Measuring Engineering Quality in Airplane

Development

by

Ammar Asfour

B.Sc., University of Texas, Austin, 2008

Submitted to the Department of Aeronautics and Astronautics and the MIT Sloan School

of Management in partial fulfillment of the requirements for the degrees of

wo

Master of Science in Aeronautics and Astronautics

and

C=)

LL0

Z

Master of Business Administration

2

Uj J

in conjunction with the Leaders for Global Operations Program at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

@

Ammar Asfour, MMXV. All rights reserved.

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and electronic

copies of this thesis document in whole or in part in any medium now known or hereafter created.

Signature redacted

. . . . ./.

. .. .. .. ..

.

A uthor .....

Department of Aeronautics and Astrona

s and the MIT Sloan School of Management

May 8 2015

Signature redacted

............

C ertified by .... . . . . . . . . . . . .WO - - - - - - - - - - Olivier de Weck, Thesis Supervisor

and Engineering Systems Division

Astronautics

and

Aeronautics

of

Professor

Certified by.

Sianature redacted

6)

Approved by .......

...............................-

Bradley Morrison, Thesis Supervisor

Senior Lecturer, MIT Sloan School of Management

Signature redacted.

Paulo C. Lozano

Chair, Aeronautics and Astronautics Gra uate Program Committee

A

Approved by.............

Signature

redacted

. .... ..

..........

Maura Herson

Director, MBA Program, MIT Sloan School of Management

<

Cif.

Measuring Engineering Quality in Airplane Development

by

Ammar Asfour

Submitted to the Department of Aeronautics and Astronautics and the MIT Sloan School

of Management on May 8, 2015, in partial fulfillment of the requirements for the degrees of

Master of Science in Aeronautics and Astronautics

and

Master of Business Administration

Abstract

This project was motivated by the desire to apply quality metrics to the multiple stages of the

airplane development process at Boeing Commercial Airplanes. This project first identified

integration and process discipline as most critical towards final quality of the engineering

work. Integration, defined as the path and connectivity between teams and activities, was

studied by analyzing performance of a small engineering support team. To understand the

effects of early stage quality on later stages, i.e. process discipline, a system dynamics model

was developed focusing on the design and development of components with suppliers. The

case study regarding integration focused on the engineering work as a four-steps process:

Inputs, Engineering Activities, Output and Customer Review. All unplanned reworked

deliverables of a 5-7 members engineering team were analyzed. The study tracked the process

step at which the error was first caused. The results found that 21% of unplanned engineering

rework was caused due to inadequate delivery of inputs to the requested engineering work.

Furthermore, the 21% of unplanned engineering rework had the highest hours per reworked

deliverable of any stages. Over all, 75% of engineering rework was due mainly to the process

rather than the actual technical engineering work. The system dynamic modeling achieved

two main results: showcased the necessity to simplify the process, and the importance of

accounting for iterations in engineering. Through the group-modeling discussions with the

process owner, it was evident the need to provide clear checkpoints and reviews of the

engineering work. Furthermore, discovering engineering rework within a given stage has the

same effect as delivering first-pass engineering quality. This project provided a methodology

to work with engineering teams to measure their quality performance. Furthermore, it

has the potential to show the thresholds of quality from one stage to another in Airplane

Development.

Thesis Supervisor: Olivier de Weck

Title: Professor of Aeronautics and Astronautics and Engineering Systems Division

Thesis Supervisor: Bradley Morrison

Title: Senior Lecturer, MIT Sloan School of Management

2

Acknowledgments

First, I would like to express my gratitude to the Boeing Airplane Development Quality

Organization and its leadership for making this opportunity possible. While at Boeing, this

project was received with the utmost courteous and supportive attitudes and there are many

without whom this work could have not been completed. Thank you.

Then, I would like to thank my advisors for providing the guidance and support through

a challenging journey. Their insight allowed me to navigate a sea of complex managerial and

engineering issues to understand and analyze.

The Leaders for Global Operations program made this opportunity possible. The LGO

Network, my MIT family, has inspired me every day to challenge myself. My classmates

have made this journey through the LGO program a unique and an enriching one.

