C8A: “ A” Certificate Program in Textiles Name of Program Sr.No Course

advertisement

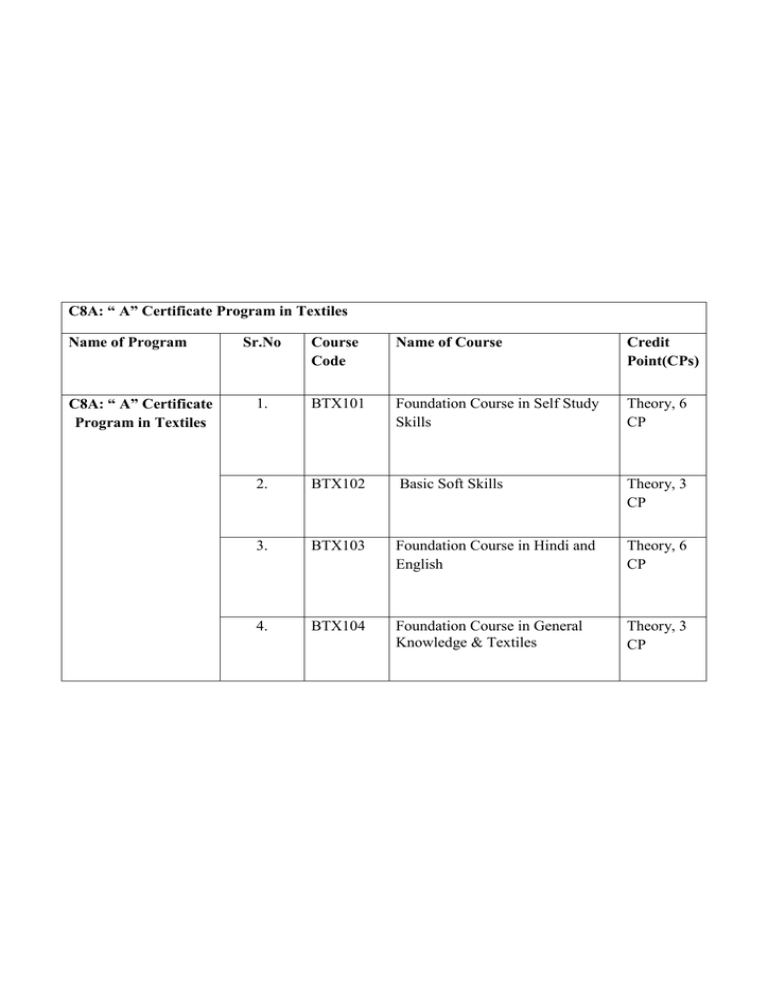

C8A: “ A” Certificate Program in Textiles Name of Program C8A: “ A” Certificate Program in Textiles Sr.No Course Code Name of Course Credit Point(CPs) 1. BTX101 Foundation Course in Self Study Skills Theory, 6 CP 2. BTX102 Basic Soft Skills Theory, 3 CP 3. BTX103 Foundation Course in Hindi and English Theory, 6 CP 4. BTX104 Foundation Course in General Knowledge & Textiles Theory, 3 CP C8B: “B” Certificate Program in Textiles C8B: “B” Certificate Program in Textiles 1. BTX105 Advanced Soft Skills Theory, 3 CP 2. BTX106 ICT literacy Theory, 3 CP 3. BTX107 Foundation Course in Social Sciences Theory, 6 CP 4. BTX108 Elements of Textiles : Processes , Products and applications Theory, 6 CP C8B: ”B” Certificate Programme in Textiles Syllabus: 1. BTX 105 : † ò›ü¾Æü֮Ûü ÃÖÖ °ò ™ü×ÃÛú»ÃÖ ¯ÖãßÖÛú 1 - þ֟Ö:“ÖÖ ¾Ö ‡ŸÖ¸üÖ“Ó ÖÖ ×¾ÖÛúÖÃÖ ‘Ö™üÛú 1 - ÝÖ™üÖ´Ö¬µÖê ÛúÖ´Ö Ûú¸üÞÖê 1.2 •Ö㮵ÖÖ ´ÖÖ®Ö×ÃÖÛúŸÖêŸÖæ®Ö ²ÖÖÆêü¸ü ¯Ö›üÞÖê 1.3 ÃÖÓãÖêÃÖÖšüß ÃÖÓ‘ÖÖ“Öê ´ÖÆüŸ¾Ö 1.3.1 ÃÖÓãÖêŸÖᯙ ‰ú¬¾ÖÔÝÖÖ´Öß †Ö×ÞÖ †¬ÖÖêÝÖÖ´Öß ¿ÖŒŸÖß 1.4 ÃÖÓ‘ÖÖ“Öß ¾µÖÖܵÖÖ †Ö×ÞÖ ±úÖµÖ¤êü 1,5 ÃÖÓ‘ÖÖ“Öê ¯ÖÏÛúÖ¸ü 1,6 ÃÖÓ‘Ö²ÖÖÓ¬ÖÞÖß»ÖÖ Ûú¬Öß ÃÖãºþ¾ÖÖŸÖ ÆüÖŸê Öê? 1,7 ¯Ö׸üÞÖÖ´ÖÛúÖ¸üÛú ¾Ö ˆ¢Ö´Ö ÛúÖµÖÔ Ûú¸üÞÖÖ-µÖÖ ÃÖÓ‘ÖÖ“Öß ¾Öî׿Ö™ü¶ê 1.8 ˆŸ¯ÖÖ¤üÛú ÃÖÓ‘Ö ÛúÃÖÖ ÛúÖ´Ö Ûú¸üŸÖÖê? 1.9 ÃÖÓ‘Ö²ÖÖÓ¬ÖÞÖß“Öê “ÖÛÎú 1.10 ÃÖÓ‘ÖÖ“µÖÖ ×¾ÖÛúÖÃÖÖ“Öß ¯ÖÏÝÖŸÖß 1.11 ÃÖÓ‘Ö²ÖÖÓ¬ÖÞÖß“Öê ®Ö´Öã®Öê 1.12 ÃÖÓ‘ÖÖ“µÖÖ ÛúÖµÖÔ¯ÖϾÖÞÖŸÖê“Öê ¯ÖÏÖºþ¯Ö 1.13 ÃÖÓ‘ÖÖ“µÖÖ ×¾ÖÛúÖÃÖÖ“µÖÖ ¯ÖÖµÖ-µÖÖÓ“Öê ¯ÖÏÖºþ¯Ö 1.14 ÃÖÓ‘Ö²ÖÖÓ¬ÖÞÖß“Öß ¯Ö›üŸÖÖôûÞÖß ÃÖæ“Öß 1.15 ÃÖÓ‘Ö ×¾ÖÛúÖÃÖÖ“Öê Ûúôûß“Öê ´Öã§üê 1.16 ÛúÖ´Ö Ûú¸üÞÖÖ-µÖÖ ÃÖÓ‘ÖÖŸÖᯙ ³Öæ×´ÖÛúÖ 1.17 ¾µÖŒŸÖà®ÖÖ µÖ¿ÖþÖß ÃÖÓ‘Ö ²Ö®Ö×¾ÖÞµÖÖ“Öß ÃÖÖŸÖ ŸÖŸ¾Öê ‘Ö™üÛú 2 : þ֟Ö:“Öê †Ö×ÞÖ ‡ŸÖ¸üÖ“Ó Öê ¾µÖ׌ŸÖŸ¾Ö ¯ÖÏŸµÖÖê•Ö®ÖÖ®Öê ÃÖÓ¾ÖÙ¬ÖŸÖ Ûú¸üÞÖê 2.2 ÃÖ¢ÖÖ ´ÆüÞÖ•Öê ÛúÖµÖ? 2.3 ÃÖŸÖÖŸÖ †Ö×ÞÖ ¯ÖÏŸµÖÖµÖÖê•Ö®Ö 2.4 ¯ÖÏŸµÖÖµÖÖê•Ö®Ö ´ÆüÞÖ•Öê ÛúÖµÖ? 2.4.1 þÖÖ¬µÖÖµÖ 2.4.2 ¯ÖÏŸµÖÖµÖÖê•Ö®Ö Ûú¿ÖÖÃÖÖšüß? 2.5 ¯ÖÏŸµÖÖµÖÖê•Ö®ÖÖŸÖᯙ †›ü£Öôêû 2.5.1 ¾µÖ¾ÖãÖÖ¯ÖÛúÖÛú›æü®Ö ÆüÖÞê ÖÖ¸êü †›ü£Öôêû 2.5.2 Ûú´ÖÔ“ÖÖ¸üß¾ÖÝÖÖÔŸÖᯙ †›ü£Öôêû 2.5.3 ¯Ö׸ü×ã֟Öß ØÛú¾ÖÖ ÃÖÓãÖêŸÖᯙ †›ü£Öôêû 2.6 ¯ÖÏŸµÖÖµÖÖê•Ö®Ö : ÛúÖµÖ †ÖÆêü †Ö×ÞÖ ÛúÖµÖ ®ÖÖÆüß 2.7 µÖ¿ÖþÖß ¯ÖÏŸµÖÖµÖÖê•Ö®ÖÖ“µÖÖ †Öšü ¯ÖÖµÖ-µÖÖ ‘Ö™üÛú 3 : ÃÖõÖ´ÖßÛú¸üÞÖÖ«üÖ¸êü ¾Ö ˆ¯Ö•Ö“Ö ÛúÖî¿Ö»µÖê ×¾ÖÛú×ÃÖŸÖ Ûúºþ®Ö þ֟Ö:“µÖÖ ¾Ö ‡ŸÖ¸üÖ“Ó µÖÖ ¾µÖ׌ŸÖ´ÖŸ¾ÖÖ“Öê ÃÖÓ¾Ö¬ÖÔ®Ö Ûú¸üÞÖê 3.2 3.3 3.4 3.5 ´ÖÖÞÖÃÖÖÓ“Öê ÃÖõÖ´ÖßÛú¸üÞÖ ¾µÖÖ¾ÖÃÖÖ×µÖÛú ¾ÖÖŸÖÖ¾Ö¸üÞÖÖ´Ö¬µÖê ÃÖõÖ´ÖßÛú¸üÞÖ Ûú¸üÞÖê ÃÖõÖ´ÖßÛú¸üÞÖ ´ÆüÞÖ•Öê ÛúÖµÖ? ÃÖõÖ´ÖßÛú¸üÞÖ ÆüÖ ®ÖêŸÖ韾ÖÖ“ÖÖ ´ÖÆüŸ¾Ö¯ÖæÞÖÔ (†Ö¾Ö¿µÖÛú) ‘Ö™üÛú †ÖÆêü 3.5.1 ×¾ÖÛúÖÃÖ †Ö×ÞÖ ÃÖõÖ´ÖßÛú¸üÞÖÖ“Öê ¯Ö׸üÞÖÖ´Ö 3.5.2 ÃÖÓãÖÖŸ´ÖÛú ¯Ö׸üÞÖÖ´ÖÛúÖ¸üÛúŸÖꓵÖÖ ×¾Ö¬ÖÖÔ¸üÛúÖÓ“Öê ¯ÖÏÖºþ¯Ö 3.6 ÝÖãŸÓ Ö¾ÖÞÖßÛú †Ö×ÞÖ ˆ¯Ö•Ö“Ö ÛúÖî¿Ö»µÖ ´ÆüÞÖ•Öê ÛúÖµÖ? 3.6.1 ˆ¯Ö•ÖŸÖ ÛúÖî¿Ö»µÖ ´ÆüÞÖ•Öê ÛúÖµÖ? 3.6.2 ˆ¯Ö•ÖŸÖ ÛúÖî¿Ö»µÖÖÓ“Öê ¾µÖ¾ÖãÖÖ¯Ö®Ö ØÛú¾ÖÖ ´ÖÖ®Ö¾Öß ³ÖÖÓ›ü¾Ö»ÖÖ“Öê ¾µÖ¾ÖãÖÖ¯Ö®Ö ´ÆüÞÖ•Öê ÛúÖµÖ? 3.6.3 ˆ¯Ö•ÖŸÖ ÛúÖî¿Ö»µÖÖ“µÖÖ ó̵־ÖãÖÖ¯Ö®ÖÖŸÖ †ÓŸÖ³ÖæŸÔ Ö ÝÖÖê™üß 3.6.4 ˆ¯Ö•ÖŸÖ Ûãú¿Ö»Ö ×¾Öºþ¬¤ü ´ÖÖÆüߟÖÝÖÖ¸ü Û´ÖÔ“ÖÖ¸üß ¾ÖÝÖÔ 3.6.5 ¾ÖŸÖÔ´ÖÖ®Ö †Ö×ÞÖ ³Ö×¾ÖµÖÖŸÖ ¯Öãœüê •ÖÖÞµÖÖÃÖÖšüß ÃÖÓãÖÖÓ®Öß ¤üÖê®Ö ÝÖÖê™üà¾Ö¸ü ³Ö¸ü ªÖµÖ»ÖÖ Æü¾ÖÖ 3.7 ®ÖÖêÛú¸ü¾ÖÝÖÖÔ“Öß ÝÖãÓŸÖ¾ÖÞÖæÛú Ö×ÞÖ ˆ¯Ö•Ö“Ö ÛúÖî¿Ö»µÖÖÓ“Öß ×¾ÖÛúÖÃÖ ¯ÖÏ×ÛÎúµÖÖ ‘Ö™üÛú 4 : ¯Öϸê üÌÞÖÖ ¤êü‰ú®Ö þ֟Ö:“Öê †Ö×ÞÖ ‡ŸÖ¸üÖ“Ó Öê ¾µÖ׌ŸÖŸ¾Ö ÃÖÓ¾ÖÙ¬ÖŸÖ Ûú¸üÞÖê 4.2 ¯Öϸê üÞÖê“Öß ¾µÖÖܵÖÖ 4.3 ¯Öϸê üÞÖÖ ´ÆüÞÖ•Öê ÛúÖµÖ? 