REPORT OF EDUCATIONAL VISIT AT Koyna DAM’s HYDRO-ELECTRIC POWER PLANT

advertisement

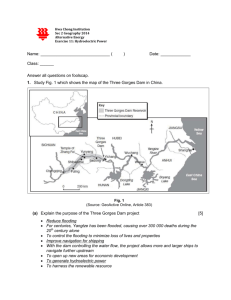

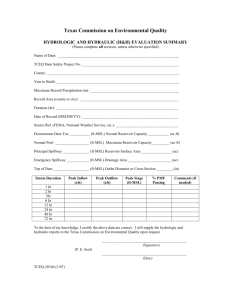

REPORT OF EDUCATIONAL VISIT AT Koyna DAM’s HYDRO-ELECTRIC POWER PLANT CLASS: T.E. CIVIL VPCOE , BARAMATI DATE:(04/09/2015) HYDRO-ELECTRIC POWER PLANT AIM: TO STUDY ABOUT HYDRO ELECTRIC POWER PLANT. 1|P ag e INTRODUCTION: Hydroelectric Power -- what is it? It is a form of energy … a renewable resource. Hydropower provides about 96 percent of the renewable energy in the United States. Other renewable resources include geothermal, wave power, tidal power, wind power, and solar power. Hydroelectric power plants do not use up resources to create electricity nor do they pollute the air, land, or water, as other power plants may. Hydroelectric power has played an important part in the development of this Nation's electric power industry. Both small and large hydroelectric power developments were instrumental in the early expansion of the electric power industry. Hydroelectric power comes from flowing water … winter and spring runoff from mountain streams and clear lakes. Water, when it is falling by the force of gravity, can be used to turn turbines and generators that produce electricity. Hydroelectric power is important to our Nation. Growing populations and modern technologies require vast amounts of electricity for creating, building, and expanding. Hydropower is an essential contributor in the national power grid because of its ability to respond quickly to rapidly varying loads or system disturbances, which base load plants with steam systems powered by combustion or nuclear processes cannot accommodate. Reclamations 47big hydro power plants throughout the India produce an average of 25556.5MWh (megawatt-hours) per year, enough to meet the residential needs of more than 25 million people. This is the electrical energy equivalent of about 150 million barrels of oil. Hydroelectric power plants are the most efficient means of producing electric energy. The efficiency of today's hydroelectric plant is about 90 percent. Hydroelectric plants do not create air pollution, the fuel--falling water--is not consumed, projects have long lives relative to other forms of energy generation, and hydroelectric generators respond quickly to changing system conditions. These favorable characteristics continue to make hydroelectric projects attractive sources of electric power. 2|P ag e HOW HYDROPOWER IS GENERATED: Hydroelectric power comes from water at work, water in motion. It can be seen as a form of solar energy, as the sun powers the hydrologic cycle which gives the earth its water. In the hydrologic cycle, atmospheric water reaches the earth=s surface as precipitation. Some of this water evaporates, but much of it either percolates into the soil or becomes surface runoff. Water from rain and melting snow eventually reaches ponds, lakes, reservoirs, or oceans where evaporation is constantly occurring. Moisture percolating into the soil may become ground water (subsurface water), some of which also enters water bodies through springs or underground streams. Ground water may move upward through soil during dry periods and may return to the atmosphere by evaporation. Water vapor passes into the atmosphere by evaporation then circulates, condenses into clouds, and some returns to earth as precipitation. Thus, the water cycle is complete. Nature ensures that water is a renewable resource. Fig: Hydrological Cycle GENERATING POWER: In nature, energy cannot be created or destroyed, but its form can change. In generating electricity, no new energy is created. Actually one form of energy is converted to another form. To generate electricity, water must be in motion. This is kinetic (moving) energy. When flowing water turns blades in a turbine, the form is changed to mechanical (machine) energy. The turbine 3|P ag e turns the generator rotor which then converts this mechanical energy into another energy form -electricity. Since water is the initial source of energy, we call this hydroelectric power or hydropower for short. At facilities called hydroelectric power plants, hydropower is generated. Some power plants are located on rivers, streams, and canals, but for a reliable water supply, dams are needed. Dams store water for later release for such purposes as irrigation, domestic and industrial use, and power generation. The reservoir acts much like a battery, storing water to be released as needed to generate power. The dam creates a height from which water flows. A pipe (penstock) carries the water from the reservoir to the turbine. The fast-moving water pushes the turbine blades, something like a pinwheel in the wind. The waters force