Real-time 3-d Localization using Radar and Passive

advertisement

Real-time 3-d Localization using

Radar and Passive

Surface Acoustic Wave Transponders

by

Jason Michael LaPenta

@

Submitted to the Department of Media Arts and Sciences,

School of Architecture and Planning

in partial fulfillment of the requirements for the degree of

Masters of Science

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

August 2007

~

2007. All rights reserved.

Massachusetts Institu f ecinzo

A uthor ...........................

Depart'ment of Media Arts and Sciences,

School of Architecture and Planning

Agnt

Certified by.

1 1 th,

2007

.................

Professor Joseph A. Paradiso

MIT Media Laboratory

ThesiyuuefvW

Read by.

Prof4sor Henry I. Smith

Department of Electrical Engineering & Computer Science

I

..

TfiesisReade

Read by.

Principal Research Scientist V. Michael Bove, Jr.

MIT Media Laboratory

The s Reader

Accepted by.......

I

MSSCHPUSETS NSTITE

OF TECHNOLOGY

4I 2007

RSEP

LIBRARIE

iUi

.....

D V,.b Uy .R

Chairperson, Departmental Committee on Graduate Students

Program in Media Arts and Sciences

ROTCH

2

Real-time 3-d Localization using

Radar and Passive

Surface Acoustic Wave Transponders

by

Jason Michael LaPenta

Submitted to the Department of Media Arts and Sciences,

School of Architecture and Planning

on August 1 1 th, 2007, in partial fulfillment of the

requirements for the degree of

Masters of Science

Abstract

This thesis covers ongoing work into the design, fabrication, implementation, and

characterization of novel passive transponders that allow range measurements at short

range and at high update rates. Multiple RADAR measurement stations use phaseencoded chirps to selectively track individual transponders by triangulation of range

and/or angle measurements. Nanofabrication processes are utilized to fabricate the

passive surface acoustic wave transponders used in this thesis. These transponders

have advantages over existing solutions with their small size (mm x mm), zero-power,

high-accuracy, and kilohertz update rates. Commercial applications such as human

machine interfaces, virtual training environments, security, inventory control, computer gaming, and biomedical research exist.

A brief review of existing tracking technologies including a discussion of how their

shortcomings are overcome by this system is included. Surface acoustic wave (SAW)

device design and modeling is covered with particular attention paid to implementation of passive transponders. A method under development to fabricate SAW devices

with features as small as 300nm is then covered in detail. The electronic design of

the radar chirp transmitter and receiver are covered along with the design and implementation of the test electronics. Results from experiments conducted to characterize

device performance are given.

Thesis Supervisor: Professor Joseph A. Paradiso

Title: MIT Media Laboratory

4

Biography

Jason LaPenta received his B.S. in Electrical engineering from the University of Illinois in UrbanaChampaign (UIUC) in January of 2001. He specialized in control systems and worked at a research assistant on vision tracking projects. While

at UIUC, Jason's summers were spent interning at

Philips Semiconductors (Zhrich, Switzerland), Boeing (Seattle, Washington), and Procter and Gamble

(Cincinnati, Ohio). After graduation, Jason worked

for five years in the control systems group at MIT Lincoln Laboratories on such

projects as the Mars laser communication experiment.

Jason left Lincoln Laboratory in 2005 to pursue graduate research at the MIT

Media Laboratory in the Responsive Environments Group headed by Professor Joseph

Paradiso.

While that demands of graduate school leave little free-time, when available Jason

enjoys Underwater Hockey, caving, kayaking, sailing, and woodworking.

6

Acknowledgments

This thesis, and all the wonderful opportunities I have had at MIT were possible

because of my adviser Professor Joe Paradiso, the Responsive Environments Group,

and the Media Laboratory community. Without professor Paradiso's commitment

to this project, especially obtaining the substantial resources necessary, none of this

work would have been possible. I would like to especially thank Professor Paradiso

for all of the hard work put into this project.

Microfabrication would have been an insurmountable obstacle without the generous support and dedication of the faculty, scientist, students, and staff of the Experimental Microfabrication Laboratory (EML), Nanostructure Laboratory (NSL),

and Research Laboratory of Electronics (RLE). From the very first day I stepped

into a fabrication laboratory, knowing absolutely nothing about applied fabrication,

Kurt Broderick patiently mentored me through every step of fabrication to realize

my first operational devices. I want to thank all the people at the the Nanostructures

Laboratory, who demonstrated a truly exceptional level of collaboration, helpfulness,

and openness that I'm am very lucky to have been a part of. Laboratory directors

Professor Karl Berggren and Professor Hank Smith provided invaluable insight into

many of the fabrication problems I encountered. Their hard work and dedication provided the laboratory, tools, and environment of collaboration essential to fabricating

my high-frequency devices. James Daley worked very hard to keep all the temperamental laboratory machinery running smoothly and promptly provided me with all

the supplies and processing I needed. Many long hours were spent by Mark Mondol

checking and writing my designs using the VS-26 SEBL tool and teaching me to use

the Raith-150 SEBL tool. Whenever I had a quick question, Tim Savas would drop

what he was doing to answer and show me the proper methods. In consulting with

Tim I learned a lot about practical fabrication considerations that are only learned

in application. There are too many students who helped me in NSL to mention here,

though I greatly thank all of them and the NSL community.

Daniel Smalley, a friend and fellow Media Arts and Sciences graduate student, gave

an enormous amount of advice during our many discussions of our similar projects. I

would like to thanks Daniel for the countless hours of conversation through which his

suggestions and insights saved even more hours of work. A special thanks to Roshni

Cooper, the undergraduate research assistant whose hard work implementing the user

interface and FPGA code allowed me to focus on fabrication while collecting data.

And I especially thank my wife Cindy for all she has done during the most demanding time of my life.

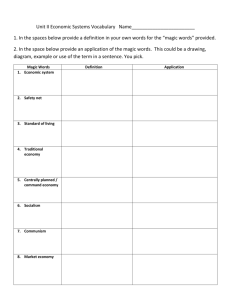

Contents

1

2

23

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .30

1.1

Analysis

1.2

M otivation. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

34

1.3

Related Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

39

Surface Acoustic Wave Devices

. . . .

2.1

Properties of Lithium Niobate.. . . . . . . . . . . . . . . .

2.2

Modeling........ . . . . . . . . . . . .

2.3

D esign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . ...

42

43

48

57

3 Micro-Fabrication

3.1

Mask Design and Layout . . . . . . . . . . . . . . . . . . . . . . . . .

3.2

Substrates.

3.3

Substrate Preparation and Cleaning...... . . . . .

3.4

Lithography..... . . . . .

.

...........................

. . . . . . . . . . . .

. . .

62

. . ...

69

. ...

71

. . . . . . . . .

74

. . . . . . . . . .

76

3.4.1

Photoresists........ . . . . . . . . . .

3.4.2

Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

77

3.4.3

Contact Lithography . . . . . . . . . . . . . . . . . . . . . . .

78

3.4.4

Conformable Vacuum Mask Lithography

3.4.5

Scanning Electron Beam Lithography . . . . . . . . . . . . . .

9

. . . . . . . . ...

79

80

3.4.6

Exposure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.7

Resist Developing...... . .

. . . . . . . . . . . . . . . .

3.5

D escum

3.6

Deposition...................

... .... .

3.7

Lift-off and Etching

. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8

Mounting/Packaging...... . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . ..

. . . . . . . . .

4 Electronic Design

85

86

88

90

96

99

4.1

System Architecture........... . . . . . . . . . . . .

. . ..

102

4.2

Analog Components and Test Equipment.. . . . . . . . .

. . . . .

106

4.3

Impedance Matching............ . . . . . . . . . . . . .

. .

111

4.4

SAW Filter Measurements......... . . . . .

4.5

SAW Transponder Measurements..............

4.6

FPGA Hardware Description........... . . .

4.7

Softw are . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

.. .

. . .

113

. ..

115

. . . . ..