Most importantly, my sincere and deepest thank to my family to whom I am eternally

indebted for their love and faith. My parents, Ahmad and Huda, my sister, Yasmin, and my

brother, Omar were my biggest supporters. Thank you. Shukran.

3

Contents

1 Introduction

2

3

4

9

1.1

Problem Statem ent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

1.2

Project Motivation and Company Background . . . . . . . . . . . . . . . . .

11

1.3

Rework in New Product Development . . . . . . . . . . . . . . . . . . . . . .

12

1.4

Study Approach and Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

Critical Factors of Engineering Quality in Airplane Development

15

2.1

Engineering Quality: The Magnitude of the Challenge . . . . . . . . . . . . .

16

2.2

Product's Complexity Impact on Product Development . . . . . . . . . . . .

17

2.3

Hypothesis: Integration and Process Discipline . . . . . . . . . . . . . . . . .

20

Integration in Airplane Development Process

22

3.1

. . . . . . . . . . . . . . . . . . . . . . . .

23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Case Study Scope and Approach

3.1.1

Scope

3.1.2

A pproach

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

3.2

Case Study Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

3.3

Conclusions and Recommendations

27

. . . . . . . . . . . . . . . . . . . . . . .

Applying System Dynamics to Airplane Development Process

29

4.1

System Dynamics in Product Development . . . . . . . . . . . . . . . . . . .

29

4.1.1

Applications of System Dynamics in Product Development . . . . . .

30

4.1.2

System Dynamic Model Structure for Product Development

. . . . .

32

. . . . . . . . . . . . . . . . . . . . . . . . .

37

4.2

Modelling Approach and Scope

4

4.3

4.4

5

4.2.1

Approach

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

4.2.2

Scope

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

4.2.3

The Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

R esults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39

. . . . . . . . . . . .

39

4.3.1

Quality of the Requirement Development Stage

4.3.2

Quality of the Design Stage

. . . . . . . . . . . . . . . . . . . . . . .

41

4.3.3

Quality of Both Stages . . . . . . . . . . . . . . . . . . . . . . . . . .

42

. . . . . . . . . . . . . . . . . . . . . . .

42

4.4.1

Conclusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

4.4.2

Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

Conclusions and Recommendations

47

Conclusions

A Interview Questions and Sample Answers

49

A.1

Interview Guidelines

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49

A.2

Samples of Interviews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

5

List of Figures

1-1

High view of the airplane development process at Boeing Commercial Airplanes 10

1-2

The additional costs and time delays for both the 787Dreamliner and 747-81

programs at Boeing. [6][3][11][23][24]

. . . . . . . . . . . . . . . . . . . . . .

12

1-3

The main stages and phases of the project supporting this thesis . . . . . . .

14

2-1

An analysis of number of engineering rework in Airplane Systems of Airplane

B program.

The hours and number of changes are normalized within this

table. The table emphasizes the number of changes occurring at a design and

requirem ents level.

2-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The percentage of non-conformities that required engineering change requests.

It is calculated as an average of each 10 airplanes

2-3

17

. . . . . . . . . . . . . . .

18

A study comparing the number of releases of design work related to the EFA

. . . . . . . . . . . . . . . . . .

18

3-1

The steps followed in studying the integration related case. . . . . . . . . . .

24

3-2

The results of the case study. The data here is normalized. . . . . . . . . . .

25

4-1

deWeck's system dynamic model.[8] . . . . . . . . . . . . . . . . . . . . . . .

31

4-2

The foundation of Cooper's models, the rework loop. [14] . . . . . . . . . . .

32

4-3

The causal loops presented by Cooper which tells the story of project man-

function within different airplane programs.

agem ent at Flour. [14]

4-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Multiple phases representation of any product development project as shown

by Ford's 1997 work. [12] . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

33

4-5

The basic stock and flow structure of a single product development phase as

shown in Ford's 1997. [12]

4-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quality factors affecting the basic single product development phase in Ford's

1997 work. This graph also shows the internal concurrences. [12] . . . . . . .

4-7

34

35

The addition of upstream and downstream quality effects. This figure shows

how a single product development phase connects with other phases through

stocks of tasks to be coordinated. [12] . . . . . . . . . . . . . . . . . . . . . .

36

4-8

The stages represented in the model built for this case

38

4-9

The results of varying quality factors in components requirement stage while

. . . . . . . . . . . .

quality is constant in other stages. This figure shows the effects on time of

completion.

