LETTER TO THE EDITOR

advertisement

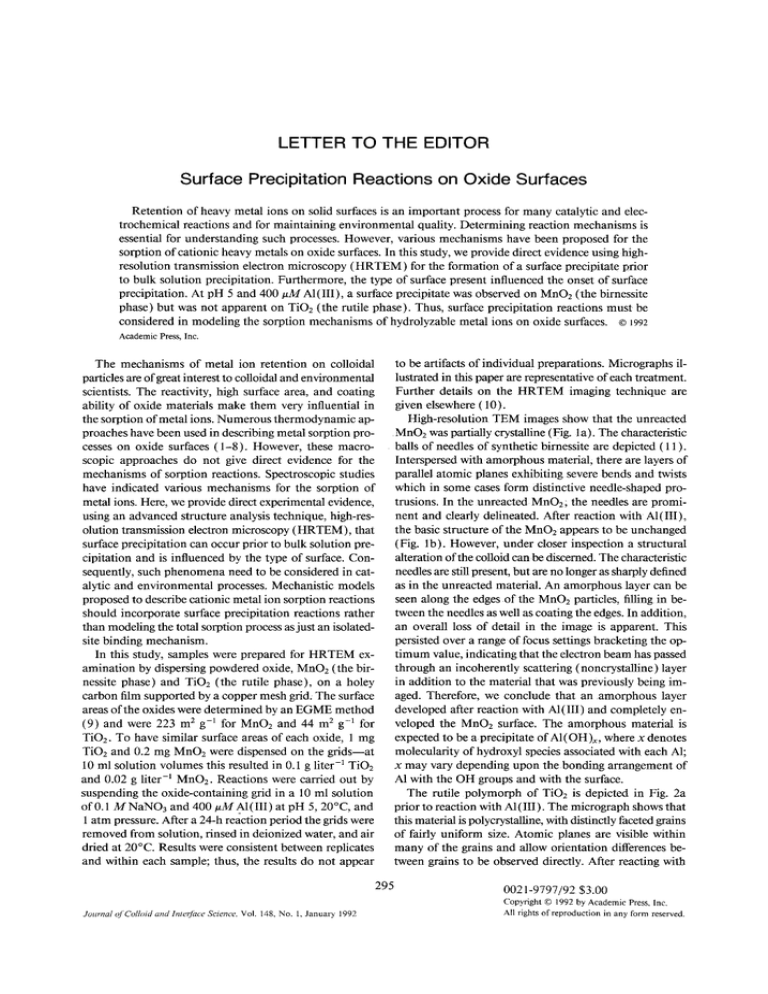

LETTER TO THE EDITOR Surface Precipitation Reactions on Oxide Surfaces Retention of heavy metal ions on solid surfaces is an important process for many catalytic and electrochemical reactions and for maintaining environmental quality. Determining reaction mechanisms is essential for understanding such processes. However, various mechanisms have been proposed for the sorption of cationic heavy metals on oxide surfaces. In this study, we provide direct evidence using highresolution transmission electron microscopy (HRTEM) for the formation of a surface precipitate prior to bulk solution precipitation. Furthermore, the type of surface present influenced the onset of surface precipitation. At pH 5 and 400 ttM A1(III), a surface precipitate was observed on M nO2 (the birnessite phase) but was not apparent on TiO2 (the rutile phase). Thus, surface precipitation reactions must be considered in modeling the sorption mechanisms of hydrolyzable metal ions on oxide surfaces. ©1992 Academic Press, Inc. The mechanisms of metal ion retention on colloidal particles are of great interest to colloidal and environmental scientists. The reactivity, high surface area, and coating ability of oxide materials make them very influential in the sorption of metal ions. Numerous thermodynamic approaches have been used in describing metal sorption processes on oxide surfaces (1-8). However, these macroscopic approaches do not give direct evidence for the mechanisms of sorption reactions. Spectroscopic studies have indicated various mechanisms for the sorption of metal ions. Here, we provide direct experimental evidence, using an advanced structure analysis technique, high-resolution transmission electron microscopy (HRTEM), that surface precipitation can occur prior to bulk solution precipitation and is influenced by the type of surface. Consequently, such phenomena need to be considered in catalytic and environmental processes. Mechanistic models proposed to describe cationic metal ion sorption reactions should incorporate surface precipitation reactions rather than modeling the total sorption process as just an isolatedsite binding mechanism. In this study, samples were prepared for HRTEM examination by dispersing powdered oxide, MnO2 (the birnessite phase) and TiO2 (the rutile phase), on a holey carbon film supported by a copper mesh grid: The surface areas of the oxides were determined by an EGME method (9) and were 223 m 2 g-i for MnO2 and 44 m 2 g-1 for TiO2. To have similar surface areas of each oxide, 1 mg TiO2 and 0.2 mg MnO2 were dispensed on the grids--at 10 ml solution volumes this resulted in 0.1 g liter -a TiO2 and 0.02 g liter -l MnO2. Reactions were carried out by suspending the oxide-containing grid in a 10 ml solution of 0.1 M NaNO3 and 400 #M _AI(III) at pH 5, 20°C, and 1 atm pressure. After a 24-h reaction period the grids were removed from solution, rinsed in deionized water, and air dried at 20°C. Results were consistent between replicates and within each sample; thus, the results do not appear 295 Journal of Colloid and lnter/~tce Science. Vol. 148, No. 1, Januapy 1992 to be artifacts of individual preparations. Micrographs illustrated in this paper are representative of each treatment. Further details on the HRTEM imaging technique are given elsewhere (10). High-resolution TEM images show that the unreacted MnO2 was partially crystalline (Fig. la). The characteristic balls of needles of synthetic birnessite are depicted ( 11 ). Interspersed with amorphous material, there are layers of parallel atomic planes exhibiting severe bends and twists which in some cases form distinctive needle-shaped protrusions. In the unreacted MnO2; the needles are prominent and clearly delineated. After reaction with AI(III), the basic structure of the MnO2 appears to be unchanged (Fig. lb). However, under closer inspection a structural alteration of