DOE/ET-51013-241 PFC/RR/87-19 Concepts for Tokamak Plasma X-Ray

advertisement

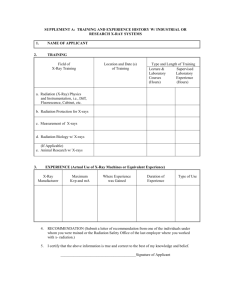

PFC/RR/87-19 DOE/ET-51013-241 Concepts for Tokamak Plasma X-Ray Sources for Lithography and Other Applications L. Bromberg, R. Petrasso, and D. R. Cohn March 18, 1988 Plasma Fusion Centert Massachusetts Institute of Technology Cambridge, Massachusetts 02139 USA tSupported by Department of Energy No. DE-AC02-78ET51013. Reproduction, translation, publication, use and disposal in whole or in part, by or for the United States government is permitted. Abstract Concepts for tokamak plasma X-ray sources for lithography and other applications are described. Line radiation from neon-like germanium and selenium and helium and hydrogen-like aluminum is employed. An arrangement for control of the penumbral shadow required for lithography is discussed. An illustrative system design using a modest size tokamak with a high aspect ratio, superconducting magnets and steady state current drive is presented. Although a tokamak source could require significantly more electrical input power than a synchrotron, it could provide advantages of large, uniformly exposed areas, the possibility of a narrower X-ray spectrum, and substantial improvement in capability if a reduced mask-wafer distance in proximity printing can be used. 2 1 Introduction The use of X-rays for submicron lithography was proposed in 1972 by Spears and Smith [1]. By employing much shorter wavelengths than characteristic of optical techniques, very small linewidths (< 10-6 m) can be obtained, resulting in increased component density in integrated circuits. Soft X-rays with wavelengths around 10A (~ 1 keV) are preferred for lithograpic applications. Important limits are (a) optimal absorption in the resist, resulting in relatively uniform exposure across the resist but without creating a large number of secondary electrons; (b) sufficient transmission through vacuum windows and the mask substrate. [2] If the mask is in contact with the wafer, the mask could damage the resist on the wafer, decreasing the yield. Eventually the mask itself could be damaged by the buildup of resist material. In order to avoid the problems associated with contact printing the mask should be separated by a small distance from the resist (proximity imaging). A clear image of the mask on the resist is facilitated by radiation from a point source or by parallel rays. Several approaches have been proposed for the X-ray source, including electron bombardment sources[3], laser-produced plasmas[4], Z-pinch plasmas[5, 6] and synchrotrons [7). These sources are typically characterized by very small Xray beam dimensions (for the synchrotron, the effective dimension is the beam radius). This property allows for collimation of the radiation. For a review of X-ray lithography, see Neureuther [2]. In plasmas, X-ray radiation becomes an important power loss mechanism when the plasma is contaminated with impurities, especially high-Z impurities. Line radiation and, to a lesser extent, bremstrahlung can account for a dominant fraction of the input power. In the case of discharges with background ions with nuclear charge significantly greater than hydrogen (Ne, for example), the characteristics of the radiation are determined by the dominant line radiation (either from the high-Z background plasma or by a plasma contaminant), the electron 3 temperature and the plasma density profiles. Under appropriate conditions the radiation will lie in the soft X-ray spectrum region. Tokamaks have been the most successful magnetically confined plasma device. (For a review of tokamak status, see Furth [8]). The possible use of tokamaks as sources of X-ray radiation for applications such as atomic physics experiments and instrument calibration has been considered. [9, 10]. Petrasso [9] has considered a X-ray lithography system assuming pulsed ohmically heated tokamaks and determined that such tokamaks were not likely to be competitive for wafer production due to low average power. However, they could be sufficient for testing other parts of a lithography system (such as masks, resists, etc) and other applications