on the turbine blades turns the rotor, the moving part of the electric generator. When coils of wire on the rotor sweep past the generator=s stationary coil (stator), electricity is produced. This concept was discovered by Michael Faraday in 1831 when he found that electricity could be generated by rotating magnets within copper coils. then the water has completed its task, it flows on unchanged to serve other needs . Fig: Schematic diagram of Hydro-power generation TRANSMITTING POWER: Once the electricity is produced, it must be delivered to where it is needed -- our homes, schools, offices, factories, etc. Dams are often in remote locations and power must be transmitted 4|P ag e over some distance to its users. Vast networks of transmission lines and facilities are used to bring electricity to us in a form we can use. All the electricity made at a power plant comes first through transformers which raise the voltage so it can travel long distances through power lines. (Voltage is the pressure that forces an electric current through a wire.) At local substations, transformers reduce the voltage so electricity can be divided up and directed throughout an area. Transformers on poles (or buried underground, in some neighborhoods) further reduce the electric power to the right voltage for appliances and use in the home. When electricity gets to our homes, we buy it by the kilowatt-hour, and a meter measures how much we while hydroelectric power plants are one source of electricity, other sources include power plants that burn fossil fuels or split atoms to create steam which in turn is used to generate power. Gas-turbine, solar, geothermal, and wind-powered systems are other sources. All these power plants may use the same system of transmission lines and stations in an area to bring power to you. By use of this A power grid,” electricity can be interchanged among several utility systems to meet varying demands. So the electricity lighting your reading lamp now may be from a hydroelectric power plant, a wind generator, a nuclear facility, or a coal, gas, or oil-fired power plant … or a combination of these. COMPONENTS: The water flowing in the river comprises of kinetic energy and potential energy. In hydroelectric power plant and the potential energy of water is utilized to produce electricity. There are 8 important components of hydroelectric power plant as below. Dam Water reservoir Intake or control gate The penstock Water turbine Generators Transformer 5|P ag e Tailrace DAM: The dam is the most important component of hydroelectric power plant. In fact the name ‘Dam’ is considered to be synonymous to the ‘Hydroelectric power plant’. The dam is built on a large river that has abundant quantity of water throughout the year. The dam is built at location where the height of the river is sufficiently high so as to get maximum possible potential energy from water. WATER RESERVOIR: Water reservoir is the place behind the dam where the dam where water is stored. The water in the reservoir is located at the height above the rest of the dam structure. The height of water in the reservoir decides how much potential energy water possesses. Higher the height of water more is the potential energy. The high position of water in the reservoir also enables it to move downwards effortlessly due to gravity. The height of water in the reservoir is higher than the natural height of water flowing in the river, hence water in reservoir is considered to be altered equilibrium. This also helps to increase the overall potential energy of water, which helps ultimately produce more electricity in the power generation unit. INTAKE OR CONTROL GATES: These are the gates built on the inside of the dam. The water from reservoir is released and controlled through these gates. These are called inlet gates because water enters the power generation unit through these gates. When the control gates are opened the water flows due to gravity through penstocks and towards the turbines. The water flowing through the gates possesses potential as well as kinetic energy. THE PENSTOCK: The penstock is the long pipe or the shaft that carries the water flowing from the reservoir towards the power generation unit that comprises of the turbines and generator. The water in the penstock possesses kinetic energy due to its motion and potential energy due to its height. The total amount of power generated in the hydroelectric power plant depends on the height of the 6|P ag e water reservoir and the amount of water flowing through the penstock. The amount of water flowing through the penstock is controlled by the control gates. WATER TURBINES: The water flowing from the penstock is allowed to enter the power generation unit that