116

5 Testing and Characterization

6

82

123

127

5.1

SAW Device Ox2C9 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

127

5.2

SAW Device Ox2E8 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

133

5.3

SAW Device OxOE3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

135

Conclusion

137

Bibliography

141

A Lithography Masks

151

A.1

Mask 1 Generation Scripts....... . . . .

A.2 Mask 2 & 3 Generation Scripts..... . . . .

10

. . . . . . . . . . . . .

151

. . . . . . . . . . . .

178

B Fabrication Processes

B.1 Device Fabrication Process Details

B.1.1

Cleaning. . . . . . . . . . . .

189

. . . . . . . . . . . . . . . . . . . 189

. . . . . . . . . . . . . . . . 189

B.1.2 Lithography . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

B.1.3 Lift-Off and Etching . . . . . . . . . . . . . . . . . . . . . . . 194

B.1.4 Vacuum Mask Fabrication . . . . . . . . . . . . . . . . . . . . 196

B.1.5 Raith 150 Operational Procedure . . . . . . . . . . . . . . . . 198

C OAI documentation

205

C.1 Housing Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

C.2 Mask Chuck Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . 214

D Auxiliary Electronics

217

E FPGA VHDL/C/XPS

227

F MATLAB Source Code

257

12

List of Figures

1-1

Notational diagram of three measurement stations tracking a single

SAW transponder....... . . . . . . . . . . . . . . .

. . . . . .

25

1-2 Hypothetical SAW transponder to illustrate the approach taken for

identification and common mode rejection. The IDTs are shown with

phase-shift encoding.

1-3

. . . . . . . . . . . . . . . . . . . . . . . . . .

26

Illustrates the signal flow of RF received and transmitted signal and

27

surface waves, along with the effects of the signal processing. ....

1-4 Macro illustration of signals received by measurements stations at different locations (not to scale either in time or magnitude).

1-5

. . . . . .

28

Digitization scheme for enhanced low-cost identification and timing.

Each digital channel, a or b, represents the thresholded receive signal

at a particular cutoff.

1-6

. . . . . . . . . . . . . . . . . . . . . . . . . .

28

. . .

29

Time measurement to peak of the correlated signal... . . .

1-7 Illustrates the time-of-flight of the interrogation pulse being returned

by a multipath object and a transponder. . . . . . . . . . . . . . . . .

30

2-1

Simplified diagram of basic SAW transponder functional components[1]. 40

2-2

Saw correlator with corresponding code and output pulse waveform.

"time / position" is the waveform over time at a single point between

IDTs, or the waveform over position between IDTs at a particular time.

41

2-3

Illustration of the crystal cut of a 128 -RY wafer[2], with an X-Flat,

from Crystal Technologies Inc...... . . . . . . . . .

2-4

.... ...

. . . . ..

43

SAW filter made with mask 1. Device Ox2C9, 25 finger pairs that are

200pm long........................

2-6

42

Illustration of the crystal cut of a Y wafer [2], with a Z-Flat, from

Crystal Technologies Inc............

2-5

. . . . . . .

.... ..

. ..

44

MATLAB simulation of the normalized impulse response of a 323MHz

SAW band-pass filter shown if figure 2-5... . . . . .

. . . . . . .

45

2-7

Result of an impulse through device Ox2C9 as recorded on an oscilloscope. 47

2-8

Parameters for the design of a SAW IDT in this project.

2-9

The three types of SAW reflectors were implemented on mask 1.

. . . . . . .

. .

48

50

2-10 Narrow-band output correlator with n = 5 Barker code illustration. .

50

2-11 Narrow-band output trace for figure 2-10.

51

. . . . . . . . . . . . . . .

2-12 Narrow-band output correlator with code [1, 1, 1, 0,1 1,1,1,1, 1] utilizing one finger-pair encoding............ . . . . .

. . . . .

52

2-13 Narrow-band correlator response for device fabricated on mask 3, shown

in figure 2-12. Generated with nb.m in appendix F.

. . . . . . ..

52

2-14 Wide-band output correlator illustration with n = 5 Barker code with

two finger-pair encoding....... . . . . . .

. . . . . . . . . . . .

53

2-15 Wide-band output trace for figure 2-14.

. . . . . . . . . . . . . . . .

53

. . . . . . . . . . . . . . . . . . . . . .

54

2-16 Wide-band output correlator.

2-17 Wide-band correlator response for device fabricated on mask 3, shown

in figure 2-16. Generated with wb.m in appendix F....

. . . . ..

54

2-18 Dual narrow-band transponder with a Barker code of length five with

a five finger encoding....... . . . . .

. . . . . . . . . . . . . . .

55

2-19 Dual narrow-band transponder's simulated waveform. The "rx signal"

was transmitted by the measurement station and is what the input IDT

sees. The "first response" and "second response" are the waveforms

from each output IDT. . . . . . . . . . . . . . . . . . . . . . . . . . .

55

2-20 Simulation including the effect of surface waves originating from the

output IDTs of the transponder shown in figure 2-18.....

. . ..

56

3-1

Simplified one-step lift-off process. . . . . . . . . . . . . . . . . . . .

60

3-2

Simplified wet-etch process.

61

3-3

Artwork for mask 1 showing a die section.

. . . . . . . . . . . . . . .

63

3-4

Typical layout of a device on Mask 1. . . . . . . . . . . . . . . . . . .

63

3-5

Artwork for mask 2.

65

3-6

Artwork for mask 3 version 2. Bond-pads and leads are on a different

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

layer than the devices...... . . . . . . . . . . . . . . . . . .

. .

68

3-7

Artwork for mask 3 version 3. . . . . . . . . . . . . . . . . . . . . . .

69

3-8

Micrography of PMMA scum on a quartz light-field mask with chrome. 73

3-9

Typical lithography process steps used in this project. SEBL or contact

printing can be used to transfer a pattern to the photoresist. ....

75

3-10 Spin curve of 3 parts Anisole to 1 part PMMA 950k All. . . . . . . .

77

3-11 Fringe patterns resulting from imperfect contact between mask and

substrate while under vacuum and illuminated with a green monochromatic light. This shows the OAI 77mm chuck with a top-down rubber

gasket over the mask. The mask was 1mm quartz and the substrate

was a 77mm silicon wafer...... . . . . . .

. . . . . . . . . . .

.

80

3-12 Simplified diagram of a SEBL tool. The detector is used for imaging

test particles that are used to adjust for focus, aberration, stigmation,

and write field alignment.

. . . . . . . . . . . . . . . . . . . . . . . .

81

3-13 Micrographs of field stitching problems. . . . . . . . . . . . . . . . . .

82

3-14 Exposure test features allow inspection of focus, dose, and development

parameters...................

...

. . . . . . . . ...

83

3-15 Micrograph of a dose matrix written in 100nm of PMMA on Quartz.

Exposed with the Raith 150 SEBL tool.

. . . . . . . . . . . . . . . .

83

3-16 The top micrograph shows clearing problems with PMMA on Quartz.

The bottom two exposure show improperly cleared (left) and properly

cleared (right) 4im grating of PMMA on Silicon. The darker areas are

PMMA and the light areas are substrate. These exposures were made

with the OAI deep-UV exposure tool in NSL.

. . . . . . . . . . . . .

84

3-17 Developed exposure/developing test features showing the degree of

over/under developing. The left panel shows underdeveloped clearing

problems, and the right panel shows overdeveloping. The center panel

show ideal exposure, with the two boxes coming into perfect contact.

3-18 Changes in width of 1.1pm lines due to developer temperature.

. . .

85

86

3-19 Exaggerated illustration of the effect on resist profile from RIE or

plasma asher descum processes. The top figure is the photoresist profile

after development and before any descum step . . . . . . . . . . . . .

87

3-20 Etch depth vs. time of 106nm PMMA on Si in 02 plasma asher using

50W power and 0.305psi average pressure. Thickness measured with

an ellipsometer.................

. . . . . . . . . . . ...