where high flux and high duty cycle are not required. The potential of tokamaks can be significantly enhanced with the use of RF current drive [11, 12] and RF heating [13]. Not only the power densities are increased, but the source could become steady state. The lack of consideration of tokamaks as sources for X-ray lithography has largely been due to the fact that they are extended sources of X-ray radiation. In the past extended sources of radiation have been dismissed for application for X-ray lithography because of the need of control of the penumbral shadow (as will be discussed in detail in section 2). As a consequence, investigation of the use of plasmas as X-ray sources for lithography has been directed towards extremely dense and small sources [3- 7] with very high power densities. In this paper we discuss concepts for tokamak devices as X-rays sources for lithography as well as other applications. In section 2, the requirements for X-ray lithography are described. Section 3 discusses the properties of tokamak plasmas dominated by X-ray emission. Section 4 describes the properties of collimated Xray radiation at the wafer. In section 5, tokamak power balance and current drive is discussed. An illustrative tokamak X-ray system for lithographic application is described in section 6. Finally, in section 7 a short comparison between tokamaks, synchrotrons and other sources for lithographic applications is made. 4 2 Requirements for X-ray lithography. A schematic diagram of the X-ray source/wafer geometry is shown in Figure la. The preferred method of exposure used with X-ray lithography is non-contact printing. The mask is placed a distance a away from the wafer to be exposed, and the mask is placed a distance I from the effective source. In the case of the tokamak the source is of extended geometry, and it is necessary to collimate. This is done by placing a plate with a small aperture (diameter d) to allow some of the radiation through. A plan view of a tokamak X-ray source is shown in Figure 1b. The limit on the size of the aperture d is determined by the allowed value of the penumbral shadow of the X-ray radiation as it passes through the mask. The extent of the penumbra is given by [1) d penumbr, = (1) - The farther away that the source is located from the wafer, the larger the permissible hole for a constant penumbral size. This has an effect on the optimization of the system. Presently assumed values of a are around 30 um (14]. Penumbral blurring is of concern only for finite size sources. For point sources (such as laser produced plasmas) and for synchrotrons (where the energy is radiated tangentially to the electron orbit with a small diverging angle of 1 - 2 mrad) blurring is not significant. A second limitation for X-ray lithography is diffraction. Diffraction of the tranmsitted radiation could be substantial, and ultimately restricts the minimum linewith achievable with proximity imaging X-ray lithography. A conservative estimate of the minimum linewidth as limited by Fresnel diffraction is determined by Wmin = v2_.W where A is the x-ray wavelength [15]. For the parameters used in x-ray lithography, (A = 10A and Wmin = 0.25p.m), the gap can be as large as 25 itm. For smaller linewidths, the mask-wafer spacing has to be decreased further. As a consequence, there is strong motivation to reduce the value of a. 5 Typical values of the resist sensitivity for X-rays with wavelengths ~ 5-15 x 10-10 m are anywhere from 100 - 10000 J/m 2 (10 - 1000 mJ/cm 2 ). Therefore, the required intensities of the X-rays at the resist for an exposure of a few seconds are 10 - 1000 W/m 2 (1 - 100 mW/cm 2 ). 