the colloid can be discerned. The characteristic needles are still present, but are no longer as sharply defined as in the unreacted material. An amorphous layer can be seen along the edges of the MnO2 particles, filling in between the needles as well as coating the edges. In addition, an overall loss of detail in the image is apparent. This persisted over a range of focus settings bracketing the optimum value, indicating that the electron beam has passed through an incoherently scattering (noncrystalline) layer in addition to the material that was previously being imaged. Therefore, we conclude that an amorphous layer developed after reaction with AI(III) and completely enveloped the MnO2 surface. The amorphous material is expected to be a precipitate of A1(OH)x, where x denotes molecularity of hydroxyl species associated with each A1; x may vary depending upon the bonding arrangement of A1 with the OH groups and with the surface. The rutile polymorph of TiO2 is depicted in Fig. 2a prior to reaction with A1(III). The micrograph shows that this material is polycrystalline, with distinctly faceted grains of fairly uniform size. Atomic planes are visible within many of the grains and allow orientation differences between grains to be observed directly. After reacting with 0021-9797/92 $3.00 Copyright © 1992 by Academic Press, Inc. All rights of reproduction in any form reserved. 296 LETTER TO THE EDITOR FIG. 1. High-resolution TEM image of (a) unreacted MnO2 (the bimessite phase) and (b) MnO2 after reaction with 400 # M AI(III) at pH 5. After MnO2 has reacted with AI(III), an amorphous layer has enveloped the MnO2 surface, which is shown by the amorphous material deposited at the edges of the needle structures and a resulting overall loss of detail in the image. A1(III ) (Fig. 2b), the TiO2 appears to be unaltered. Even very close inspection of the images does not reveal the formation of a surface precipitate; the crystalline structure remains unchanged, and no amorphous material is present. The MnOz and TiO2 surfaces differ in their ability to induce surface precipitation in systems of 400 I~M A1(III) at pH 5. At pH 5, the MnO2 (zero point of charge, ZPC Journal of Colloid and Interface Science, Vol. 148, No. 1, January 1992 = 2.8) (13) surface was strongly negatively charged, while TiO2 (ZPC = 6.7) was positively charged. The absence of a precipitate on the surface of the TiO2 discounts the possibility that a colloid acts only as a nucleation site for the formation of a precipitate. The enhancement of precipitation in between the needles of the MnO2 may be due to electrostatic effects, which are increased due to the close 297 LETTER TO THE EDITOR F1G. 2. High-resolution TEM image of (a) unreacted TiO2 and (b) TiO2 after reaction with 400 u M AI(III) at pH 5. The TiO2 structure appears to be unaltered after reacting with AI(III); no amorphous material can be seen on the surface structure. proximity of the charged surfaces, rather than simply an abundance of nucleation sites. Hence, the lack of precipitation in the TiO2-AI(III) system substantiates (i) that surface precipitation can occur prior to bulk solution precipitation (as exemplified by the MnO2 system in this study), and (ii) that the properties of the surface do affect the formation of a surface precipitate. Hypothesized mechanisms for cationic metal sorption on oxide surfaces include adsorption of the free ion or hydrolysis products (3-7), adsorption of polymerized species ( 13, 14), surface cluster formation (15), and the formation of a surface precipitate ( l, 8, 16-19 ). The multinuclear metal species observed at lower surface coverages by spectroscopic techniques ( 14, 15) may be a precursor Journal ~fColloid and lnter/bcz, Science, Vol. 148,No. 1, January1992 298 LETTER TO THE EDITOR to the formation of a surface precipitate. The mass action balance proposed by Bleam and McBride (15) to explain the progression from isolated-site binding to