88

3-21 Results from 2sec of 02 plasma asher and RIE descum methods. The

figures show Cr on Quartz and Cr on PMMA before the liftoff step.

10nm of PMMA were taken off with the 02 asher. 7nm of PMMA

were taken off with the RIE............

.... . . .

. ...

3-22 Effect of off-angle deposition on side-wall coating. . . . . . . . . . . .

89

89

3-23 Micrograph of a problem encounter when depositing 40nm Cr onto

100nm of PMMA on an SiO2 wafer using the NSL evaporation tool. .

90

3-24 Undercut allows solvent to dissolve photoresist and remove metal overlay. 90

3-25 Damage likely resulting from too much sonication (> 1min) during

lift-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92

3-26 Incomplete liftoff problems as a result of too much chrome being deposited. Shows 500nm line-widths with 210nm of chrome on quartz.

The desired thickness of chrome was 100nm. The PMMA thickness

was 250nm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

93

3-27 SEM of bridging caused by poor profile and photoresist that was too

thin for the thickness of metal deposited. . . . . . . . . . . . . . . . .

93

3-28 Illustration of lift-off problems when the metal on top of the photoresist

bridges to the metal on the substrate. . . . . . . . . . . . . . . . . . .

94

3-29 SEM showing a wafer after deposition and before lift-off. The images

of the 100nm gold particles in the bottom left are given as a reference

for im age quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

94

3-30 Micrograph showing a patch of incomplete lift-off due to inspection by

the SEM before liftoff to take the image shown in figure 3-29. ....

95

3-31 Test patterns of Cr on Quartz and Cr on PMMA on Quartz. Same

sample as shown in figures 3-29 & 3-30.

. . . . . . . . . . . . . . . .

95

3-32 Show the change in image contrast before and after the etch has been

completed. PMMA was used as a photoresist on top of chrome and

quartz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

96

3-33 SAW test devices mounted to a package, wire-bonded, and soldered to

a test P C B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Conceptual measurement station transceiver block diagram.

98

. . . . . 100

4-2

Measurement station FPGA and transmitter block diagram. . . . . . 102

4-3

Photo of NECL clock generator (part number PRL-174ANT-1350) and

NECL to LVPECL logic level translator (part number PRL-460ANLPD). 103

4-4 Photo of Xilinx ML405 evaluation board........ .

. . . . ...

104

4-5 Illustration of signal conversion from digital to RF. . . . . . . . . . . 105

4-6 Photo of analog components from Mini-Circuits@. . . . . . . . . . . . 108

4-7 323MHz antennas made from 16-AWG copper wire and an SMA connector. Used for preliminary isolated indoor tests.

4-8

. . . . . . . . . . 110

RF Network Vector Analyzer test setup for reflectance and impedance

measurements............ . .

. . . . . . . . . . . . . . . ...

111

4-9 Simple L matching network [3, 4]. . . . . . . . . . . . . . . . . . . . .111

4-10 Measured Smith chart on the RF Network Vector Analyzer of a SAW

transponder........... . . . . . . . . . . . . . . .

. . . . . . 112

4-11 RF Network Vector Analyzer test setup for Transmittance measurements. 113

4-12 Measured transmission chart of a SAW filter on the RF Network Vector

Analyzer. Notice the anti-resonance artifact, which is ignored for this

work............. . . . . .

. . . . . . . . . . . . . . . . ...

114

4-13 Setup for transient measurements of a SAW filter using an oscilloscope. 114

4-14 Test setup for SAW transponder measurements. . . . . . . . . . . . . 115

4-15 SAW transponder measurements using antennas. . . . . . . . . . . . . 115

4-16 Block diagram of FPGA PowerPC processor configuration. . . . . . . 119

4-17 Top level block diagram of chirp2 VHDL code. . . . . . . . . . . . . . 120

4-18 VHDL code organizational block diagram of the "chirp2" peripheral

implementing the rocketIO multi-gigabit-transceiver and support FPGA

cores... ...............

...

..

. . .. . .......

4-19 chirp-ui.pl User interface program written in PERL..

.. ...

. . ...

121

124

5-1

Drawing of SAW filter device Ox2C9 . . . . . . . . . . . . . . . . . . . 129

5-2

Frequency response from 50MHz to 1GHz. The pass band is at

322.249MH z. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

5-3

Pass-band bandwidth shown as ~ 20MHz . . . . . . . . . . . . . . . 130

5-4 Smith chart before impedance matching circuit. . . . . . . . . . . . . 130

5-5

Smith chart after impedance matching circuit with 27nH and 10pF. . 131

5-6

Internal reflection between two IDTs in device Ox2C9. . . . . . . . . . 131

5-7

Example of inter-finger reflections within a single IDT. . . . . . . . . 132

5-8

Drawing of SAW filter device Ox2E8 . . . . . . . . . . . . . . . . . . . 133

5-9

The sloped frequency response is due to electromagnetic feed-through[5].

134

5-10 Impulse response of SAW filter Device Ox2E8. The number of cycles

has been labeled (1,10,and 20). Channel Z2 is the zoomed view of

Channel C 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

5-11 Drawing of SAW filter device OxOe3 . . . . . . . . . . . . . . . . . . . 136

5-12 The four cycle chirp response of device OxOE3.

Channel Z3 is the

zoomed view of the first reflection on Channel C3. . . . . . . . . . . . 136

B-1 Illustrates the process for making devices by first writing a pattern to a

1mm quartz mask master, then transferring the pattern using contact

lithography to a conformal mask, and finally patterning the lithium

niobate substrate to make the desired devices. . . . . . . . . . . . . . 196

C-1 OAI deep-UV aligner radiation shield.

Made from Standard Cast

Acrylic, 0.236inch thick Clear with Bronze Tint, McMaster part numbers. 8505K921, 8505K941, and 8505K951. . . . . . . . . . . . . . . . 206

C-2 OAI 3inch chuck assembly. . . . . . . . . . . . . . . . . . . . . . . . . 214

C-3 OAI 3inch chuck assembly. . . . . . . . . . . . . . . . . . . . . . . . . 215

D-1 Analog test board. Holds SAW test package, low-noise amplifiers, and

power regulators...... . . . . .

. . . . . . . . . .

. . . . . . . . 217

D-2 Closeup of one low-noise amplifier channel. . . . . . . . . . . . . . . . 217

D-3 PCT top-side silkscreen.............. . . . . . . . .

D-4 PCB top-side metal layer..... . . . . .

. . . . 218

. . . . . . . . . . . . . . 218

List of Tables

1.1

Comparison between widely used localization systems and SAW transpon-

der [6, 7, 8, 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

3.1

Steps to convert a file to .kic for use on the VS-26. . . . . . . . . . .

66

3.2

Processing costs and time estimates to process one mask with lift-off.

This does not include meteorology......... . . . . . . .

.. .

3.3

Suppliers and specifications of substrates used. *Amorphous SiO2 .

4.1

Components used in this project that were purchased from MiniCircuits

67

.

70

... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.1 Specifications for device 0x2C9

. . . . . . . .

5.2 Specifications for device Ox2E8

. . . . . . . . 133

5.3 Specifications for device OxOE3

. . . . . . . . 135

B.1 Alconox" cleaning procedure.

128

. . . . . . . . . . . . . . . . . . . . . . 189

B.2 Ultrasonic cleaning with Acetone. . . . . . . . .....

. . . . . . .

190

B.3 Piranha cleaning procedure. . . . . . . . . . . . . . . . . . . . . . . . 190

B.4 RCA or standard clean 1 (SC-1) procedure.

B.5 Photoresist coating procedure.

. . . . . . . . . . . . . . 190

. . . . . . . . . . . . . . . . . . . . . 191

B.6 Exposing using the EML high-resolution MJB3 aligner.

. . . . . . . 192

B.7 Exposing using the NSL OAI. . . . . . . . . . . . . . . . . . . . . . . 192

B.8 PMMA development procedure.. . . . . . . . . . . . . . .