4.4 ¯Öϸê üÞÖê“Öê ×ÃÖ¬¤üÖŸÓ Ö 4.4.1 †²ÖÎÖÆü´Ö ´ÖÖ Ãò »ÖÖê“ÖÖ ÝÖ¸ü•Ö ¾Ö“ÖÔÃ¾Ö ×ÃÖ¬¤üÖŸÓ Ö 4.4.2 ›üÝ»ÖÃÖ ´ÖòÛúÝÖÏÝê ÖÏÖ òÝÖ¸ü µÖÖÓ“ÖÖ ×ÃÖ¬¤üÖÓŸÖ X †Ö×ÞÖ ×ÃÖ¬¤üÖŸÖ Y 4.4.3 ±Ïúê ›ü׸üÛú Æü—ÖÔ²ÖÝÖÔ“ÖÖ ¯Öϸê üÞÖÖ †Ö¸üÖÝê µÖ ×ÃÖ¬¤üÖŸÓ Ö 4.4.4 ‹»™ü®Ö ´ÖêµÖÖê µÖÖÓ“Öê µÖÖêÝÖ¤üÖ®Ö 4.4.5 ¾ÖÎæ´Ö µÖÖÓ“ÖÖ ¯Ö׸üÞÖÖ´ÖÖÓ“Öê ×ã֟Öß–ÖÖ®Ö ×¾Ö. †¯ÖêõÖÖ ×ÃÖ¬¤üÖŸÓ Ö 4.4.6 ¯ÖÖê™Ôü¸ü †Ö×ÞÖ »ÖÖ »ò Ö¸ü µÖÖÓ“Öê ¯ÖÏÖºþ¯Ö 4.4.7 Œ»Öê™ü®Ö †Ö»›ü¸ü±ú¸ü µÖÖÓ“ÖÖ †×ß֟¾Ö ¯Ö¸üïָü ÃÖÓ²ÖÓ¬Ö †ÃÖ»µÖÖ“Öß ³ÖÖ¾Ö®ÖÖ - ¾ÖÖœü (ERG) ×ÃÖ¬¤üÖŸÓ Ö 4.4.8 ´ÖòÛúŒ»Öê»ÖÑ›ü µÖÖÓ“ÖÖ ÝÖ¸ü•Ö ×ÃÖ¬¤üÖŸÓ Ö 4.5 ŸÖã´Ö“µÖÖ Ûú´ÖÔ“ÖÖ¸üß¾ÖÝÖÖÔ»ÖÖ ÛúÃÖê ¯ÖÏ×ê ¸üŸÖ Ûú¸üÖ»Ö? 4.5.1 ¯ÖµÖì¾ÖêõÖÛúÖ®Öê »ÖõÖÖŸÖ ‘ÖêÞµÖÖ“Öê ÛúÖÆüß ÃÖ»»Öê 4.6 ÛúÖ´ÖÖ´Ö¬Öᯙ ¯Öϸê üÞÖÖ×¾ÖÂÖµÖÛú ÃÖã¯ŸÖ ÝÖãÞÖ ¾ÖÖœü¾ÖÞÖê 4.6.1 ÛúÖ´ÖÖŸÖᯙ ¯ÖÏê¸üÛú ÃÖã¯ŸÖ ×ÝÖÞÖÃÖÓܵÖÖ/ÛúÖ´ÖÖ“Öê ®Öî¤üÖ×®ÖÛú ÃÖ¾ÖìõÖÞÖ ¯ÖÏ¿®ÖÖ¾Ö»Öß 4.7 ÃÖÓãÖÖÓ´Ö¬µÖê ¯Öϸê üÞÖÖ¤üÖµÖß ÛúÖµÖÔÛúÎ ´ÖÖÓ“Öê ×¾ÖÛúÃÖ®Ö Ûú¸üÞÖê 4.8 ÃÖ´ÖÖ¯ŸÖß“µÖÖ ®ÖÖë¤üß ¾Ö ÃÖÖ¸üÖ¿Ó Ö ‘Ö™üÛú 5 : ®ÖêŸÖ韾ÖÖ«üÖ¸êü þ֟Ö:“µÖÖ †Ö×ÞÖ ‡ŸÖ¸üÖ“Ó µÖÖ ¾µÖ׌ŸÖ´ÖŸ¾ÖÖ“Öê ÃÖÓ¾Ö¬ÖÔ®Ö Ûú¸üÞÖê 5.2 ®ÖêŸÖéŸ¾Ö ´ÆüÞÖ•Öê ÛúÖµÖ? 5.2.1 †ÖÞÖÜÖß ÛúÖÆüß ¾µÖÖܵÖÖ 5.2.2 ®ÖêŸÖ韾ÖÖ“µÖÖ ³Öæ×´ÖÛêú×¾ÖÂÖµÖß ŸÖµÖÖ¸ü †ÃÖÞµÖÖ“ÖÖ Ã¾ÖÖ¬µÖÖµÖ 5.3 ¾µÖŒŸÖß»ÖÖ µÖ¿ÖþÖß ®ÖêŸÖÖ ÆüÖÞê µÖÖÃÖÖšüß Ûú¿ÖÖ“Öß ÝÖ¸ü•Ö †ÖÆêü? 5.3.1 ÃÖ•ÖÔ®Ö¿Öᯙ ®ÖꟵÖÖ“µÖÖ ¾µÖ׌ŸÖ´ÖŸ¾ÖÖŸÖᯙ ¾ÖêÝÖôûß †ÖêôûÜÖŸÖÖ µÖêÞÖÖ¸üß ¾Öî׿Ö™ü¶ê 5.4 ®ÖêŸÖ韾ÖÖ“Öê ×ÃÖ¬¤üÖÓŸÖ 5.4.1 ®ÖêŸÖ韾ÖÖ“ÖÖ ¯Ö׸ü¾ÖŸÖÔ®ÖßµÖ ×ÃÖ¬¤üÖŸÓ Ö 5.4.2 ®ÖêŸÖê ¾µÖ¾ÖãÖÖ¯ÖÛú ®Ö¾ÆêüŸÖ 5.4.3 ¯Ö׸ü¾ÖŸÖÔ®ÖßµÖ †Ö×ÞÖ ¾µÖÖ¾ÖÆüÖ׸üÛú ®ÖꟵÖÖÓ“Öß ¾Öî׿Ö™ü¶ê 5.4.4 ¯Ö׸ü¾ÖŸÖÔ¾ÖßµÖ †Ö×ÞÖ ¾µÖÖ¾ÖÆüÖ׸üÛú ®ÖêŸÖ韾ÖÖ¾Ö¸ü þÖÖ¬µÖÖµÖ 5.5 †®ÖãÛú¸üÞÖßµÖ ®ÖêŸÖ韾ÖÖ“ÖÖ ×ÃÖ¬¤üÖŸÓ Ö 5.5.1 †®ÖãÛú¸üÞÖßµÖ ®ÖêŸÖ韾ÖÖ“µÖÖ 10 •Ö²ÖÖ²Ö¤üÖ-µÖÖ ¯ÖãßÖÛú 5 : †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÛúÖî¿Ö»µÖê ‘Ö™üÛú 1 : †ÖŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ‘Ö : ´ÖÆüŸ¾Ö †Ö×ÞÖ ±úÖµÖ¤êü 1.3 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö †Ö×ÞÖ ŸµÖÖ“Öê ±úÖµÖ¤êü 1.3.1 ¿ÖÖ¸üß׸üÛú, ²ÖÖî׬¤üÛú ¾Ö ÃÖÖ´ÖÖוÖÛú ×¾ÖÛúÖÃÖ 1.3.2 ´Öß ÛúÖêÞÖ µÖÖ ¯ÖÏ¿®ÖÖ“Öê ˆ¢Ö¸ü 1.3.3 Ã¾Ö ¾Ö Ã¾Ö – ÃÖÓÛú»¯Ö®Öê“ÖÖ ×¾ÖÛúÖÃÖ 1.3.4 †Ö¯Ö»Öê ´ÖÖ®Ö×ÃÖÛú þÖÖãµÖ 1.3.5 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö ¾Ö ¿Ö¸ü߸ü¿ÖÖáÖßµÖ ¥ü“Öß 1.3.6 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ‘Ö ¾Ö ÃÖ´ÖÖ•ÖîןÖÆüÖ×ÃÖÛú ¥ü™üß 1.3.7 ¾µÖÖ¾ÖÃÖÖ×µÖÛú µÖ¿Ö ¾Ö †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö 1.3.8 ¾µÖŒŸÖß“ÖÖ Ã¾Ö, Ã¾Ö - ÃÖÓÛú»¯Ö®ÖÖ ¾Ö †ÖŸ´Ö×¾ÖÂÛúÖ¸ü 1.4 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö †Ö×ÞÖ ¾µÖ׌ŸÖ´ÖŸ¾Ö 1.4.1 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö †Ö×ÞÖ ¾µÖ׌ŸÖ´ÖŸ¾ÖÖ“ÖÖ ×«ü×´ÖŸÖßµÖ ×ÃÖ¬¤üÖŸÓ Ö 1.5 †ÖÓŸÖ¸ü¾µÖŒŸÖßÛú ÃÖÓ²ÖÓ¬Ö †Ö×ÞÖ ÃÖÖ´ÖÖוÖÛú ¾Ö ÃÖÖÓÃÛéúןÖÛú ¯Ö׸ü¾ÖêõÖ ‘Ö™üÛú 2 :×¾Ö×®Ö´ÖµÖ ×¾Ö¿»ÖêÂÖÞÖ (™Òüò ®—ÖòŒ¿Ö®Ö»Ö † ®ò Öò×»ÖÃÖßÃÖ) 2.2 ×¾ÖÂÖµÖ - ×¾Ö¾Öê“Ö®Ö 2.2.1 ºþ¯Ö¸êüÂÖÖ 2.2.2 ×¾Ö×®Ö´ÖµÖ ×¾Ö¿»ÖêÂÖÞÖÖ“Öß ³Öæ×´ÖÛúÖ 2.2.3 ×¾Ö×®Ö´ÖµÖ ×¾Ö¿»ÖêÂÖÞÖÖŸÖÖ»Ö ´ÖÆüŸ¾ÖÖ“µÖÖ ÃÖÓÛú»¯Ö®ÖÖ 2.3 ´ÖÖ®Ö×ÃÖÛú †Æü´ÖË †¾ÖãÖÖ (‡ÝÖÖêÙêü™üË ÃÖ) 2.3.1 ´ÖÖ®Ö×ÃÖÛú †Æü´ÖË †¾ÖãÖÖÓ“µÖÖ ×®Ö¤üÖ®ÖÖ“µÖÖ ÜÖãÞÖÖ 2.3.2 †Æü´ÖË †¾ÖãÖÖ ÃÖÓ²ÖÓ¬ÖÖŸÖᯙ ´ÖÆüŸ¾ÖÖ“Öê ´Öã§üê 2.3.3 ÃÖÓŸÖã×»ÖŸÖ ¾µÖ׌ŸÖ´ÖŸ¾Ö 2.3.4 †Æü´Ö“µÖÖ ¯ÖÏ´ÖÖÞÖÖ“Öê ¸êüÜÖÖ×“Ö¡Ö (‡ÝÖÖêÝÖÏ´ò Ö) 2.3.5 †Æü´Ö †¾ÖãÖÖÓ“Öê ¯ÖÏÖŸµÖ×õÖÛú 2.4 ×¾Ö×®Ö´ÖµÖ ×¾Ö¿»ÖêÂÖÞÖ 2.4.1 ÃÖÓ¯ÖÏêÂÖÞÖÖŸÖß»Ö ×¾Ö×®Ö´ÖµÖÖ“Öê ¯ÖÏÛúÖ¸ü 2.5 •Öß¾Ö®Ö ¥ü×™üÛúÖê®Ö, ¯Öϸê üÛúê †Ö×ÞÖ ÜÖêôû (Life Positions, Strokes and Games) 2.5.1 “ÖÖ¸ü •Öß¾Ö®Ö ¥ü×™üÛúÖê®Ö 2.5.2 ¯Öϸê üÛúê 2.5.3 »ÖÖêÛú ”ãû¯Öê ÜÖêôû ÜÖêôûŸÖÖŸÖ ‘Ö™üÛú 3 : †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö : •ÖÖêÆòü¸üß ¯ÖÏÖºþ¯Ö 3.2 •ÖÖêÆüò ¸üß ÝÖ¾ÖÖõÖ ¯ÖÏÖºþ¯Ö : ×¾ÖÂÖµÖ ×¾Ö¾Öê“Ö®Ö 3.2.1 Ã¾Ö ¯ÖÏןִÖÖ ¾Ö ÃÖÖ´ÖÖוÖÛú ¯ÖÏןִÖÖ 3.2.2 ¾ÖÖÃŸÖ¾Ö ¯ÖÏןִÖê“Öß •ÖÖÞÖ 3.3 •ÖÖêÆüò ¸üß ÝÖ¾ÖÖõÖ ¯ÖÏÖºþ¯Ö : ¾ÖÞÖÔ®Ö 3.3.1 “ÖÖ¸üÆüß ³ÖÖÝÖÖÓ“Öê õÖê¡Ö Ûú´Öß - •ÖÖÃŸÖ Ûú¸üÞÖê 3.3.2 ¯Öã®Ö³ÖÔ¸üÞÖÖ“Öß ¤êü¾ÖÖÞÖ - ‘Öê¾ÖÖÞÖ 3.4 ¯Öã®Ö³ÖÔ¸üÞÖ : ‹Ûú ÛúÖî¿Ö»µÖ 3.4.1 ¯Öã®Ö³ÖÔ¸üÞÖ ¾µÖÖ¯ÖÛú ÃÖÓÛú»¯Ö®ÖÖ 3.4.2 ¯Öã®Ö³ÖÔ¸üÞÖÖ“Öß ¤êü¾ÖÖÞÖ - ‘Öê¾ÖÖÞÖ 3.4.3 ¯Öã®Ö³ÖÔ¸üÞÖÖ“Öß ¯Ö׸üÞÖÖ´ÖÛúÖ¸üÛúŸÖÖ : ÛúÖÆüß ŸÖŸ¾Öê ‘Ö™üÛú - 4 : †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö : ×¾ÖÀ¾ÖÖÃÖ †Ö×ÞÖ ¯ÖÖ¸ü¤ü¿ÖÔÛúŸÖê“Öß ³Öæ×´ÖÛúÖ (¸üÖ»ê Ö †Ö ±ò ú ™ÒüÙü †Ñ›ü ™üÖ®ÃÖÔ¯Ö¸ü®ÃÖß ‡®Ö ‡Ó™ü¸ü¯ÖÃÖÔ®Ö»Ö ×¸ü»Öê¿Ö®ÃÖ) 4.3 ×¾ÖÀ¾ÖÖÃÖ : þֺþ¯Ö †Ö×ÞÖ ¾µÖÖܵÖÖ 4.3.1 ×¾ÖÀ¾ÖÖÃÖæ ¾µÖŒŸÖß“Öß »ÖõÖÞÖê 4.3.2 ×¾ÖÀ¾ÖÖÃÖ šêü¾ÖÞµÖÖŸÖᯙ ´Öæ»ÖŸÖŸ¾Öê 4.3.3 ×¾ÖÀ¾ÖÖÃÖ †Ö×ÞÖ ×¾ÖÀ¾ÖÖÃÖÖÆÔüŸÖÖ 4.3.4 ×¾ÖÀ¾ÖÖÃÖ †Ö×ÞÖ ¯ÖÖ¸ü¤ü¿ÖÔÛúŸÖÖ 4.3.5 ¯ÖÏÖŸµÖ×õÖÛú 4.4 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ×¾Ö×®Ö´ÖµÖ : ×¾ÖÀ¾ÖÖÃÖ ×®ÖÙ´ÖŸÖß“Öê ¯ÖÏÖºþ¯Ö 4.5 ×¾ÖÀ¾ÖÖÃÖ †£Ö¾ÖÖ †×¾ÖÀ¾ÖÖÃÖ ×®ÖÙ´ÖŸÖß»ÖÖ ÃÖÖʳÖæŸÖ †×³Ö¾Öé¢Öß 4.5.1 ‘Ö×®Ö™ü †ÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬ÖÖ“Öß »ÖõÖÞÖê 4.6 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ×¾ÖÀ¾ÖÖÃÖ †Ö×ÞÖ ÃÖÓãÖÖÓ“Öê µÖ¿Ö 4.6.1 ¯Ö¸üïָü ×¾ÖÀ¾ÖÖÃÖ †Ö×ÞÖ ÃÖ¢ÖÖÃÖÓ‘ÖÂÖÔ 4.6.2 ÃÖÆüµÖÖêÝÖ †Ö×ÞÖ ÃÖÆüÛúÖµÖÔ ¾Ö ¯Ö¸üïָü ×¾ÖÀ¾ÖÖÃÖ ‘Ö™üÛú 5 - †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö : †¾µÖŒŸÖ ´Ö®ÖÖê¾µÖÖ¯ÖÖ¸üÖ“Ó ÖÖ ŸÖôû (†Ó•Ö¸üÓÖÑ›üË ÝÓ Ö ‡Ó™ü¸ü¯ÖÃÖÔ®Ö»Ö †Ó›ü¸ü¾Ö»›Ôü) 5.2 ×¾ÖÂÖµÖ ×¾Ö¾Öê“Ö®Ö 5.2.1 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÝÖ¸ü•ÖÖ : ¿Öã™üË —Ö µÖÖÓ“ÖÖ ×ÃÖ¬¤üÖŸÓ Ö 5.2.2 FIRO “Öß ¹ý¯Ö¸êüÂÖÖ 5.3 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÝÖ¸ü•ÖÖÓ“Öê ˆÝÖ´ÖãÖÖ®Ö 5.4 þֳÖÖ¾ÖÖ®Öãºþ¯Ö 5.5 ¾ÖÞÖÔ®Ö×¾ÖÂÖµÖÛú ÃÖ´ÖõÖÖ ¾Ö »ÖõÖÞÖê ¯ÖãßÖÛú 6 : ŸÖÖÞÖŸÖÞÖÖ¾Ö ¾µÖ¾ÖãÖÖ¯Ö®Ö ‘Ö™üÛú 1 : ŸÖÖÞÖŸÖÞÖÖ¾Ö : ÃÖÓÛú»¯Ö®ÖÖ †Ö×ÞÖ ÝÖãÞÖ¬Ö´ÖÔ 1.1 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“Öß ÃÖÓÛú»¯Ö®ÖÖ 1.2 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ¾Ö¸ü“Öê ¯Öæ¾Öá“Öê ×®Ö¾Ö›üÛú ÛúÖ´Ö (†³µÖÖÃÖ) 1.3 ¯ÖÏÖ“Öß®Ö ³ÖÖ¸üŸÖßµÖ ¾ÖÖ›Ëü.´ÖµÖÖŸÖᯙ ŸÖÖÞÖŸÖÞÖÖ¾Ö 1.4 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“Öß ¾µÖÖܵÖÖ †Ö×ÞÖ ÝÖãÞÖ¬Ö´ÖÔ 1.5 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖÓ“Öê ¯ÖÏÛúÖ¸ü : µÖæÙÒüê ÃÖ, ®µÖæÙÒüê ÃÖ ¾Ö ×›üÙÒêüÃÖ 1.6 ŸÖÖÞÖŸÖÞÖÖ¾Ö ¾Ö ÛúÖµÖÔ¯ÖϾÖÞÖŸÖÖ ‘Ö™üÛú 2 : ¾µÖÖ¾ÖÃÖÖ×µÖÛú ŸÖÖÞÖŸÖÞÖÖ¾Ö ×®ÖÙ´ÖŸÖß Ûú¸üÞÖÖ-µÖÖ ‘Ö™üÛúÖÓ“Öê ×¾Ö×¾Ö¬Ö ¯ÖÏÛúÖ¸ü 2.1 ŸÖÖÞÖŸÖÞÖÖ¾Ö ×®ÖÙ´ÖŸÖß Ûú¸üÞÖÖ¸êü ¾µÖ׌ŸÖÝÖŸÖ ‘Ö™üÛú 2.1.1 ¾ÖµÖ 2.1.2 Ø»ÖÝÖ 2.1.3 õÖ´ÖŸÖÖ †Ö×ÞÖ †®Öã³Ö¾Ö 2.1.4 ÃÖÖ´ÖÖוÖÛú - †ÖÙ£ÖÛú ¤ü•ÖÖÔ 2.2 ŸÖÖÞÖŸÖÞÖÖ¾Ö ×®Ö¸ü×´ÖŸÖß Ûú¸üÞÖÖ¸êü ¾µÖ׌ŸÖ´ÖŸ¾ÖÖŸÖᯙ ‘Ö™üÛú 2.2.1 ™üÖ‡Ô¯Ö - ¾ÖŸÖÔ®ÖÖ“Öß ¹ý¯Ö¸êüÜÖÖ 2.2.2 ™üÖ‡Ô¯Ö - ‹ ¾µÖ׌ŸÖ´ÖŸ¾Ö ¿ÖÖê׬ÖÛúÖ 2.2.3 ×®ÖµÖÓ¡ÖÞÖÖ“Öê Ûëú¦ü 2.2.4 ³ÖÖ¾Ö®ÖÖ¿Ö߻֟ÖÖ 2.3 ³Öæ×´ÖÛúÖÓ¾Ö¸ü †Ö¬ÖÖ׸üŸÖ ŸÖÖÞÖŸÖÞÖÖ¾Ö ×®ÖÙ´ÖŸÖß Ûú¸üÞÖÖ¸êü ‘Ö™üÛú 2.4 ŸÖÖÞÖŸÖÞÖÖ¾Ö ×®ÖÙ´ÖŸÖß Ûú¸üÞÖÖ¸êü ÃÖÓãÖêŸÖᯙ ‘Ö™üÛú 2.4.1 ®ÖÖêÛú¸üߟÖᯙ ŸÖÖÞÖŸÖÞÖÖ¾Ö 2.4.2 †ÖÓŸÖ¸ü¾µÖ׌ŸÖÛú ÃÖÓ²ÖÓ¬Ö 2.4.3 Ûú׸ü†¸ü“ÖÖ ×¾ÖÛúÖÃÖ 2.4.4 ÃÖÓãÖÖŸÖᯙ ¸ü“Ö®ÖÖ ¾Ö ¾ÖÖŸÖÖ¾Ö¸üÞÖ 2.5 ÃÖÓãÖê²ÖÖÆêü¸üᯙ ‘Ö™üÛú, †ÖµÖãµÖÖŸÖᯙ ´ÖÆüŸ¾ÖÖ“Öê ¯ÖÏÃÖÓÝÖ †Ö×ÞÖ ¤îü®ÖÓפü®Ö ÃÖÓ‘ÖÂÖÔ 2.5.1 ÛúÖ´Ö †Ö×ÞÖ ÛúÖ´ÖÖ²ÖÖÆêü¸üᯙ ŸÖÖÞÖŸÖÞÖÖ¾Ö †Ö×ÞÖ ¤üÖ®ê Ö Ûú׸ü†¸ü Ûú¸üÞÖÖ¸üß Ûãú™ãüÓ ²Öê 2.5.2 ÛúÖ´Ö †Ö×ÞÖ †ÖµÖãµÖÖŸÖᯙ ŸÖÖÞÖŸÖÞÖÖ¾Ö 2.5.3 ÛúÖ´Ö †Ö×ÞÖ ¤îü®ÖÓפü®Ö ÃÖÓ‘ÖÂÖÔ 2.5.4 ÛúÖ´ÖÖŸÖᯙ ŸÖÖÞÖŸÖÞÖÖ¾Ö ¯ÖÏ¿®ÖÖ¾Ö»Öß ‘Ö™üÛú 3 : ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÜÖãÞÖÖ †Ö×ÞÖ »ÖõÖÞÖê 3.1 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÃÖ¸Óü¾ÖÃÖÖ¬ÖÖ¸üÞÖ ¿ÖÖ¸üß׸üÛú ÜÖãÞÖÖ ¾Ö »ÖõÖÞÖê 3.2 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÃÖ¾ÖÔÃÖÖ¬ÖÖ¸üÞÖ ²ÖÖî׬¤üÛú ÜÖãÞÖÖ ¾Ö »ÖõÖÞÖê 3.3 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÃÖ¾ÖÔÃÖÖ¬ÖÖ¸üÞÖ ³ÖÖ¾Ö×®ÖÛú ÜÖãÞÖÖ ¾Ö »ÖõÖÞÖê 3.4 ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÃÖ¾ÖÔÃÖÖ¬ÖÖ¸üÞÖ ¾ÖŸÖÔ®Ö×¾ÖÂÖµÖÛú ÜÖãÞÖÖ ¾Ö »ÖõÖÞÖê 3.5 ¾µÖÖ¾ÖÃÖÖ×µÖÛú ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“µÖÖ ÛúÖÆüß ÜÖãÞÖÖ ¾Ö »ÖõÖÞÖÖÓ“µÖÖ ¿ÖŒµÖŸÖÖ ‘Ö™üÛú 4 : ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ¿Öß •Öãôû¾Öæ®Ö ‘ÖêÞÖê 4.1 •Öãôû¾Öæ®Ö ‘ÖêÞµÖÖ“Öß ¾µÖÖܵÖÖ 4.2 •Öãôû¾Öæ®Ö ‘ÖêÞµÖÖ“Öê ´ÖÆüŸ¾Ö 4.3 •Öãôû¾Öæ®Ö ‘ÖêÞµÖÖ“Öß ÛúÖµÖì 4.4 •Öãôû¾Öæ®Ö ‘ÖêÞµÖÖ“Öê ´ÖŸÖ¯ÖϾÖÖÆü/´ÖÖÝÖÔ 4.5 •Öãôû¾Öæ®Ö ‘ÖêÞµÖÖ“Öê ¯ÖÏÛúÖ¸ü /›üÖ¾Ö¯Öê“Ö ‘Ö™üÛú 5 : ŸÖÖÞÖŸÖÞÖÖ¾ÖÖ“ÖÖ ¯ÖÏןֲÖÓ¬Ö †Ö×ÞÖ ¾µÖ¾ÖãÖÖ¯Ö®Ö 5.1 ŸÖÓ¡Ö †Ö×ÞÖ ¯Ö¬¤üŸÖß 5.2 ¾ÖîµÖ׌ŸÖÛú ßָü 5.3 ¾µÖÖ¾ÖÃÖÖ×µÖÛú ßָü 5.4 ׿Ö×£Ö»ÖßÛú¸üÞÖÖ“ÖÖ †³µÖÖÃÖ 2. BTX 106 : †ÖµÖ. ÃÖß. ™üß. ×»Ö™ü¸üÃÖß ¯ÖãßÖÛú 1 -ÃÖÓÝÖÞÖÛúÖ“Öß †ÖêôûÜÖ †Ö×ÞÖ ×›ü•Öß™ü»Ö »ÖÖ‡Ô±úÙüÖ‡Ô»Ö ‘Ö™üÛú 1 : ÃÖÓÝÖÞÖÛúÖ“Öß †ÖêôûÜÖ 1.3 ÃÖÓÝÖÞÖÛúÖ“Öß †ÖêôûÜÖ ÃÖÓÝÖÞÖÛúÖ“Öê ×¾Ö×¾Ö¬Ö ¯ÖÏÛúÖ¸ü ÃÖÓÝÖÞÖÛúÖ“Öê ³ÖÖÝÖ Ûúß ²ÖÖê›üÔ “Öß ¸ü“Ö®ÖÖ ´ÖÖ‰úÃÖ“ÖÖ ¾ÖÖ¯Ö¸ü 1.4 ÃÖÓÝÖÞÖÛúÖ“Öß ¯Ö׸ü³ÖÖÂÖÖ ÆüÖ›Ôü¾Öꆸü †ÖѯָêüØ™üÝÖ ×ÃÖ×Ùü´Ö×¾ÖÂÖµÖß ¯ÖÏÖÝê ÖÏò´Ö †Ö×ÞÖ ›êü™üÖ ®Öê™ü¾ÖŒÃÖÔ“Öß †ÖêôûÜÖ ‡Ó¸ü®Öê™ü 1.5 ÃÖÓÝÖÞÖÛúÖ“Öê ÛúÖµÖÔ †Ö×ÞÖ ¾Öî׿Ö™ü¶ê ÃÖÓÝÖÞÖÛúÖ“Öê ¯ÖÏÛúÖ¸ü ´Öê´Ö¸üß×¾ÖÂÖµÖß ÃÖÓÝÖÞÖÛúÖ“Öß ÛúÖµÖÔõÖ´ÖŸÖÖ ¯ÖÏÖ›ê ü׌™ü×¾Æü™üß ¯ÖÏÖÝê ÖÏ´Ñ ÃÖ Ûú´µÖã×®ÖÛêú¿Ö®Ö ¯ÖÏÖÝê ÖÏÑ´ÃÖ ¿ÖîõÖ×ÞÖÛú †Ö×ÞÖ Ûú¸ü´ÖÞÖãÛúß“Öê ¯ÖÏÖÝê ÖÏ´Ñ Ö 1.6 †ÖѯָêüØ™üÝÖ ×ÃÖ×Ùü´Ö †ÖѯָêüØ™üÝÖ ×ÃÖ×Ùü´Ö“Öß ÛúÖµÖì ؾ֛üÖ•ê Ö ×¾ÆüÙüÖ“Öß †ÖêôûÜÖ Ã™üÖ™Ôü ´Öê®Öæ´Ö¬Öᯙ ¯ÖµÖÖÔµÖ (†Öѯֿ֮ÃÖ) ؾ֛üÖ•ê Ö´Ö¬Öᯙ ¯ÖÏÖÝê ÖÏ´Ñ ÃÖ“ÖÖ ¾ÖÖ¯Ö¸ü ±úÖ‡Ô»ÃÖ †Ö×ÞÖ ±úÖê»›ü¸ü“Öê ¾µÖ¾ÖãÖÖ¯Ö®Ö ±úÖ‡Ô»ÃÖ“Öß ÆüÖŸÖÖôûÞÖß 1.7 Ûú׸ü†¸ü“µÖÖ ÃÖÓ¬Öß ÃÖÓÝÖÞÖÛúÖ“ÖÖ ×¾Ö×¾Ö¬Ö õÖê¡ÖÖÓŸÖᯙ ¾ÖÖ¯Ö¸ü Ûú׸ü†¸ü“µÖÖ ÃÖÓ¬Öà“ÖÖ †ÖœüÖ¾ÖÖ ‘Ö™üÛú 2 : ×›ü•Öß™ü»Ö »ÖÖ‡Ô±úÙüÖ‡Ô»Ö 2.3 ×›ü•Öß™ü»Ö •Öß¾Ö®Ö¿Öî»Öß“ÖÖ †®Öã³Ö¾Ö ×›ü•Öß™ü»Ö ŸÖÓ¡Ö–ÖÖ®ÖÖ“Öê ±úÖµÖ¤êü ×›ü•Öß™ü»Ö ŸÖÓ¡Ö–ÖÖ®Ö †Ö×ÞÖ ×´Ö×›üµÖÖ ×›ü¾ÆüÖ‡ÃÖêÃÖ 2.4 ×›ü•Öß™ü»Ö †ÖÑ×›ü†Öê×¾ÖÂÖµÖß ×›ü•Öß™ü»Ö †ÖÑ×›ü†Öê“Öß ¾Öî׿Ö™ü¶ê ×›ü•Öß™ü»Ö †ÖÑ×›ü†Öê“Öê ¹ý¯ÖÖÓŸÖ¸üÞÖ †Ö×ÞÖ ÛúÖѯÖß ¯ÖÏ×ÛÎúµÖê“ÖÖ †ÖœüÖ¾ÖÖ ×Ã¯Ö“Ö ×¸üÛú×ÝÖÏ¿Ö®Ö †Ö×ÞÖ ØÃÖ£Öê×ÃÖÃÖ 2.5 ×›ü•Öß™ü»Ö ×¾Æü×›ü†Öê×¾ÖÂÖµÖß ×›ü•Öß™ü»Ö ×¾Æü×›ü†Öê“Öß ¾Öî׿Ö™ü¶ê ×›ü•Öß™ü»Ö ×¾Æü×›ü†Öê“Öê ÃÖÓÛú»Ö®Ö †Ö×ÞÖ †Ö‰ú™ü¯Öã™ü ±úÖѸü´Öê™üÃÖ ¾Öê²Ö ×¾Æü×›ü†Öê“Öê ŸÖÓ¡Ö–ÖÖ®Ö 2.6 ×›ü•Öß™ü»Ö ±úÖê™üÖêÝÖÏÖ±úß ×›ü•Öß™ü»Ö ±úÖê™üÖÝê ÖÏÖ±úß“Öß †ÖêôûÜÖ ×›ü•Öß™ü»Ö ‡´Öê•Ö“Öê ¾µÖ¾ÖãÖÖ¯Ö®Ö †Ö×ÞÖ ‹×›üØ™üÝÖ ×›ü•Öß™ü»Ö ‡´Öê•Ö دÖÏØ™üÝÖ×¾ÖÂÖµÖß ×›ü•Öß™ü»Ö ŸÖÓ¡Ö–ÖÖ®Ö †Ö×ÞÖ ŸÖã´Ö“Öê ÛúÖµÖÔãÖôû ´ÖÖ×ÆüŸÖß ¯ÖÏÃÖÖ¸üÛú ´ÆüÞÖæ®Ö Ûú׸ü†¸ü“Öß ÃÖÓ¬Öß ´ÖÖ×ÆüŸÖß - ŸÖÓ¡Ö–ÖÖ®Ö ¾µÖ¾ÖÃÖÖ×µÖÛú ´ÆüÞÖæ®Ö Ûú׸ü†¸ü“µÖÖ ÃÖÓ¬Öß ÃÖÖÑ°™ü¾Öꆸü ›êü¾Æü»Ö¯Ö¸ü ´ÆüÞÖæ®Ö Ûú׸ü†¸ü“µÖÖ ÃÖÓ¬Öß ¯ÖãßÖÛú 2 - ¯ÖÏÖê›ü׌™ü¾Æüß™üß ¯ÖÏÖêÝÖÏ´Ñ ÃÖ ‘Ö™üÛú : 1 ¯ÖÏÖ›ê ü׌™ü¾Æüß™üß ¯ÖÏÖÝê ÖÏ´Ñ ÃÖ 1.3 ¯ÖÏÖ›ê ü׌™ü¾Æüß™üß ¯ÖÏÖÝê ÖÏ´Ñ ÃÖ“Öß †ÖêôûÜÖ ¯ÖÏÖ›ê ü׌™ü×¾Æü™üß ¯ÖÏÖÝê ÖÏ´Ñ ÃÖ×¾ÖÂÖµÖß 1.4 ÛúÖÑ´Ö®Ö ÃÖã×¾Ö¬ÖÖ †Ö×ÞÖ Ûú´ÖÖÓ›üË ÃÖ ÝÖÏÖ×ÓÏ ±úÛú»Ö µÖã—Ö¸ü ‡Ó™ü¸ü±úê ÃÖ (×¾ÖÂÖµÖß) ¯ÖÖч™Ó ü¸ü“ÖÖ ¾ÖÖ¯Ö¸ü ( ¯ÖÖч™Ó ü¸ü ¾ÖÖ¯ÖºþµÖÖ) ׸ü²Ö®Ö“µÖÖ ´Ö¤üŸÖß®Öê ÛúÖ´Ö Ûú¸üŸÖÖ®ÖÖ ™æü»Ö²ÖÖÃÖÔ“ÖÖ ¾ÖÖ¯Ö¸ü (™æü»Ö²ÖÖÃÖÔ ¾ÖÖ¯Ö¸üŸÖÖ®ÖÖ ) ( ™æü»Ö²ÖÖÃÖÔ“ÖÖ ˆ¯ÖµÖÖêÝÖ) ´Ö•ÖÛæú¸ü ×»ÖÆüßÞµÖÖÃÖÖšüß Ûúß - ²ÖÖê›Ôü“ÖÖ ¾ÖÖ¯Ö¸ü Ûúß - ²ÖÖ›Ôü“Öß ¯ÖÏÝÖŸÖ ŸÖÓ¡Öê (†Ñ›ü¾ÆüÖ®ÖË, Û ßÖ - ²ÖÖê›Ôü ™êü׌®ÖÛú ) 1.5 ¾Ö›Ôü¯ÖÏÖÃê