comprise of the turbines and generator. When water falls on the blades of the turbines the kinetic and potential energy converts into the rotational motion of the blades of the turbines. Due to rotation of blades the shaft of the turbine also rotates. The turbine shaft is enclosed inside the generator. In most of the hydroelectric power plants there are more than one power generation units comprising of the turbine and generator. There is the large difference in height between the level of turbine and level of water in the reservoir. This difference in height, also called as head of water, decides the total amount of power that can be generated in the hydroelectric power plant. GENERATORS: It is in the generator where the electricity is produced. The shaft of the water turbine rotates in the generator, which produces alternating current in the coils of the generator. It is the rotation of the shaft inside the generator that produces magnetic field which is converted into electricity by electromagnetic field induction. Hence the rotation of the shaft of the turbine is crucial for the production of electricity and these achieved by the kinetic and potential energy of water. Thus in hydroelectricity power plants potential energy of water is converted into electricity. TRANSFORMER: The electricity generated inside the generator is not of sufficient voltage. The transformer converts the alternating current produced from within the generator to the high voltage current. Current is supplied to the supplied coil, from where it passes to the outlet coil. The power supply from the transformer is connected to the nation grid, from where the power is distributed for the domestic and industrial use. TAIL RACE: 7|P ag e The water that has been used to rotate the turbine blades and turbines shaft levels the power generation unit entering the pipeline called as the tailrace. From here the water flows into the main river. The height of water in the tailrace is much below the height of water in the water reservoir behind the dam. The potential energy of water in the tailrace has been used to generate electricity. The water flowing out from the tailrace joints the natural flow of water. During the rainy seasons when there is excess water in the dams, it is allow overflowing through the gates in water reservoir to the low level natural flow of water. If the river is very large, then in multiple dams can be constructed across the river at various locations. RUN OFF RIVER POWERPLANTS: 1) Run off river hydroelectric plants without pondIn the run off river type of hydroelectric power plants the running water of the river is used for the generation of electricity. There is no facility for storing the water. 2) Run off river hydroelectric plants with pondThese types of run off river hydroelectric power plants usually produced the power during peak loads. During the day time and off peak periods they don’t produced power and the water is stored in large pond. PUMPED STORAGE POWERPLANTS: These plants supply the peak load for the base load power plant and pumped all or a portion of their own water supply. SELECTION OF SITE FOR A HYDRO-ELECTRIC POWERPLANT: Some point that should be given importance while selecting a site for hydroelectric power stations is given below. Availability of water: Since the primary requirement for a hydroelectric power station is the availability of huge amount of water such a plant should be built at a place (Ex. River and Canal) where adequate water is available at a good head. Storage of water: There are wide variations in water supply form a river or canal during the year. This makes its necessary to store water by constructing a dam in order to insure 8|P ag e the generation of power throughout the year. The storage helps in equalizing the flow of water so that any excess quantity of water at a certain period of the year can be made available during times of very low flow in the river. This leads to the conclusion that site selected for hydroelectric plant should provide adequate facility for erecting a dam and storage of water. Cost and type of land:The land for the construction of plant should be available at the reasonable price. Further the bearing capacity of the soil should be adequate to withstand the installation of heavy equipment. Transportation facilities: The site selected for the hydroelectric plant should be accessible by rail and road so that necessary equipment and machinery could be easily transported. It is clear from the above mentioned factors that ideal choice of site for such a plant is near a river in hilly areas where dam can be conventionally built at large reservoir can be obtained. ADVANTAGES AND DISADVANTAGES OF HYDRO POWERPLANT: ADVANTAGES 1) Renewable source of energy there by saves scares fuel reserves. 