. . . . 193

B.9 NR7-1000P development procedure. . . . . . . . . . . . . . . . . . . . 193

B.10 Lift-off of PMMA.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

B.11 Lift-off of NR7-1000P............. . . . . . . . . . .

. . . . 194

B. 12 Etching chrome to fabricated a patterned mask..... . . . . .

B.13 Process steps for making a conformal mask.

. . 195

. . . . . . . . . . . . . . 197

D.1 Parts list for test board. . . . . . . . . . . . . . . .

. . . . . . . . 219

Chapter 1

Introduction

Unhindered localization of objects is desirable for many applications from human

computer interaction to product tracking to security. Many researchers and companies

have sited tracking of people with special needs, prisoners, or workers in hazardous

situations as useful applications of localization[10].

What this project proposes is

the use of Surface Acoustic Wave (SAW) devices engineered in a particular fashion to

function as transponders for a distributed radar tracking network. The radar network

would track the location of the SAW transponders in 3-d with an update rate on

the order of 10kHz with 10cm accuracy. Improvements over these estimations are

conceivable in an optimized implementation. A patent application covering the work

in this thesis was filed on March

7 th,

2006 under the title "Real-time ranging and

angle measurements using Radar and Surface Acoustic Wave Transponders."

This thesis covers all of the work completed to date on this project. While ranging

results have not yet been obtained, a lot of important progress and experience has been

garnered. About two to four months of work remains before initial results are ready.

The approach taken for the overall system is covered. The transponder design progress

that has been made to date is given as well as future plans for investigation. Micro-

CHAPTER 1. INTRODUCTION

fabrication of the devices is extensively covered, however processes for 1.1pm linewidths have not yet been attained (we are only two to three weeks from fabrication

of working 1.1pm devices). The development of a measurement station is underway.

The FPGA programs, firmware, and approach are described in detail. Analog RF

circuits have been constructed, and recent results will be discussed. There is some

work that was done for this project that will not be discussed and is as follows;

An analog time-to-digital converter was designed and built, but is impractical and

unsuited for time-of-flight ranging in this project.

Analog circuits were built to

generate a chirp before the FPGA was available. A low-noise amplifier was designed,

analyzed, extensively simulated, and built; the details of this amplifier have been

left-out because the design is being debugged.

There are two major components of this system; the SAW transponder and the

radar measurement station.

A SAW transponder reflects a short pulse of received RF energy back to the measurement station as a phase-encoded pattern of data. An arrangement of correlators

and impedance-modulated reflectors on the surface of the SAW transponder return

encoded data patterns back to the antenna for retransmission to the measurement

station. Several published techniques for selection, identification, and encoding of

data with the tags will be applied as well as some novel designs. [11, 12, 13]

SAW devices were originally developed in the 1960's[5, 14, 15]. Their function is

based on the principle of generating surface acoustic waves in a piezoelectric substrate.

SAW devices are extensively used as passive narrow-band-pass filters in commercial

communications equipment such as cellular telephones. Innovation continues with

the use of SAW devices for RF-ID applications[12, 16, 17, 10]. The unique properties

of SAW devices theoretically makes them an ideal technology for this novel real-time

tracking solution.

Radar has been utilized for decades to track a multitude of targets such as aircraft, weather patterns, and cars. Active transponders assist radar identification by

responding with an encoded signature. This allows the radar to determine exactly

what object is being tracked. Transponders are used in almost all airplanes to aid air

traffic controllers in identification [18, 19].

V

Antenna

measurement

station

transponders

optional

measurement

stations

return

(x,,Y,.z,)

signals

interrogation

signal

X

a

Figure 1-1: Notational diagram of three measurement stations tracking a single SAW

transponder.

Each radar measurement station will measure time-of-flight and/or angle of arrival

of the signal returned by the SAW transponder, figure 1-1.

Simple triangulation

calculations are performed on the data from three or more measurement stations to

localize a tag. Only one measurement from all of the measurement stations, either

time-of-flight or angle-of-arrival, is necessary to localize. However, using more than

the minimum necessary signals will improve accuracy.

For the simplified system

described in this work, the location of the measurement stations must be fixed and

known by the algorithm.

Figure 1-2 shows a simplified saw tag with phase encoding used to illustrate the approach we intend to take. The inter-digital transducers (IDTs) convert the electrical

CHAPTER 1. INTRODUCTION

Figure 1-2: Hypothetical SAW transponder to illustrate the approach taken for identification and common mode rejection. The IDTs are shown with phase-shift encoding.

energy into a surface wave (details will be covered in chapter 2). A SAW transponder must be selective to a particular signal, thus the phase encoding. To enhance

signal-to-noise and reduce background radar clutter, a built-in delay between the

received signal and retransmitted signal must be implemented. A mechanism must

also be provided to compensate for effects of temperature on the surface velocity of

the SAW device. In this example three different IDTs implement the phase encoding.

The codes for this example are very short (five and six bits in length). An actual tag

would have up to 128bit code lengths. This particular tag has different receive and

transmit codes.

The distance between the IDTs builds in a delay between when the radar signal

is received and retransmitted. In this case, IDT 1 has been designed to be selected

by the radar chirp from the measurement station, while IDTs 2 & 3 do not correlate

to this signal. Because the distance between IDT 1 and IDT 2 is different than the

distance between IDT 1 and IDT 3, and the propagation speed is the same, the time

between them may be used to take out common mode surface velocity variations.

ADT

-v

c

received signal

7

r~%,

dominant surface signal

SAW wave from coded lODT/

,,~7

~AWtransponder

second transmitted signal

first transmitted signal

Figure 1-3: Illustrates the signal flow of RF received and transmitted signal and

surface waves, along with the effects of the signal processing.

The various signal processing at the different places along the transponder are

illustrated in figure 1-3. For the following discussion secondary reflections and uncorrelated signals are not accounted for. Chapter 2 will cover secondary reflections as

well as other higher-order effects. The signal received by the transponder's antenna

from the measurement station in this example is a Barker code[5, 14]. A Barker code

correlated by the proper IDT will create a SAW pulse with unity side-lobes. Other

codes are generated pseudo-randomly and the simulated and selected for acceptable

side-lobe attenuation[14]. In this case only IDT 1 correlates to this received code.

IDTs 2 & 3 do not correlate and launch only a small surface wave. When the surface

wave launched by IDT 1 reaches IDT 2 & 3 the transponded signal is transmitted as

a convolution of the surface wave and the phase encoded IDTs. This waveform is represented below their respective IDTs. In this case the same waveform is transmitted

28

CHAPTER 1. INTRODUCTION

by both IDTs, but they may have different encodings if desired.

4-

interrogation chirp

primary measurement station

secondary measurement station

time

Figure 1-4: Macro illustration of signals received by measurements stations at different

locations (not to scale either in time or magnitude).

The transmitted and transponded signals may be received by multiple measurement stations. Each additional measurement station would relay the station's position and the time measured from the interrogation chirp to the received signals to the

primary measurement station. Figure 1-4 shows the temporal waveforms from two

measurement stations. The primary measurement station in this example is further

away from the transponder than the secondary measurement station.

analog signal

a. b

digital a.

t=ta

time

Figure 1-5: Digitization scheme for enhanced low-cost identification and timing. Each

digital channel, a or b, represents the thresholded receive signal at a particular cutoff.

Figure 1-6: Time measurement to peak of the correlated signal.

The approach taken to accurately measure the time delay is illustrated with figures

1-5 & 1-6. The waveform will be measured by clipping and digitizing the received

signal at high-speed.

The digitized waveform will be captured using the multi-

gigabit-receiver (covered in section 4.6). In this example, one digitization channel is

used to capture data at two times, represented by (a.) and (b.) in figure 1-5. The

digitized waveforms are then auto-correlated to the expected waveform as calculated

using a SAW transponder model[20].

