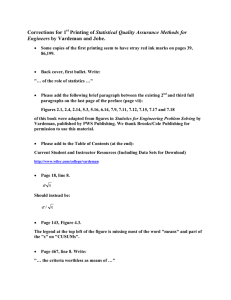

IE 361 Module 11

advertisement

IE 361 Module 11 Shewhart Control Charts for Measurements ("Variables" Data) Reading: Section 3.2, Statistical Quality Assurance Methods for Engineers Prof. Steve Vardeman and Prof. Max Morris Vardeman and Morris (Iowa State University) Iowa State University IE 361 Module 11 1 / 20 Shewhart Control Charts for Measurements In this module we consider Shewhart control charts for measurements (or so called "variables data" in old time SQC jargon). As our featured example, we will use the data from an IE 361 Deming drama. These are recorded in the …gure on panel 3. (The "red bag" was an earlier version of the current "brown bag," i.e. had process parameters µ = 5 and σ = 1.715 and was approximately normal.) Vardeman and Morris (Iowa State University) IE 361 Module 11 2 / 20 Deming Drama Data Figure: Data from an IE 361 Deming Drama Vardeman and Morris (Iowa State University) IE 361 Module 11 3 / 20 Charts for Means We introduced the topic of Shewhart control charts in Module 10 using the most famous of all such charts, the x̄ charts. To review, we saw that the (approximately) normal distribution of x̄ (with mean µx̄ = µ and p σx̄ = σ/ n) leads to standards given control limits for x̄ σ UCLx = µ + 3 p n and LCLx = µ σ 3p n Further, we saw that in a retrospective situation like that illustrated on panel 3 where sample means x̄ and sample ranges R are computed, estimates µ̂ = x and σ̂ = R̄/d2 can be substituted to produce retrospective control limits for x̄ UCLx = x + 3 Vardeman and Morris (Iowa State University) R̄ p d2 n and IE 361 Module 11 LCLx = x 3 R̄ p d2 n 4 / 20 Charts for Means (Example 11-1) In fact, it is traditional to set A2 = 3 p d2 n and rewrite these retrospective control limits as UCLx = x + A2 R̄ and LCLx = x A2 R̄ Example 11-1 We saw in Module 10 that (since for the brown bag µ = 5 and σ = 1.715) standards given control limits for x̄ are 1.715 UCLx = 5 + 3 p = 7.3 5 and LCLx = 5 1.715 3 p = 2.7 5 These limits are marked on the x̄ control chart on panel 3 and we can see that if they had been applied to x̄’s in real time, process change would have been detected at sample 16. Vardeman and Morris (Iowa State University) IE 361 Module 11 5 / 20 Charts for Means Example 11-1 continued The 18 sample means and ranges from panel 3 average to x = 5.744 and R̄ = 4.278 So retrospective limits for x̄ are (since the sample size is n = 5) UCLx = 5.744 + .577 (4.278) = 8.21 LCLx = 5.744 = 3.28 and .577 (4.278) When these limits are applied retrospectively to the 18 sample means, we see that the last 3 values are outside of these, and there is thus evidence of process instability in the data on panel 3. Vardeman and Morris (Iowa State University) IE 361 Module 11 6 / 20 Charts for Ranges It is traditional (not as it turns out best practice, but traditional) to use an R chart as a companion to an x̄ chart. (An s chart to be discussed next is actually a better choice than an R chart, but historical precedent makes R charts continue to be common.) The x̄ chart is primarily useful for monitoring process aim, while an R (or s) chart is primarily a tool for monitoring process spread or short term variation. In order to identify appropriate control limits for R one needs to know some probability facts about R based on a sample of size n from a normal distribution. As it turns out, R has a (non-standard) probability distribution (not one you met in Stat 231) with mean proportional to the standard deviation of the sampled process. The constant of proportionality is the d2 that we have used to turn ranges into estimates of standard deviations, that is µR = d2 σ Vardeman and Morris (Iowa State University) IE 361 Module 11 7 / 20 Charts for Ranges (Standards Given Limits) Further, the standard deviation of the probability distribution for R is proportional to the standard deviation of the sampled process. The constant of proportionality is called d3 . That is, σR = d3 σ Taken together, these probability facts about R produce standards given control