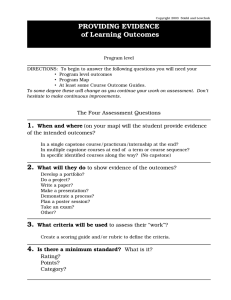

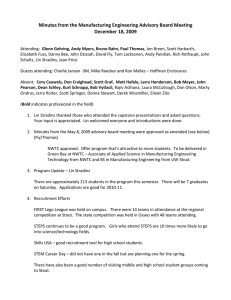

Minutes from the Manufacturing Engineering Advisory Board Meeting December 17, 2010

advertisement

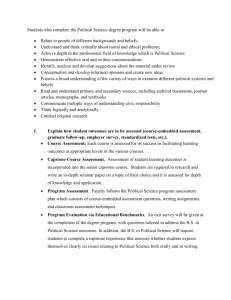

Minutes from the Manufacturing Engineering Advisory Board Meeting December 17, 2010 Attending: Glenn Gehring, Matt Hafele, Kurt Schnapp, Paul Thomas, Ben Ferron (student), Elizabeth Fuss (student), Jerome Johnson, Tom Lacksonen, Rich Rothaupt, Scott Springer, Lin Stradins, Derek Wissmiller, Eileen Zito, Dan Bee, Jeff Anderson Absent: Cory Cauwels, Don Craighead, Scott Graf, Ron Malles, Andy Myers, Bob Meyer, Don Olson, Bruno Rahn, Dean Schley, Bob Vytlacil, Rajiv Asthana, Christopher Bendel, John Dzissah, David Fly, Mike Galloy, Cheng Liu, Laura McCullough, Jerry Roiter, Forrest Schultz (Bold indicates professional in the field) 1. Lin Stradins thanked those who attended the capstone presentations and asked questions. Your input is appreciated. Lin welcomed everyone and introductions were done. 2. Minutes from the May 14, 2010 meeting were approved as distributed (Zito/Thomas). 3. Program Update – Lin Stradins There are 218 total students in the program this semester. Eighteen are graduating tomorrow. Some of the current graduates are getting multiple offers. 29 out of 33 graduates from spring semester are working. Co-op numbers are good. The number of applications for next year is not as solid as last year. The numbers are down for all majors on campus. Admissions office is behind on processing applications. 4. Recruitment Efforts STEPS continues to be a good way to bring women into engineering and mathematics. There were 19 teams on campus for the FIRST Lego League tournament. 182 high school students were on campus for STEM Career day. We offered more activities and longer time period with each group. Paul Thomas asked about contacting students who are home schooled. It was suggested that a notice could be put in the paper or the alumni news. The number of middle school groups visiting has been increasing. Also community colleges have been visiting. Dan Bee indicated that enrollment in the tech school is growing. Ideas to increase recruitment efforts were discussed: work with former graduates who want to tie in with Stout, send current engineering students to high schools (i.e. students in organizations SME, SWE), have co-op students present about their co-op experience at high schools (include template about program information and a video clip of student projects), and recruit at Minnesota schools. Graduates who did not do co-ops are having a harder time getting jobs. Motion Passed A motion was made, seconded and passed to revise the program that a co-op be required and students do a presentation at a high school. (Springer/ Rothaupt) A program change will be processed requiring manufacturing engineering students to perform a co-op/internship. 5. ABET Campus Visit The ABET campus visit was in October. There were no deficiencies. There was one weakness – mapping of course objectives to program outcomes. Two concerns were identified: 1) review of program objectives with constituencies, and 2) implement process to facilitate continuous improvement of program. Revised materials need to be submitted by May. Gloria Rogers who heads training at ABET was on campus recently. She had some very helpful information. 6. Review of Program Objectives 1) In demand by manufacturing employers 2) Recognized for their ability to apply manufacturing engineering expertise (measured by employers/graduates, do after 1 and 5 years, survey goes to graduate and they ask employer to fill out) 3) Graduates recognized for their leadership and team work skills (taught in capstone classes) 4) Continue to develop professionally (leadership roles taken in professional organization, continue education) Program objectives were reviewed and discussed with the decision that no changes are necessary. Strengths: upgrading of manufacturing engineering lab/facilities, benefit of hands on faculty, had DVD of student capstone projects. Contact companies for donation of tools. CAM class working with Adam Kramschuster (plastics engineering program director) on a collaborative project. Recognized innovation and problem solving (Danny). Add creativity – how would measure? #2 – measure by promotion and career advancement. 7. Open Discussion The program at Green Bay does not have enough students so there are scheduling problems. The program is not tied to the B.S. manufacturing engineering program for ABET accreditation. Courses are not being taught by our faculty. We need to increase the number of students in the program or the program will be pulled. Scott asked if the program should be converted to an engineering technology program and/or if the idea should be proposed to the tech school? ABET accreditation is important to some programs. Plastics engineering and computer engineering will also be seeking ABET accreditation. Push to get ET accredited. Should a concentration be reopened under ET – it could be more universal? Review outcomes? New outcomes that graduate will have practical experience? Send out ahead of time to advisory board? – Scott Springer Perhaps there could be additional resources available for capstone projects (technical assistance) – Paul Thomas A general assessment could be done prior to the final project – Tom Lacksonen Perhaps a person who is a leader in a specific area could come to a mid term presentation – Elizabeth Fuss Some technical support in controls would be helpful – Ben Ferron Capstone projects pull in everything that’s been learned. It’s a good recruitment tool for prospective students to see capstone projects - Rich Rothaupt All capstone projects use process design – Tom Lacksonen Include NWMOC staff in capstone projects/presentations. 8. Next Meeting The spring meeting will be held on Friday, May 13 with capstone presentations starting at 10:00 am.