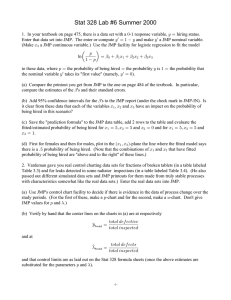

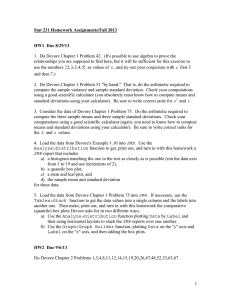

IE 361 Homework Set #1 Fall 2004

advertisement

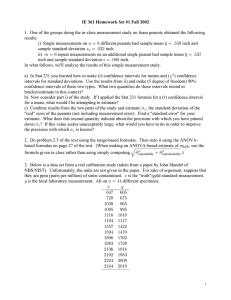

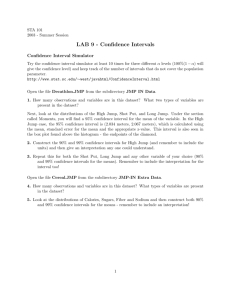

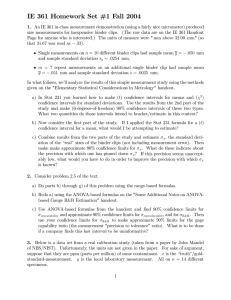

IE 361 Homework Set #1 Fall 2004 1. An IE 361 in-class measurement demonstration (using a fairly nice micrometer) produced size measurements for inexpensive binder clips. (The raw data are on the IE 361 Handout Page for anyone who is interested.) The units of measure were " mm above 32.00 mm" (so that 31.67 was read as −.33). • Single measurements on n = 10 different binder clips had sample mean y = −.050 mm and sample standard deviation sy = .0254 mm. • m = 7 repeat measurements on an additional single binder clip had sample mean y = −.051 mm and sample standard deviation s = .0035 mm. In what follows, we’ll analyze the results of this simple measurement study using the methods given on the "Elementary Statistical Considerations in Metrology" handout. a) In Stat 231 you learned how to make (t) confidence intervals for means and (χ2 ) confidence intervals for standard deviations. Use the results from the 2nd part of the study and make (6-degrees-of-freedom) 90% confidence intervals of these two types. What two quantities do those intervals intend to bracket/estimate in this context? b) Now consider the first part of the study. If I applied the Stat 231 formula for a (t) confidence interval for a mean, what would I be attempting to estimate? c) Combine results from the two parts of the study and estimate σ x , the standard deviation of the “real” sizes of the binder clips (not including measurement error). Then make make approximate 90% confidence limits for σ x . What do these indicate about the precision with which one has pinned down σ x ? If this precision seems unacceptably low, what would you have to do in order to improve the precision with which σ x is known? 2. Consider problem 2.5 of the text. a) Do parts b) through g) of this problem using the range-based formulas. b) Redo a) using the ANOVA-based formulas on the "Some Additional Notes on ANOVAbased Gauge R&R Estimation" handout. c) Use ANOVA-based formulas from the handout and find 90% confidence limits for σ repeatability and approximate 90% confidence limits for σ reproducibility and for σ R&R . Then use your confidence limits for σ R&R to make approximate 90% limits for the gage capability ratio (the measurement "precision to tolerance" ratio). What is to be done if a company finds this last interval to be uninformative? 3. Below is a data set from a real calibration study (taken from a paper by John Mandel of NBS/NIST). Unfortunately, the units are not given in the paper. For sake of argument, suppose that they are ppm (parts per million) of some contaminant. x is the “truth”/goldstandard-measurement. y is the local laboratory measurement. All on n = 14 different specimens. 1 x 647 728 1039 1095 1116 1194 1557 1594 1896 1983 2136 2192 2224 2244 y 605 675 965 995 1018 1117 1422 1470 1762 1739 1918 1983 2008 2010 a) Fit a simple linear regression model to these data. For a fixed x/specimen, what do you estimate “σ measurement ” to be at the local laboratory? What “conversion formula” do you recommend for translating “local lab measurements” to estimated “gold standard measurements”? b) A new specimen is measured as y = 2000 at the local laboratory. Give an approximate 95% confidence interval for the “true”/gold standard value for this specimen. Do this two way. First simply read one interval off a plot of 95% prediction intervals for an additional y at various fixed values of x. Then use the approximate confidence interval formula given in class and on the “Class Outline” handout. You can get help with using the JMP statistical package by looking at http://www.stat.iastate.edu/resources/jmp.html or by using the statistical software primer written for Vardeman and Jobe’s Basic Engineering Data Collection and Analysis available both at http://www.duxbury.com/default.htm (under the “Book Companions”) and in a local/development version at http://www.public.iastate.edu/∼vardeman/book_site/index.html To do the ANOVA part of Problem 2, you will need to enter 3 columns of length 60 into the JMP worksheet. The first should give part numbers, the second should give operator numbers and the third should give the measurements. After entering the data, click on the “Part” column heading, go to the “Cols” menu and choose “Column Info.” There make sure that the “Modeling Type” is “Nominal.” Do the same for the “Operator” column. Then from the “Analyze” menu choose “Fit Model.” You’ll get a dialogue box. The “Measurement” variable gets entered into the “Y” part of the box. The “Part” and “Operator” variables get entered into the “Construct Model Effects” part of the box. Then by highlighting the “Part” variable in the “Select Columns” list and the “Operator” variable already in the “Construct Model Effects” part of the box and clicking the “Cross” button, you can 2 add the interaction effects to the model. Then clicking “Run Model” will get you a JMP analysis. The “Effect Tests” part of the report contains the necessary sums of squares and degrees of freedom to make the necessary estimates. To do Problem 3, you will need to enter 2 columns of length 14 into a new data table. The first should give x and the second should give y. After entering the data, click on “Fit Y by X” under the “Analyze” menu. Put the x variable in the “Factor” part of the dialogue box and the y variable in the “Response” part of the dialogue box and click on “OK.” This will bring up a scatterplot (that can be re-sized to improve resolution if you wish). Click the red triangle on the bar above the plot and bring up a menu. Select “Fit Line.” This will produce a SLR analysis for these data (and plot the least squares line). If you then click on the red triangle by the “Linear Fit” bar below the plot, you can bring up a menu that includes an entry “Confid Curves Indiv.” Checking that option will put 95% prediction limits for an additional y at the various x’s on the plot. You can then select the cross-hair tool from the JMP toolbar and read off values on these plots of prediction limits. Other values you’ll √ need (like MSE) can be read from the JMP report. Simple descriptive statistics for the columns (like x and sx ) can be gotten by choosing “Distribution” from the “Analyze” menu. 3