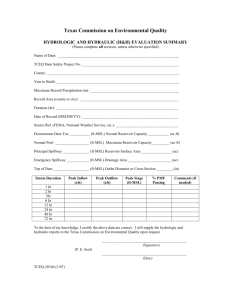

AN INVESTIGATION HYDRO-ELECTRIO POSSIBILITIES FOR FAM POWER MASSACHUSETTS.

advertisement

AN

INVESTIGATION

OF THE

HYDRO-ELECTRIO POSSIBILITIES FOR FAM POWER

OF

A

SMIALL BROOK Ill METHUEII,

MASSACHUSETTS.

ci~

/

\

~Q

t~s

Ile

4

AN

ITVESTIGATIOI

OF THE

HYDRO-IECTRIC POSSIBILITIES FOR F1ALM PIOVER

OF

SIL/JL

A

BROOK IN UETHUEN, MASSACHUSETTS.

A

Thesis

Submitted to

The Faculty of the Massachusetts Institute of Technology.

By:

Edwin C. Schatz

Harold L. Townend.

ACKINOWTLIDGE1E=ETT

Throughout the course of work on this thesis

we have received encouragement, guidance, suggestions and cons:tructive criticism from Prof. Barrows

of the Civil Engineering Department.

For the assist-

ance that Prof. Barrows has given us, we wish to thank

him.

7e also wish to thank Mr. Mayo of the S. Morgan

Smith Company, Mr. Garratt of the Remco Wood Stave

Pipe Company, and the General Electric Company for

their advice and quotations.

TABLE OF CONT MTTS

INTRODUCTION.

. . . .

* .

.

.

.

.

. .

.

. .

.

. .

1.IETHOD OF INVESTIGATION

.

THE DAM . . . . . . . .

.

0

.

.

0

.

.

0

. .

THE SPILL'lAY. .

.

.

.

.

.

.

.

. . 0 0 .

THE PIPE LINE

.

.

.

.

.

.

.

.

. ...

POWER PLANT.RI?20AIT

. .

.

EFFICIENCY OF THE UNIIT.

COST OF PLANT.

COST OF PO1dER.

RECOMIhENDATIONS.

0 0

0

. . .

. .

.

. ..

.

.

.

0

. . .

.

.

.

"

5

.

0

"

6

17

-

21

.

.

0

II 23

. . .

.

" 24

. .

.

" 25

. . . .

.

0

0

. .

.

Graph (lost head vs Q.)

APPENDIX B

C

Efficiency Curve Generator

"

Turbine

APPENDIX E

Overall Efficiency

APPENDIX F

Data for Curves

APPENDIX G

17eir Readings

APPENDIX H

17iring Diagram

APPENDIX I

Cross-Section of Dam

APPENDIX J

Topographical Map

APPENDIX K

Power House Layout

.

14

16

"? 22

.

-11

-

0

.

4

15

. . 0 . 0

0

-

" 12 -

..

APPENDIX A

i

.

0 0 0

APPENDICES:

APPENDIX D

. Page 1

. .

. . . . .

.

- *.

0

IrTRODUCTION

The purpose of this paper is to investigate and

report upon the hydro-electric possibilities of a small

brook for farm power.

In recent years the development of hydroelectric stations has been rapid and of great value to

Most of these stations are of considerable

the country.

size, being situated along large rivers.

The small de-

velopment has not, on the other hand, received much

attention.

This is due to the fact that the power com-

panies are not interested in small units and the individual

owner of a site does not, as a rule, realize the possibilities of the small stream.

The State of New York has con-

ducted an investigation along these lines, which speaks

very favorably of the small station, finding that the cost

of maintenance of the plant is very small, the first cost

being in almost every case the controlling factor.

The site investigated for this particular

paper, is in Methuen, Massachusetts, on the farm of Mr.

Richard Batty.

The power is to be used, to a very large

extent, for lighting the different farm buildings, and

to run small motors in and about the home.

The source of power is the Bare Meadow Brook,

a small stream with a flow of about one and one-half cubic feet per second.

it is fed by springs.

The flow is fairly consistent, as

After rains and freshets, the

quantity of water in the brook is considerably larger,

but due to the nature of the drainage area, the peak

values are of short duration.

As the flow is small, storage is necessary.