2) Economical source of power. 3) Non-polluting and hence environment friendly 4) Reliable energy source with approximately 90% availability. 5) Low generation cost compare with other energy sources. 6) Indigenous inexhaustible perpetual and renewable energy source. 7) Low operation and maintenance cost. 8) Possible to build power plant of high capacity. 9) Plant equipment is simple. 10) Socio economic benefits being located usually remote areas. 11) Higher efficiency, 95%-98%. 12) Fuel is not burned so there is minimal pollution. 13) Water to run the power plant is provided free by nature. 14) Its renewable rainfall renews the water in the reservoir, so the fuel is almost always there. 9|P ag e DISADVANTAGES: 1) Susceptible to vagaries of nature such a draught. 2) Longer construction period and high initial cost. 3) Lose of large land due to reservoir. 4) Non availability of suitable size of sites for the construction of time. 5) Displacement of large population from reservoir area and rehabilitation. 6) Environment takes aspect reservoir verses river ecology. 7) High cost of transmission system for remote site. 8) They use up valuable and limited natural resources. KEY FACTS ABOUT HYDROPOWER PLANTS: 1) Worldwide, above 20% of all electricity is generated by hydropower. 2) Hydropower is clean. It prevents the burning of 20 billion gallons of oil or 120 million tons of coal each year. 3) Hydropower does not produced greenhouse gases or other air pollution. 4) Hydropower leaves behind no waste. 5) Hydropower is the most efficient way to generate electricity. Modern hydro turbines can convert as much as the 90% of available energy into electricity. The best fossil fuel plants are only above 50% efficient. 6) Hydropower is the leading source of renewable energy. It provides more than 97% of all electricity generated by renewable energy sources. Other sources including solar, geothermal, wind and biomass account for less than 3% of renewable electricity production. Department of Civil Engineering of Vidya Pratishthan’s College of Engineering, organized one day educational visit to Koyna Dam and its hydroelectric power plant, Koynanagar (near Patan), Maharashtra on 04th September 2015 for 75 T.E. Civil Engineering students along with 7 staff members to study different aspects of Hydroelectric power generation and discharge through spillway. 10 | P a g e Visit was organized with the prior permission and under guidance of honorable Dr. S. B. Deosarkar Sir, Prof. V. U. Deshmukh (Principal, VPCOE), Prof. G. N. Narule (Head of Civil Engg Dept.). Er. Pravin Kolhe Sir from Irrigation dept-Pune helped us a lot to take permission of visit from regional office of Irrigation Department. Er. Bagade Sir (Executive Engineer) of Koyna Dam kindly permitted us for Visit of Dam. Mr. Choudhari sir and his team guided us during Visit of Dam and showed us all Dam features. Mr. Satish Taware sir (PRO, VPCOE) helped us in arranging Buses from Venkatesh Travels, Baramati with good drivers who took and brought us back safely. Our teachers Prof. Dilip G. Patil, Prof. Ms. B.V. Sawant, Prof Mr. A.A. Vaidya, Prof Mr. A. C. Choudhary (Assistant professor Mechanical Department), Mr. S. M. Jadhav (Administrative officer VPCOE) along with Mr. Kate U. R. (Technical assistantMech Dept), Mr. Kiran Taware (Assistant) took hard efforts in planning and arranging this highly successful visit. Students of T.E. Civil specially Yadav Ajay(Class representative-Boys), Shende Akshay, Satpute Pratik, Sul Rahul, Choudhar Priyanka(Class representative-Girls), Madhusudan Yadav, Dinesh Kore, Holkar Prajakta, Chandgude Priyanka, Memane Komal, Thorat Sangram, Gadhave Kalpak, Dhanawade Vinay and some other students took the initiative & under the continuous guidance of our teachers, made the visit a grand success. Students left the college for visit on 04th September at 5.15 am and did breakfast on the way at Patan and then we moved towards ‘Koyna Dam, Koynanagar’ and reached at 10.00 AM. At first we visited ‘Nehru Memorial’ near dam site where they showed us a short film regarding ‘Lake tapping done in Koyna Dam in 2012 and @ hydropower generation project details’. This film was very informative for us. After watching this short film we had lunch arranged by them near dam site. Then we all moved in a seminar hall where Er. Bagade saheb and Executive engineer of hydro power generation plant gave us presentation on how the working and construction of dam is carried out and how power is generated in hydro-power plant on dam site. They also gave us information about http://www.rtsfros.com/RTDAS/ where even we can check the available water in the dams, rainfall in particular