Biodiesel

advertisement

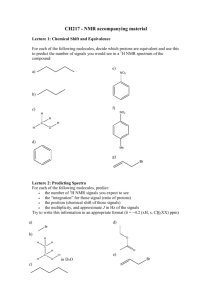

Biodiesel Many of the foods that we eat are rich in triacylglycerols— i.e. fat. The ancient process of saponification turns fat into soap. For example, animal fat and wood ash (which contains potassium carbonate) could be boiled together in a cauldron; the products are fatty acid salts (soap) and glycerol (glycerine). To chemists, the term “saponification” refers to the irreversible hydrolysis of any ester with aqueous base. If an ester and base are combined with an alcohol instead of water, transesterification can occur. The reaction is very similar to saponification (alcoholysis of an ester vs. hydrolysis), but with a key difference that it is a reversible rather than an irreversible process. Methanolysis of fats (transesterification with methanol) produces fatty acid methyl esters, or FAMEs. This process is of great interest, because FAMEs are a type of biodiesel. Saponification and transesterification are illustrated below for trimyristin, which is a major constituent of nutmegs. O HO - (stochiometric) e.g. K 2CO3, H 2O O K a soap O O O O HO OH OH + O glycerol (glycerine) O trimyristin (a fat from nutmegs) O MeO - (catalytic) MeOH MeO a FAME (biodiesel) While a nutmegmobile may not be cost-effective, many less expensive oils such as soybean and corn, are starting to become valid options as fuels. For example, waste cooking oil has been converted to biodiesel to fuel buses and delivery vehicles. A product of ester hydrolysis is a carboxylic acid (a fatty acid, if a fat is being hydrolyzed), but under basic conditions this is then essentially irreversibly deprotonated to the carboxylate anion. In contrast, the product of transesterification is another ester; the reaction is reversible, and the ester product is free to react with the original alcohol and revert to starting material. A common strategy used to drive a transesterification to completion is to use the alcohol reactant as solvent, i.e in large excess. Another key difference between saponification and transesterification is that a stoichiometric amount of base is needed for saponification (because it is consumed in the final deprotonation of the carboxylic acid product), but transesterification only requires a catalytic amount of base. In this lab, you will prepare biodiesel, and then assess your product’s quality by NMR and IR spectroscopy, by measuring its viscosity, and by using it as fuel in a model airplane engine. Hazards Methanol, cooking oil, biodiesel, ether, castor oil and TLC solvents are flammable liquids. Methanol is toxic when ingested. Anhydrous potassium carbonate is an irritant and caustic. Perform all chemical operation in the fume hood. Any spilled oil is a slipping hazard and must be cleaned up immediately. Procedure: Day 1 Assume that the molecular weight of the oil is ~880 g/mol, which is a reasonable estimate. Tare a 250-mL, three-neck, round-bottom flask and then, using a funnel, add 50 mL of vegetable oil. Make sure you record the type of vegetable oil (e.g canola, safflower, …), the brand name, and its mass in your laboratory notebook. Add a mass of powdered, anhydrous K2CO3 that equals 6% of the mass of oil. Calculate the amount of methanol required to have a 6:1 molar ratio of methanol to oil (i.e. twice the stoichiometric amount). Add the calculated amount of methanol to the reaction flask. Equip the reaction flask with a football-shaped magnetic stirbar, reflux condenser (middle neck), thermometer (one side neck) and stopper (other neck). The condenser does not need a water supply if the reaction temperature is kept below 65 °C. Make sure that the thermometer bulb is well above the stirbar to avoid breakage. Arrange a magnetic stirrer and a heating mantle so that the mantle is supported by an iron ring and suspended close to the stirrer. Place the reaction apparatus in the heating mantle, and make sure that the middle joint is securely clamped to a support. Start the stirrer and run it at a high speed (being careful that the thermometer bulb won’t risk being hit by the stirbar) to ensure good mixing between the methanol and vegetable oil. Note the time and temperature in your notebook. The reaction will require 20-25 minutes at 60-65 °C with good stirring. Temperatures higher than that may cause methanol to distill out of the reaction mixture, so you may have turn off the heat all together to avoid overheating. The reaction mixture will become clearer and less viscous as the reaction proceeds. If desired, the reaction can be monitored by TLC using PAA stain and 85:15:1 hexanes:ether:acetic acid as eluent. When the reaction is finished, slowly add 25-38 mL of 1.2 M acetic acid to neutralize the KHCO3 (CO2 gas will escape!). When the addition is complete and gas evolution has subsided, stir the reaction mixture vigorously for a few minutes and then transfer to a 250-mL separatory funnel. Let the mixture stand until the bottom layer of glycrine and methanol has separated cleanly from the upper layer of biodiesel. Carefully drain the lower layer, then pour the top layer out the top of the separatory funnel and into an Erlenmeyer flask. Dry your biodiesel with anhydrous MgSO4, then filter into a tared 100mL round-bottom flask. Obtain the mass, then prepare an NMR sample (CDCl3 solvent). Stopper the flask; seal it with parafilm; and label the flask with your name, lab section, date, and “biodiesel”. Leave it in your fume hood until next day. Procedure: Day 2 Obtain your NMR spectrum from your TA. You will need to analyze your data further in Mnova (vide infra), but it will indicate if your material is of sufficient quality for ignition