6 3 Properties of high-Zff plasmas The transport of impurities in tokamak plasmas is not generally well under- stood. In the case of pellet injection and neutral beam heating, however, some of the experimental results can be successfully modelled by using neoclassical transport theory (16]. Neoclassical theory predicts that under the appropriate circumstances the impurities drift towards the center of the plasma [17]. Experimentally this has been observed in several experiments, both with and without pellet injection, [17, 18, 19] with the consequence that the impurities concentrate in the axis of the machine. This condition permits the selection of the radiation to be emitted, as will be shown below. In this paper it is assumed that the background ion density (in this case, hydrogen) is given by ( a2 (2) n1 (r) = ni.e(~/a4) (3) (1- nb(r) = n, while the impurity ion concentration is where n,. and ni. are the densities of the background plasma ions and impurity ions on the plasma axis, a is the plasma minor radius, ai represents the width of the impurity concentration and will be a free parameter in what follows. The impurity density is more peaked than the background plasma density. The electron temperature is determined by T,(r) = T..e(-r 2 /) where aT determines the width of the temperature profile. (4) For typical ohmic heated plasma discharges [8], a= a 14)(1/2 q with q defined as a= T q= B, 7 (6) Here BT and B, are the toroidal and poloidal field of the plasma and R is the plasma major radius, q is the plasma safety factor (successful plasma operation can occur only for q > 2). [8] The correct choice of impurity is crucial in order to obtain emission of the desired spectrum. Typical emission rates from high-Z material (in this case, germanium) as a function of temperature are shown in Figure 2. The flat region around T - 1.3 keV is due to radiation of Ne-like ion of germanium. The peak at the lower energy results from radiation of Kr-like ions of germanium. Although the emission rate is much higher for the Kr-like germanium, the spectrum of this radiation is softer than for the Ne-like case. The spectrum of the radiation for the Kr-like germanium peaks around 0.1 - 0.2 keV and around 1.3 keV for Ne-like germanium. The 1.3 keV Ne-like germanium radiation could be employed as a source in the 10A region generally considered for lithography. The 0.1 - 0.2 keV peaks may also be useful for various applications. Figure 2 is calculated using a coronal equilibrium model [20]. This approximation is good for the central region of the plasma, where the characteristic times for ionization and recombination are significantly shorter than the typical transport times. Furthermore tokamak plasmas are transparent to soft X-ray radiation. The emission rate shown in Figure 2 is typical of a large number of elements. The radiation spectrum can be tuned by using different plasma contaminants. Table 1 shows the principal lines emitted by germanium, selenium and aluminum. The indicated lines are the strongest lines and are listed in order of importance. Also indicated in the table is T,ot, the approximately optimum temperature for achieving neon-like ions in germanium and selenium and helium-like ions in aluminum. Under such conditions, most of the radiated power is in the dominant lines. The strong variation of the impurity radiation with temperature shown in Figure 2 can be used, as will be shown below, in order to obtain relatively narrow characteristic lines. Simply stated, the condition for narrow radiation spectrum 8 reduces to the requirement that the electron temperature profile be substantially broader than the impurity density profile. Higher energy radiation (2000-2500 eV) can be achieved if higher Z elements such as yttrium (Z = 39) and molybdenum (Z = 42) are used (both with neonlike states). The advantages of these materials are that they are solid at room temperature and are non-toxic. This greatly facilitates the safe production of pellets and also avoids contamination of the interior of the tokamak, which will on occasion be depressurized. An interesting observation is that the power density of the X-ray radiation on axis could be larger than the on-axis input power density [211. This is energetically possible due to a heat transfer from the outer regions of the plasma into the plasma axis. This phenomena is especially pronounced in the presence of hydrogen pellet injection. Another method of producing soft X-rays with a tokamak is by using bremstrahlung radiation (that is, using free-free transitions). However, we found that under most conditions line radiation was a much more efficient mechanism for radiating energy. Furthermore, the