The correlated output waveform may look

like the one presented in figure 1-6. The correlated waveform will have a peak and

that time displacement measurement will be used to derive the time-of-fight for

triangulation. Pseudo-random transponder codes will be selected for auto-correlated

signals that have significant correlated peaks to allow for improved signal-to-noise

performance. The time measurements from the different digitized channels will be

approximated into one measurement by averaging the results. Of course, what is

achievable in practice depends on many factors, some of which are the signal-tonoise ratio of the sampling circuitry, operating environment, multipath effects, and

interference of other tags.

CHAPTER 1. INTRODUCTION

1.1

Analysis

(1340ns)

(1005ns)

(670ns)

a gm

station

ili

ili

object

tag1

(335ns)

Om

multi-path

(670ns)

loom

distance(time)

200m

Figure 1-7: Illustrates the time-of-flight of the interrogation pulse being returned by

a multipath object and a transponder.

The following is a simple analysis of the requirements and expected performance

of the proposed system. The limiting factors for how fast a tag's position can be read

is the maximum distance to a tag and the read-out

/

read-in time. For a maximum

range of 100m, the round trip time for a pulse is 2 - 100m C = 670ns, where c is the

speed of light. To allow for background radar clutter to dissipate, a delay is added

to the maximum round-trip time. For all signals within 200m to dissipate, we need

a total delay of lps before the SAW transponders return the signal. Thus the total

delay between the time the radar chirp is transmitted and the return signal is received

must be at least 1.3ps. A 32-bit code at 2.4GHz will take 13ns and considering the

returned signal is a 64-bit convolved waveform, the total time for both is only 40ns.

Using three measurement stations with one transmitting and two listening, a single

update can take place in 1.4pis, or at a rate of 700kHz. This is a very impressive 3-d

localization rate in terms of available technology. Resolution improvements could be

attained by integrating the result over time.

The demonstration system will be shifting received data in at a rate of 2.4GHz.

Two phase-locked multi-gigabit-transceivers (explained in section 4.6) channels will

be used to double the sampling rate, thus satisfying Nyquist to achieve 2.4GHz

1.1.

ANALYSIS

overall. A very stable clock with 100ppm stability over half an hour drives the receiver,

which has no significant effect on range measurements. The peak-to-peak clock jitter

is

2 0 ps,

which results in an error of 3mm. Given the round-trip time to and from the

target is measured, a factor of two advantage is realized. The best achievable range

resolution given the hardware available to us would then be:

1

1

f

2.4-109

2c- = 2 - 3.8 - 108

= 6.25cm

(1.1)

Temperature effects on the surface wave velocity of the transponder is a concern.

The properties of LiNbO3 , including temperature dependent effects, will be discussed

in more detail in chapter 2. For the purposes of this example, a typical SAW substrate has a characteristic surface velocity of 3992m/s and temperature coefficient

of 75ppm/C. Effect due to temperature changes may be compensated for through

measurement and calibration.

To analyze the performance improvement with temperature measurement compensation consider the dual reflector configuration.

The amount of error for the

will be calculated first as a comparison for the com-

uncompensated design,

euncomp,

pensated error, ecomp.

For the 100m maximum range, a delay of di = 670ns will

be required (Refer to figure 1-7). As a starting point, a d 2 = 100ns delay between

the temperature measurement dual reflectors will be chosen. Assuming a temperature discrepancy between the measurement station and the SAW transponder to be

terror

= 10"C(a very conservative estimate), the approximate error in the distance

measurement would then be;

dv

= Vsubterrortcoeff

= 3992-

=3s

10"C - 75 P

(1.2)

CHAPTER 1. INTRODUCTION

Where

Vsub

is the substrate surface velocity of 128 LiNbO 3 , and tcoeff is the associated

temperature coefficient[5]. With a surface length between the input IDT and the first

reflector of

1=

d1

Vsub '

(1.3)

= 3992m/s - 670ns

= 2.7mm

lending to a distance measurement error of approximately;

euncomp =

'*

1d-

(Vsub

-v

- 670ns -

= 3

[67

2.7mm

(3992m/s - 3m/s) 1

(1.4)

= 151mm

An error of 15 1mm is decent, and probably much worse than what would be

expected under normal conditions. However, such an error would be a significant

degradation of achievable performance. As briefly discussed at the beginning of chapter 1, a multi-reflector scheme will be used to determine the temperature of the

SAW transponder. Several schemes for using SAW transponders to measure temperature and or compensate for temperature have been developed and implemented

by others[21, 22]. By using temperature compensation methods much better results

should be attainable. SAW transponders have been demonstrated to measure temperature with a resolution of 0.02"C[21]. With such precise temperature measurements

the error due to temperature may be reduced through compensation to;

dv =

Vsubterrortcoeff

=3992

.

s

= 6 mm

s

0.02 0C - 75 0C

oC

(1.5)

1.1. ANALYSIS

lending to a distance measurement error of approximately;

ecomp= C.

=

3 -108.

=

0.3mm

-

(Vub

670ns 1

dv)]

2.7mm

(3992m/s - 6mm/s)_

(1.6)

Therefore, with only 0.3mm of error due to temperature effects, they can be safely

ignored for the application and design discussed in this thesis.

Given we are using a low-cost FPGA to digitize the received signal, measuring

temperature will be a problem. By utilizing the fast oscilloscope we will be able to

measure the temperature accurately enough to prove the concept. Later more capable

receiver electronics will be designed to create a cost-effective independent solution.

Another issue with system utilizing RF for tracking is the degradation and spoofing due to multipath[18]. The 2.4GHz carrier frequency is susceptible to multi-path

in environments where the transponder does not have line-of-sight to all the measurement stations. The problem of accurate localization becomes one of observability,

which is out of the scope of this thesis. There several approaches that would help with

mitigating effects of multipath such as positioning or adding measurement stations or

implementation of Kalman filtering or estimation techniques[23, 24, 25, 26, 27, 28, 29].

By using the same correlation techniques explained at the beginning of this chapter

and in section 2.3, multiple echos due to multipath can be detected and corrected

for[19]. Continuing work after the basic goals of this project are met will include implementation and research into algorithms that exploit system state and constraints

to mitigate the effects of multipath.

CHAPTER 1. INTRODUCTION

1.2

Motivation

Probably the most lucrative application for a passive localization system is asset,

people, and/or animal tracking. The ability to locate products and possessions in

real-time and 3-d will improve security and retrieval of items with significant improvements over existing technologies, such as RFID.

Encoding human body motion is an example of a dynamic application which illustrates the utility of 3-d tracking[30]. Traditionally body motion has been recorded

with vision instrumented rooms[31], inertial measurement units (IMU)[32], or ultrasonic sensors[33]. A person wearing chip-sized SAW transponders sewn into the

wrists, ankles, and joints of their clothing would have their body motion tracked in

real-time. Such encoding could be used for a variety of human computer interfaces.

Two of the many applications which this system is uniquely suited for include allowing unhindered natural motion in a virtual reality environment, training a robot

through intuitive movements, or interactive computer games.

Because of their small size, low-cost, and the ability to use numerous tags, SAW

transponders are well suited for disposable applications such as tracking animals, for

research, or domestic control. An additional benefit of SAW transponders is that

they do not requiring external power and their useful life is virtually unlimited and

maintenance free.

1.3. RELATED WORK

1.3

Related Work

Existing technologies are inadequate for the applications a SAW localization system is

suited for. Ultrasonic transponders are bulky, require a power source, and have limited

line-of-sight and are susceptible to environmental interference. IMUs are bulky, costly,

require a power source, and are limited by drift, bandwidth, and accuracy. A visionbased tracking system requires a carefully controlled environment to ensure line-ofsight and sufficient contrast between the obtrusive visual markers and background

objects. Differential GPS systems are bulky, costly, mainly limited to outdoors, and

have marginal update rates[34]. The key advantages of SAW based transponders is

an unintrusive, robust, and low-cost tracking system with high update rates that can

be deployed with thousand of tags. The applications of localizing SAW transponders

is broad and poorly met by existing solutions.

