Early Detection of Reliability Problems Using Information From Warranty Databases Huaiqing Wu

advertisement

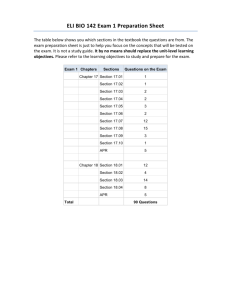

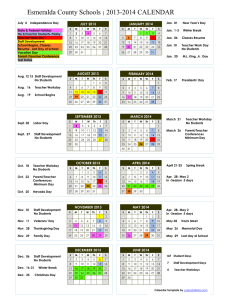

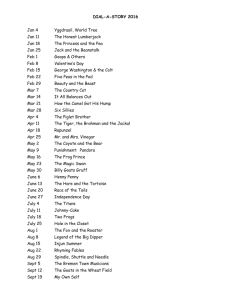

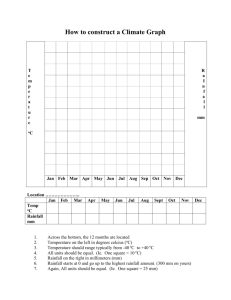

Overview Early Detection of Reliability Problems Using Information From Warranty Databases • Background and motivation • Example: automobile “VIN” and “Warranty Report” databases. Huaiqing Wu • Statistical formulation of the detection problem. William Q. Meeker • Allocation of false alarm probabilities. over time. Department of Statistics Iowa State University Balance power • Critical values for the early detection monitoring procedure. Ames, IA 50011 www.public.iastate.edu/˜wqmeeker • Average run length. • Summarization of monitoring procedure behavior. August 16, 2001 • Concluding remarks. 1 2 Previous Work Background and Motivation • General warranty topics: 1996) • Serious, unanticipated reliability problems arise • Early detection can save large amounts of money and customer good will • Statistical detection rules in a warranty database can identify or warn of serious reliability problems long before they would otherwise be discovered • Monitoring existing warranty data bases will add little additional costs Blischke and Murthy (1994, • General reviews of statistical methods: Robinson and McDonald (1991), Lawless and Kalbfleisch (1992), and Lawless (1998) • Dealing with messy data problems: Suzuki (1985a, b), Kalbfleisch and Lawless (1988), Lawless, Hu, and Cao (1995), Hu, Lawless, and Suzuki (1998), Karim, Yamamoto, and Suzuki (2001a), and Wang and Suzuki (2001a, b) • Detecting a change point from marginal count warranty data: Karim, Yamamoto, and Suzuki (2001b) 3 4 Fraction of Automobiles with Warranty Reports in the First Four Months of Service Versus Production Month for 12 Different Labor Codes Automobile “VIN” and “Warranty Report” Databases • VIN (production) database 5 1996 1996 1997 Apr Dec Aug Build Month 1998 Apr 1996 1996 1997 Apr Dec Aug Build Month 1998 Apr 0.012 0.008 0.004 0.0 Fraction With Reports After 4 Months 0.003 0.001 1994 Dec 1995 Aug 1996 1996 1997 Apr Dec Aug Build Month 1996 1996 1997 Apr Dec Aug Build Month 1998 Apr 1998 Apr 0.003 0.002 0.001 1994 Dec 1995 Aug 1996 1996 1997 Apr Dec Aug Build Month 1998 Apr Labor Code H1240 [1048] Fraction With Reports After 4 Months 0.004 1995 Aug 1996 1996 1997 Apr Dec Aug Build Month 0.0 1998 Apr Labor Code E9995 [985] 1994 Dec 1995 Aug Labor Code D3044 [777] Fraction With Reports After 4 Months 0.04 0.03 0.02 0.01 1994 Dec Fraction With Reports After 4 Months 0.004 0.002 1995 Aug 1998 Apr 0.0 1998 Apr Labor Code E0432 [823] 1994 Dec 1996 1996 1997 Apr Dec Aug Build Month 0.0020 1996 1996 1997 Apr Dec Aug Build Month 1995 Aug Labor Code C6881 [631] 0.0010 1995 Aug Labor Code B7876 [359] 0.0 1994 Dec 0.0 0.015 1995 Aug 1994 Dec Fraction With Reports After 4 Months 0.010 0.004 0.0 1998 Apr Labor Code D3088 [784] 1994 Dec 1998 Apr 0.002 1996 1996 1997 Apr Dec Aug Build Month 1996 1996 1997 Apr Dec Aug Build Month Labor Code C3348 [535] Fraction With Reports After 4 Months 0.004 0.002 Fraction With Reports After 4 Months 0.0 1995 Aug 1995 Aug 0.0 Fraction With Reports After 4 Months 0.0004 0.0 1994 Dec Fraction With Reports After 4 Months Also contains cost, dealership code, and other information 1994 Dec 0.005 1,350,675 records with 1,908 unique labor codes 1998 Apr 0.0 Warranty reports received between January 1995 and November 1998 1996 1996 1997 Apr Dec Aug Build Month Labor Code C3301 [530] Fraction With Reports After 4 Months • Warranty report database 1995 Aug Labor Code B0608 [197] 0.0 1994 Dec Provides date of sale and other production information Labor Code A5580 [149] Fraction With Reports After 4 Months 0.0020 0.0010 0.0 566,406 unique VINs Labor Code A0357 [14] Fraction With Reports After 4 Months One record for each automobile for a particular “platform” manufactured between January 1995 and August 1998 1994 Dec 1995 Aug 1996 1996 1997 Apr Dec Aug Build Month 1998 Apr 6 Retrospective View Giving the Fraction of Automobiles with Labor Code C0140 Warranty Reports in the First Four Months of Service versus Production Month General Formulation of the Detection Problem • Generalization of Shewhart process monitoring schemes 0.004 0.005 • One month used as the production/ time in service period in examples 0.002 0.003 • Data for a given production period accrue sequentially (due to variability in sale date and tracking by time in service) 0.001 • Nonparametric