Wastewater Engineering Typical Variation of Municipal Water Demand and Wastewater Flow

advertisement

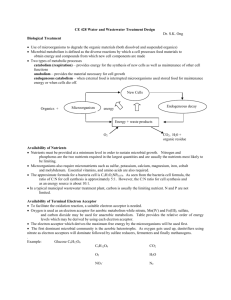

CE 326 Principles of Environmental Engineering Wastewater Engineering Flows Typical Variation of Municipal Water Demand and Wastewater Flow Average daily design flow rate – average flow over a 24 hour period Peak design flow rate – usually _______ times the average design flow rate depending on population, composition of communities. The factor 2 to 2.5 is normally termed as the ___________________. Others Average dry weather flow (ADW) – daily average flow rate usually in the summer when runoff is not occurring Average wet weather flow (AWW) – daily average flow for wettest 30 consecutive days Wastewater Treatment Systems may be classified under two broad categories: ___________________ – biological treatment processes in which microorganisms responsible for the conversion of waste constituents are maintained in suspension within the liquid. Example, activated sludge process (Boone wastewater treatment plant) ________________________ – microorganisms are attached to some inert medium such as rocks, ceramic or plastic materials. Also known as fixed film processes, example, trickling filters (Ames Wastewater treatment plant) Generalized Flow diagram of an activated sludge plant 1 Generalized diagram for a single stage trickling filter Microbial Growth and Substrate Degradation The processes by which living organisms assimilate and use food for subsistence, growth and reproduction is called metabolism. Two types of metabolic processes ________________ (________________) – provides material necessary for cell growth ____________ (____________) – provides energy for the synthesis of new cells as well as maintenance of other cell functions ________________ catabolism – when external food is interrupted, microorganisms used stored food for maintenance energy or cells will die off. Anabolism (synthesis) New Cells (biomass) Organic compounds + Endogeneous catabolism Microorganisms Energy, waste products (CO2, H2O and organic residues) Microorganisms may be classified in many ways: (i) based on gross nutrition (energy, carbon, electron source) (ii) according to whether they use oxygen or not (iii) by preferred temperature ranges 2 Based on nutrition Groups carbon source energy source electron source _____________________________________________________________________________________ ___________________________________________________________________________________ Based on oxygen use - _________________, an organism which requires oxygen as an electron acceptor and which can grow at normal atmospheric partial pressure (aerobic system) - __________________ – cannot survive in the presence of oxygen (anaerobic system) - ___________________ – can use oxygen as electron acceptor under certain conditions but grows in the absence of oxygen Based on temprature - _______________ – temperature range _______________C, optimum temperature of 15+5o C; minimum temperature 0o C or below. The water temperature of oceans is less than 20 o C and with an average temperature of 5o C. Pollution of oceans such as oil spills rely on psychrophilles in the assimilating the pollutants. - _______________: temperature range between ____________ C; include most microorganisms which inhabit in humans (ex., pathogens) since the body temperature of a normal human is 37 o C. Anaerobic sludge digesters are operated at 35o C and are generally populated by mesophilic bacteria. - _________________: temperature range from ____________ C, optimum temperature above 45 o C; some can tolerate temperatures as high as 100o C (ex., blue-green algae in hot springs or in hot water heaters); some may be facultative thermophiles in that their range extends into the mesophilic zone. Growth in Mixed Culture The growth cycle of the microorganisms with a fixed amount of substrate may be characterized as shown in the figure below with various distinctive phases. - in nature and in engineered applications such as wastewater treatment, a mix culture of microorganisms exists where they compete for food. Because of the large numbers and mixed cultures of microorganisms, it is more convenient to measure the total biomass present rather than the numbers of each specific microorganism. The notation commonly used for the total biomass present is X. In wastewater, one of the methods of measurement 3 (which is not accurate but convenient) is the volatile suspended solids (VSS). Sometimes it is referred to as mixed liquor volatile suspended solids. In the log-phase growth phase for a mixed culture, the rate expression for the biomass change is given by: where X = growth rate constant (t-1) = biomass (mg/L) The above equation only accounts