Many commercial indoor location and tracking systems have been implemented

or are in development.

Chipcon has developed a hardware core that uses signal

strength and bit-error-rate to estimate the relative location of transceivers [35, 34].

A system of using small active tags was developed by Carios for the use of tracking

objects at high-speed, such as soccer balls. An asset tracking system was developed

by Ubisense utilizing ultra-wide-band technology[36]. All of these systems have one

thing in common, bulky active tags, a major disadvantage in comparison to the

passive SAW transponders.

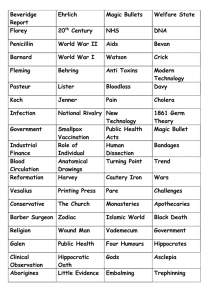

Meaningful quantitative comparisons between the mentioned technologies is difficult as there are many application specific trade-offs which affect performance. A few

of the inherent trade-offs are between accuracy, power, cost, update rate, and effective

range. For simplicity, many assumptions were made while compiling the data shown

in figure 1.1[31]. The best performance as stated from the vendor's documentation

sheet was assumed. Minimal external interference under the best conditions were

CHAPTER 1. INTRODUCTION

uTags

Differential GPS

Vision

Ultrasonic

Radar

1x1 cm

< 2g

$1.00

$5k

< 10cm

1-100kHz

0

1-100m

16x9x17 cm

1.4kg

$lk-$10k

NA

< 5cm(xy), < 10cm(z)

1-20Hz

5W

NA

4x4 cm

<i

$0.30

~ $10k

< 2cm

30-60Hz

0

1-10m

5x5x5 cm

~ 100g

~ $100.00

NA

< 1c,

~ 120Hz

200mW

1-10m

NA

NA

NA

$2k+

meters

1Hz

0

miles

Yes

Yes

no

Yes

Yes

In/Out

In/Out

In

In/Out

Out

Chipcon

Carios

Ubisense

varies

varies

unknown

unknown

2x2x0.5 cm

5g est.

57 EUR

200k EUR

5.8x9.2x1 cm

45g

50 EUR

15k EUR

Resolution

1 - 2m

1 - 2cm

20cm

Sample Rate

Power/Tag

Range

ID

In/Out Doors

varies

100mW

70m

Yes

In/Out

100kHz

70mW-175mW

300m

Yes

In/Out

39Hz

unknown

50m

Yes

In/Out

I

Tag Size

Tag Weight

Cost/Tag

Reader Cost

Resolution

Sample Rate

Power/Tag

Range

ID

In/Out Doors

Tag Size

Tag Weight

Cost/Tag

Reader Cost

Table 1.1: Comparison between widely used localization systems and SAW transponder [6, 7, 8, 9].

implied on some data sheets, and nominal specifications were given by other data

sheets. A comprehensive comparison is out of the scope of this thesis, however table

1.1 illustrates how SAW transponders are uniquely suited for a niche which existing

technologies do not fill.

Design and fabrication of SAW filters and correlators has been extensively researched. The uses of SAW devices is expanding in the area of chemical sensing,

optics, and RFID applications[13, 37, 38]. SAW devices are emerging in such novel

uses as an optical wave-guide scanning system to steer a laser beam using the birefringent properties of LiNbO 3 [39]. Shortly after this project was started companies

producing SAW devices for RFID application started to appear[17, 40]. The market

1.3. RELATED WORK

37

for utilizing SAW RFID technology is relatively untapped, probably for several reason including the amount invested in other RFID technologies, recent developments

in SAW designs, and the prior difficulty in manufacturing and reading SAW devices

in comparison to other technologies. A search of the literature has not yielded any

projects relating SAW transponders to ranging and localization similar to the goals

and methods of this project.

38

CHAPTER 1. INTRODUCTION

Chapter 2

Surface Acoustic Wave Devices

This chapter covers the basic concept of SAW functionality, the approach taken to

model these devices for this project, and an explanation of the device designs implemented on masks 1 through 3. The approach taken to tackle the complexity of this

project was to iterate on design, modeling, fabrication, and testing of SAW devices.

Simple models that were used in the beginning will become more sophisticated and

accurate with each iteration. Using real test data at each step will verify our increasingly sophisticated models and designs, as well as progressively build experience

with fabrication, electronics, and design. Existing methods for encoding data into

the SAW transponders will also be experimented with, but are not the primary focus

of this project.

Acoustic surface waves are a physical, as opposed to electromagnetic, compression

disturbance moving along the surface of a substrate. Visualizing waves on the surface

of a SAW device as ripples on a pond can be helpful with understanding the transient

operation of these devices. Surface waves can be initiated in many ways depending on

the substrate. The SAW devices in this project consists of a piezoelectric substrate

patterned with a thin film of aluminum. When electrical signals are applied to the

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

metal on surface of the piezoelectric substrate, the electric field causes a physical

disturbance. A cyclical electrical field causes ripples to be generated. To magnify the

response, many input features are actuated in resonance for constructive interference

of the waves[5].

The SAW transponders in this project consists of a piezoelectric substrate patterned with a thin film of aluminum. Any type of conductive metal can be used

to make the IDT, however there is a trade-off between adhesion, resistance, and

weight. Some metals have poor adhesion to LiNbO3 . Even though they are very

thin (~ 200nm), the weight of the metal fingers causes signal attenuation and reflections. Aluminum was chosen for reasonable adhesion to LiNbO3 , low mass, and low

resistivity.

substrate

reflectors

bond pad

input IDT

Figure 2-1: Simplified diagram of basic SAW transponder functional components[1].

A notational diagram of the patterning used for a simplified SAW transponder is

shown in figure 2-1. An antenna is connected to the bond-pads which couples the

RF chirp into the transponder. The inter-digital transducer (IDT) is a linear array

of metal fingers which change incident electrical energy from the bond-pads into a

surface acoustic wave on the piezoelectric substrate. This wave travels along at a slow

velocity (in comparison to RF) until reflecting off discontinuities on the path of travel

such as metallic strips of reflectors. The reflected signals return to the IDT and are

retransmitted via the antenna to the base-station. The gap between the IDT and the

first reflector builds in a delay between the incident RF burst to the first reflector,

which allows multi-path clutter to diminish before a rebroadcast, ensuring the base

station receives a clear signal from the SAW transponder [13, 5, 14].

Anytime the surface wave encounters a discontinuity, three things may happen.

Some of the energy in the wave may be reflected, continue on unaffected, or be dissipated. Any pattern of material may cause a disturbance or transformation of surface

waves traveling underneath. Every finger in an IDT or reflector will reflect some of

an incident wave. These reflected waves will then interact with other fingers to repeat

the process until all of the energy has been dissipated. Secondary reflections can be

a significant problem and pose a design challenge by ruining the desired response, or

they may be exploited as part of the design.

Clever designs of SAW patterns allows sophisticated signal processing of the surface wave. Proper design of the patterns will even cause the substrate to steer light[39].

As well as being periodically resonant, SAW patterns are also designed to resonate

to a specific sequence of patterns, as in the case of SAW correlators[5, 14].

RF wave inmatch

surface wave out

RF wave in

time

positio

ie/p

Figure 2-2: Saw correlator with corresponding code and output pulse waveform. "time

/ position"is the waveform over time at a single point between IDTs, or the waveform

over position between IDTs at a particular time.

The design of phase-shift SAW correlators involves alternating the arrangement

of the IDT finger pairs. Figure 2-2 shows a SAW correlator IDT with the respective

matching waveform.

As the waveform enters the IDT, at each cycle each finger

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

pair starts a wave of a certain polarity. These waves constructively or destructively

interact. With the proper input waveform, the total sum of the waves interfering

with each other will give the maximum response, which is launched along the surface

towards another IDT or reflector. The "RF wave in match" in figure 2-2 illustrates

how the input waveform matches to the IDT's finger pair polarity. In this example

the correlated sequence is a Barker code which results in a pulse surface wave with

side lobes of unity magnitude[14, 5]. Design and simulation of SAW correlators will

be covered in is sections 2.2 & 2.3.