area, estimated rainfall for next 3 days in Krishna-Bhima basin etc. 11 | P a g e Fig: Executive Er. Bagade saheb giving presentation to the students Executive Er. of hydro power generation giving presentation to the students 12 | P a g e After this presentation and question & answer session we all moved towards the actual Dam site at about 3:00 pm where security checkup of all the students and staff were done. We had already got photo ID passes for visit to dam Fig: Students along with Engineers (Koyna Dam in background) 13 | P a g e KOYNA DAM KOYNA DAM Koyna river is a major tributary to Krishna. Koyna originates near Mahabaleshwar township which is a famous hill station in Sahyadri Range. Unlike other rivers which flow either eastward or westward immediately after origin, Koyna river flows in a north - south direction almost parallel to the continental divide for a distance of 65 Kms. from Mahabaleshwar to village Helwak, skirting King Shivaji's fort Pratapgadh. At village Helwak, it turns sharply eastwards, travels for about 56 Kms and joins River Krishna at Karad. It’s a peculiar confluence where both the rivers meet head on. This confluence is aptly named as Preeti Sangam. The catchment of the River Course up till Helwak, has an average rainfall of above 5000 mm. Up to Koyna Dam, the catchment area is 891.78 Sq. Km. (344.32 Sq. Miles). The average annual yield with 75% dependability is 120 TMC 14 | P a g e Maharashtra is gifted by Sahyadri ranges. Average height of the range is around 750 m, which suddenly drops by 600 m to a level of 150 m in just 100/200 meters and then tapers down to sea level in further 50 Kms on western side SPECIFICATIONS OF KOYNA DAM 1 Name of the Project Koyna Hydro Electric Project, Stage I & II a) Name of the Dam Koyna Dam b) Year of Completion 1963 c) Design Purpose Hydro Electric Project and Irrigation Project 2 3 4 Location of Dam a) Village Deshmukhwadi b) Taluka Patan c) District Satara River Valley (Source of Water) a) Name of stream Koyna River b) Name of Sub Basin Koyna Sub Basin (K-1) c) Name of Main Basin Krishna Basin Reservoir a) Catchment area 891.78 Sq.Km b) Average annual rainfall (near dam site) 5350 mm c) Yield & utilisation dependability (adopted 90% for design) d) Capacity 15 | P a g e 5 6 7 1. Gross 2980.68 M CUM/ 105 .26 TMC 2. Live 2684.51 M CUM/ 94 .80 TMC 3. Dead 296.17 M CUM/ 10 .46 TMC 4. From Spillway crest to top of the gate 908.18 M CUM/ 32.07 TMC Flood Discharged at Dam Site. a) Maximum Observed 3637.77 Cumecs / 128467 Cusecs. b) Inglis 3766 Cumecs / 133000 Cusecs. c) Probable max flood 7220 Cumecs / 255000 Cusecs. d) Water Spread at FRL 119.69 Sq.Km/ 29575.55 Acres. e) Project affected villages 98 villages. f) Project affected families 9069 Nos. Dam a) Max height (Above river bed) 85.35 M b) Max height (Above foundation) 103.02 M c) Length 807.72 M / 2650' d) Top of Dam 654.97 M / 2148'10" e) Top Width of Dam 10.70 to 14.80 M/35.10' to 48.55' f) Spillway gates 6 Nos. Tainer type 12.50 M X 7.62M / 41' X 25' g) M.W.L 650.41 m / 2133'10" h) F.R.L 649.95 m / 2132'5" i) M.D.D.L 618.00 m /1996'6" j) Spilway crest 640.81 m / 2102' 5" Spilllway Details a) Total Length 88.71 m / 291' b) Head Over Crest at F.R.L 9.14 m / 30' c) Head Over Crest at M.W.L 9.60 m/ 31' 6" 16 | P a g e 8 9 d) Flood discharge at F.R.L 5082.87 Cumecs/ 179500 Cusecs. e) Flood discharged at M.W.L 5465.15 Cumecs/ 193000 Cusecs. River Sluice a) Size 1.21 X 2.28 m / 4' X 7' 6" b) Level 587.06 m / 1926' 1" c)Storage at this level 68.4 Mcum/2415 Mcft. d)Maxmum discharged 84.95 Cumecs/ 3000 Cusecs. Penstock for KDPH 2 Nos. a) Size 2.43 m diameter/ 8' b) Centre Line Level 592.50 m / 1943' 11" c) Maximum discharge (for two penstocks) 67.96 Cumecs / 2400 Cusces. Hydro electric power plant Students carefully studied and observed the generation of electricity by turbines. The topography near the initial regime of Koyna River is very favorable for the location of Hydro Electric Project. There is a sheer vertical drop of 487.68 meters (1600 feet) on west side of the reservoir. The continental devide is only 56 Km. (35miles) from the Arabian Sea, and separates the land between the 579 meter (1900 feet) high ground of Koyna on the Eastern Side of the Sahyadri Range and the 152 m (500 feet) high base on an escarpment on its Western Side. This has rendered a high head Hydro Electric Scheme feasible at economical cost. Since the rock through which the tunnels pass is excellent basalt rock, it was possible to take advantage of this rock by transmitting part pressure of water to rock and part to steel plates which led to economy. Straight excavation of pressure shafts resulted in reduction in the length and saving in cost of Steel plates and annular concrete & thus enabled adoption