Transmission Enhancement in an Array of Subwavelength Slits in Aluminum

advertisement

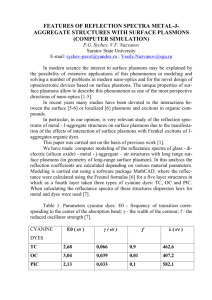

◆ Transmission Enhancement in an Array of Subwavelength Slits in Aluminum Due to Surface Plasmon Resonances Ho Bun Chan, Zsolt Marcet, Dustin Carr, John Eric Bower, Ray Cirelli, Ed Ferry, Fred P. Klemens, John F. Miner, Chien-Shing Pai, and J. Ashley Taylor The coupling of light to surface plasmons through periodic subwavelength metallic structures could strongly modify the optical properties of a metal film. We demonstrate that the optical transmission through an array of subwavelength slits is as high as 80% at resonance, even though the width of each slit is almost 10 times smaller than the wavelength and the slits occupy only 25% of the area of the metal. Numerical calculations suggest that the field intensity is strongly enhanced near the metal surface. The field enhancement could be used for generating nonlinear optical effects and for high sensitivity detection of nanomechanical displacement. © 2005 Lucent Technologies Inc. Introduction Surface Plasmons on a Metallic Surface Advances in fabrication technologies have made it possible to create artificial structures with features smaller than the wavelength of light. The interaction of light with matter at the subwavelength scale has led to new optical devices and continues to generate fascinating science. For example photonic crystals [13] utilize periodic variations in the dielectric function at the scale of wavelength to manipulate light. Another example involves near-field optical microscopy where light is channeled through subwavelength apertures to overcome the diffraction limit in optical microscopy [6]. Here, we focus on surface plasmon subwavelength optical devices [3] in which the surface of metal is artificially structured to tailor the properties of surface plasmons and their interaction with light. We will discuss basics of surface plasmons on a metal surface and describe the transmission properties of nanostructured metallic films that we fabricated. Surface plasmons are collective excitations of the electron density guided by a metal-dielectric interface [23]. They are solutions to Maxwell’s equations in which the charge oscillations are localized at the metal boundary (see Figure 1). The charge oscillation takes place in the longitudinal (x) direction parallel to the wavevector, as shown in Figure 1a. The charge density fluctuation is associated with an electromagnetic field that is maximum at the surface and decays exponentially away from it. On a smooth metal surface, the dispersion relation for surface plasmons is given by k⫽ e1e2 1兾2 v b , a c e1 ⫹ e2 (1) where e1 and e2 are the dielectric functions of the metal and the dielectric, respectively. Figure 1b is a Bell Labs Technical Journal 10(3), 143–150 (2005) © 2005 Lucent Technologies Inc. Published by Wiley Periodicals, Inc. Published online in Wiley InterScience (www.interscience.wiley.com). • DOI: 10.1002/bltj.20109 sketch of the dispersion relation of surface plasmons. For a smooth metal surface, light does not couple to surface plasmons because surface plasmons have a longer wavevector than light waves of the same frequency propagating along the surface [24]. However, the presence of a periodic structure on the metal surface can make up for this momentum difference and enable the direct coupling of light to surface plasmons. Surface plasmons have been a subject of intense research due to their potential applications in a variety of disciplines, including miniature photonic circuits [14, 17], biochemical sensing [11], microscopy, and high density optical data storage [26]. Surface plasmonic devices typically involve the excitation of surface plasmons by light on a metal surface. The surface plasmons are then guided to specific locations by structures that are artificially fabricated on the metal surface. At the final step, the surface plasmons are converted back into light. Therefore, instead of controlling light directly, these optical devices operate by manipulation of surface plasmons. By varying the wavelength, incident angle, and polarization of the incident light, surface plasmons can be launched in controllable directions [9]. A number of different structures, such as waveguides [4, 7], reflectors [4], nanoparticle chains [16], nanoshells [22], and hole arrays [8], have been created for manipulating surface plasmons. One remarkable kz Panel 1. Abbreviations, Acronyms, and Terms 1D—One-dimensional