commands and inertia, CG estimation, the divert force commands contribute to the mass estimation. In this trial, the

microsat was excited only in the Y-axis as seen in Figure (4-7). The initial diverts

in this simulation were to simulate the deployment of the microsat away from the

docking bay and were extraneous to the purpose of parameter convergence. However,

they proved to converge the mass estimate to within 5% of the true value as seen in

Figure (4-7). The divert oscillation at 16 seconds provided little if any improvement

in mass estimation from the initial divert contribution.

45

Control Roll Torque N-m

0.4

0 .2 --

0

- -..

.

- 0 .2 -. ..

-0.4

. - .. -

. .. . . .

. -.

- . . .- . . .

- . .

. .

- . . . . .-.

0

-...-.

2

4

6

.-..

8

10

12

Control Pitch Torque N-m

.- \..

14

16

18

20

18

20

1

-

0.5 ......... ----

-

0

- -

- 0 .5 --- -------1

0

2

4

6

8

10

12

Control Yaw Torque N-m

14

16

1

---

0

.- . -..-..-.-.-.-..-.-.-.-.

. .. .. .. . . . . . . .

- 0 .5 -.. . .. . . -.

-1

0

2

4

6

8

10

time (s)

N

-.-.

12

14

16

18

20

Figure 4-2: Simulation 1: Control torques on each axis resulting from execution of the

mission plan. Though all the torque commands are perfectly balanced with opposite

commands during the open loop excitations, large control torques are evident when

attempting to return to initial orientation, suggesting large deviations in orientation

due to inter-axis torque disturbances. The oscillations at 2, 6, and 10 seconds show the

open loop control roll, pitch, and yaw, respectively to induce parameter convergence.

46

X axis moment of inertia kg-rn 2

0.8

.. .. . .

.

- - - -

--

_

-

0.6

. . .. . ....

*

..

-

.

0.4

0.2

Estimate

0

True value

--

-

S-

-Filter

"precision"

-0.2

)

2

4

6

8

10

12

14

Y axis moment of inertia kg-rn2

16

18

20

5

4

3

2

1

.

-- Estimate

_- True valueFilter "precision"

- -

0

C)

2

4

6

8

10

12

14

Z axis moment of inertia kg-m 2

16

18

20

5

------------ -

-

4

3

2

.......

. .

~ .. .~~.~

1

0

I

)

2

-Estimate

-..

...

T rue va lueFilter "precision"

.

........I

4

6

8

10

12

14

16

18

20

time (s)

Figure 4-3: Simulation 1: Three axis moment of inertia (MOI) estimate plot showing

the convergence from initial moment estimates of zero to the true moment represented

by the horizontal line. The "precision" boundary for each plot is the 'true' value

±/ Pkkwith k = 1 for X-axis MOI, k = 4 for Y-axis MOI, k = 6 for Z-axis MOI. The

"precision" remains nearly constant from 12 to 20 seconds because there is no direct

excitation of these modes during that period.

47

2

X-Y product of inertia kg-m

0.5

0

-

-0.5

)

2

4

6

-

14

12

10

8

X-Z product of inertia kg-m2

Estimate

True value

Filter "precision"

16

18

20

0.5

0

Estimate

--- True value

V7

-0.5

)

2

4

Filter "precision"

6

12

10

8

Y-Z product of inertia kg-m

14

16

18

20

2

0.5

0

-

-

Estimate

True value

-- Filter "precision"

J

0

2

4

6

8

10

12

14

16

18

20

time (s)

Figure 4-4: Simulation 1: Three inter-axis product of inertia (POI) estimate plot

showing the convergence from zero initial values to the true product represented by

the horizontal line. The "precision" boundary for each plot is the 'true' value ±Pkk

with k = 2 for X-Y POI, k = 3 for X-Z POI, k = 5 for Y-Z POI. Though tapering

significantly at the beginning of the simulation, the "precision" envelopes remain

wide at the end of the simulation from lack of direct excitation, which indicates the

current residual error is more significant than previous residual error when calculating

the current estimate.

48

Z Axis

Induced Yaw w CG x 0bservable

Potential CG

locations along

line

Fapplied,

y-direction

so Y Axis

No Induced Pitch

y

CGY NOT Observable

Induced Roll-

CGZ Observable

X Axis

Figure 4-5: Diagram showing uncertainty in CG location based on diverts only in

Y direction. There is no difference in dynamics as the CG location varies along the

Y-axis.

49

CG location along X-axis

0.1

0.08

0.06

ile "rciin

Estimate

-

0.04

-

-True

-.-.

0.02

0

0

2

4

12

10

8

6

value

Filter "precision"

14

2C

18

16

CG location along Y-axis

4

2

-

0

- - - - -

- --

- - --

-- --

- --

-- Estimate

-2 -.

.-

.

-

True value

Filter "precision"

- - - ---4 ... . .. . . .... . ... . . ..................................................

14

16

12

10

8

6

4

2

0

18

2(

CG location along Z-axis

0.1

0.08

0.06

0.04 0.02

0

. . . ... . .

.... . ..-.

0

2

..

4

6

E stim a te

--..

-- True value

-..-...

Filter "precision"

10

8

-..

12

14

16

18

.. .

20

time (s)

Figure 4-6: Simulation 1 Center of gravity (CG) location estimate with respect

to the initial CG location corresponding to the focus of the divert thrusters on the

microsat. The true CG deviation from the focus in Simulation 1 is 0.1 m in X, Y, and

Z directions. The CG location in the Y direction is unobservable, and thus, there is

no change from initial values. (see Figure 4-5). The "precision" boundary for each

plot is the 'true' value ± Pkkwith k = 7 for CG along X-axis, k = 8 for CG along

Y-axis, k = 9 for CG along Z-axis.