This is to be accomplished by means of a dam.

The most

economical dan proved to be an earthern one, located as

is shown on the map (Appendix J.)

Since the material of

which it would be made is rather porous, a loam core is

necessary.

The soil for the dam could be taken from the

spillway section and from the hills on either side of the

brook, while the loam can be scraped from the surface of

the ground.

The flooded areas is all pasture land and at

present of very little value, and is practically all in

the property of Mr. Batty.

An additional head of five feet can be obtained by

means of a 225 foot pipe line.

The additional cost of in-

stallation of the plant would be more than offset by the

3.

head gained and the more economical use of the water.

The pond would be kept at practically a constant head - not over a foot deviation either way, except

when the demand for power was very urgent.

It would not

be feasible to allow the water to drop more than a foot

because the inflow is so small that if the head is once

lowered, it Will require some time to build up again, unless the plant were shut down for a considerable period.

The power house will be a small wood-frame

building, containing a vertical reaction turbine, a

generator,

governor and switchboard.

a McCormick,

11.4 H.P.,

The wheel will be

576 R.P.M. vertical set turbine

operating under a 19 foot head.

The generator will be

a direct current, compound wound General Electric 7 LN

unit, and would be connected to the turbine with a quarter

turn belt.

A Woodward governor will be installed to

operate the wicket gate mechanism.

The entire development will cost about

5,000,

and will cut the cost per K.W.H., the present selling

price by the local power company, of ".125 to

.041 at

the switchboard, the saving per year will be approximately '250.

The cost of the development per horsepower

'440, is high, as would be expected from so small a plant.

4.0

The cost could be cut dovm considerably if the omer

undertook to build the dam and power house himself, and

this is the logical thing for him to do.

The chances of the plant being shut down, due

to repairs for any long period of time, are very small,

but since it might possibly happen, it would be necessary

to tie in with the power system of Lawrence as a safeguard.

5.

LETHOD OF INVESTIGATION.

The amount of water available was determined by weir measurement.

A triangular weir

with a 90O notch was erected in the stream for

this purpose.

An old dam was utilized in the lo-

cation of the weir.

This did not prove entirely

satisfactory, since the water seeped through the

dam to a slight degree.

The readings were all a

trifle low for this reason.

However, it was de-

cided that the value of 1.5 second feet was a reasonable value to allow for the stream at all times.

The amount of head available was determined by a set of levels.

A topographical map

of the site was made by plane table work in the

early part of the summer of 1922, in order to determine the amount of storage and the best location

of the dam.

0.

THE DAM.

In the consideration of this project,

since the governing condition is that of the

available water and the economical utilization

thereof, a means of control is essentially important.

The control of the water should be

brought about by means of a storage reservoir.

Due to the character of the topography at this

particular site, this can easily be made by means

of a dam located, as shown on the map.

In order to locate the dam properly,

several factors must be considered.

First, utilize

all of the available head; second, allow adequate

storage; third, guard against damage to property

of adjacent owners due to flood conditions at the

high water stage; fourth, a minimum of material;

fifth, a good foundation.

These factors must be

balanced, the one against the other, and that solution determined upon which is most economical.

The foundation should,

built upon ledge rock.

if

possible, be

A careful study of the site

7.

and of the territory surrounding did not disclose any

traces of the presence of ledge rock.

In fact, it dis-

closed that the hill over which the brook fell was what

is known as a drumlin, or a hill made up of the drift

deposited by one of the glacial movements from the north.

Therefore, one of the conditions was eliminated in this

project.

The other features are all more closely related to one another.

It was determined by a set of

levels that the top of the dam could not go over a certain elevation, since this would tend to cause the water

to flood back over the property of the land owner directly upstream.

Obviously, it should be built high

enough so that every foot of head that is available would

be used.

It was decided, then, that the top of the dam

would come at elevation 105, in order to meet the two above

named conditions.

Having fixed the elevation of the top, it next

became necessary to determine the location of the dam in

respect to its position on the stream.

This must be so

arranged that the water could be stored during the part

of the day that the plant was not in operation.

More-

over, it was decided that during this time no water should

be allowed to flow through the spillway.