The time of completion is normalized against an ideal quality

case of zero errors.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

4-10 The results of varying quality factors in components requirement stage while

quality is constant in other stages. This figure shows the effects on amount of

work needed. The amount of work is normalized against an ideal quality case

of zero errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

4-11 The results of considering schedule pressures while varying quality factors in

components requirement stage with quality is constant in other stages. This

figure shows the effects on time of completion.

The time of completion is

normalized against an ideal quality case of zero errors.

. . . . . . . . . . . .

42

4-12 The results of considering schedule pressures while varying quality factors in

components requirement stage with quality is constant in other stages. This

figure shows the effects on amount of work needed. The amount of work is

normalized against an ideal quality case of zero errors.

. . . . . . . . . . . .

43

4-13 The results of varying quality factors the design stage while quality is constant

in other stages. This figure shows the effects on time of completion. The time

of completion is normalized against an ideal quality case of zero errors.

7

. . .

43

4-14 The results of varying quality factors in the design stage while quality is

constant in other stages.

This figure shows the effects on amount of work

needed. The amount of work is normalized against an ideal quality case of

zero errors.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

4-15 The results of varying quality factors in both the components requirement

stage and the design stage. This figure shows the effects on time of completion.

The time of completion is normalized against an ideal quality case of zero errors. 44

8

Chapter 1

Introduction

The first chapter will introduce the problem statement, the motivation and the company

background, the scope, and approach of the study.

1.1

Problem Statement

Airplane Development process entails a long process and years of engineering development.

For example, the development of 787-8 took 7 years since the program launch in 2004 [11],

the Airbus A350XWB was launched in 2004 and finally delivered in 2015. [17]. Moreover,

even airplanes that are new variants of established designs take 3-4 years. The development

of the Airbus A330NEO which is a variant on the A330 is anticipated to take 3-4 years. [2].

The complication, magnitude, and scope of new plane development dictate such a lengthy

time.

The Boeing 777 Aircraft is constituted of 3,000,000 parts provided by 500 global

suppliers. [5]

It's therefore not uncommon for integration and testing between parts and systems to

happen years after the initial requirements, design, and engineering details completed. Figure

1-1 shows, at a high level, the Airplane Development process adopted at Boeing Commercial

Airplanes. This figure shows a the conceptual approach of Boeing's airplane development.

The actual development process is a detailed multiple stages processes. At the end of each

stage there is a review of particular goals, metrics, and milestones. The v-model shows how

the process begins with a very high-level, customer focused approach.

9

At that stage the

..n

Product

-

Definition

Transition to full

production

Certification

Requirements

Detailed Design L

Individual

components

Integration and

Testing

Component level

development

level

Time

Figure 1-1: High view of the airplane development process at Boeing Commercial Airplanes

customer needs are defined, and the product's answer to those needs is proposed. The next

stage begins the actual overall decision of airplane design. For example, will the airplane

have two or four engines. Then the actual requirements for the airplane and consequently the

different systems begins. This point is the most detailed point of the development process;

the engineering teams are working developing the particular hydraulic systems for the tires,

for example. Once the different systems are designed, prototyped, and individually tested,

the integration and testing of the large sub-assemblies begin. Finally, the whole airplane is

integrated together and goes through testing which leads to the FAA certification signaling

that the airplane is ready to move into production.

During the integration and testing phase several issues may appear regarding the technical and engineering work that would require rework of such design. In this instance, the

engineering work is considered as "poor quality." Given the months, if not years, of work

put in by multiple teams and functions addressing an engineering rework become costly and

timely. Furthermore, the increase in cost and time are exponential due to the significant

effort put in place for change management.

Engineering Quality is defined as delivering the engineering work per the customer re'The actual process is a proprietary detailed process that entails several stages and reviews at the end of

each stage.

10

quired performance to the consumer (manufacturing/production) on time and on budget.

The Airplane Development Quality Organization was established to improve the quality of

the Engineering work. The motivation of this project is to first understand the most critical levers for engineering quality, and second to measure the quality of engineering such as

to detect poor engineering quality using leading indicators to eliminate poor quality from

propagating to later stages.