testing. Look for evidence of unreacted vegetable oil. Any doublet of doublets (dd) signals in the 3.5-4.5 ppm region indicate remaining glyceride (O-CH2-CH). Also look for any signs of water (broad singlet). Obtain an infrared spectrum of your product and make note of any bands that are evidence for your desired product, or of possible contaminants. Determine the relative viscosities of the product and the starting oil. The relative viscosities of biodiesel vs the oils can readily be determined by timing their passage through a buret (your TA will demonstrate the technique). Relative Viscosity = (oil time)/(biodiesel time). You should see that the biodiesel is markedly less viscous than the starting cooking oil. Engine Test Your TA will demonstrate use of the biodiesel in a model airplane engine. The biodiesel will be mixed as follows: % by volume: Ether 40%, Biodiesel 40%, Castor Oil 20% Interpreting Biodiesel NMR spectra Most of us are aware that all fats are not created equally. In general, we have probably heard that polyunsaturated fats are particularly good for us, and that saturated fats are particulary bad. In terms of chemical structure, this is illustrated for methyl esters of: (a) linoleic acid, which is derived from a polyunsaturated fat, (b) oleic acid, derived from a monounsaturated fat, and (c) stearic acid, from a saturated fat. a 5.26-5.43 ppm H H H 0.89 ppm H3C C H2 2.78 ppm 1.1–2.3 ppm b O H O 3.65 ppm methyl ester of linoleic acid (omega 6 polyunsaturated acid) 1.1–2.3 ppm 1.1–2.3 ppm 1.1–2.3 ppm 3.67 ppm O H3C 0.89 ppm CH3 O H CH3 methyl ester of oleic acid (a monounsaturated acid) H 5.6–5.1 ppm c 0.89 ppm H3C 3.67 ppm O O CH3 methyl ester of stearic acid (a saturated acid) 1.1–2.3 ppm Our knowledge of NMR spectroscopy allows us to distinguish these different types of fats. Thus, both poly- and mono-unsaturated fats possess resonances at 5.6-5.1 ppm in the 1H NMR spectrum, attributable to the alkene protons. However, only the polyunsaturated fats will possess peaks at 2.6-2.8 ppm, attributable to ‘doubly allylic’ protons. The NMR spectrum of a typical FAME is shown on the next page, with the structure of methyl linoleate superimposed, to illustrate typical chemical shifts found for protons in FAMEs. Note that the small triplet near 1.0 isn’t an impurity, but is indicative of small amounts of omega-3 fatty acid (CH3-CH2-CH=CH-). A typical FAME mixture, illustrating typical chemical shifts for various protons Worksheet: analysing oil from different sources The spectrum of one student’s biodiesel mixture is shown on the next page. It will be used to demonstrate the following calculations you will be performing for your own sample. Determine the average number of carbons and hydrogens. This can be done by standardizing your NMR integration to the methyl ester resonance. We know that this resonance is equal to 3 hydrogens. In Mnova, you can click on the integral curve and normalize it to 3H. Then, we can add all the integrals together to arrive at 35.34 hydrogens on average (2.91 + 3 + 1.36 + 2.01 + 3.37 + 2.65 + 17.06 + 2.98). Now, we can approximate the number of carbons by assuming that the peaks from 5.15.6 ppm are methine resonances, that the peaks from 1.0-3.0 ppm are methylene resonances, and that the peaks at ~3.6 ppm and ~0.9 ppm are methyl resonances. There is one carbon per methine H, or per two methylene Hs, or per 3 methyl Hs. Using the numbers from the spectrum below, we get [2.91 + (26.45/2) + (5.99/3)] = ~18C. We also need to add in the carbon from the carbonyl, bringing our total to 19 carbons. Thus, we estimate an average formula of C19H36O2 (rounding the number of hydrogens up to the nearest even number) for the FAME, and thus an average length of 18 carbons for the fatty acids themselves. NMR of a student’s FAME product Approximate the average unsaturation number. For our example above, C19H36O2, the unsaturation number is 2, indicating one unsaturation in the fatty acid (the other being the carbonyl). However, since the hydrogens integrated substantially lower than 36, there are considerable amounts of polyunsaturated fatty acids present as well. Calculate the ratio of polyunsaturated to monounsaturated fats. Assuming that almost all of the polyunsaturated FAMEs are dienes (i.e. the amount of FAMEs containing 3 or more C=C bonds), the integrations from your NMR can be used to calculate the ratio of polyunsaturated FAMEs to monounsaturated FAMEs, and thus indirectly the ratio of polyunsaturated to monounsaturated fats in your oil sample. However, the vinylic hydrogens in the 5.0-5.6 ppm region overlap, so we can’t directly use their integrations to calculate this ratio. Fortunately, the signal at around 2.6-2.8 ppm is specific for polyunsaturated fats (the doubly-allylic methylenes), and is clearly resolved. So, we can derive a formula that allows us to calculate the ratio, using only the integrals for the vinylic and doubly-allylic hydrogens. Let VT = the total integral for the vinylic region (5.0-5.6 ppm) Let D = the total integral for the doubly allylic methylene protons (2.6-2.8 ppm) In a polyunsaturated fat, there are four vinylic Hs for every two doubly-allylic Hs. So: VP = 2D = the total contribution to VT coming from polyunsaturated fats. Therefore: VM = VT – VP = the total contribution to VT coming from monounsaturated fats. Every monounsaturated fat has two vinylic Hs. Every polyunsaturated fat has two doubly-allylic Hs. Therefor the ratio of polyunsaturated to monounsaturated fats is D D or V! V! − 2D Using the sample spectrum: 1.36 = 7.16 2.91 − (2 × 1.36) So the ratio of polyunsaturated to monounsaturated fats in the oil is about 7:1.