50

(a)

Force command (Y-Axis Divert) N

3

I

I

12

14

2

-.

1

0

-1

-2

-3

)

2

4

6

8

(b)

10

time (s)

16

18

20

Total Mass kg

22

20

18

16

Estimate

-

True value

-

-

14

12

)

..

2

..-

4

6

-

8

10

time (s)

12

14

Filter "precision"

16

18

20

Figure 4-7: Simulation 1: Commanded force plot showing the initial divert away from

the bay, and the divert oscillations at 16 seconds. Simulation 1 contained diverts in

the Y (lateral) direction only. Plot (b) shows the estimated total mass for the microsat

in Simulation 1 revealing correlation between mass convergence and command force

excitations. Since the mass estimate is filtered separately from the other estimates,

the "precision" boundary is only the 'true' value ± P2 .

51

4.2.3

Refined Simulation

The second single-body simulation closely approximates the proposed experimental

trial and uses nearly the same mission profile as the first simulation. The microsat

simulation parameters match the speculated mass parameters of the prototype, and

the sensor noise also matches the precision of the IMU data on the prototype microsat.

(See Table 4.2) However, one important detail from the experimental setup that is

not modeled in this simulation is the mass contribution from the dynamic air bearing.

The air bearing itself contains pressurized air tanks and the structure for supporting

the microsat and thus, has a significant mass. The mass contribution appears only

in the total mass parameter because the air bearing is constrained to translate with

the microsat, but not rotate. Therefore, the total mass value is set at 25 kg, 5 kg

higher than the previous simulation to account for the added mass of the air bearing.

The mission profile for the second simulation differs only in the frequency of divert

oscillation at 16 seconds. The divert pulses last for approximately 100 ms as opposed

to 250 ms in the first simulation.

As in the first simulation, all the open loop torque commands are balanced with

opposite commands. Barely noticeable attitude corrections between excitation periods indicate attitude deviations produced by the small products of inertia during the

oscillating rotations and sensor error (See Figure 4-8). Despite the sensor noise and

the effects from inter-axis torque coupling, the relatively inactive controller between

excitation periods indicates a well balanced system.

The inertia matrix does not converge as quickly in this trial. Rather the moments

and products of inertia converge more predictably as each mode is excited. Though

the estimates do not converge as rapidly between excitations, the minute control

actions taken to maintain attitude also contribute to the convergence of the moment

of inertia terms as seen in the initial steps in the Y-axis and Z-axis plots in Figure

(4-9). One interesting anomaly in the product of inertia estimates is the immediate

step following the excitation of the roll and pitch axis at 4 seconds. Though seemingly

large, the deviations from the true values remain within the precision envelope. At

52

Microsat Mass Property

(Calculated at end of second trial)

'True'

Value

'Estimated'

Value

Moment of Inertia Ixx [kgm2]

0.35

0.35

Moment of Inertia Iyy [kgm2]

2.5

2.49

Moment of Inertia Izz [kgm2]

2.0

2.00

Product of Inertia Ixy [kgm2]

-0.01

-0.01

Product of Inertia Ixz [kgm2]

-0.05

-0.05

Product of Inertia Iyz [kgm2]

0.06

0.06

0

0.00

0

0.00

through which all divert jets fire [m]

0

0.00

Total Mass [kg]

25

14.18

Moment arm about X-axis from zero deviation CG to ACS Jet [m]

0.1475

Not estimated

Moment arm about Y-axis from zero deviation CG to ACS Jet [m]

0.2575

Not estimated

Moment arm about Z-axis from zero deviation CG to ACS Jet [m]

0.2575

Not estimated

ACS jet thrust [lbf]

0.25

Not estimated

Divert jet thrust [lbf]

0.50

Not estimated

o magnitude

Accelerometer noise 6 o- magnitude

0.0001

Not estimated

0.02

Not estimated

Center of Gravity X-axis deviation from point

through which all divert jets fire [m]

Center of Gravity Y-axis deviation from point

through which all divert jets fire [m]

Center of Gravity Z-axis deviation from point

Gyro noise 6

Table 4.2: Microsat parameters for second simulation showing the approximate mass

properties and sensor noise values of the experimental vehicle.

53

the end of the second simulated trial, all products of inertia converged to the relatively

tiny true values.

Because both the true CG locations and the initial CG location are assumed to be

zero, the unobservability of the CG location along the Y-axis is not apparent except

for the unperturbed precision envelope. The envelope never converges on the true Y

location for the CG due to lack of excitations in that mode. The X and Y-axis CG

estimates remain near zero as indicated by the millimeter scaling in Figure (4-11).

The behavior of the mass estimate initially mimics that of the first trial. However, immediately after the initial divert excitations cease, the mass estimate slowly

diverges from the true value. In the presence of applied force, the noise contribution

from the accelerometer is small by comparison; however, when the force excitations

cease, the algorithm still observes acceleration from noise. Therefore, the mass estimates continue to change though the force input has stopped. When the Y-axis

divert oscillations return at 16 seconds, the mass estimate again begins to converge

with the true value.

The mass estimate behavior shown in Figure (4-12) reveals interesting assumptions within the filter. The precision envelope does not follow the mass estimate as

the noise drives the estimate toward zero. Instead, the filter believes the sensor noise

to be good data, thus decreasing the covariance on the assumption that the mass was

decreasing. This occurs because the 'ghost' accelerations from the noise multiplied

with the current estimated mass always produces an error when compared with the

zero applied diverts; the filter assumes the only mass that could account for an acceleration when no force is applied is zero mass. Thus, from 2 to 16 seconds when there

are no applied forces, the mass estimate tends to zero because of the noise.

54

Control Roll Torque N-m

0.4

0.2

0

-0.2

-0.4

)

2

4

6

8

10

12

14