Computations

showed that by placing the dam at the position shown, the

water would not waste over the top under ordinary condi-

8.

tions until storage had been in progress for approxiSince the plant will normally

mately twenty hours.

be run from eight to ten hours per day, there is sufficient leeway to prevent the waste of water.

This location, however, would not permit the

utilization of all the head available.

In order to get

this full head, by means of a dam, its position would

need to be over 200 feet farther downstream.

This would

be very uneconomical, since it would necessitate a very

long and rather high dam.

Moreover, the increase in the

amount of material in the structure would make it prohibitive.

The-ultimate solution, then, was to place

the dam as shown and convey the water through a pipe

line to the power house, 225 feet below the dam.

The

site chosen was peculiarly well adapted to the construction, since at this point the brook is flanked on either

side by high hills,

the ravine is narrow and deep; and

by building a dam fifteen feet in height (at the highest

point)

it was found that a total head of 19 feet could

be obtained.

Fourteen feet of the head would be ob-

tained by the use of the dam, and the other five by the

use of the pipe line.

Several types of dams were considered.

The

only practical type was found to be an earth fill dam,

9.

made up of the material taken from the spillway and

from the hills on either side.

The width of the top should be eight feet,

based upon the engineering practices in the matter of

earth dams and the formula for the width of the top.

(71

1/5 h

4

5 ft.)

The side slopes of the dam would depend

largely upon the material of construction and the angle

of repose; with a slightly lower grade on the upstream

side.

The final slopes decided upon were 3:1 upstream,

and 2:1 for the dovmstream sides.

The slope should be

protected, on the upstream side, against wave action.

This protection can easily be obtained by facing the

slope with stones and boulders raked out of the material

used in the embankment.

The downstream side should be

protected to insure against washing away during a heavy

rainstorm.

Either gravel or sodded slopes furnish the

proper protection required in this regard.

Gravel, how-

ever, would make the cost of the dam increase very considerably, and so a sodded slope was decided upon.

The amount of fill in the dam, under the

arrangement decided upon was computed to be 2000 cubic

yards.

This material would be taken from the hills on

10.

either side of the dam, and from the spillway location

which is shown on the map.

In a general way, the more impervious material

(not taking into account the core) should be placed on

the water side of the dam.

Theoretically, if the water

seeps through the core, it is better to have it leak

through the remainder of the dam as quickly as possible,

unless, of course, a sufficient velocity is acquired

to start washing out the material.

Since the material used in the dam would be

rather porous, it necessitated putting in a core of

some impervious material.

Concrete, while making the

dam practically impervious, would add quite materially

to the cost of the plant.

Clay and loam were then considered.

Yhile

there is clay in that vicinity, it is not in very great

abundance and the cost of hauling would make this prohibitive.

of all.

Loam, then, seemed to be the most feasible

This could be scraped off the surface, and with

only a short haul, could be placed in the core.

The amount of material necessary in the core,

is rather an indefinite proposition.

has shown that if

Practice, however,

the inner core is 20O or over, of the

11.

material, the result makes a dam very nearly impervious.

It was decided, therefore, to make the

core twenty feet in width at the bottom of the highest section, and three feet wide at the top, the side

slopes about 1 horizontal to l-2 vertical, making a

total of 520 cubic yards of loan, or about 25%o of the

fill.

12.

THE SPILLVT;AY

The spillway was designed to carry a

maximum of 200 second feet of water around the dam.

It will have a base width of five feet with sixty

degree side slopes.

As the average run-off of this

locality is 1.5 second feet per square mile of draining area,

anl the area drained is but two and a half

square miles, it is readily seen that there is a very

safe margin in the 200 second feet assumption.

It

is quite possible that there will never be any demand

for such a large channel.

This is due to the flat

drainage area, and the correspondingly slow run-off

tendency, and the existence of several ponds above the

site which would tend to hold in check any sudden

fluctuation in the run-off.

The channel will be surfaced with rock in

order to insure better flow in times of necessity.

The reason for picking such a relatively large section

and lining the channel with rock is that the spillway

is the only means there is of protecting the dam, in

case of an exceptionally heavy and long protracted

rainy spell.

There will be flashboards,

two feet high,

placed at the entrance of the spillway.

The bottom

of the boards will be at elevation 103, and as the

pond will be at elevation 104, there will be one

foot of water in the channel above the flashboards

on the water side at all times.