the formation of multinuclear sorbed clusters with increases in solution metal concentration may explain the formation of a surface precipitate at the even greater solution metal ion concentrations used here. Direct evidence has also been obtained using X-ray photoelectron spectroscopy (XPS) for the formation of a Co(H) surface precipitate on oxide surfaces ( 17-19). Crowther et al. (19) observed XPS spectra characteristic of Co(OH)2 on the surface of a synthetic birnessite when critical pH and Co (II) concentrations were exceeded, However, the results of the XPS studies have been questioned (14). As demonstrated here, HRTEM provides a tool for obtaining direct evidence for the formation of a surface precipitate. Clearly, the MnO2 surface structure underwent an alteration, while the TiO2 surface appeared unaltered. The formation of a surface metal precipitate prior to bulk solution precipitation has important implications for environmental quality and catalytic processes. Surface precipitation represents a means of metal removal from solution which will be less subject to desorption reactions releasing metals back to solution--only dissolution of the precipitate will release the metal to solution. Moreover, the surface precipitate will mask the properties of the original sorbent, and only the surface properties of the metal hydroxide will be exhibited by the resulting conglomerated colloid. ACKNOWLEDGMENT The HRTEM facilities used were at the National Center for Electron Microscopy, Lawrence Berkeley Laboratory, which are funded by the Director, Office of Energy Research, Office of Basic Energy Sciences, Materials Sciences Division of the U:SI Department of Energy. REFERENCES 1. James, R, O., and Healy, T. W., J. Colloid lnterJace ScL 40, 53 (I972). 2. James; R. O., and Healy, T. W., J. Colloid Interface Sci. 40, 65 (1972). 3. Yates, D. E, Levine, S., and Healy, T. W., J. Chem. Soc: Faraday Trans. 1 70, 1807 (1974). 4. Schihdter, P. W., and Stumm, W., in "Aquatic Surface Chemistry" (W. Stumm, Ed.), p. 83. Wiley-Interscience, New York, 1987. 5. Davis, J. A:, James, R. O., and Leckie, J. O., J. Colloid Interface Sci. 63, 480 ( 1978 ). Journalof Colloidandlntel:t~weScience.Vol. 148,No. I, January 1992 6. Bowden, J. W., Bolland, M. C. A., Posner, A. M., and Quirk, J. P., Nature 245, 81 (1973). 7. Burube, Y. G., and de Bruyn, P. L., J. Colloidlnterface Sci. 27, 305 (1968). 8. Farley, K. J., Dzombak, D. A., and Morel, M. M., J. Colloid Interface Sci. 106, 226 ( 1985 ). 9. Heilman, M. C., Carter, D. L., and Gonzalez, C. L., Soil Sci. 100, 409 ( 1965 ). 10. Fendorf, M , Fendorf, S. E., Sparks, D. L., and Gronsky, R., in "Proceedings of the 49th Annual Meeting of the Electron Microscopy Society of America" (G. W. Bailey, Ed.), San Francisco Press, San Francisco, 1991. 11. McKenzie, R. M., in "Minerals in the Soil Environment" (J. B. Dixon and S. B. Weed, Eds.), p. 181. SSSA, 1979. 12. Fendorf, S. E., and Zasoski, R. J., Environ. Sci. Technol., in press. 13. Alvarez, R., and Sparks, D. L., Nature 318, 649 (1985). 14. Brown, G. E., Jr., Parks, G. A., and Chisholm-Brause, C. J., Chimia 43, 248 (1989). 15. Bleam, W. F., and McBride, M. B., J. Colloidlnterface Sci. 110, 335 (1986). 16. Murray, J. W., and Dillard, J. G., Geochim. Cosrnochim. Acta. 43, 781 (1979). 17. Tewari, P. H., and Lee, W., Z Colloid InterJitce Sci. 52, 77 (1975). 18. Murray, J. W., and Dillard, J. G., Geochim. Cosmochim. Acta. 43, 781 (1979). 19. Crowther, D. L., Dillard, J. G., and Murray, J. W., Geochim. Cosmochim. Acta 47, 1399 (1983). SCOTT E. FENDORF 1 DONALD L. SPARKS Department of Plant and Soil Science University of Delaware Newark, Delaware 19717-1303 MARK FENDORF RONALD GRONSKY Materials" Science Division Lawrence Berkeley Laboratory and Department o f Materials Science and Mineral Engineering University of California Berkeley, California 94720 Received July 15, 1991; accepted October 8, 1991 To whom correspondence should be addressed.