ÖêÃÖÃÖÔ ¯ÖÏÖÝê ÖÏ´Ñ Ö“Öß †ÖêôûÜÖ ¾Ö›Ôü 2007 ¾ÖÖ¯ÖºþµÖÖ ™êüŒÃ™ü ‹×›üØ™üÝÖ †Ö×ÞÖ ±úÖѸü´ÖêØ™üÝÖ ™êü²Ö»ÃÖ †Ö×ÞÖ ×“Ö¡ÖÖÓ“ÖÖ ¾ÖÖ¯Ö¸ü ±Ïúã ±ú׸üØ›üÝÖ ›êüÃÛú™üÖ ¯ò Ö ¯Öײ»ÖØ¿ÖÝÖ×¾ÖÂÖµÖ ‘Ö™üÛú 2 : ¯ÖÏÖ›ê ü׌™ü¾Æüß™üß ¯ÖÏÖÝê ÖÏ´ò ÃÖ ³ÖÖÝÖ - 2 2.3 ïÖÏ›ê ü¿Öß™ü ¯ÖÏÖÝê ÖÏ´Ñ Ö“Öß †ÖêôûÜÖ Ã¯ÖÏ›ê ü¿Öß™ü 2007 ×¾ÖÂÖµÖß ›êü™üÖ ‹Ó™üÒ ß ÝÖ×ÞÖŸÖß ÃÖæ¡ÖÖÓ“ÖÖ ¾ÖÖ¯Ö¸ü (¯Ö¸ü±úÖÑÚ´ÖÝÖ ´ÖÑ£Öê´ÖÑ×™üÛú»Ö ™üÖÃŒÃÖ) †Ö»ÖêÜÖ Ã¯ÖÏ›ê ü¿Öß™ü ¯ÖÏ™Ó ü ÛúºþµÖÖ 2.4 ¯ÖÏ—ê Öë™êü¿Ö®Ö ¯ÖÏÖÝê ÖÏ´Ñ Ö“Öß †ÖêôûÜÖ ¯ÖÏ—ê Öê™üê ¿Ö®Ö ¯ÖÏÖêÝÖÏò´Ö ‹ŒÃ¯»ÖÖꆸü ÛúºþµÖÖ ¯ÖÏ—ê Öë™üê ¿Ö®Ö ŸÖµÖÖ¸ü ÛúºþµÖÖ ÝÖÏÖ×±úŒÃÖ †Ö×ÞÖ ´Ö×»™ü×´Ö×›üµÖÖ“ÖÖ ÃÖ´ÖÖ¾Öê¿Ö ¯ÖÏ—ê Öë™üê ¿Ö®Ö Ø¯ÖÏ™ü 2.5 ›êü™üÖ¾ÖêÃÖ ¯ÖÏÖêÝÖÏ´ò Ö“Öß †ÖêôûÜÖ ›êü™üÖ²ÖêÃÖ×¾ÖÂÖµÖß ›êü™üÖ²ÖêÃÖ ŸÖµÖÖ¸ü ÛúºþµÖÖ ¸êüÛúÖ ›ò üÔ ÃÖË ÆüÖŸÖÖôûŸÖÖ®ÖÖ ›êü™üÖ²ÖêÃÖ Œ¾Öê׸ü•Ö ׸ü¯ÖÖê™üÔ ÃÖ ¯ÖãßÖÛú 3 : ‡Ó™ü¸ü®Öê™ü, ¾Ö»›Ôü ¾ÖÖ‡Ô›ü ¾Öê²Ö †Ö×ÞÖ ÃÖÓÝÖÞÖÛú ÃÖã¸üõÖÖ ‘Ö™üÛú 1 - ‡Ó™ü¸ü®Öê™ü †Ö×ÞÖ ¾Ö»›Ôü ¾ÖÖ‡Ô›ü ¾Öê²Ö 1.3 ‡Ó™ü¸ü®Öê™ü ‡Ó™ü¸ü®Öê™ü“Öê ˆ¯ÖµÖÖêÝÖ ‡Ó™ü¸ü®Öê™ü“µÖÖ •ÖÖê›üÞÖÖÃÖÖšüß †Ö¾Ö¿µÖÛú ÃË Ö»Ö껵ÖÖ ²ÖÖ²Öß ‡Ó™ü¸ü®Öê™ü •ÖÖê›üÞÖß“Öê ¯ÖÏÛúÖ¸ü ²ÖÑ›ü×¾Ö›ü£Ö×¾ÖÂÖµÖß 1.4 ¾Ö»›Ôü ¾ÖÖ‡Ô›ü ¾Öê²Ö ¾Öê²Ö“Öß †ÖêôûÜÖ ¾Öê²Ö †›Òüê ÃÖêÃÖ×¾ÖÂÖµÖß ‡Ó™ü¸ü®Öê™ü ‹ŒÃÖ¯»ÖÖꆸü¸ü 7 ¾Ö¸ü ÛúÖ´Ö Ûú¸üŸÖÖ®ÖÖ ´ÖÖ×ÆüŸÖß“ÖÖ ¿ÖÖê¬Ö ‘ÖêŸÖÖ®ÖÖ ‡Ô ÛúÖ ´ò ÖÃÖÔ“Öß ŸÖÖë›ü†ÖêôûÜÖ 1.5 ‡Ô - ´Öê»Ö ¾ÖÖ¯Ö¸üŸÖÖ®ÖÖ ‡Ô - ´Öê»Ö“Öß †ÖêôûÜÖ ‡Ô - ´Öê»Ö ÃÖÓ¤êü¿Ö ×»ÖÆüßÞÖê †Ö×ÞÖ ¯ÖÖšü×¾ÖÞÖê ‡Ô - ´Öê»Ö ÃÖÓ¤êü¿ÖÖ“Öê ¾µÖ¾ÖãÖÖ¯Ö®Ö ‡Ô - ´Öê»Ö“Öê ׿Ö™üÖ“ÖÖ¸ü 1.6 ‡Ó™ü¸ü®Öê™ü¾Ö¸ü ÃÖÓ¯ÖÛÔú ÃÖÖ¬ÖÞµÖÖ“µÖÖ ‡ŸÖ¸ü ¯Ö¬¤üŸÖß †Ö ®ò Ö»ÖÖ‡Ô®Ö Ûú´µÖã×®Ö×™ü•Ö ‡®Ã™Óü™ü ´ÖêÃÖêØ•ÖÝÖ“Öß ÛúÖµÖÔ¯Ö¬¤üŸÖß ¾Öê²Ö¾Ö¸ü¯ÖÏÛúÖ¿Ö®Ö Ûú¸üÞÖê ‘Ö™üÛú 2 - ÃÖÓÝÖÞÖÛúÖ“Öß ÃÖã¸ü×õÖŸÖŸÖÖ †Ö×ÞÖ ÝÖÖê¯Ö®ÖßµÖŸÖÖ 2.3 ÃÖÓÝÖÞÖÛú ÃÖã¸ü×õÖŸÖŸÖÖ †Ö×ÞÖ ÝÖÖê¯Ö®ÖßµÖŸÖÖ ÃÖÓÝÖÞÖÛú ÃÖã¸üõÖÖ †Ö×ÞÖ ÝÖÖê¯Ö®ÖßµÖ“ÖÖ ´ÆüÞÖ•Öê ÛúÖµÖ? ®ÖîÃÖÙÝÖÛú ¬ÖÖêÛúê ®ÖîÃÖÙÝÖÛú ¬ÖÖêÛúê ™üÖôûÞµÖÖ“Öê ˆ¯ÖÖµÖ ´ÖÖ®Ö¾Ö×®ÖÙ´ÖŸÖ ¬ÖÖêÛúê ´ÖÖ®Ö¾Ö×®ÖÙ´ÖŸÖ ¬ÖÖêÛúê ™üÖôûÞµÖÖ“Öê ˆ¯ÖÖµÖ 2.4 ÃÖÓÝÖÞÖÛúÖ“Öê ÃÖÓ¸üõÖÞÖ ÃÖÓÝÖÞÖÛú ÃÖã¸üõÖê²ÖÖ²ÖŸÖ ´ÖÖÝÖÔ¤ü¿ÖÔ®Ö ÃÖã¸ü×õÖŸÖ †Ö ®ò Ö»ÖÖ‡Ô®Ö †Ö×ÞÖ ®Öê™ü¾ÖÛÔú ™ÒÑü—ÖòŒ¿Ö®Ö Ûú¸üÞµÖÖÃÖÖšüß ‡Ô - ´Öê»Ö †Ö×ÞÖ ‡Ó®Ã™Óü™ü ´ÖêÃÖêØ•ÖÝÖ ÃÖã¸üõÖê“Öê ˆ¯ÖÖµÖ 2.5 †Ö¯Ö»µÖÖ Ûãú™ãüÓ²ÖÖ“Öê ×ÃÖŒµÖã׸ü™üß £ÖЙê ü¯ÖÖÃÖæ®Ö ÃÖÓ¸üõÖÞÖ ÝÖÖê¯Ö®ÖßµÖŸÖÖ ¸üÖÜÖÞµÖÖÃÖÖšüß †Ö ®ò Ö»ÖÖ‡Ô®Ö ×¯ÖÏ›êü™üÃÖÔ †Ö ®ò Ö»ÖÖ‡Ô®Ö ×¯ÖÏ›êü™üÃÖÔ¯ÖÖÃÖæ®Ö ²Ö“ÖÖ¾Ö 2.6 ÃÖÓÝÖÞÖÛú ÃÖã¸ü×õÖŸÖ †Ö×ÞÖ †ªµÖÖ¾ÖŸÖ ÛúÃÖÖ šêü¾ÖÖ»Ö ÃÖÓÝÖÞÖÛú ×ÃÖŒµÖã׸ü™üß ÃÖêØ™üÝÖ ÛúÖ ×ò ®±úÝÖ¸ü Ûú¸üÞÖê ÃÖÓÝÖÞÖÛú †ªµÖÖ¾ÖŸÖ šêü¾ÖÞÖê ²ÖÖî׬¤üÛú ÃÖÓ¯Ö¤üÖ Ã¾ÖÖ×´ÖŸ¾Ö ÆüŒÛúÖ“Öê ˆ»»ÖÓ‘Ö®Ö †Ö×ÞÖ ¯ÖÏןֲÖÓ¬ÖÖŸ´ÖÛú ˆ¯ÖÖµÖ ´ÖÖ×ÆüŸÖß ÆüßÖÖÓŸÖ¸üÞÖÖ×¾ÖÂÖµÖß“µÖÖ ÛúÖµÖ¤êü¿Ö߸ü ²ÖÖ²Öß 3. BTX 107 : Samajik shastrancha Aadhistan Abhyaskaram 4. BTX108: Elements of Textiles: Processes, Products & Applications 4 Textile Manufacturing Processes 4 Textile Products and Applications 4 Non Apparel Textile Applications 4.1.1 Conversion of Fibres to Yarn Cotton system, Silk System, Woolen System 4.1.2 Conversion of Yarns to Fabric Weaving, Knitting, Non Woven, Braiding, lace works, nets 4.1.3 Wet Processing of Textiles Dyeing, Bleaching, Printing, Finishing chemical finsihes and mechanical finishing, 4.1.4 Conversion of fabrics to garments Types of garments, operations in garment making, Cutting Sewing, Finishing, Printing, Surface ornamentation. 