of underground Power House. Thus Koyna Stage I&II Power Station went underground for the purpose of economy and safety. The Project subsequently developed in four stages to reach power production capacity today totaling to 1960 MW. 17 | P a g e Power House Stage I and II accommodates 4 generators of 65 MW capacity and 4 generators of 75 MW capacity, totaling to 560 MW as a base station with 60% load factor The tail water of stage I & II power house was initially released in Vashishthi River at KRL 133.20 m (433.00 feet). To utilize this unused residual head before the water goes to the Arabian Sea, the water was then diverted in adjoining Vaitarni Valley through a 4.5 Km long tunnel and was stored behind a dam, called Kolkewadi Dam, 497 m long and 56.80 m high, to generate 320 MW with four machines of 80 MW each in the Dam Foot Power House. This is called as Stage III, which was designed as a peaking station with 24% load factor. Water for Irrigation was being released eastwards through a River Sluice in the main dam till 1980. To use the static head of height of reservoir, a dam foot Power House was constructed on right flank of the Dam during 1975 to 1980. 2 generators of 20 MW capacities are installed in this Power House, thereby generating 40 MW in Irrigation Rotation Period. Around 1985 it was realized that there is a vast diurnal hourly fluctuation in the power demand. Maximum power demand in morning peak (7 to 11 am) period and in evening peak (7 to 11 pm) period was as much as 15000 MW, while in between period it slowly reduces to 9000 MW. It was concluded that hydro power stations need not be run at 60% power factor. They can be run only in peak hours with 25% (or even less) Power factor. Then I&II stage PH was generating at 60% PF and utilizing 67.5 TMC of water. If the PF is reduced, westward water 18 | P a g e quota cannot be fully utilized. If a parallel Power House is built, and both the Power Houses are run with 25% PF, then the quota can be utilized fully. This concept gave rise to the IV stage Power House of Koyna Project. Accordingly a new Powerhouse comprising of 4 generators of 250 MW each was constructed and commissioned in 1999/2000. The stage wise generation capacity of each Powerhouse is tabulated below Stage Units Installed Capacity I) 4 X70 MW 280 MW II) 4 X 80MW 320 MW III) 4 X 80 MW 320 MW IV) 4 X 250 MW 1000 MW 2 X 20 MW 40 MW KDPH Total 1960 MW Students and staff of VPCOE with Dam officials After visiting dam and taking all the information regarding hydro power plant we started our backward journey at 7:00 pm. At about 9:00 pm we stoped at Satara for having dinner in Shivsagar hotel (Pure Veg), avoiding dinner on highway considering safety of students . After 19 | P a g e having dinner we started our further journey at about 10:00 pm and came back in VPCOE campus at 1:20 am. Regarding the visit students are extremely thankful to Prof. Dr. S. B. Deosarkar, Prof. V. U. Deshmuk (Principal VPCOE) Er. Pravin Kolhe sir, Er. Bagade saheb (The Executive EngineerLoyna Dam), Er. Pravin Ghorpade (Engineer from Irrigation Dept), HOD Civil Engineering department Prof. G. N Narule, Prof. Dilip G. Patil, Prof. Ms. B.V. Sawant, Prof Mr. A.A. Vaidya, Prof Mr. A. C. Choudhary (Assistant professor Mechanical Department), Mr. S. M. Jadhav (Administrative officer VPCOE) along with Mr. Kate U. R. (Technical assistant-Mech Dept), Mr. Kiran Taware (Assistant)and student coordinators of visit . List of Staff Members who visited Koyna Dam Project: 1 Prof. Dilip G. Patil 2 Prof. Ms. B. V. Sawant 3 Prof. A. A. Vaidya 4 Prof. A.C.Choudhary 5 Mr. Sandeep M. Jadhav 6 Mr. U. R. Kate 7 Mr. Kiran D. Taware QUESTIONS: 1) What are the major components of a Hydroelectric Power Plant? 2) How is energy generated in a hydroelectric power plant? 3) What are the advantages of construction of a hydroelectric power plant? 4) What are the disadvantages of construction of a hydroelectric power plant? 5) What is the significance of Dam? 6) What is Hydrograph and its significance? 7) What is Mass Curve? 20 | P a g e 8) What is the use of Spillway? 9) What is Penstock? 10) What is water hammering phenomenon? 11) What is the function of surge tank? 12) What is meant by water hammer? 13) How are hydro power plants classified? 14) Name the major parts of a hydro power plant? 15) Which type of Turbine was used where you visited and why? 16) What was the Hydro Power generation capacity of plant which you visited? References: 1. http://koynaproject.org/ 2. http://www.ctgpc.com/introduction/introduction_a.php 3. http://bhakranangaldam.com/ 4. http://idukki.nic.in/dam-hist.htm 5. http://idukkidam.blogspot.in/ 6. http://www.usbr.gov/lc/hooverdam/ 7. http://water.usgs.gov/edu/hybiggest.html 21 | P a g e