spectrum of bremstrahlung radiation is undesirable since it is broad. For the plasma conditions that we will consider in this paper, the bremstrahlung radiation plays a minor role. 9 4 Power density at the wafer for extended sources In this section the radiation density at the wafer is approximately calculated. It can be shown that the optimum location of the viewing port is tangential to the plasma, as shown in Figure 1b. The reasons for this are two-fold: not only is the power density at the wafer maximized, but the radiation from the center of the plasma is also maximized with the net result of a narrower spectrum than possible for perpendicular viewing. In what follows, therefore, it is assumed that the viewing is tangential. An approximate formula for the power density at the wafer can be obtained the following way. The power density (X-ray flux) at the wafer APm.f, from a small radiating volume located at (p, z) is given by AG e APW,.Awafer = Pvol(pz)4 A(Z z) 2 dz dA, (7) where Awafer is the area of the wafer, A.., is the area of the aperture, P,,,I(p, z) is the emission power density at (p, z), dzdA, is the differential plasma volume under consideration, and Z, is the distance between the radius of tangency and the aperture (Figure 1b). For the conditions of interest, p < diameter of the aperture d < Zo - z and the . It is necessary to carry out the integration both in the radial (p) and axial (z) directions. dA, is small due to the typical dimensions that are considered for X-ray lithography (the aperture size is typically 0.01 m and the wafer-to-aperture distance is typically 1 m). As a consequence the plasma properties in the radiating volume vary slowly in the radial direction p. Neglecting the radial variations and the integrating in the radial direction, (7) becomes APafCVA.wGje, = P, (Zp) A'e 47r(Z. - z)i A, dz (8) A, is determined from the geometry in Figure la, A, ~ Awafer ( 10 Z (9) where we have again assumed that d < t. Combining (8) and (9) and integrating, the power density at the wafer is given by Ps.. A=s PoA(z )dz = A . P,.(z)dz . (10) The size of the field with relatively uniform exposure is determined next. Using geometrical considerations, the diameter of the uniformly exposed area at the wafer location d 1,.16 is given by daf., 2 (11) where ai is the radial extent of the impurity profile in the tokamak. For the type of numbers used in this paper, Z./ = 0.25, d = 0.01 m and the effective size of the source is 0.012 - 0.025 m. The allowed wafer size is 0.7d..f,. because the wafers are usually of square shape, not circular. In principle, then, it would be possible to expose wafers of substantial size (- 0.07 - 0.15 m) provided that a solution is found to the practical problems of manufacturing and stability of the mask [2]. The values of the exposure fields that are being considered today for X-ray lithography are approximately 0.03 - 0.05 m. The diameter of the aperture d is determined by penumbra. The area of the aperture A.,.,. is then given by A.,., = d2 = ' (6mpenumra For submicron lithography, a typical number for , (12) 2 is 1 x 10-r m (0.1 'm) [2]. Combining (10) and (12), Pwfr = 8.. P,.(z) dz 11 (13) 5 Pulsed operation: Inductive current drive A reason for the limited interest in inductively driven tokamaks (with ohmic drive) for lithography is the limited power input (and consequently output power). The plasma current is limited by MHD stability, i.e., the requirement that q > 1 on axis.[8] The ohmic input power density is Pohmic = 7 2 :-=3 oZeff /2 BT) 2 (14) where Y = ioZff/T.3/2 is the plasma resistivity, Zq 1 is related to the impurity concentration, Zeff = Z(niZi)/ E(nZ). For tokamaks with BT : 5 T, R = 1 m and T. - 1.3 keV, the central power density is P,.1 = 2.5 - 5 MW/M 3 . This number is relatively low for X-ray lithography, because it implies relatively low power density at the location of the mask (as discussed in section 6). This power limit can be removed by operation with auxiliary heating, and will be discussed in the next section. Due to the pulsed nature of today's tokamaks and to the limit in the input ohmic power, a X-ray lithography system would required a large number of pulses per exposure with a high duty cycle for adequate wafer throughtput. The in- ductively driven tokamak plasmas, however, could be used for applications where high throughput is not required, such as testing resists, masks, aligners and other non-lithography applications. [9, 10] If pulsed, the ramp up and ramp down of the plasma should be relatively fast, implying large power requirements. fraction (- The power supplies represent a large 1/2 - 1/4) of the cost of present tokamak systems. If steady state plasma operation is used, the magnet supplies can be minimized by the use of superconducting technology. 