In order to make

a tight joint, the section of the spillway where the

flashboards are placed will have concrete sides and

bottom.

The flashboards will be removable and be

made of one inch spruce timber.

The spillway will be located as shown on

the map,

brook.

circling the hill

on the south side of the

This location was decided upon in order to

insure against the water wasted coming into contact

with the downstream side of the dam.

The spillway

could possibly be built nearer the brook and at a

smaller cost, but the risk of damage to the dam would

more than offset the additional cost necessitated by

locating the spillway channel, as shown.

The excavation necessary can all be accomplished by scraping, some of the material being

used for the dam and the remainder wasted over the side

of the hill.

The estimated cost of constructing the dam

and spillway, using the excavation of the one for the

14.

fill of the other, is

1200, which can be cut

down quite materially if the owner plans to build

these two portions of the plant himself.

15.

THE PIPE LIIT.

The amount of power that can be developed

by any hydro-electric station is limited by the quantity of water and the available head.

The amount of

water which can be used in this project is limited to

approximately 1.5 second feet, and therefore, if a

greater head can be obtained by the use of a pipe line,

it would prove advantageous.

It was found that by

using a pipe line 225 feet long, an additional head

of five feet could be obtained.

Numerous types of pipe could be used in

this development.

Several kinds of steel and iron

pipes were investigated as well as wood stave pipe.

Steel has a longer life than the wood stave, but it has

the disadvantage of a very large cost, and that it will

corrode.

Wood stave pipe is very suitable for low

head developments and has some advantages over steel,

some of vhich are:- low first cost; it does not corrode; it has a lower coefficient of friction - which

does not become greater with age as in the case of

iron pipes, - and it tends to prevent freezing of the

water, due to the fact that wood is an excellent non-

16.

conductor of heat.

The manufacturers of Remco machine

woudi wood stave claim that their pipe will not burst

if frozen, because the wood can absorb to some degree

the expansion due to the formation of ice in the pipe.

A gate valve will be installed in the pipe

line at a point on the lower side of the dam.

This

will be used only as a protective measure andi

will be

closed only when repairs are being made on the pipe

line or on the turbine, and during extremely cold

weather, to prevent freezing.

The turbine gates will prevent the waste

of water at all other times, since the leakage is only

a very small percentage of its rated capacity.

The pipe will be an 18" Remco machine wou.id

wood stave pipe, and will be laid in a shallow ditch

to protect it from the action of the weather and sun,

and it is estimated that the pipe will last for fifty

or sixty years.

A trash rack is necessary at the mouth of

the pipe in order to keep the floating objects from

entering the pipe line and damaging the turbine.

This

will be made of heavy wire screening and will be painted to prevent rusting.

17.

POWER PLANT.

The power house will be a wood frame

structure, 12 feet wide and 16 feet long, set on a

concrete foundation.

The house will contain the

turbine, governor, generator, and switchboard.

Two types of turbines are at present in use,

the impulse wheel and the reaction turbine.

The im-

pulse wheel is particularly adapted to high head developments, but must be set at an elevation sufficiently high that a free discharge is obtained.

The vertical reaction turbine is well adapted

for low head developments since it may be operated at

the level of the tail water and thus utilize the entire

head.

This type of wheel will also develop a high

specific speed, which is essential in this development.

It

was decided to install a vertical re-

action turbine, and because of the small size, it was

necessary to pick a stock size.

Turbines made by the James Leffel Company

and the S. Morgan Smith Company were then investigated

and it was found that the 9 inch McCormick 11.4 H.P.

vertical turbine, manufactured by the S. Morgan Smith

Company, was best suited to the project.

This turbine

18.

operates under a 19 foot head, running at 575 R.P.M.

and uses about 6.6 second feet of water.

The turbine will be connected to the generator by a quarter turn belt.

As the rated speeds of

the turbine and generator are not the same, it will

become necessary to use pulleys of different sizes.

The pulley supplied with the turbine is 4 inches wide,

with a 24 inch diameter.

The generator will be oper-

ated at 1700 R.P.M., therefore, since the turbine

runs 575 R.P.M., an eight inch pulley will be required on the generator.

A four inch belt will be used.

will easily carry the necessary load.

This size

It will be

turned through ninety degrees, since the shaft of the

turbine is vertical, while that of the generator is

horizontal.