4.2.1 Yarns - Single, Double, Multifold 4.2.2 Yarns - Warp, Weft, Hosiery, Types of single yarns - Carded, Combed, Compact, Types of Double yarns -Dry Ring doubled, Wet Ring Doubled, TFO yarns, Cabled yarns Difference between warp, weft and hosiery yarn, important quality requirements 4.2.3 Woven Fabrics Different weaves, plain, twill, sateen, honey comb, terms and definitions of jeans, drills, shirting, suiting, bottom weights, sarees, dress materials 4.2.4 Knitted Fabrics 4.3.1 Industrial Textiles 4.3.2 Home Textiles knitted fabrics for T-shirts, intimate wear (Under garments), Baniyans, gloves, socks, sweaters, Tyre cords, Ropes, V-Belts, Conveyors, Filters, Curtains, Sofa covers, Floor covers, table cloths, Bed covers, bags, 4.3.3 Geo Textiles Road making, Laying railway lines, canal base, Drainage, Seeping resistors, Filtration, reinforcement, retaining walls, erosion control, 4.3.4 Medical Textiles Fibres used for medical textiles, Surgical clothing gowns, Beddings, Sheets, Pillow cover, Uniforms, Surgical hosiery, Caps, Masks, Wipes, Gowns, Masks, Surgical cover drapes, Blankets, Coverstock, Surgical hosiery, Protective clothing, Surgical covers, D C8C: “C” Certificate Program in Textiles C8C: “C” Certificate Program in Textiles 1. BTX201 2. BTX202 Personality Development Economics for All Theory, 6 CP Theory, 6 CP 3. BTX203 Material Handling in Textiles Theory, 3 CP 4. BTX204 Safety Management in Textiles Theory, 3 CP BTX201: Personality Development BTX203 Material Handling in Textiles 1 Introduction to Material Handling 2 Handling of fibres in loose form 3 Handling of yarns Need and concepts Material Handling - Definitions, Need for material handling, Material handling as a necessary evil Timely handling Value loss or addition and material handling, Abuse of human potential Handling by men vs handling by machines Stacking in advance and just in time transportation. Cotton field to spinning mill Transporting kapas to ginning factories, handling cotton in ginning factories, transporting cotton bales to spinning mills Handling of fibres from Cotton Bringing bales to mixing, transporting cotton pneumatically godown to Mixing and in Blow room Transportation of laps, Handling of Laps in blow room, Transporting and stacking, Handling of laps in comber preparation, transporting and stacking. Handling slivers and speed frame bobbins Transportation ofcard cans, transportation of drawing cans, transportation of comber cans, transportation of speed frame bobbins. Ring Cops and open end cheeses Handling in post spinning Handling of ring bobbins, Handling of open end cheeses, Handling of cones, handling of hanks, handling of soft packages for dyeing, Handling of processed yarns Handling of bleached yarn hanks, Handling of bleached yarn on soft packages, handling of dyed yarns, Handling of mercerised yarns. Handling beams Transporting and stacking warp beams, transporting and stacking sized beams. 4 Handling of Fabrics and garments Handling grey woven fabrics Handling Grey Knitted Fabrics BTX204 Safety management in Textile 1 Environment and Hygiene handling cloth rolls doffed, handling fabric after grey inspection, Delivering fabrics to processing or garmenting Handling doffed knitted rolls, handling fabric after inspection, delivering knitted rolls to processing or garmenting. Handling fabrics before garmenting Receivingand stacking fabric rolls, taking samples for testin, laying and relaxing fabric bits, handling of cut panels Handling garments Transporting sewn garments to finishing, hanling garments after