2.1

Properties of Lithium Niobate

The design of the SAW devices in this project is limited by the properties of LiNbO3.

Lithium niobate was chosen for several reasons. The high coupling-coefficient, or

the amount of electrical energy transfered to the surface wave, of LiNbO3 is much

better than many other suitable materials[5, 2]. LiNbO3 also has a relatively high

characteristic surface wave velocity. Faster surface velocities enables higher frequency

devices to have larger metal patterns, making fabrication easier.

+z

'

I28drection of propaaton

+y.

Figure 2-3: Illustration of the crystal cut of a 128*-RY wafer[2], with an X-Flat, from

Crystal Technologies Inc.

The crystalline structures of LiNbO3 , constrains the surface waves to move along a

particular direction. Varying the orientation of the crystalline structure with respect

2.2. MODELING

Y0* direction of propagation

+Z

+y.

Figure 2-4: Illustration of the crystal cut of a Y wafer [2], with a Z-Flat, from Crystal

Technologies Inc.

to the surface of the wafer changes the properties of substrate. Some of the properties

affected by the crystalline orientation are the surface velocity, coupling coefficient, and

temperature dependency [14, 41, 2]. The 128*-RY lithium niobate wafer cut has the

best coupling coefficient (K 2 = 5.3%) and surface velocity (3992m/s) with a decent

temperature degradation coefficient (75ppm/*C). All of the devices discussed in this

thesis were made with 128*-RY wafers, though devices were also fabricated out of

Y-cut wafers.

The effects of temperature on the surface velocity of LiNbO3 SAW devices has

been well characterized[5]. Changes in temperature cause a shift in the band-pass

SAW center frequencies of a SAW filter[14, 5].

Most implementations appear to

safely ignore temperature effects. In cases where the surface velocity is critical, some

designs use a heater to control temperature[14]. Some transducers exploit the temperature dependence of lithium niobate to measure temperature[2 1]. For this project,

subtracting out the effects of temperature on the ranging solution will be important.

2.2

Modeling

Accurately modeling a SAW device's response to stimulus is very complicated. Higher

order finger reflections are usually modeled using finite-element-analysis (FEA) or

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

boundary-element-analysis (BEA). Several methods of modeling finger pairs in FEA

or BEA exist, such the P-Matrix, S-Matrix, coupling-of-modes (COM) modeling

methods[5]. FEA and BEA are both computational intensive, time consuming, and

not particularly intuitive. Intuition into the operation of SAW devices is essential

for understanding the effects of design choices.

The design of more complicated

implementations lead to longer simulations, making visualizing SAW responses even

more important.

A simple method of simulation was explored to quickly obtain some experience

with the macro characteristics of SAW behavior. The approach taken estimates the

loss in power resulting from first-order finger reflections given the initial acoustic

waveform. The resulting surface waves are then convolved with the output IDT to

simulate the electrical output generated by the surface waves.

absorption block

200pmr

input IDT

output IDT

Figure 2-5: SAW filter made with mask 1. Device Ox2C9, 25 finger pairs that are

200pm long.

A simple example illustrating simplified modeling is shown in figures 2-6. This is

the simulated impulse response through a SAW filter as designed and implemented

on mask 1, which is shown in figure 2-5. The surface wave response is modeled by a

sine wave in which each finger pair corresponds to one cycle. The magnitude of the

surface wave, at any given point between the two IDTs, decreases with time because

of reflection caused by the input IDT fingers. Another way to visualize this is that

at the moment the impulse couples into the IDT there is a surface wave generated

45

2.2. MODELING

Electrical output at second IDT

Input generated surface acoustic wave

0.8

0.8

0.6

0.6

0.4

0.4

00

(D

=

E

0

N

-0.2

-

CU

E -0.4

C

0.2

-

0.2

E

CU

-0.2

E -0.4

,

C

0

-0.6,

-0.6

-0.8'

-0.8

0

20

40

ns

60

80

0

50

ns

100

150

Figure 2-6: MATLAB" simulation of the normalized impulse response of a 323MHz

SAW band-pass filter shown if figure 2-5.

that spans the IDT with no attenuation of signal. This surface wave travels out from

each IDT finger pair in both directions, and anytime an individual cycle encounters

a finger some of the energy is lost due to reflection and absorption. As the surface

wave couples into the output IDT, further attenuation occurs due to reflections. By

convolving the two waveforms resulting from the geometry of the input and output

IDTs, the electrical signal at the output can be estimated as shown to the right in

m

figure 2-6. The code used to generate this simulation is given in MATLAB appendix

F.

An oscilloscope trace from the actual device corresponding to this simulation is

shown in figure 2-7. The test setup and data collection procedures are detailed in

section 4.4. The first 25 cycles correspond very closely to the simulation, because only

first order effects of finger reflections are dominant. As the surface wave moves further

across the output IDT the secondary reflection start to have a visible impact, which is

why the tail end of the test data deviates from the simulated output. Reflections will

continue to bounce back and forth between the two IDTs, and internal IDT fingers,

until all the surface waves have dissipated. This effect, shown in section 5.1, is also

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

MATLAB 1 : MATLAB source for simulation in figure 2-6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

% Simple simulation of the impulse

or 25

% of a response 50 fingers

% finger pairs , saw filter

f = 323e6;

% frequency = 323 MHz

w = 2*pi*f;

% omega

p = 1/f;

% period

pairs

fingerPs = 25 % number of finger

% time step is 100ps

t = 0:100e-12: fingerPs*p;

% model input pulse

in-p = (1-t*f/40).*sin(w*t);

% normalize

in-p = in-p./max(in-p);

pulse

% model output

out-p = conv(in-p , in-p);

% normalize

out-p = out-p./max(max(out-p),-min(outp ));

not covered by this model. The purpose of the higher order models is to take into

account multiple finger reflections.

2.2. MODELING

Measuwe

vake

status

PI:freq(C2)

318.1 MHz

A

P2:freq(C3) P3:ddely(C2,...

1.853 GHz

A

P4;freq(C2)

318.1 MHz

A

PS:---

PS:---

P7:- - -

X1-

37.95trs

AX- -lR85lns

-79.90ns -1/&X= -. 485 MHz

X2-

P8:-- -

Figure 2-7: Result of an impulse through device 0x209 as recorded on an oscilloscope.

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

2.3

Design

Only a simplified number of design parameters were specified for the first devices.

The center frequency of the mask 1 designs was primary specification. The complete

frequency response has been ignored for simplicity.

bond-pad

width

line-width

bond-pad

height

length

apodization

rail width

pitch

Figure 2-8: Parameters for the design of a SAW IDT in this project.

Figure 2-8 summarizes the basic parameters for the devices on mask 1. The finger

pitch along with the characteristic surface velocity determines the resonant frequency

of the IDT.

V

AV(2.1)

2 -p

where v is the characteristic surface wave velocity, A is the surface wave-length, and

f is the

center frequency[5].

For the devices with 3pum line-widths, and a pitch of 6pm on a 128 0-RY crystal cut with a surface velocity of 3992m/s, the center frequency is 332MHz. This

differs from the measured center frequency response of 323MHz, which may be due

to secondary effects such as electromagnetic feedthrough, triple-transit-interference,

capacitive effects of the fingers, or the RF-Network Vector Analyzer that we were

2.3. DESIGN

using was out of calibration (the calibration was last done over ten years ago). More

investigation into the discrepancy is underway.

Apodization, or the amount of finger overlap, may be varied to evoke a certain

response from a SAW filter. For example a sinc-function apodization of the IDT will

yield a flat pass-band response. The simple filter devices on mask 1 had constant

apodization.