12 6 Steady-state operation: RF current drive In order to obtain adequate power density at the wafer it may be necessary to enhance the ohmic heating power input, since power balance implies that the net power radiated can not be greater than the input power. The auxiliary power used for this purpose could simultaneously fill the need of steady state current drive. Driving the currents with RF waves that impart their momentum to the plasma electrons has been proposed theoretically [11] and proven experimentally (12). Although attainement of sufficiently high value of current drive per unit of input power is a concern for fusion reactor applications, it does not appear to be so for the X-ray lithographic applications considered here. This is because of the auxiliary input power required in order to provide for the radiating power. The figure of merit for RF current drive is IRn, IPRtF pR= (15) where I, is the plasma current and PRF is the power required to drive the plasma current. For present day experiments, -y = 0.1 - 0.2. There is small degradation of the value of y due to the presence of the impurities. The power to drive the plasma current is radiated away with very high efficiency. The RF frequency, if lower hybrid waves are employed for the dual purpose of heating and current drive, is given by w = 2WLf > 2 W(16) V1+ Wpi,/"$c, where w,. = n~e2 /eom, and wi = nie 2 /e.m, are the electron and the ion plasma frequencies and w,,. = eB/m. is the electron cyclotron frequency. m. and mi are the electron and ion masses, e is the charge of the electron and e. is the permeability of free space. WLH is defined as the lower-hybrid frequency. For the parameters in this paper, the required RF frequency lies in the range 6 - 10 GHz. The value of the toroidal field is determined by the requirement of penetration of the auxiliary heating and current drive power to the center of the plasma. For 13 the values of plasma density and sizes required for X-ray lithography applications, the toroidal field should be in the 5 - 10 T range. 14 System integration 7 Illustrative parameters for a steady state tokamak X-ray source system are shown in Table 2a. In order to minimize the power requirement it is assumed that the toroidal and poloidal field magnets are superconducting. The peak field at the coil is 12 T and the overall current density in the magnet is 10 MA/m2, values that are easily achievable with superconducting magnets. The use of superconducting magnets is further facilitated by the steady state nature of the discharge. Plasma parameters are shown in Table 2b. Note that the central electron density is increased by a factor of approximately 3 due to the presence of the impurities. The impurity is germanium. The power density at the wafer is independent of 1, the distance between the wafer and the aperture (Figure 1 and equation (13)). The typical 1/r 2 drop- off of the power density that would normally be observed for fixed aperture size is balanced by the increase in the aperture size, resulting in no net decrease in the power density at the wafer. For large values of I (larger than considered in this paper), the model breaks down and the radiation decreases with increasing distance. (Mathematically, the assumption of small variation of P,.1 with p breaks down). If the mask/wafer distance is decreased, the size of the aperture and the power density at the wafer can be increased for fixed penumbral shadow thickness. For fixed penumbral size, the power density at the wafer scales as Pwf,, = -- 2 (see equation (13)). This