NJNC—New Jersey Nanotechnology Consortium RCWA—Rigorous coupled wave analysis TM—Transverse magnetic property of surface plasmons is their ability to channel light and concentrate the optical energy in subwavelength structures, resulting in dramatic enhancement of the local electromagnetic field. For instance, in surface-enhanced Raman spectroscopy [20], the roughness of the metal surface enables incident light to excite surface plasmon resonance at certain wavelengths, leading to enormous enhancement of the Raman cross section for molecules adsorbed on the surface. The discovery of extraordinarily large transmission through subwavelength hole arrays in optically thick metal films by Ebbesen and coworkers [8] has sparked additional interests in the field of surface plasmons. Even at wavelengths as large as ten times the diameter of an individual hole, transmission efficiencies were observed to be orders of magnitudes larger than predictions from standard aperture theory. In some cases, the total transmission exceeds the Dielectric 2 ckx E kx ⫺⫺⫺ ⫹⫹⫹ ⫺⫺⫺ ⫹⫹⫹ ⫺⫺⫺ SP Metal 1 kx (a) (b) (a) Electromagnetic field and charge of surface plasmons propagating along a metal-dielectric interface in the x direction. (b) Dispersion relation of surface plasmons on a smooth metal surface. Figure 1. Surface plasmons propagating along a metal-dielectric interface and the corresponding dispersion relations. 144 Bell Labs Technical Journal fractional area of the holes. While surface plasmons are believed to play a crucial role, the origin of the large enhancement in transmission remains a subject of intense research. In a simple picture, light is coupled to surface plasmons through the periodic structure at the incident surface. The surface plasmons are Bragg scattered by the array of holes to set up localized surface plasmons modes in the vicinity of the holes. The evanescent field of the surface plasmon modes tunnels through the holes to the other side of the metal film and re-radiates into light of the same frequency and momentum as the incident wave. Since the pioneering experiment of Ebbesen and coworkers on subwavelength hole arrays, a number of other geometries, including 1D slit arrays [2, 5, 12, 21], annular apertures [1], and a single hole or slit surrounded by periodic corrugations [15], have been shown by various researchers to possess extraordinary transmission and beaming characteristics. Transmission Properties of Fabricated Nanostructured Metallic Films Using the fabrication facilities at the New Jersey Nanotechnology Consortium (NJNC), we have fabricated nanostructured aluminum layers that couple to surface plasmons. Post-processing of the structures and measurement of the optical properties are performed at University of Florida. The structures consist of a 1D array of slits in an aluminum layer that is completely surrounded by silicon oxide. The silicon oxide and metallic layers are initially fabricated on a silicon substrate and subsequently transferred to a transparent quartz substrate, as we will describe in the next paragraph. Starting with a blank silicon wafer, a layer of silicon oxide is deposited by chemical vapor deposition, followed by a layer of aluminum deposited by sputtering. The aluminum layer is patterned by deep ultraviolet or electron beam lithography and etched to create the slits. Another layer of silicon oxide is then deposited. This layer of silicon oxide fills the trenches and ensures that the aluminum is completely surrounded by silicon oxide. The silicon oxide layer is then planarized by chemical mechanical polishing to eliminate any topography resulting from the underlying aluminum slits. The metal layer is therefore completely surrounded by silicon oxide, ensuring that the surface plasmon resonances for the upper and lower interfaces occur at the same wavelength. In Figure 2, 2a shows a cross-section of such a structure (sample A) with a period of 2 mm, slit width of 0.4 mm and aluminum thickness of 0.41 mm. After completion of the fabrication steps on the silicon substrate, the top surface of the structure is glued onto a transparent quartz substrate with an optical adhesive. The silicon wafer is then completely removed by a combination of wet etching and mechanical polishing. The aluminum layers are hence transferred onto the quartz substrate in the final structure, with the topmost layer in the final structure corresponding to the first silicon oxide layer deposited on the silicon substrate. Figure 2b shows the zero