finishing, packing and despatching, Dust Control Providing dust filters in the machines, controlling ventilation, handling dusty wastes. Providing enclosures, exhausts, ventilation, water showers Control of chemical fumes Control of heat in the working Providing good ventilation, exhausting hot air, area Control of noise and providing Reason for noise liberation, maintenance of machines, providing adequate safe sufficient light light 2 Accidents while on job Accidents due to worker errors Wearing loose clothes, coming drunk to the work, inadequate training, bypassing while working on machines of safety switches, safety locks and not following the safety precautions, using compressed air for cleaning themselves. Accidents due to machine malfunctioning Improper maintenance and settings, poor humidity conditions leading to lappings, not calibrating the pressure gauges, not monitoring the pressure vessels and compressors. Accidents in material handling Overlaoding the trolleys, obstacles in the alleys, narrow alleys, not maintaining the material handling equipments. Accidents due to poor house keeping 3 Fire accidents 4 Safety regulations Blocking the entrances, keeping materials near to electrical control boards, keeping clothes, bags, tiffen boxes on the machines, keeping materials in passages, Fires due to mechanical friction Lapping, bearing jams, improper suction leading to jamming of materials, poor quality lubricants, improper settings. Fires due to electrical short Loose wires, low capacity cables and wires, improper control of voltage circuites fluctuations, improper selection of motors, Fires due to negligence of workers and staff Not adhering to fire safety norms, not maintaining the fire extinguishers, stacking materials near control panels, stacking inflamable materials near to wastes, smoking in banned areas, lighting lamps for making pooja in the production area. Fires due to natural reasons Lightenings, too low humidity leading to static charges. Machine layouts Distance between machines, distance between walls and machines, enry and exit points, Different types of fire extinguishers, hydrants, soda acid, CO2, foam etc, smoke snsors and activators Fire extinguishers First aid boxes and safety gadgets Materials in First aid box, maintenance of first aid box, providing rest room, ambulance Stackingand disposing of hazardous materials Collection, stacking and Disposal of hazardous materials and wastes. C8D: “D” Certificate Program in Textiles C8D: “D” Certificate Program in Textiles 1. BTX205 Office Management Theory, 6 CP 2. BTX206 Business Communication Theory, 6 CP 3. BTX207 Quality Management System Theory, 3 CP 4. BTX208 Quality Aspects in Textiles Theory, 3 CP textile-d1.jpg 1 of 1 https://mail.google.com/_/scs/mail-static/_/js/k=gmail.main.en.oMX3... 05-08-2014 16:52 textile-d2.jpg 1 of 1 https://mail.google.com/_/scs/mail-static/_/js/k=gmail.main.en.oMX3... 