relation also breaks down for very small values of ., for the same reason that the model breaks down for large values of 1. Table 3 shows the characteristics of the X-ray lithography system resulting from using the illustrative parameters in Tables 2a and 2b. Pt,,, the total power radiated for the conditions indicated in Tables 2 and 3 is 2 MW. The plasma current is ~ 0.3 MA. Therefore, the heating system (needed to balance the power losses, in this case the radiation) also approximately matches 15 what is needed for current drive (t..q = 0.08). If ohmic input were the only power source, for the parameters in Table 2 the total radiated power would be < 0.5 MW (at which point all the ohmic power is radiated). Therefore, for ohmic drive the power at the wafer would be more than a factor of 4 lower than for the auxiliary heated case. As an illustration, for a total exposure area of 10-1 m 2 (twelve wafers each with an exposure area of ~ 100 cm 2 ), the total X-ray power that that is utilized is 15 W. The system efficiency is then ~ 3 x 10-6. The total power efficiency r, defined as P.f,/Ptt can be increased in a number of ways. As mentioned previously, the mask/wafer spacing can be reduced. Another possibility is to minimize the first wall of the device. The X-ray power of a tokamak is distributed approximately uniformly on the first wall, of which only a small region is used (the area of the apertures). Therefore it should be possible to reduce the power required by decreasing the first wall area, that is, increasing the aspect ratio. Figure 3 shows r as a function of the plasma minor radius. The parameters in Figure 3 are drawn for a machine with R = 1 m, nb = 2 x 1020 m- 3 ni = 0.17 x 1020 m-3 , T, = 1.7 keV, I = 2 m and a = 3 x 10' m (30 am). It is assumed that a and aT = 0.45a (17) Although an attractive possibility for decreasing the power input to the plasma, there may be practical problems associated with very large aspect ratio that require further investigation. The plasma current, for instance, decreases with increasing aspect ratio and may be too low for confinement. Furthermore, it may be hard to couple several megawatts into a machine with minor radius of less than 0.1 m. For the illustrative case in Tables 2 and 3, it is assumed that the aspect ratio is 10. A layout of a system with 12 exposure stations is shown in Figure 4. There 16 are 6 tangential ports, each port serving two lithography stations. The distance between the plasma and the wafer is determined by the size of the lithographic station for the case of 12 ports. It is assumed that each station is 0.8 m wide. Smaller distances could be achieved (but without resulting in increased power density at the wafer, as was shown above) for smaller number of lithographic stations. There are substantial magnetic fields at the location of the lithographic stations and the wafer. Nonmagnetic material should be used. The value of the magnetic field is 10- - 3 x 10' T (10-30 Gauss). The minimization of the mag- netic field at the lithographic station could be more limiting than size limitations of the lithographic station. 17 8 Cornparison with other sources of X-ray radiation Table IV compares tokamaks and synchrotrons for X-ray lithography appli- cations. The power density on the mask depends strongly on s, the mask-wafer distance (equation (13)). If a could be reduced from the generally used value of 30 pm to a value of 5 - 15 pm, there will be substantial benefits both in terms of reduced exposure time and reduced Fresnel diffraction. The peak power and the average power on a ~ 20 cm 2 exposure field are given. Due to the very small vertical X-ray beam size in the synchrotron (typically 5 mm), either the wafer or the beam should be scanned to provide the exposure field for a 20 cm 2 mask. If large masks could eventually be employed (providing, for example, 100 cm 2 fields), it could be possible to use the tokamak X-ray source to provide a single wafer without any scanning. Advantages of the synchrotron with respect to the steady state tokamak are: a) the electrical input power required is substantially smaller for the synchrotron due to the natural