order transmission spectrum of sample A with transverse magnetic (TM) polarization (electric field perpendicular to slits). A transmission peak can be identified at wavelength of ⬃3.2 mm. The maximum transmission is as large as 38% even though the fractional area of the slits is only 20% and the peak wavelength is much larger than the slit widths. Taking into account the refractive index of silicon oxide (⬃1.53), the wavelength of light in silicon oxide at which peak transmission occurs is close to the periodicity of the structure (2 mm). In Figure 3, 3a shows the transmission spectrum of sample B with different parameters: metal thickness of 0.3 mm, a different slit width of about 0.25 mm and periodicity of 1 mm. The transmission peak has shifted to a lower wavelength of ⬃1.7 mm. The peak transmission wavelength in silicon oxide remains comparable to the periodicity of the grating. The peak transmission is even more pronounced than sample A, reaching 80% for TM polarization. The transmission peaks in samples A and B are associated with the coupled surface plasmons mode of transmission through narrow slits [21] in a metal layer. Some authors refer to such resonance as horizontal surface plasmon resonances [5]. At these resonances, the incident light excites surface plasmons on the first surface through the periodic structure. Surface plasmons on the first surface then couple to surface plasmons on the other surface through the slits, which in turn re-radiate into light of the same frequency and momentum as the incident wave. The Bell Labs Technical Journal 145 Silicon oxide Aluminum Silicon oxide Silicon 1 1 0.8 0.8 Transmission Transmission (a) 0.6 0.4 0.2 (b) 0 0.6 0.4 0.2 (c) 1.5 2 2.5 3 3.5 Wavelength (m) 4 0 1.5 2 2.5 3 3.5 Wavelength (m) 4 RCWA—Rigorous coupled wave analysis TM—Traverse magnetic (a) Scanning electron micrograph of the cross section of sample A. The thickness of aluminum is 0.4 m. Each slit is about 0.4 m wide and the periodicity is 2 m. (b) Measured transmission for TM polarized light for sample A. The peak transmission exceeds the fractional area of the slits by almost a factor of 2. (c) Numerical calculation of the transmission using RCWA. Figure 2. Scanning electron micrograph and measured and calculated optical transmission for sample A. wavelength at peak transmission depends largely on the periodicity of the slit array. As the thickness of the metal layer increases, the transmission peak shifts to longer wavelengths and eventually transforms into waveguide resonances (or vertical surface plasmons modes) for deep slits [2, 10, 21]. We compare our preliminary experimental results to numerical simulations using rigorous coupled wave analysis (RCWA). RCWA is a numerical method that analyzes transmission and reflection of periodic structures [18, 19]. In RCWA, the structure is divided into multiple layers. The calculation involves spatial 146 Bell Labs Technical Journal Fourier expansion of the electromagnetic field and dielectric functions in each layer. The electromagnetic field determined by RCWA satisfies Maxwell’s equation within each layer as well as the boundary conditions between adjacent layers. The numerical accuracy is only limited by the number of orders used in the Fourier expansion. Detailed descriptions of the RCWA algorithms can be found in [18 and 19]. Figures 2c and 3b plot the calculated transmission through sample A and sample B using RCWA, showing peaks at ⬃3.5 mm and ⬃1.7 mm, respectively, in reasonable agreement with our measurement. 1 0.8 0.8 Transmission Transmission 1 0.6 0.4 0.2 0 0.6 0.4 0.2 1.5 2 3 2.5 Wavelength (m) 3.5 4 (a) 0 1.5 2 2.5 3 Wavelength (m) 3.5 4 (b) (a) Measured transmission for TM polarized light for sample B. The thickness of aluminum is 0.3 m. Each slit is about 0.25 m wide and the periodicity is 1 m. The peak transmission exceeds the fractional area of the slits by almost a factor of 3. (b) Numerical calculation of the transmission using RCWA. RCWA—Rigorous coupled wave analysis TM—Transverse magnetic Figure 3. Measured and calculated transmission for sample B. Figure 4 shows the RCWA calculation of the electric field for a structure with parameters similar to sample B at resonance. For simplicity, the silicon oxide layers are assumed to extend through all space above and below the metal layer. The magnetic fields are directed out of the page and the magnitude is represented by the grayscale, while the arrows represent the electric fields. The electric field is highly concentrated at