limits for R UCLR = (d2 + 3d3 )σ and LCLR = (d2 3d3 )σ or, if one de…nes D2 = (d2 + 3d3 ) and D1 = (d2 3d3 ) these standards given limits are UCLR = D2 σ Vardeman and Morris (Iowa State University) and IE 361 Module 11 LCLR = D1 σ 8 / 20 Charts for Ranges (Retrospective Limits) Further, in a retrospective situation like that illustrated in Figure 1 where R’s are computed, the estimate σ̂ = R̄/d2 can be substituted to produce retrospective control limits for R UCLR = D2 R̄/d2 and LCLR = D1 R̄/d2 and D3 = It is traditional to set D4 = D2 d2 D1 d2 and rewrite these retrospective control limits as UCLR = D4 R̄ Vardeman and Morris (Iowa State University) and IE 361 Module 11 LCLR = D3 R̄ 9 / 20 Charts for Ranges Example 11-2 Since σ = 1.715 for the brown bag, a standards given upper control limit for R based on n = 5 is UCLR = 4.918 (1.715) = 8.43 (No standards given lower control limit is typically used, because for a sample size of only n = 5, the di¤erence (d2 3d3 ) turns out to be negative.) This limit is marked on the R control chart in panel 3 and we can see that if it had been applied to R’s in real time, process change would have been detected at sample 16. Recalling that the 18 sample means and ranges from panel 3 average to R̄ = 4.278, a retrospective upper control limit for R is UCLR = 2.115 (4.278) = 9.05 When this limit is applied retrospectively to the 18 sample ranges, we see that the 16th sample range plots "out of control" and there is evidence of process instability in data in panel 3. Vardeman and Morris (Iowa State University) IE 361 Module 11 10 / 20 Charts for Standard Deviations (Basis) s charts represent a superior alternative to R charts. At the price of requiring more than "by hand" calculation (sample standard deviations being more di¢ cult to compute than sample ranges), they provide typically quicker detection of process changes. In order to identify appropriate control limits for s one needs to know some probability facts about s based on a sample of size n from a normal distribution. It is a fact mentioned in Stat 231 (that actually stands behind the standard con…dence limits for σ) that (n 1) s 2 /σ2 has a χ2 probability distribution. It turns out to follow from this fact that s has mean proportional to the standard deviation of the sampled process. The constant of proportionality is something called c4 . That is, µ s = c4 σ Vardeman and Morris (Iowa State University) IE 361 Module 11 11 / 20 Charts for Standard Deviations (Basis and Standards Given Limits) Further, the standard deviation of the random variable s is proportional to the standard deviation of the sampled process. The constant of proportionality is called c5 . That is, σ s = c5 σ Taken together, these probability facts about s produce standards given control limits UCLs = (c4 + 3c5 )σ and LCLs = (c4 3c5 )σ or, if one de…nes B6 = (c4 + 3c5 ) and B5 = (c4 3c5 ) these standards given limits are UCLs = B6 σ Vardeman and Morris (Iowa State University) and IE 361 Module 11 LCLs = B5 σ 12 / 20 Charts for Standard Deviations (Retrospective Limits) Further, in a retrospective situation like that illustrated on panel 3, where s values (instead of R values) are computed, the estimate σ̂ = s̄/c4 can be substituted to produce retrospective control limits for s UCLs = B6 s̄/c4 and LCLs = B5 s̄/c4 and B3 = It is traditional to set B4 = B6 c4 B5 c4 and rewrite these retrospective control limits as UCLs = B4 s̄ Vardeman and Morris (Iowa State University) and IE 361 Module 11 LCLs = B3 s̄ 13 / 20 Standard Deviations and Retrospective Charts for Means A …nal bit of development concerning retrospective s-based calculations is this. Using σ̂ = s̄/c4 , possible retrospective x̄ chart limits are UCLx = x + 3 s̄ p c4 n LCLx = x and and it is traditional to set A3 = 3 s̄ p c4 n 3 p c4 n and rewrite these retrospective control limits as UCLx = x + A3 s̄ Vardeman and Morris (Iowa State University) and IE 361 Module 11 LCLx = x A3 s̄ 14 / 20 Charts for Standard Deviations Example 11-3 (Standards Given) Since σ = 1.715 for the brown bag, a