05-08-2014 16:53 BTX 207 Quality Management Systems 1 Need and evolution Changing customer expectations Changes in culture, changes in technology, changes in purchasing power Reasons for deviations in quality Concepts of Quality Management Men, Machine, Material, Methods, Consistency in their use History of development of QMS World war and its impact on economy, evolution of quality systems in japan, evolution of BS 5750 and ISO 9000, Quality award systems Principles of ISO 9000 Eight Principles and their explanations. Clauses of ISO 9000 Auditing for ISO 9000 Eight clauses and brief explanation Need for audits, Types of audits, the quality of auditor, reporting audit findings, taking actions ISO 9000 Certification Process of certification, adequacy audits, ceritification audits, surveilance audits, responsibilities of an ISO 9000 certified company 3 Compliance to legal requirement Concept of Social Accountability Why industry should be accountable to the society, expectations from an industry 4 Social Responsibility Introduction to SA 8000 Introduction to C-TPAT Introduction to WRAP Concepts Evolution and clauses of SA 8000 Evolution and clauses of C-TPAt Evolution and clauses of WRAP Concepts of Social Responsibility, Society and the industry 2 Documented Quality Systems Objectives, development of systems, following of systems, auditing of systems, involvement of people. Getting quality while adhering to legal and regulatory requirements Stake holders Different stake holders, requirements of each stake holder Community Role of community in supporting the growth of industry Community development initiatives Housing, roads, schools, hospitals, social gatherings, relief funds, trusts. Quality Requirements Basic quality requirements of fibres to be used in Textiles like length, fineness, strength, shade uniformity, Quality norms Normal quality norms of cotton, wool, silk and manmade fibres, Quality Variations Variations and its impacts. Impact of length variations on appearance and strength, Impact of strength variations on strength, Impact of shade variations within and between lots Blend variations Impact of blend variation on strngth, appearance, durability, pilling etc, impact on cost, Basic quality parameters of yarn Importance of basic yarn quality parameters like count, strength, twist, uniformity, hairiness, Yarn Quality and Fabric Quality Specific requiremnets Effect of yarn parameters on fabric quality General requirement of yarns for various weaving and knitting activities., Simple testing methods Checking count, lea strength, twist, and Evenness of yarns BTX 208 Quality aspects in Textiles 1 Raw Material Quality 2 Yarn Quality 3 Fabric Quality 4 Garment Quality Basic Quality Parameters of Fabric Understanding ends and picks, course and wales, width, weave, pattern or design, colour and feel Importnce of various quality parameters Importance of basic fabric quality requirements like width, GSM, cover, feel, shade and design. General defects in fabrics, Yran related defects, loom related defects, knitting related defects, processing related defecdts. fabric inspection Checking the fabric dimensions, fabric weight, fabric construction, inspecting and grading the fabrics. Perception of quality in Understanding style, measurement requirements, fit, and presentation garment, Deviation from customer need Variations in measurements, difference in stitch quality, deviations in buttons, trims, and actual garment, Alternate end use for garments, Understanding the deviations, possibility of rework, possibility of altering the garment to fit in next size, offering garments for alternate customer. Normal quality problems. Uneven shrinkages, seam quality, improper labelling, mix up of sizes, shade variations, improper fixing of buttons.