the surface of the metal layer and in the slits. At these locations, the electric field intensity is enhanced by up to a factor of 44 compared to the far-field regions. Potential Applications Apart from the remarkable transmission properties of these metallic nanostructures, the strongly enhanced local fields on the metal surfaces have potential in other novel applications. One possibility is to reduce the optical power required to produce nonlinear optical effects. The enhanced electromagnetic 4.5 4 3.5 3 2.5 2 1.5 1 0.5 Calculated electromagnetic field for sample B at peak transmission. Electric fields are denoted by arrows. Magnetic fields are directed out of the page, with magnitude represented by the gray scale. Figure 4. Electromagnetic field distribution for sample B at resonance. Bell Labs Technical Journal 147 fields of the surface plasmons on rough metal surfaces have already found numerous uses. For instance, in surface-enhanced Raman spectroscopy [20], molecules adsorbed on the rough surface of metals display huge enhancement of the cross section due to the local field enhancement. The subject of nonlinear optics is concerned with the effects arising from the nonlinear response of a medium to electric fields in the optical frequency range. Examples of nonlinear effects include frequency conversion, higher harmonic generations, parametric amplifications, and optical bistability. Nonlinear optics has become a major focus of scientific research and engineering because of its potential for applications in optical computing and optical devices such as electro-optic modulators, optical parametric amplifiers, switches, filters, and frequency conversion devices. The main barrier to applications of nonlinear optics is the small optical nonlinearity of most materials. In fact, intense pulsed lasers are usually required to reveal the nonlinear properties. By placing nonlinear optical material on the surface of the subwavelength metallic structures, the enhanced local electromagnetic fields could be used to reduce the optical power required for nonlinear optical effects. In addition, surface plasmons can be used to improve the sensitivity and versatility of optical detection of displacement in micromechanical devices. The surface plasmons channel the optical energy through the slits that are much smaller than the wavelength, building up intense local fields. Nanomechanical movement in the vicinity of these fields is expected to lead to large changes in the transmitted light intensity. Mechanical transducers involving surface plasmons could have far-reaching impacts in inertial sensing and ultra-sensitive force detection. Furthermore, the electromagnetic fields and the induced charges associated with the surface plasmons exert forces on the metallic elements. Due to the enhancement of electromagnetic fields, such forces could be strong enough to create motion in micromechanical components. The coupling of surface plasmons with mechanical degrees of freedom could lead to new schemes for actuating micromechanical components with lasers. Subwavelength metallic structures possess remarkable transmission properties that are accompanied by 148 Bell Labs Technical Journal strong enhancement of electromagnetic field near the surface. Understanding the propagation of surface plasmons in complex metallic nanostructures is of fundamental interest and practical importance in designing surface plasmon photonic devices that could become important building blocks in future nanooptical systems. References [1] F. I. Baida and D. Van Labeke, “ThreeDimensional Structures for Enhanced Transmission Through a Metallic Film: Annular Aperture Arrays,” Phys. Rev. B, 67 (2003), 1–7. [2] A. Barbara, P. Quemerais, E. Bustarret, and T. Lopez-Rios, “Optical Transmission Through Subwavelength Metallic Gratings,” Phys. Rev. B, 66:16 (2002), 1403. [3] W. L. Barnes, A. Dereux, and T. W. Ebbesen, “Surface Plasmon Subwavelength Optics,” Nature, 424 (2003), 824–830. [4] S. I. Bozhevolnyi, J. Erland, K. Leosson, P. M. W. Skovgaard and J. M. Hvam, “Waveguiding in Surface Plasmon Polariton Band Gap Structures,” Phys. Rev. Lett., 86 (2001), 3008–3011. [5] S. Collin, F. Pardo, R. Teissier, and J. L. Pelouard, “Horizontal and Vertical Surface Resonances in Transmission Metallic Gratings,” J. Optics A–Pure and Appl. Optics, 4 (2002), S154–S160. [6] D. Courjon, Near Field Microscopy and Near Field Optics, Imperial College Press, London, UK, (2003). [7] H. Ditlbacher, J. R. Krenn, G. Schider, A. Leitner, and