standards given upper control limit for s is UCLs = 1.964 (1.715) = 3.37 (No standards given lower control limit is typically used, because for a sample size of only n = 5, the di¤erence (c4 3c5 ) is negative.) Below are the 18 sample standard deviations corresponding to the data on panel 3. Sample 1 2 3 4 5 6 7 8 9 10 s 1.82 1.92 1.82 1.14 1.14 1.48 .89 .45 1.82 0 11 12 13 14 15 16 17 18 .84 1.22 1.10 .89 2.35 5.63 2.88 3.58 It is evident that if the standards given control limit had been applied to these s’s in real time, process change would have been detected at sample 16. Vardeman and Morris (Iowa State University) IE 361 Module 11 15 / 20 Charts for Standard Deviations Example 11-3 (Retrospective) The 18 values s average to s̄ = 30.97/18 = 1.72. So a retrospective upper control limit for s for the data of panel 3 is UCLs = 2.089 (1.72) = 3.59 When this limit is applied retrospectively, the 16th s plots "out of control" and there is thus evidence of process instability. Further, retrospective control limits for x̄ based on sample standard deviations are UCLx = 5.774 + 1.427 (1.72) = 8.23 and LCLx = 5.774 + 1.427 (1.72) = 3.32 When these limits are applied retrospectively to the data of panel 3, the last 3 values x are outside of them, and there is again evidence of process instability. Vardeman and Morris (Iowa State University) IE 361 Module 11 16 / 20 Charts for Medians A computationally simpler alternative to the x̄ chart is the Shewhart median (x̃) chart. Finding a median requires only putting a data set in order smallest to largest and then …nding the middle value, x̃. This is a measure of process aim like the mean. But is it generally not as reliable as the mean. Di¤erently put, it generally takes longer to detect process change using medians than using means. But in some rare contexts, considerations of computational simplicity may outweigh this lack of sensitivity. In order to identify appropriate control limits for x̃ one needs to know some probability facts about x̃ based on a sample of size n from a normal distribution. x̃ has a (non-standard) probability distribution (not one met in Stat 231) with mean equal to the process mean and standard deviation larger than that of x̄ by a multiplicative factor that we will call κ. That is σ µx̃ = µ and σx̃ = κ p n where a small table of values for κ is given on page 72 of SQAME. Vardeman and Morris (Iowa State University) IE 361 Module 11 17 / 20 Charts for Medians These facts suggest standards given control limits for x̃ σ UCLx̃ = µ + 3κ p n and LCLx̃ = µ σ 3κ p n (Any sensible estimates of µ and σ could further be used to make retrospective limits for x̃.) Example 11-4 Since for the brown bag process µ = 5 and σ = 1.715, standards given control limits for x̃ based on n = 5 are 1.715 UCLx̃ = 5 + 3 (1.197) p = 7.75 5 and LCLx̃ = 5 Vardeman and Morris (Iowa State University) 1.715 3 (1.197) p = 2.25 5 IE 361 Module 11 18 / 20 Charts for Medians Example 11-4 The 18 sample medians for the data of panel 3 are as below Sample x̃ 1 2 3 4 5 6 4 5 4 5 5 4 15 16 17 18 5 12 9 8 7 5 8 5 9 5 10 4 11 4 12 5 13 6 14 5 So if the standards given control limits had been applied to x̃’s in real time, process change would have been detected at sample 16. Vardeman and Morris (Iowa State University) IE 361 Module 11 19 / 20 Two Reminders It is worth saying again that control limits are NOT engineering speci…cations nor vice versa. In Module 10 we said and now say again that a process can be stable without being acceptable and vice versa. The table below again compares these two fundamentally di¤erent concepts. Control Limits have to do with process stability apply to Q usually derive from process data Speci…cations have to do with product acceptability apply to individuals, x derive from performance requirements It is also worth saying that Table 3.11, page 107 of SQAME, summarizes the control limit formulas for both the "measurements data" of this module and for the "attributes data" of Module 13. Vardeman and Morris (Iowa State University) IE 361 Module 11 20 / 20