collimation of the radiation even though both the synchrotron and the tokamak radiate most of the power; b) The magnets of the synchrotron are comparable to the poloidal field magnets of the tokamak, but the tokamak has the additional requirement of the toroidal field magnets; c) the synchrotron is a significantly more established technology. Possible advantages of the steady state tokamak are: a) large uniformly exposed areas, with the possibility of exposing large fields (10 cm across) if desired. As mentioned previously, the beam and/or the wafer would have to be moved to accomplish the same with the synchrotron, resulting in increased complexity and increased time exposure requirements; b) the spectrum from the tokamak is narrower than the synchrotron, with two or three closely spaced lines as opposed to a the synchrotron's broad band spectrum; c) the tokamak source attractiveness would be enhanced substantially over the synchrotron if the distance between the wafer and the substrate can be decreased; d) the tokamak source is not polarized, in contrast with the synchrotron; e) the basic tokamak size is smaller than the 18 synchrotron. While the pulsed sources (both laser produced plasmas and 3-pinches) have attained considerable success, there are still fundamental problems. The large power densities a-pinches erodes the electrodes, and the presence of debris requires extra steps for preventing coating of the mask (for windowless systems) or the windows. Finally, the broad spectrum and the large instantaneous powers result in substantial heating of the mask and the resist. 19 Conclusions X-ray lithography using a tokamak plasma confinement has been analyzed. A modest size, steady state tokamak could be an source of narrow band X-ray radiation from line-emission of plasma impurities. Tunability could be provided by varying the plasma conditions and the impurity. In order to drive the plasma current and enhance the radiation power, lower hybrid waves are used. A high aspect ratio design is used to improve overall efficiency. A total power of 2 MW at a frequency of 6 - 10 GHz is employed for the dual purpose of plasma heating and current drive. The power at the wafer is - 7.5 mW/cm 2 and - 30 mW/cm 2 for mask-wafer spacings of 30 jtm and 15 pm, respectively. The geometry of such a system was briefly studied, and it seems that up to 12 stations can be placed around 6 ports of the tokamak. The tokamak might provide advantages of uniform,large area exposure, relatively narrow spectrum and significant tunability. However, cost and the lack of established high duty factor operation could prevent its development as a competitive technology for lithography. Reduction of the mask-wafer spacing could be very beneficial both in terms of reduced exposure time and decreased Fresnel diffraction. Another possibility is significantly reduced tokamak drive power requirements. For example, if the mask-wafer can be decreased to 15 jpm, the tokamak drive power could be reduced to - 0.5 MW, while keeping the power density in the wafer constant. A tokamak X-ray source may also find other uses. These include solid state physics studies, imaging of biological samples and instrument calibration. Some of these applications may not require the high power or the steady state operation, and may be implemented lower performance tokamak devices. 20 Acknowledgements One of the authors (LB) would like to express thanks to Prof. H. Smith for very useful discussions. The authors are also indebted to Dr. P. Bonoli for helpful discussions about current drive. 21 References 1 D.L. Spears and H.I. Smith, Electron. Lett 8 102 (1972); D.L. Spears and H.I. Smith, Solid State Tech. 15 21 (1972). 2 A.R. Neureuther, in Synchrotron Radiation Research, H. Winick and S. Donach ed., Plenum Press, N.Y. (1980) 3 See, for example: D. Maydan, G.A. Coquin, J.R. Maldonado, S. Somekh, D.Y. Lou and G.N. Taylor, IEEE Thans. Electron Devices ED-22, no.7 429 (1975) 4 H.M. Epstein, P.J. Mallozi and B.E. Campbell, Proc SPIE 385 141 (1983) 5 J.S. Pearlman and J.C. Riordan, J. Vac. Sci. Technol. 