The number of finger pairs and length of the apodization determines the input

capacitance of the IDT. Capacitance per unit length is a fundamental property of

the particular substrate and crystal cut used. For 128 0-RY cut lithium niobate, the

capacitance per finger pair per unit length is 5pF/cm/finger-pair.Therefore:

Ct = cf - 100(cm/m) - a, - f,

(2.2)

Where C is the total IDT capacitance, cf is the fundamental capacitance per finger

pair per unit length, a, is the apodization in meters, and

f, is

the number of finger

pairs. For device Ox2C9 detailed in section 5.1, a, = 200pm, cf = 5pF/cm/pairs,and

f, =

25 resulting in a Ct of 2.39pF, which is close to the measured input capacitance

of 2.13pF.

The bond pads were made large enough for easy wire-bonding. They were much

larger than necessary in an attempt to mitigate the problems caused by the thin

metal and fragile substrate. The width of the rails only needs to be wide enough to

ensure the signal is not attenuated substantially due to their internal resistance. An

absorption block, see figure 2-5, stops unwanted signals from reflecting back towards

the IDT. The 200pm width chosen was arbitrary for this design. Future designs will

use angled reflectors that won't take up as much device area[14].

Three different reflectors for encoding of the return signature were tried on mask

1, shown in figure 2-9. The "open" reflector had the largest return response of the

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

open

short

interleaved

Figure 2-9: The three types of SAW reflectors were implemented on mask 1.

three designs and was the only design to return a significant signal. Not much time

was taken to characterize the different reflectors for lack of equipment and because

fabricating the 915MHz devices became the priority.

SAW correlators are extensively used in SAW filter and communications applications [11, 12, 13, 5]. Implementation of SAW correlators for encoding was one of

the goals of mask 2 & 3. Several 915MHz narrow-band and wide-band correlator

designs were made, with three of them explained here. To keep this stage of the

project as uncomplicated as possible, secondary effects, such as reflections, have been

ignored in the following examples and corresponding simulations. Secondary effects

will need to be account for in future designs. The Matlab M scripts used to generate

the simulation for the following are located in appending F.

input IDT

output

IDT

1 1 1 0 1

Figure 2-10: Narrow-band output correlator with n = 5 Barker code illustration.

A narrow-band correlator consists of a tightly packed set of IDT fingers for a

continuous code. To encode '0' or '1', the phase of the finger is reversed from one to

2.3. DESIGN

Figure 2-11: Narrow-band output trace for figure 2-10.

another (see the digits under the finger pairs of output IDT in figure 2-10). When

the proper code couples into the input IDT, the resulting SAW waveform will create

a peaked waveform at the output. Multiple finger-pairs may be used to implement

the encoding which increases the total amount of energy in the signals and increases

signal peaking. A simplified narrow-band SAW configuration is shown in figure 2-10

with a Barker code of length five encoding. The proper code received by the input

IDT will result in the signal shown in figure 2-11 at the output. Notice the continuous

nature of the output waveform.

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

input IDT

I

4-- output IDT

Figure 2-12: Narrow-band output correlator with code [1, 1, 1, 0, 1, 1, 1, 1, 1, 1] utilizing one finger-pair encoding.

Figure 2-13: Narrow-band correlator response for device fabricated on mask 3, shown

in figure 2-12. Generated with nb.m in appendix F.

Figure 2-12 shows a design for a narrow-band SAW correlator on mask 1. This

devices has a code that is different from the Barker sets of codes, resulting in a unique

signature to the optimal interrogation code. The expected output is shown in figure

2-13.

2.3. DESIGN

output IDT

input IDT

II|1|

|

|

|

Figure 2-14: Wide-band output correlator illustration with n = 5 Barker code with

two finger-pair encoding.

Figure 2-15: Wide-band output trace for figure 2-14.

A wide-band correlator differs from a narrow-band correlator by interspersing

the phase encoded signal with a delay based on the number of fingers at the input.

When the set of delayed pulses matches the output code the output waveform peaks,

as shown in figure 2-14.

- M111

I

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

input IDT

output IDT

Figure 2-16: Wide-band output correlator.

jwl

q"qr-

i

T

Ah.

"Iqw-

Figure 2-17: Wide-band correlator response for device fabricated on mask 3, shown

in figure 2-16. Generated with wb.m in appendix F.

Figure 2-16 shows the layout of a wide-band SAW correlator on mask 3. The

five finger input does not have an encoding. The output encoding is implemented in

the output IDT. A Barker code of length five was used, which with the correct input

sequence gives the output waveform in figure 2-17.

2.3. DESIGN

input IDT

output IDTs

Figure 2-18: Dual narrow-band transponder with a Barker code of length five with a

five finger encoding.

rx signal

first response

0

rn

second response

400ns

Figure 2-19: Dual narrow-band transponder's simulated waveform. The "rx signal"

was transmitted by the measurement station and is what the input IDT sees. The

'first response" and "second response" are the waveforms from each output IDT.

Measuring and compensating for temperature will be tried with the design in figure

2-18. This dual narrow-band transponder has three IDTs which will give two distinct

responses as explained by the example in chapter 1. An actual implementation would

have all three IDTs connected to the same antenna. They were left disconnected in

this design to allow independent testing of each port. Figure 2-19 shows the expected

waveform when the correct code sequence is received by the input IDT and probed at

the output IDTs. The phase relationship and the distance between the two responses

I

CHAPTER 2. SURFACE ACOUSTIC WAVE DEVICES

56

will be proportional to the temperature of the substrate.

rxsignal

0

first response

second response

400ns

Figure 2-20: Simulation including the effect of surface waves originating from the

output IDTs of the transponder shown in figure 2-18.

Figure 2-19 does not contain the effects of the initial input signal coupling into the

output IDTs in the configuration where all IDTs are connected to the same source

/

antenna. When the input IDTs and output IDTs are connected to a common

antenna (typical for a self-contained transponder), the output IDTs also generate

a signal from the output to the input IDT. This signal combine with the signals

originating from the input IDT to create the slightly distorted waveform shown in

figure 2-20. In the future, designs we will exploit the ability to use all three IDTs

as input and output transducers, to both increase the returned power and enhance

encoding and temperature compensation.

Chapter 3

Micro-Fabrication

Fabricating devices with feature sizes in the rage of micrometers to nanometers

requires specialized sciences, engineering, and a significant degree of art.

High-

resolution processing is carried out in a clean-room facility with a variety of chemical

processing and meteorology tools. The path generally taken to constructing nanostructures as created in this project starts with design and layout of artwork describing the desired features with a CAD tool. A scanning-electron-beam-lithography

(SEBL) tool then writes this CAD artwork into a photoresist on a wafer. The wafer

may be the final substrate or an optical mask used to duplicate the artwork onto

the desired substrate. The photoresist is then developed with a chemical solution

to remove areas of photoresist. The substrate now contains a transfered pattern of

exposed material onto which more material (i.e. metal, oxide) may be deposited or

removed. After the deposition or etching step, the remaining photoresist is stripped

from the wafer leaving the desired features. When the devices are completed, they

are cut up into small rectangles, mounted to packages, and electrical leads are wirebonded from pins on the package to pads on a device. Also note that nanofabrication

may be carried out with processes other than lithography, such as nanoimprint and

CHAPTER 3. MICRO-FABRICATION

atomic force patterning technologies, which use physical means to transfer a pattern

[42, 43].

There are many emerging methods and applications of nanotechnology being developed on a variety of novel custom fabrication tools at MIT. The use of shared

experimental fabrication tools, as opposed to commercial production tools, made developing a processes much more difficult. Many of the tools required a significant

amount of experimentation to yield the desired results.

Adding to existing chal-

lenges, some of the tools would behave differently after other lab users processed with

them. Many factors and a array of processing variables made fabricating working

devices a daunting challenge. As with most research projects, costs vary widely and

are difficult to project ahead of time without significant experience. For this type of

work a typical budget runs between $7000 and $8000 USD per semester. This project

was my first exposure to micro-fabrication, and I have learned an enormous amount

about the field. Topics in this chapter aim to explain all the challenging problems

and their solutions, as well as all the process details that went into fabricating these

devices necessary to reproduce this work.

The devices in this project were fabricated utilizing the resources of several MIT