The generator to be used is a flat or

slightly over-compounded generator.

at 7 K.7J; 125 volts, and 1700 R.P.M.

It is rated

The generator

was selected of slightly lower capacity than the

turbine to take account of the belt loss and the

losses in the generator itself.

Direct current will be used as this type

of power is advantageous wherever the transmission

line is short, because it gives better speed regulation with motors, and is as good, or better, than

19.

alternating current for lighting purposes.

An in-

duction generator could not be used because there is

no synchronous motor load.

A direct current genera-

tor is cheaper than a synchronous generator and requires no exciter.

The load center is only about

300 feet from the power house, and so the power loss

in the line will be small.

It is not feasible to generate power at a

higher voltage than 125, because the lighting system

used in this locality is rated at 110 volts and it

may become necessary to use the central station for

standby service.

,

The voltage of the load must be kept prac-

tically constant.

This is especially necessary in a

lighting load as it is expected to come on this plant,

and a variation of voltage will prove costly for two

important reasons:- a higher voltage causes a decrease in the life of the filament, while a lower

voltage means a very decided decrease in the efficiency of the lamps.

To maintain a constant- voltage,

must be kept constant.

the speed

To do this, a Woodward me-

chanical governor is to be installed.

A Tirrill vol-

tage regulator could be used, but this apparatus

20.

operates independently of the turbine, and has the

disadvantage that it would not act as a speed protective device.

The Woodward governor, on the other

hand, operates the wicket gates of the turbine. Thus,

if the load drops off, the generator and turbine tend

to speed up.

The governor will then cut down the

quantity of water supplied, causing an economical use

of the water as well as a means of regulating the voltage.

The switching apparatus will be on one

panel.

The panel will consist of a field rheostat,

fuses, switch, ammeter, voltmeter, and a ground detector.

The fuses will have ample capacity for

the generator and will be used as a protection

against a direct short circuit of the entire system.

Each branch circuit will be protected by smaller

fuses.

This arrangement enables the generator to

supply power to most of the load even though there is

a short circuit in some branch.

The ammeter and voltmeter are not essential

to the operation of the plant but are of practical

value, since they may be used to learn the output of

the plant.

The ammeter also enables one to detect

partial short circuits.

21.

The system will be connected to ground

through a ground detector.

This consists of two

low power lights connected in series across the line

and connected to ground at a point midway between the

two.

The ground connection is made through a galvan-

ized iron pipe, which is driven five or six feet into

the ground, which, being damp, is a good conductor.

The ground detector operates to show when a break in

the insulation occurs.

A single break is of no im-

portance in itself, but in case of a second break, a

short circuit may occur.

The instant a break in the

insulation is made, a connection to ground is obtained,

and one of the lights burn more brightly than the

other.

This is a warning to repair the break before

a short circuit occurs.

There will be no devices to protect against

lightning, because any danger from this source is

practically nil.

The line will not be exposed to

any great degree and the capacitance of the line will

be low, due to the fact that it is short and close to

the ground, with wires of small diameter.

22.

EFFICIENCY OF THE UNIT

The overall efficiency of the plant cannot

The generator

be much greater than sixty percent.

and turbine will operate at slightly over eighty

percent efficiency.

The losses in the pipe line and

belt transmission of power are small, but should also

be considered.

The belt loss will be assumed as five

percent in the computations to obtain the overall

efficiency.

The efficiency curve of the turbine (Appendix

B and C) was plotted from data furnished by the General Electric Company.

The efficiency curve of the turbine (Appendix

D) was plotted from a Holyoke test

466, made January

17, 1890, upon a 12 inch wheel of the same series as

the wheel to be installed.

A study of the curves shows that to obtain

a good economy, the plant should be operated at a load

varying from five to seven kilowatts.

At smaller loads

the turbine and generator losses increase rapidly; at

higher loads the turbine and pipe losses increase

rapidly.

23.

COST OF PLAITT

The detailed cost of the plant follows:

Dan an& Spillway

V1200.00

Vood stave pipe (225 feet) A. V. Garratt Co.

600.00

9-inch McCormick turbine

S. Morgan Smith Co.

275.00

Iron flume for turbine

S.

210.00

Morgan Smith Co.