for growth, but if die-off of microorganism is included, then: where kd is the endogeneous decay rate constant (t-1) Monod developed an empirical growth model where the growth rate changes with biomass X and the substrate concentration. where constant (t-1) S Ks M = maximum growth rate = concentration of food in solution (mg/L) = half velocity or half saturation constant (mg/L) A plot of the growth rate is as shown below, where if S >> Ks then maximum growth is achieved, if S << Ks then the system is food limited, the growth rate is dependent on the amount of food or substrate present We can relate the rate of biomass production to the rate of substrate (food) utilization by using an empirical coefficient called the yield coefficient or factor. The yield coefficient, Y, is defined as the mass of microorganisms formed per unit mass of substrate used. Y = fraction of food mass converted to biomass = mg/L of Biomass/mg/L of food utilized Therefore we can write: The above equations are used to develop most of the equations for substrate utilization and biomass production for wastewater engineering. 4 Activated Sludge Process In a typical municipal wastewater, carbon is usually the “limiting” substrate with sufficient nitrogen and phosphorus and trace nutrients. Equations for an activated sludge process can be derived by assuming the following: Q, So Q + Qr Q e, X e, S V, X, S V, X Influent effluent Aeration tank Secondary settling tank Q r, X r, S (recycle) where Q Qr Qw Qe X Xe Xr So S Q w, X r (waste) = wastewater flow rate (L/day) = recycle flow (L/day) = waste flow rate (L/day) = effluent flow rate (L/day) = Q - Qw = concentration of biomass in aeration tank (mg/L) (reported as Mixed Liquor volatile suspended solids (MLVSS) = concentration of biomass in the effluent (mg/L) (reported as MLVSS) = recycle biomass concentration (mg/L) (reported as MLVSS) = influent substrate concentration (mg/L) =effluent substrate concentration (mg/L) Assumptions: Completely mixed conditions No biomass in influent and Xe is negligible No biological activity in settling tank Steady state conditions Sludge wasted from settling tank Solids retention tank (SRT) based on solids in aeration tank Mass balance for substrate (S) under steady state conditions Substrate degraded = Mass of substrate in - Mass of substrate out Mass balance for biomass (X) under steady state conditions Biomass wasted = Mass of biomass in – Mass of Biomass out + Biomass Growth Based on the two mass balances and using Monod’s equation for growth of biomass: where and dX X k d X dt S m Ks S dS 1 dX 1 mSX dt Y dt Y K s S 5 m Ks kd Y = growth rate constant (day-1) = maximum growth rate constant (day-1) = half velocity constant (mg/L) = endogeneous decay rate (day-1) = yield coefficient (mg/L of biomass produced per mg/L of substrate utilized) Example, mass balance for biomass: V XS dX QX o [Q w X r (Q Q w )X e ] V m k d X dt Ks S Mass Balance for substrate: V m XS dS QS o (Q Q w )S Q w S V dt Y(K s S) Assuming steady state conditions, i.e., dX/dt and dS/dt = 0, the biomass X and the effluent substrate is given by: c is defined as the solids retention time and is defined as the time the biomass remains in the system and is given by the ratio of the mass of biomass in the reactor to the mass of the biomass removed from the system each day. is the hydraulic retention time (HRT), given by V/Q Typical values for domestic wastewater: SRT or c = 7 to 20 days. HRT or = 4 hours to 24 hours m = 2 – 10, average = 6 day-1 Ks = 25 – 100, average = 60 mg/L Y = 0.4 – 0.8 average = 0.6 kd = 0.025 – 0.075 average = 0.06 day-1 6 A useful parameter in the design and operation of wastewater treatment plants is the food (substrate) to microorganism (biomass) ratio. Sludge Return Estimation - purpose is to maintain sufficient concentration of biomass in the reactor basin. MLSS in the aeration tank should be limited to 5,000 mg/L. - One method of estimating sludge return is based on an empirical measurement known as the sludge volume index (SVI). SVI is a standard laboratory test. It is used as an indicator of the settling characteristics of the sludge and therefore will have an impact on the return rates of the sludge into the aeration tank. - In this test, the suspended solids of the wastewater is measured – reported as mixed liquor suspended solids (MLSS). Next 1 liter of the mixed liquor is placed in a 1-liter graduated cylinder and the sludge is allowed to settle for 30 minutes. The volume occupied by the sludge (SV) is measured. The SVI is given by: Most activated sludge are designed to permit sludge return from 10 to 100% of the raw waste flow. Maximum return sludge concentration (mg/L) is related to the SVI as follows: Use Figure 5 – 23 to figure out the return sludge ratio (Qr/Q) 7