1.2

Project Motivation and Company Background

Boeing is facing a fierce competition from Airbus. As a result of this competition, a surge in

new Airplane Development programs occurred. As of Jan 2015, Boeing has four new airplanes

in the development phase. Consequently, Boeing Commercial Airplanes developed a new

organization, Airplane Development Organization.

This new organization was established

to focus on three things: breaking the cost curve, shortening the development time-line, and,

finally, standardizing processes and tools of the development process.

The industry competition and market pressure amplified the necessity to face, head-on,

recent challenges of new airplane developments.

Both the 747-81 and the 787 Dreamliner

were faced with obstacles and challenges that created significant delays of their development

schedule. Figure 1-2 shows the significant cost of development in addition to the delays of

both programs.

11

Figure 1-2: The additional costs and time delays for both the 787Dreamliner and 747-81

programs at Boeing. [6][3][11][23][24]

1.3

Rework in New Product Development

In this section, we review the academic literature to discuss whether engineering change and

rework is prevalent to new product development across industries.

This thesis is focused on a project addressing challenges faced by Boeing in product development. However, engineering rework is a challenge in the aerospace industry in-specific

and in product development at large. This section presents examples of product development rework challenges connecting this work to the larger discussion of rework in product

development.

Kato [18] utilized extensive value stream mapping to study the product development

at a railway vehicles manufacturer.

His goal of the study was to apply continuous lean

improvement to the product development process. He identified nine indicators to measure

waste, i.e. non-value added time, in the product development process. Of these indicators,

rework has the second highest rate of occurrence and the largest average wasted time per

occurrence among the indicators. Furthermore, he noticed that the average time spent on

one occurrence of rework increased significantly in later stages of the project.

Repenning studies the phenomena of firefighting in product development, which he defines

12

as " ... the allocation of scarce resources to solve unanticipated problems or fires ... "[22] The

study of a solving problems in product development processes is an indicator of the scale and

magnitude of such challenges. He builds system dynamic model with the stock, Design Tasks

Awaiting Rework, at the center of the model. His conclusions highlight that multi-phases

product development environments have an equilibrium points beyond which organizations

may seem to be stuck in "firefighting" mode. This insight highlights the importance and

significance of avoiding a firefighting mode to begin with.

Academic literature also discusses that many companies have poor capacity to develop

successful plans to develop new products.[10] "...Their processes are highly iterative and

depend on the enthusiasm and expertise of the individuals involved.

They often succeed

in spite of their plans, not because of them ... " This supports the importance of this work

towards understanding improvements of new product development.

1.4

Study Approach and Scope

This study tackled a very large scope in the Airplane Development process. It was, therefore, critical to define a hypothesis through qualitative analysis and understanding of the

challenges. At first, interviews with over 15 Engineers and Leaders took place to understand

some of the challenges related to the development process. Along this process, a few examples and case studies were discussed to better define the hypothesis. A hypothesis was

defined and validated with the stakeholders. It was stated that Engineering Quality can be

measured by defining and measuring process discipline as well as integration.

Figure 1-3

shows the project approach.

Thereafter, the project diverted into two case-studies to prove the hypothesis. A study

of integration relied on an analysis of all deliverables of a small engineering support team.

Integration is defined as the pathway of connections between activities. Therefore, to measure integration adequately, each team, i.e. activity, must have a clear measurement and

definition of it's input and output. The second case study uses a system dynamics modeling

to understand the effect of poor engineering quality carried to later stages in the development

process consequently highlighting how to measure process discipline quality.

13

Identifying the challenge and developing a hypothesis

System Dynamic Modeling

Developed a system dynamic

model to understand the ripple

effect of quality between

different process stages

Data Analysis

Reviewed the work of a small

engineering team to understand

the sources of rework

Results and Opportunities

Figure 1-3: The main stages and phases of the project supporting this thesis

14

Chapter 2

Critical Factors of Engineering

Quality in Airplane Development

In Engineering Systems, Quality is the most frequently mentioned of all the '-lity' attributes.

[9] However, "Quality" definition varies and depends on the context and organization. Furthermore, it is critical to note that quality in manufacturing is significantly more studied and

understood than quality of engineering development. In the context of this study, Quality

of engineering deliverables focused on the elimination of unplanned engineering rework.

