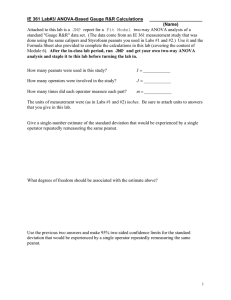

IE 361 Exam 1 Spring 2011 (Corrected)

advertisement

IE 361 Exam 1 (Corrected) Spring 2011 I have neither given nor received unauthorized assistance on this exam. ________________________________________________________ Name Date 1 Below are 25 True-False Questions, worth 2 points each. Write one of "T" or "F" in front of each. _____ 1. Modern quality assurance is fundamentally process-oriented. _____ 2. If a production process is made to be consistent/physically stable, then it will of necessity produce good/functional product. _____ 3. Most effective process improvement analysis is based on data mined from large generalpurpose databases. _____ 4. Shapes of histograms can provide clues to physical origins and thus clues about the operation of processes that generated the data being summarized. _____ 5. Complicated multi-step production processes are most effectively monitored through "end-of-the-line" inspection where a whole final product can be inspected, and causes of problems can thus be easily diagnosed. _____ 6. A bell-shaped histogram of consecutively-produced widget diameters is evidence that a production process is operating consistently over time, so nothing more can be revealed by plotting a run chart. _____ 7. A Pareto diagram is used to focus attention on the biggest causes of process problems. _____ 8. Without effective measurement systems, it is impossible to know whether a business or production process is performing well. _____ 9. Without appropriate routine collection and analysis of process data, it is impossible to know whether a business or production process is performing well. _____ 10. Measurement variation will typically inflate one's perception of process variation (based on the measurement of a sample of parts produced by a process). _____ 11. When measurement is destructive, there is no possibility of evaluating the size of pure repeatability variation. _____ 12. The width of a confidence interval for a standard deviation, , tells one about the size of . _____ 13. In order to compare biases of two measurement devices, one needs at least two "standards" (items with known values of measurands). _____ 14. Measurement device A is known to be linear, but is not known to be properly calibrated. I wish to know if device B is linear. That can be determined using A and B only if standards are available. _____ 15. A gauge R&R study typically reveals which of several operators produces the most accurate measurements. 2 _____ 16. If widget diameters have actual standard deviation .01 mm and measurement has standard deviation .01 mm , then measured diameters can be expected to exhibit a standard deviation of .02 mm . _____ 17. In an R&R context, limitations on the amount of information available on reproducibility related to a relatively small number of operators being included in the study can be overcome by use of a large number of parts. _____ 18. If a gauge capability ratio (or precision to tolerance ratio) is at least 1.00, the gauge in question is probably adequate for checking conformance to the engineering specifications under study. _____ 19. Industry standard range-based gauge R&R analyses fail to produce appropriate estimates for reproducibility and lack associated confidence interval methods. _____ 20. Measurement precision can often be improved by finding an equation to use in replacing raw measurements with transformed or adjusted measurements. _____ 21. In a go/no-go R&R study, it is theoretically impossible for two operators to each be perfectly consistent in their go/no-go calls for a part, and yet have different probabilities of calling "go." _____ 22. Repeatability variance in a go/no-go R&R study is unlike that in a measurement R&R study, because it is assumed to vary "cell-to-cell." (If the part or operator changes, it typically changes.) _____ 23. If there is no reproducibility variance in a go/no-go R&R study, then all operators must be individually perfectly consistent in their go/no-go calls. _____ 24. Confidence limits .1 .02 for the difference in two "go" call rates for a fixed part by two different operators in a go/no-go study, p1 p2 , indicates that there is no clear different in the call rates. _____ 25. In the estimation of p1 p2 based on pˆ1 .2, pˆ 2 .3, and n1 n2 10 , approximate 95% confidence limits are .1 .41 . The next 5 pages each have a 10 point "work out" problem on them (numbered W1, W2,W3,W4, and W5.). Answer all 5. 3 W1. Two operators made m 10 go/no-go calls on each of I 5 parts. The table below provides their "go" call rates. Make and interpret an appropriate 95% confidence interval for comparing overall (across all parts) "go" call rates for the two operators. Part 1 2 3 4 5 Operator #1 "go" Call Rate .2 .1 .8 .4 .9 Operator #2 "go" Call Rate .2 .3 .9 .4 1.0 Interval: Interpretation: 4 W2. 20 students each measured the size of a single Styrofoam packing peanut once. Their measurements produced a sample standard deviation of .014 in . Subsequently, a single student who missed class measured that same peanut 10 times. That person's measurements produced a standard deviation of .006 in . It is sensible here to say that the 20 measurements were observations 2 2 each having (theoretical) variance reproducibility repeatability and that the 10 measurements were 2 . observations each having (theoretical) variance repeatability This scenario is not exactly like any discussed in class, the modules, or the revision of V&J. But its basic structure is like one you've encountered, and a statistical method from class can be used to make approximate 95% confidence limits for reproducibility . Do this. 5 W3. Below is a JMP report from a data set collected to relate temperature to resistance of a carbon resistor. The report is for a fit of the model y 0 1 x 2 x 2 3 x3 to the x temperature (K) and y resistance () data pairs from the study. Plotted is the curve fit by least squares and 99.5% prediction limits for ynew at each value of x . (Simple linear regression corresponding to the simpler model y 0 1 x is clearly not appropriate here, but this cubic modeling seems to be sensible.) Consider the future use of this resistor to measure temperature. What are 95% confidence limits for the repeatability standard deviation of measured resistance at a given temperature for this resistor? What are 99.5% confidence limits for the actual temperature if a resistance of 13.0 is observed for this carbon resistor. (Indicate on the JMP report how you obtained the interval.) 6 W4. Two digital calipers are used to measure a gauge block "known" to be a 2.000 in gauge block. Summary statistics for the two sets of measurements are below. Caliper #1 n1 5 y1 2.0012 in s1 .0005 in Caliper #2 n2 10 y2 1.9998 in s2 .0008 in Give 95% confidence limits for the Caliper #1 bias for measuring 2.000 in. Give 95% confidence limits for comparing Caliper #1 and Caliper #2 biases for measuring 2.000 in. 7 W5. Here are some summary statistics from a standard gauge R&R study involving 5 operators and 10 parts where every operator measures each part 4 times SSOperator 10, SSOperator Part 6, and SSE 20 (units of sums of squares are lb 2 ). Find an estimate of R&R . Approximate degrees of freedom for ̂ R&R are ˆ 36.96 . Use this fact and your value from above to give approximate 95% confidence limits for R&R . 8