Yloodward governor

7 K.W.

generator

400.00

General Electric Co.

Power House

231.00

600.00

Switchboard panel

General Electric Co.

86.70

Gate Valves

Chapman Valve Mfg.Co

230.00

900 Bond - 24" radius

Davis & Farnum Co.

59.50

4-inch leather belt

Olmsted Flint Co.

15.00

Incidentals

192.80

Installation of apparatus

100.00

Total

Allow 15fo for contingencies

:?4200.00

630.00

Total

4830.00

24.

COST OF POIER.

Assuming the plant will be run for eight

hours per day, at an efficiency of 55 per cent.

H.

P. : 1.5 x 62.5 x .55 x 19

550

5.36 x .746

x 24

5.36

-

= 4 K-W.

Interest and. depreciation on development at 10%.

4800 x 010 = 1)480

480 - .120 per K.

W.

year.

4

_

120

= 6O.041 per K. V1. hour.

8 x 365

Cost per K.V7.H. from Lawrence Gas Co.

for a lighting load

Cost per K.VI.H.

00.125

of hydro-electric power

0.041

Saving per K.!.H.

Saving per year

-

90.084

365 days of 8 hours each

.084 x 8 x 365 = .245.

The cost of operation will be very small,

as the

process consists only in starting and, stopping of the

turbine and the lubrication of the bearings.

25.

RECOIEUTDAT IOITS

Wve conclude, from the foregoing investigation, that the plant is feasible, and recommend

that it be built.

We further recommend that the owner build

the dam, the spillway, and the power house, thus reducing the initial cost of the plant by very nearly

.41500. 00.

We also recommend that construction of the

dam and spillway be started in the early spring in

order that the dam will have had sufficient time to

become thoroughly settled before the spring freshets

of the following year.

Respectfully submitted,

A P P E N D I X

A.

.

.

.....

.T

+

' c

7

7

£

~

~A

7

7/0Lo5I

fP

I7FIT

V1

.4J2c

7_'~~~

r1

r~

-78-1OfLS-,

Ii

I117

I

7

ri

.4

__

I

I 1I

I

j

(Sec.F/')

1

7

c5~

APPENDI

CES

B&C.

11

- -

tT

-

--

_771=

-i

-

-7

-7

1

F~1

7 -

-71777

7-

I

-7

/fCCC

__~~YE

_

n

-

2~V

I T~

71 771

Qr4<j

ji-

'I'

-7

1

7.

IIt

/00

-T7

go

do-

1

1

I

I

f

7

77

40

I7£

S--

77177

---4--

/0

icr

Get'en -04

0

/

2

3

4

4

S6

T,

i

i

ol

{

.1_____

___

I

1,-I

______

[

i

I

I

1

~

I

I

_______

I

I

I

I

6>'

-

I

L

I

F~1Il

___

I

t

I

I

jili

1

1

-~

1

---

I

~-

___

o

II

/

_____

It

I

j

___

L.i:.

__

I

f

'7;

I

I

I

-

I

j~Z~

1

-1

I

II

1-

-~

I

I

I

I Ii

__________

t

1

ri-

&eflerctOr

__

I

I

I

II

I

I

04'/pa<

(/i~kV)

I

I

_________

~

6

:7

8

,'

.- '

A P PE N D I X

D.

~

III

7

77-7

ft

i--777,

I

J

Z

0

oti

_L'_5

I

_-_6_ _ _

A P P E Y D I X

E.

6

-

------

V~f~

i- A-

APPENDIX F.

DATA FOR CURVES.

The size of the pipe was limited by the

losses, due to friction.

The loss in a pipe line

in feet of head is expressed by the formula F

D

V2

2~g

where "f" is the friction coefficient of the pipe,

"1" is the length in feet, "d" the diameter in feet,

"TvI the velocity in the pipe in feet per second, and

"g1 the acceleration due to gravity.

This formula

shows that for a given quantity of water, the head

lost in the pipe is inversely proportional to the fifth

power of the diameter because the velocity is inversely

proportional to the second power of "d".

If the load cycle of the plant were known,

the most economical size of pipe could be accurately

calculated.

This would be computed by making the sum

of the value of the lost power and the depreciation

charges a minimum.

to it

The loss cannot be computed due

being dependent upon the quantity of water flowing,

and as this is a variable, it became necessary to choose

a pipe which gave a reasonable lost head without too

great a velocity.