F. R. Aussenegg, “Two-Dimensional Optics with Surface Plasmon Polaritons,” Appl. Phys. Lett., 81 (2002), 1762–1764. [8] T. W. Ebbesen, H. J. Lezec, H. F. Ghaemi, T. Thio, and P. A. Wolff, “Extraordinary Optical Transmission Through Sub-Wavelength Hole Arrays,” Nature, 391:6668 (1998), 667–669. [9] D. Egorov, B. S. Dennis, G. Blumberg, and M. I. Haftel, “Two-Dimensional Control of Surface Plasmons and Directional Beaming from Arrays of Subwavelength Apertures,” Phys. Rev. B, 70 (2004), 033404-1–033404-4. [10] F. J. Garcia-Vidal and L. Martin-Moreno, “Transmission and Focusing of Light in OneDimensional Periodically Nanostructured Metals,” Phys. Rev. B 66:15 (2002), 5412. [11] J. Homola, S. S. Yee, and G. Gauglitz, “Surface Plasmon Resonance Sensors: Review,” Sensors and Actuators B-Chemical, 54 (1999), 3–15. [12] I. R. Hooper and J. R. Sambles, “Surface Plasmon Polaritons on Narrow-Ridged Short-Pitch Metal Gratings,” Phys. Rev. B, 66:20 (2002), 5408. [13] J. D. Joannopoulos, R. D. Meade, and J. N. Winn, Photonic Crystals, Princeton Univ. Press, Princeton, NJ, 1995. [14] J. R. Krenn, A. Dereux, J. C. Weeber, E. Bourillot, Y. Lacroute, J. P. Goudonnet, G. Schider, W. Gotschy, A. Leitner, F. R. Aussenegg, and C. Girard, “Squeezing the Optical Near-Field Zone by Plasmon Coupling of Metallic Nanoparticles,” Phys. Rev. Lett., 82 (1999), 2590–2593. [15] H. J. Lezec, A. Degiron, E. Devaux, R. A. Linke, L. Martin-Moreno, F. J. Garcia-Vidal, and T. W. Ebbesen, “Beaming Light from a Subwavelength Aperture,” Science, 297:5282 (2002), 820–822. [16] S. A. Maier, M. L. Brongersma, P. G. Kik, S. Meltzer, A. A. G. Requicha, B. E. Koel, and H. A. Atwater, “Plasmonics—A Route to Nanoscale Optical Devices,” Appl. Phys. Lett., 13:19 (2001), 1501–1505. [17] S. A. Maier, P. G. Kik, H. A. Atwater, S. Meltzer, E. Harel, B. E. Koel, and A. A. G. Requicha, “Local Detection of Electromagnetic Energy Transport Below the Diffraction Limit in Metal Nanoparticle Plasmon Waveguides,” Nature Mat., 2 (2003), 229–232. [18] M. G. Moharam, E. B. Grann, D. A. Pommet, and T. K. Gaylord, “Formulation for Stable and Efficient Implementation of the Rigorous Coupled-Wave Analysis of Binary Gratings,” J. Opt. Soc. Am. A–Optics Image Science and Vision, 12 (1995), 1068–1076. [19] M. G. Moharam, D. A. Pommet, E. B. Grann, and T. K. Gaylord, “Stable Implementation of the Rigorous Coupled-Wave Analysis for Surface-Relief Gratings—Enhanced Transmittance Matrix Approach,” J. Opt. Soc. Am. A–Optics Image Science and Vision, 12 (1995), 1077–1086. [20] S. M. Nie and S. R. Emery, “Probing Single Molecules and Single Nanoparticles by SurfaceEnhanced Raman Scattering, Science,” 275:5303 (1997), 1102–1106. [21] J. A. Porto, F. J. Garcia-Vidal, and J. B. Pendry, “Transmission Resonances on Metallic Gratings with Very Narrow Slits,” Phys. Rev. Lett., 83:14 (1999), 2845–2848. [22] E. Prodan, C. Radloff, N. J. Halas, and P. Nordlander, “A Hybridization Model for the Plasmon Response of Complex Nanostructures,” Science, 302:5644 (20, 419–422. [23] H. Raether, Surface Plasmons on Smooth and Rough Surfaces and on Gratings, SpringerVerlag, Berlin, Ger., 1988. [24] J. R. Sambles, G. W. Bradbery, and F. Z. Yang, “Optical-Excitation of Surface-Plasmons—An Introduction,” Contemp. Phys., 32 (1991), 173–183. [25] J. T. Shen and P. M. Platzman, “Properties of a One-Dimensional Metallophotonic Crystal,” Phys. Rev. B, 70:3 (2004), 035101–035108. [26] T. Thio, H. J. Lezec, T. W. Ebbesen, K. M. Pellerin, G. D. Lewen, A. Nahata, and R. A. Linke, Giant Optical Transmission of SubWavelength Apertures: Physics and Applications, Nanotechnology, 13 (2002), 429–432. (Manuscript approved July 2005) HO BUN CHAN is an assistant professor in the Department of Physics at the University of Florida in Gainesville, where his job responsibilities include research and student education. He holds A.B. and Ph.D. degrees in physics from Princeton University in New Jersey and the Massachusetts Institute of Technology in Cambridge, respectively. Dr. Chan’s professional interests include microelectromechanical systems, Casimir forces, gravitation at nanoscale, fluctuations in nonlinear systems, scanning probe microscopy, surface plasmons polaritons, integrated optics, and tunneling spectroscopy of quantum Hall systems. ZSOLT MARCET is an undergraduate senior in the Department of Physics at the University of Florida in Gainesville. He assists with research in the department, and he has a special interest in plasmonic devices and numerical