A Microfluidic Platform for Combinatorial Synthesis and

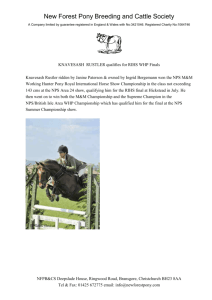

advertisement