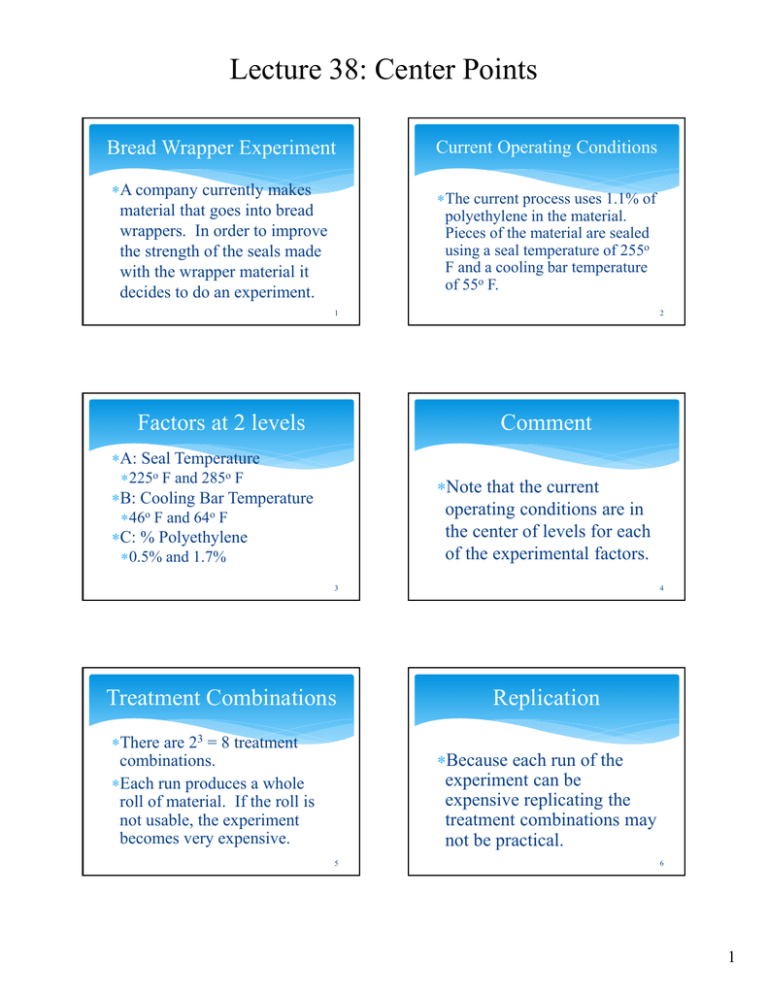

Lecture 38: Center Points Bread Wrapper Experiment Current Operating Conditions

advertisement

Lecture 38: Center Points Bread Wrapper Experiment Current Operating Conditions A company currently makes material that goes into bread wrappers. In order to improve the strength of the seals made with the wrapper material it decides to do an experiment. The current process uses 1.1% of polyethylene in the material. Pieces of the material are sealed using a seal temperature of 255o F and a cooling bar temperature of 55o F. 1 Factors at 2 levels 2 Comment A: Seal Temperature 225o F and 285o F Note that the current operating conditions are in the center of levels for each of the experimental factors. B: Cooling Bar Temperature 46o F and 64o F C: % Polyethylene 0.5% and 1.7% 3 Treatment Combinations There are 23 = 8 treatment combinations. Each run produces a whole roll of material. If the roll is not usable, the experiment becomes very expensive. 4 Replication Because each run of the experiment can be expensive replicating the treatment combinations may not be practical. 5 6 1 Lecture 38: Center Points Replication Completely Randomized Instead of replicating the treatment combinations, replicate the current operating conditions (center points). The experiment will consist of 8 treatment combinations and 4 center point replications in a completely randomized design. 7 Treatment Combinations 8 Center Points Use the data at the center points to quantify the random error variation, i.e. variation in material treated the same. Use the data at the treatment combinations to estimate the effects of the factors and interactions. 9 10 11 12 Informal Analysis A: Seal Temperature 225o F (–1): Mean = 8.525 g/in 285o F(+1): Mean = 6.775 g/in 2 Lecture 38: Center Points Informal Analysis B: Cooling Bar Temperature 46o F (–1): Mean = 7.375 g/in 64o F (+1): Mean = 7.925 g/in 13 14 15 16 17 18 Informal Analysis C: % Polyethylene 0.5 % (–1): Mean = 6.875 g/in 1.7 % (+1): Mean = 8.425 g/in Summary Increasing seal temperature tends to decrease strength a lot. Increasing cooling bar temperature tends to increase strength a little. Increasing the % polyethylene tends to increase strength a lot. 3 Lecture 38: Center Points Seal Temp and Bar Temp When seal temperature is 225o F, increasing the bar temperature tends to increase the strength. When seal temperature is 285o F, increasing the bar temperature has little effect on the strength. 19 20 21 22 Seal Temp and % Poly When seal temperature is 225o F, increasing the % polyethylene tends to increase the strength a lot. When seal temperature is 285o F, increasing the % polyethylene tends to increase the strength a little. Bar Temp and % Poly Other Interactions When bar temperature is 46o F or 64o F, increasing the % polyethylene tends to increase the strength. The only other interaction is a 3-way interaction involving all three factors. 23 24 4