JMP Analysis of a Split Plot Design

advertisement

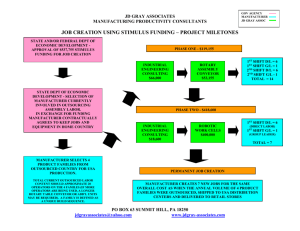

JMP Analysis of a Split Plot Design The data are from an experiment run to evaluate the cut off time for lawnmower engines. There are two factors of interest: the whole plot factor (Manufacturer) and the subplot factor (Speed). The machines act as blocks for the part of the experiment involving the Speed factor. There are four columns in the JMP Data Table: Manufacturer, Speed, Machine and Cutoff Time. Manufacturer A A A A A A A A A A A A B B B B B B B B B B B B Speed Low Low High High Low Low High High Low Low High High Low Low High High Low Low High High Low Low High High Machine 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6 6 Cutoff Time 211 230 278 278 184 188 249 272 216 232 275 271 205 217 247 251 169 168 239 252 200 187 261 242 You will need to use the Fit Model platform • The response variable, Y, is Cutoff Time • In the Construct Model Effects’ box, Add Manufacturer. Add Machine. • Highlight Machine in the Construct Model Effects’ box and highlight Manufacturer in the Select Columns box. Click on Nest. This should change Machine to Machine nested within Manufacturer: Machine[Manufacturer]. • Add Speed. • Add a Manufacturer*Speed interaction by highlighting both Manufacturer and Speed in the Select Columns box and clicking on Cross. • Be sure to ask for a Minimal Report and click on OK. The output from this analysis appears below. Note that the F-Ratio for testing for a difference between Manufacturers uses the incorrect error term. Response Cutoff Time Summary of Fit RSquare RSquare Adj Root Mean Square Error Mean of Response Observations (or Sum Wgts) 0.925432 0.892808 11.50226 230.0833 24 Analysis of Variance Source DF Model 7 Error 16 C. Total 23 Sum of Squares 26271.000 2116.833 28387.833 Mean Square 3753.00 132.30 Effect Tests Source Manufacturer Machine[Manufacturer] Speed Manufacturer*Speed Nparm 1 4 1 1 Sum of Squares 2521.500 2852.833 20886.000 10.667 DF 1 4 1 1 F Ratio 28.3669 Prob > F <.0001 F Ratio 19.0587 5.3908 157.8660 0.0806 Prob > F 0.0005 0.0061 <.0001 0.7801 Go back to the Construct Model Effects’ box and highlight Machine[Manufacturer]. Click on the red arrow to the right of Attributes and select Random Effect. Change the Method from REML (Recommended) to EMS (Traditional). This should produce the output below. Response Cutoff Time Analysis of Variance Source DF Model 7 Error 16 C. Total 23 Sum of Squares 26271.000 2116.833 28387.833 Tests wrt Random Effects Source Manufacturer Machine[Manufacturer]&Random Speed Manufacturer*Speed Mean Square 3753.00 132.30 SS MS 2521.5 2521.5 2852.83 713.208 20886 20886 10.6667 10.6667 F Ratio 28.3669 Prob > F <.0001 DF 1 4 1 1 F Ratio 3.5354 5.3908 157.8660 0.0806 Prob > F 0.1332 0.0061 <.0001 0.7801