An eighteen inch pipe was decided upon, since

F

it

came closer to the requirements than any other;

the curve of lost head in feet plotted against the

quantity of water flowing is shown in the Graph

(Appendix A).

The lost head is.made up of an entrance

loss, a loss in the bend, and a friction loss in the

pipe.

The entrance loss and the loss at the bend are

both proportional to the square of the velocity.

entrance loss being C

2 g

The

as is also the loss at the

bond; C for the entrance loss, being .5 and that for

the bend about .194.

The entrance loss will be dimin-

ished by flaring the entrance, so that the entrance

velocity will not exceed 1.5 feet per second.

The loss at the bend is a function of d/r

where "d" is the diameter of the pipe and "r" the radius

of the bend.

For this case d/r is .75,

and "0" is .194.

The velocity of the water will not exceed four feet per

second.

.194 x 16

64

The lost head at the bend cannot exceed

.048 feet, which is too small to take into

account, since the level of the water in the reservoir

will vary much more than that.

Other factors which should be taken into account in the construction of pipe lines are water, hammer

and vacuum in the pipe.

Since the pipe line in this

F.

project is very short, comparatively no danger

from water

hammer, nor vacuum is expected.

I

(1) Lost head in pipe line

q

Lost head

.619

.0047

1.238

.0167

2.166

.048

3.868

.190

5.410

.360

6.960

.575

7.740

.710

(2) Efficiency of generator ( Data from G.E. Co.)

Load

Efficiency

280%

3

83

Full

84

(3) Efficiency of Turbine

Q

(Data from Holyoke Test)

Efficiency

3.45

64.78;

4.28

72.90

5.16

81.13

5.70

82.29

6.53

80.36

(4)

Overall efficiency.

Power at dam

H.P. to turbine

H. P.

K.W.

6*48

4.83

6*45

8.64

6.44

11.78

H.P. output of

turbine

Generator input

5% belt loss

Generator

output

Overall

efficiency

H. P.

K. W.

3.,64

3*46

2*58

8.56

6.12

5.64

4.21

8.89

11.58

9*38

8.65

6*45

540

61*4

12.96

9.67

12.65

10.35

9.70

7.23

606

62.7

14.02

10.47

13.62

11.30

10.72

8.00

670

64.0

K. W.

168

34*8

51.6

F.

'IJR READINGS.

Date

Read

Sept. 8

"

.85'

9

.85

10

.83

"11

Date

Read

Oct. 1

"T

.49'

Date

Read

1ov. 1

.85'

Date

Read

Dec. 1

.60'

2

.48

"

2

.85

"t

2

.65

3

47

"

3

.84

"

3

.75

.84

"

4

46

"

4

.80

"

4

.65

12 1.10

"

5

.45

"

5

.85

"

5

.65

13 1.05

"

6

.45

"

6

.85

"

6

.70

"

14 1.00

"

7

.50

IT

7

.95

IT

7

.65

"

15

.93

it

8

.60

IT

8

1.05

it

8

.60

16 1.03

"

9

.70

"T

9

.85

It

9

.60

"

17 1.00

"

10

.70

it

10

.95

"

10

.65

"T

18

.85

"

11

.70

"

11

.75

"

11

"T 19

.75

"

12

.80

"

12

.70

"

12

i

20

.80

"

13

.80

"

13

.75

"

21

.63

i

14

.80

T

14

"

22

.63

"?

15

.90

i

15

"

23

.63

"

16

.90

"

16

.65

"

24

.55

"

17

"

17

.60

18

.60

"

we ir

broken

"

25

.50

"

18

"

26

.50

it

19

"

19

.50

"

27

.50

I

20

"

20

.90

"

28

.50

it

21

"

21

.85

.65

P.

Weir Readings (Cont'd).

Date

Read

Sept. 29

"

30

.50

.50

Date

Read

Oct. 22

Date

Read.

Uov. 22

.90

IT

23

"

23

.75

"

24

"t

24

.70

"

25

weir

"t 25

.75

"

26

broken

"

26

.65

"

27

"t

27

.60

"

28

"t

28

.60

"

29

29

.75

30

.65

.

"?

ol

K