Decision Making in the HIV/AIDS Supply ...

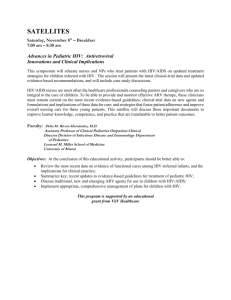

advertisement