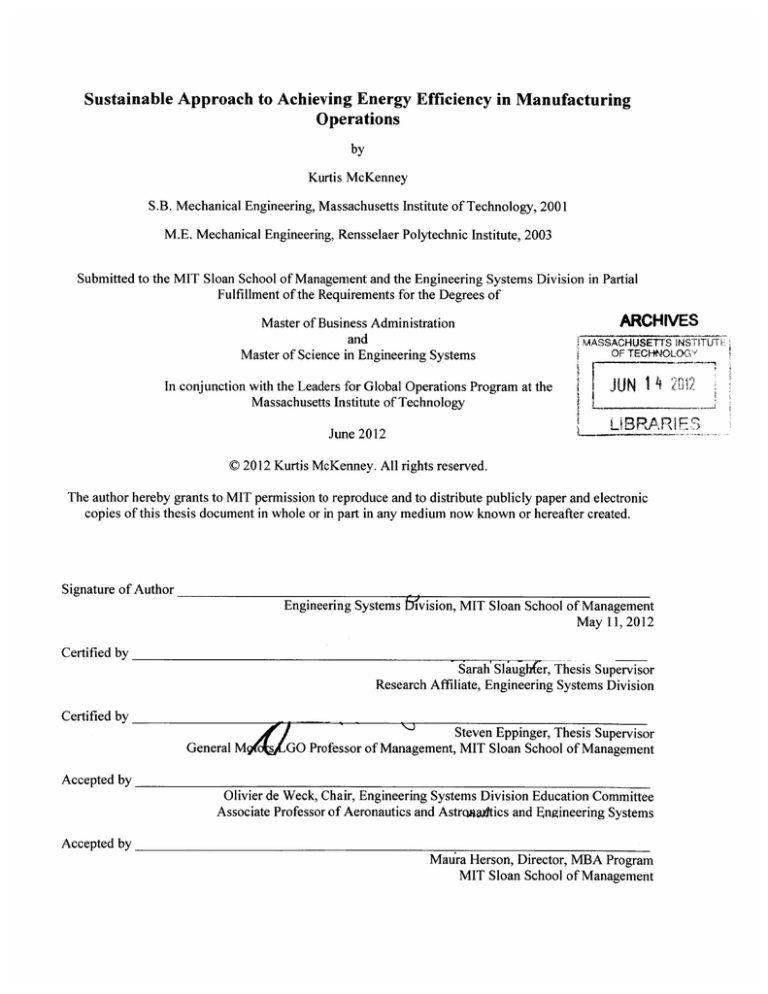

Sustainable Approach to Achieving Energy Efficiency ... Operations by

advertisement