This thesis focuses its study on the development of Airplane Systems. It was suggested

by the stakeholders of this project as a focus of the study. Airplane Systems entail many

functions within such as Hydraulics, Electrical, Avionics, Mechanical, etc. For confidentiality

reasons specific Systems will not be named.

This chapter identifies two critical factors of Quality through stakeholders' input and

analysis of data.

The first section of this chapter asks the question whether engineering

quality is a challenge. The second section proposes the hypothesis of his thesis.

15

2.1

Engineering Quality: The Magnitude of the Challenge

The design and development of any new product requires iteration.

The occurrence of

unplanned iterations poses the biggest challenge. To identify whether this is an issue, we

interviewed over 15 of Airplane Systems senior managers and engineers. Then we studied

non-conformities reported on a the production line relating to the production of Airplane A.

Stakeholders' input referenced the relationship between the different functions. For example, the following statements were repeated several times " this [other team] never give us

complete deliverables," or "we finished our work, then the [other team] told us they changed

their design " Furthermore, there were multiple references to schedule schedule "we have to

find a way to meet schedule," or "we didn't have the resources to meet our timeline." These

quotes can be of any place and all too common in any workplace. They don't indicate an

Engineering Quality Challenge.

A previous study performed regarding all rework hours for Airplane Systems of Airplane

B, figure 2-1, showed the significant hours and cost contributed to engineering rework. The

scope of this relates to only Airplane Systems. Airplane Systems group includes all systems

such as electrical, avionics, hydraulics, etc on the airplane. This study was performed by a

senior engineer of airplane B program. It was done through categorization and estimation

of rework hours of each individual engineering rework.

An analysis was performed of non-conformities logged on production line of airplane A,

figure 2-2.

Non-conformities are logged when any occurrence or incident take place that

does not allow the front line worker to complete a given job on the assembly of airplane A.

These non-conformities can range from as simple as a small tool indenture left on a screw,

to as major as a request for an engineering change.

A request for an engineering change

means that the design of a particular aspect needs to be changed so that the mechanic can

complete the job. Figure 2-2 shows percentage of a non-conformities requiring engineering

rework relevant to all non-conformities.

The percentage of engineering rework peaks to

reach almost 100% of all non conformities between aircrafts 130 and 140.

the magnitude of the challenge.

This signals

Engineering rework was still being requested even after

16

Design

28

31,136

Requirements

26

21,836

System Integration

4

4,277

Supplier/Partners

2

1,113

All numbers are normalized within this table

Figure 2-1: An analysis of number of engineering rework in Airplane Systems of Airplane

B program. The hours and number of changes are normalized within this table. The table

emphasizes the number of changes occurring at a design and requirements level.

producing 140 aircrafts. Furthermore,while the overall non-conformities number decreased

significantly as more aircrafts were produced (trend not shown in this figure), the percentage

of engineering rework continued to increase. This indicates that engineering rework persisted

longer than production errors.

Another case study of the same EFA function, figure 2-3, was performed across multiple airplane programs. The following figure shows the percentage of unplanned releases of

engineering designs across different airplane programs.

2.2

Product's Complexity Impact on Product Development

This thesis identifies and focuses on two factors that are most critical to engineering rework

in airplane development. In the previous section, we review the impact of engineering rework challenge. This section emphasizes the magnitude of the challenge by discussing the

impact of complexity on product development with the assumption that Airplanes are very

complex products. However, academic literature identified complexity of a product as one

17

100.0%

90.0%

80,0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

10

20

30

130

100 110 120

90

80

70

60

50

40

NUMBER OF AIRPLANE PRODUCED IN ORDER OF THEIR PRODUCTION

-%

140

150

160

Non-conformities that require Engineering Rework

Figure 2-2: The percentage of non-conformities that required engineering change requests.

It is calculated as an average of each 10 airplanes

B

600% baseline

Figure 2-3: A study comparing the number of releases of design work related to the EFA

function within different airplane programs.

18

of three main factors affecting the impact of engineering rework.

[15] The complexity of

airplane development, therefore, mandates that our view of the challenge cant be decoupled

from understanding the impact of complexity of the system on the product development

process. In this section, we review academic literature that analyzes the impact of complexity on product development. The academic literature in this area is is abundant whether

qualitatively or quantitatively.