simulations. DUSTIN CARR is a principal member of technical staff at Sandia National Laboratories in Albuquerque, New Mexico. He holds a B.S. degree in mathematics from Oklahoma State University in Okmulgee and M.S. and Ph.D. degrees in physics from Cornell University in Ithaca, New York. Dr. Carr, whose professional interests include nanomechanical systems, optical microelectromechanical systems, surface plasmonics, and integrated sensor systems utilizing optical readout, was selected by MIT Technology Review Magazine as one of the top 100 young innovators in technology in 2005. Bell Labs Technical Journal 149 JOHN ERIC BOWER is a member of technical staff in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey. He received a B.S. degree in physics from Pennsylvania State University at University Park and M.S. and Ph.D. degrees, also in physics, from Stevens Institute of Technology in Hoboken, New Jersey. At Bell Labs, Dr. Bower’s responsibilities include fabrication of MEMS- and nano-devices with an emphasis on metalization as well as nanotechnology project management. His professional interests include clusters, nanomaterials, and nanostructures. RAY CIRELLI is a distinguished member of technical staff in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey. He has authored over 70 technical papers and has been awarded numerous patents in the optical lithography field. He has made critical contributions to various aspects of deep-ultraviolet lithography in the areas of off-axis illumination, reflectivity control, and proximity effect correction. The current emphasis of his work is in new lithography techniques for MEMS and nanotechnology research. ED FERRY works in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey. FRED P. KLEMENS works in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey. With over 25 years of experience in plasma processing research, he has a special interest in ultra-thin polysilicon and deep silicon as well as silicon oxide etch processing. JOHN F. MINER is a member of technical staff in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey, where his current responsibilities include chemical vapor deposition of oxides and nitrides and planarization of all materials at all levels. He holds a B.S. degree in mechanical engineering from the New Jersey Institute of Technology in Newark and an M.S. 150 Bell Labs Technical Journal degree in project management from Stevens Institute of Technology in Hoboken, New Jersey. CHIEN-SHING PAI is a distinguished member of technical staff in the Nanofabrication Research Department at Bell Labs in Murray Hill, New Jersey. He received a B.S. degree in electrophysics from Chiao-Tung University in Hsin-Chu, Taiwan, and a Ph.D. degree from the University of California at San Diego. At Bell Labs, his early research focused on advanced electronic devices. He was involved in the research and development of both devices and processing for advanced CMOS technologies for ULSI applications. His work included selective-epi and silicide for front-end CMOS devices and low-k materials and multilevelinterconnect integration for sub-100 nm ULSI applications. In recent years, his work has expanded to include MEMS technology for communication and biotech applications. As a VLSI Technology Symposium committee member since 1996, Dr. Pai has organized and chaired short courses and rump sessions for the symposium for several years. J. ASHLEY TAYLOR is a member of technical staff in the Nanofabrication Research Department of the New Jersey Nanotechnology Consortium in Murray Hill, New Jersey. He received his Ph.D. in physical chemistry, with a concentration in photoionization of gaseous molecules, from the University of Houston in Texas. As a postdoctoral fellow, also at the University of Houston, he investigated the reactions of ions with surfaces. His past job responsibilities at Bell Labs include conducting studies characterizing materials used for the manufacturing of integrated circuits; developing dielectric plasma etch processes; developing plasma etch processes for low-k dielectric materials, which played an important part in the development of the 0.13 mm integrated-circuit technology; and developing processes for deep silicon plasma etch for optical MEMS devices. Currently, he is studying the interaction of liquids with nanotextured silicon surfaces. Dr. Taylor has authored more than 30 publications dealing with materials characterization and plasma etch, and he has several patent applications pending. ◆