approach (based on report counts) most appropriate for detection • Use a parametric model (e.g., Weibull or Lognormal) for prediction of future failures 0.0 Fraction With Reports After 4 Months 0.006 • Stratify by production period, time in service, and labor code 1994 Dec 1995 Apr 1995 Aug 1995 Dec 1996 Apr 1996 1996 Aug Dec Production Month 1997 Apr 1997 Aug 1997 Dec 1998 Apr 1998 Aug 7 Notation 8 Formal Detection Rule Framework • ni units produced in period i • Multiple-parameter hypothesis • nij units produced in period i and sold j periods after manufacture • Rijk number of warranty reports kth period in service for units manufactured in period i and sold in period i+(j−1) j • Sijk = =1 Rik is the cumulative number of reports for units manufactured in period i and sold in period i+(j−1) • Cijk critical limit for Sijk 0 0 H0 : λ1 ≤ λ0 1 , λ2 ≤ λ2, . . . , λM ≤ λM versus 0 0 Ha : λ1 > λ0 1 or λ2 > λ2 or . . . or λM > λM , • λ0 k values are from historical information or reliability targets • αk is the nominal false alarm probability for testing λk • The overall false alarm probability for testing the hypothesis H0 versus Ha in is • λk intensity for service period k • M number of future periods to monitor report intensities • fj fraction sold j months after production; M j=1 fj ≤ 1 • Superscript 0 (e.g., fj0) denotes historical or baseline value. α∗ = 1 − M (1 − α∗k ) ≤ 1 − k=1 M (1 − αk ) = α, k=1 • Control and allocation of false alarm probabilities should be labor code specific. 9 2nd month in service 12 8 + + 4 + 0 1 2 3 4 3rd month in service 12 8 + 4 + 0 1 2 3 4 12 8 4 0 12 8 4 0 12 8 4 0 - - - JUN 1997 + -+ - + 2 3 4 + + 1 2 3 4 + 2 3 4 -+ 1 2 3 4 12 8 4 0 + 1 - - 2 3 4 12 8 4 0 -+ 1 - -+ 1 12 8 4 0 - - - - - 2 3 4 4th month in service 12 8 4 + 0 1 2 3 4 - Cumulative Number of Reports (+) and Critical Values (-) MAY 1997 1st month in service 12 + 8 + 4 + + 0 1 2 3 4 1 JUL 1997 Production Month APR 1997 Sequential Test Monitoring Charts Labor Code C0140 Warranty Reports + Indicates Cumulative Number of Reports Sijk − Indicates Corresponding Critical Limit Cijk 10 Control and Allocation of False Alarm Probabilities • Limit M , the number of periods monitored • Simple rule: αk to be proportional to the information available for testing H0k versus Hak : 0 0 αk = C(f10 + · · · + fM −k+1)λk , • Must also allocate power for the sequential accumulation of data. We use the error spending approach developed Slud and Wei (1982) for sequential clinical trials. Sale Month Since Production 11 12 2nd month in service 0.0 Values of αjk(i) 0 1 2 3 4 0 1 2 3 4 (a) (b) 3rd month in service 4th month in service 0.0004 0.0004 0.0002 0.0002 0.0 0 1 2 3 4 0 1 (c) 2 3 0.0 0.0 0.003 0.0002 0.0 0.002 0.0004 0.0002 0.001 0.0004 Fraction With Reports After 1 Months of Service 1st month in service Nonparametric Estimate of Fraction With Reports After One Month of Service as a Function of Production Month for Data Available in July 1997. 0.004 Typical Spending Functions for Production Month May 1997 for Labor Code C0140 With α = .1% and M = 4, and ρ = .5, —; ρ = 1, · · · ; and ρ = 2, - - -. 4 (d) 1994 Dec Sale Month Since Production (MAY 1997) 1995 Mar 1995 Jun 1995 Sep 1995 Dec 1996 Mar 1996 Jun 1996 Sep 1996 Dec 1997 Mar 1997 Jun Production Month 13 Weibull Probability Plot and Weibull ML Estimate for Production Month May 1997 Based on Data Available in July 1997 (after two months in service) 14 Weibull Probability Plot for Production Month May 1997 Based on Data Available in November 1998 .02 .02 .01 - .01 Proportion with Reports Proportion with Reports .005 .003 .005 .003 - - - - - - - - - - - - - - - - - .001 .001 ^ η = 721153 - ^ β = 0.502 .0005 .0005 1 1 2 5 10 2 5 10 20 20 Months in Service Months in Service 15 16 Concluding Remarks and Extensions Average Run Length • All 1,908 labor codes were investigated. • Probability of no alarm is triggered during the first ( − 1) periods of monitoring ARL = E(N ) = ∞ Pr(N ≥ ) • Efficient monitoring should provide economical early detection, especially with modern computing/data storage capabilities =1 • Under H0 Pr(N ≥ ) = −1 i=1 • Methods implemented on 48 interesting labor codes. Results summarized in the paper. • Modeling past data is useful for setting the baseline report rates γi,−i ≥ (1 − α)−1. • Simple expression for ARL if ni is constant and fij = fj0, j = 1, . . . , M • Can also compute under specified Ha • Should monitor different production lines/shifts separately • Runs rules useful in some settings • Detection also provides input to warranty cost forecasting algorithm 17 18