19 1190 (1981) 6 I.Okada, S. Ssaitoh, S. Itabashi and H. Yoshihara, J. Vac. Sci. Technol. B. 4 243 (1986) 7 E. Spiller, D.E. Eastman, R. Feder, W.D. Grossman, W. Gudat and J. Topalian, J. Applied Phys. 47 5450 (1976) 8 For a review of tokamak research, see H.P. Furth, in Fusion (E. Teller, Ed.) Vol 1, Part A, Academic Press, N.Y. (1981) 9 R. Petrasso, private communication. 10 P. Lee, in Proceedings of the SPIE 3&h Annual International Technical Symposium on Optical and Optoelectronic Applied Sciences and Engineering (1986) (also G.A. Report GA-A18517) 11 For a review article on the theory and experiment of noninductive current drive, see Fisch, N. in Reviews of Modern Physics 59 175 (1987) 12 M. Porkolab, IEEE Trans Plasma Science, Vol PS-12 No.2 pp 107 (1984) 13 See, for example: P. Bonoli, IEEE Transaction on Plasma Science, Vol PS-12 22 No.2 pp 95 (1984) 14 See, for example: B.S. Fay and W.T. Novak, in Electron-Beam, X-ray and Ion Beam Techniques for Submicrometer lithographies V, SPIE 632 (1986) 15 H. I. Smith, Submicron Structures Technology (Lecture notes for Massachussets Institute of Technology course 6.781), 1986 16 S.P. Hirshman and D.J. Sigmar, Nucl. Fusion 21 1173 (1981) 17 See, for example: R.C. Isler, Nucl Fusion 24 1599 (1984) 18 W. Engelhardt, 0. Klueber, D. Meisel et al., in Plasma Physics and Controlled Nuclear Fusion Research (Proc. 7th Int. Conf., Innsbruck, 1978), IAEA, Vienna (1979), pp 123 19 R.D. Petrasso, D.J. Sigmar, K.W. Wenzel, J.E. Hopf, M. Greenwald, J.L. Terry and J. Parker, Phys. Rev Lett. 57 6 pp 707 (1986) 20 D.E. Post, R.V. Jensen, C.B. Tarter, W.H. Grasberger and W.A. Lokke, Atomic Data and Nuclear Tables 20 397 (1977) 21 J. Schivell, C.E. Bush, R.A. Hulse et al., Bull. Am. Phys. Soc. 32 9 pp 1808 (1987) 22 A. D. Wilson, Solid State Technology, May 1986. 23 Table 1 Dominant lines for Ge, Se, and Al Material Energy (keV) Ne-like Ge 2p-3d 1.36 2p-3s 1.225 2s-3p 1.46 Ne-like Se 2p-3d 1.63 2 p- 3 s 1.47 2s-3p 1.75 He-like Al ls-2p (All') 1.2 -0.2+0.4 1.5 -0.3+0.5 0.9 -0.2+0.3 1.6 H-like Al ls-2p (Al 1 2 ) (keV) 1.72 24 Table 2 Tokamak parameters for Tokamak source (a) Illustrative Device parameters Major radius (m) 1 Minor radius (m) 0.1 Elongation 1 Toroidal field on axis (T) 5 Plasma current (MA) 0.2 7 - q - 0.4 3 Peak field at toroidal magnet (T) 8 Current density of toroidal magnet (MA/M 2 ) 10 x 106 Stresses in magnet (MPa) 350 - 10 (a) Illustrative Plasma parameters Central hydrogen density (1020 m- 3 ) 2.0 Central impurity density (1020 m-3 ) 0.17 Central electron density (1020 m- 3 ) 6.0 Central electron temperature (keV) 1.7 ai (m) 0.025 a'r (m) 0.045 Power radiated (MW) 2 Power density at the first wall (MW/M 2 ) 0.55 25 Table 3 Ilustrative characteristics of an X-ray system based on the tokamak Total radiated power (MW) 2 Penumbral size limit (10~6 m) 0.1 Size of mask-wafer gap (10- 30 15 aperture to wafer distance (m) 2 2 Power at the wafer (W/m 2 ) 75 300 Maximum wafer size (m 2 ) .1 X .1 .1 X Number of beam lines 12 12 26 m) Table 4 Comparison of several X-ray sources synchrotron/ Storage ring Tokamak Spectrum Wideband closely spaced lines tunability source-wafer distance (m) 4-40 A easy 10 5-200 A easy 2-10 pattern distortion Fresnel blurring + Fresnel good good good homogeneity horizontal vertical poor* average intensity on 20 cm 2 muk(W/m 2 ) 500t 75 (a=30p'm) 300 (a=15Am) 220t 75 300 pulsed, high (vertical scan CW average intensity on 100 cm 2 mask (W/m 2 ) time dependence 1 - 105 Hz) From reference 22 1 mrad resulting in a beam size of 5 mm at a distance of 5m from the synchrotron. * 27 List of Figures Figure la Schematic diagram of the X-ray source/wafer geometry. Figure lb Plane view of a tokamak X-ray source. Figure 2 Emission rates from germanium. Figure 3 F as a function of the plasma minor radius. Figure 4 Layout of a system with 12 exposure stations. 2'8 RADIATING VOLUME APERTURE MASK oft WAFER wown Awafer w, A 34% .. j 4~~id~ J dAp IF iN Figure la PLASMA -H z f . .. Li .. -- WAFER APERTURE m ....... ..... . b 1 : ::*~,:~ 4-N d ....... \Io - zo -41 Figure lb mik. f I I I ' I ~ I I C 0C E. 0L I I %V1 0 a a I . . . . III CYJ I I 0 TM x I (S/ . WO)k8 j. I I I I I I 0 II 0 -W cc cmd~ to I I I N W I a I I 0 AD V co CYJ 0 (C-W) d I 9= 0 A I L V TF Figure 4