First, this section will review the definition of engineering

complexity. Then we highlight a qualitative, conceptual approach to the issue as well as a

quantitative modeling analysis.

Product complexity can take on many definitions. However, Jarratt and others highlight

the prominence of understanding complexity as the linkages between elements of a product

and their interaction together as a complete system or as a sub-system of a larger system.

[15] Understanding elements of a product is a function of its description as well as the organizational hierarchy attached to such break-down. This is an area that is heavily dependent

on the organization within which the product is developed. Regardless of the organizational

development, a product can be broken down to the number of systems, sub-systems, or

unique parts constituting it as a measure of complexity.

In a field study conducted by Jongbae and Wilemon [16] 32 companies were surveyed

regarding complexity and its impact on new product development.

The work was moti-

vated by the lack of understanding of the effects of complexity on new product development.

The survey focused on participants from the new product development organizations within

technology companies located in the United States North East region. The study results

showed that 66% of participants indicated that complexity of products led to development

cycle delays. Another significant consequence to product complexity is developing organizational and strenuous relationships within the people of a given organization. This negative

consequence is very difficult to quantify, even though it was very prominent in the results of

the survey. The survey highlights that a companys capacity to manage complexity well is a

strong competitive advantage against competitors.

The work of Weilin and Young in 2012 [26] modeled engineering change management processes in new product development through looking at the effects of the activity uncertainty,

design solution uncertainty, and environmental uncertainty, on the new product development

19

rework. When exploring overlap and rework probability, Weilin found that increase in overlap will shorten lead time at high and low rework probabilities. However, it will increase the

amount of efforts expended in completing the project. This result does not take into account

the large increase of rework effect on quality of engineering work as well as probability of

even creating more rework.

Finally, The Rule of 10 suggested first by Boehm in 1981 established the base ground to

many academic papers discussing the impact complexity an rework. [4] [13] Boehm concludes

that the cost of catching rework is exponential as a project moves from development phase

to the other. This theory suggests that performing ten changes at a given phase is equal in

cost to performing only one change at a later stage. While this theory has been discussed in

depth by many other papers whether in support or in criticizing, [13] the gist of it remains

critical 35 years later. It is far more difficult and costly to carry an engineering change at

later stages of a product development process.

2.3

Hypothesis: Integration and Process Discipline

The hypothesis of this thesis is that unplanned engineering rework can be significantly reduced through the following two factors:

1. Improved integration between engineering teams: clear understanding and measurable

quality of the input information required to complete tasks successfully will eliminate

the most time-consuming unplanned reworks.

2. Process discipline: In the multiple stage development process, each stage must have

a clearly defined set of measurable thresholds that qualify it as complete and triggers

the following stage.

The hypothesis is built on findings explained in section 2.1 of the current state of the

development process. This thesis will discuss the magnitude of improvement possible with

the added improvements. The discussion of this thesis does not eliminate the organizational

aspects affecting the challenge of unplanned engineering rework. The hypothesis implies that

20

the introduction of measurable metrics will increase transparency and accountability both

of which will drive improvements of organizational factors related to the challenge.

Both factors are founded in that a process must have a clearly defined inputs and outputs of each step. However, implementation and adoption of both factors are significantly

different. The first factor points to process management at engineering teams level. A measured metric clearly identifying the quality of required input information empowers a given

team to start a task only when they have the resources needed to complete a task. In lean

manufacturing, this practice is referred to as "full kitting." Consequently, this will drive an

improved communication behavior between all teams. For example, if team B relies on data

from team A to complete their task, and team A knows they are held accountable for any

delays due to their deliverables quality, both teams will be significantly more inclined to

communicate and discuss the tasks.

The second factor empowers the leadership of the development process at large. Using

measured thresholds and metrics adds quality to the discussion of managing a development

schedule. This thesis argues that it would be more beneficial to deviate from planned timeline and schedule to improve quality of a deliverable before starting with the new stage of

development.

21

Chapter 3

Integration in Airplane Development

Process

This chapter addresses the first factor of the hypothesis, integration, through quantitative

study of unplanned rework in a small engineering team. There is no argument about the

complexity of the airplane development process simply based on the very large number of

engineering teams involved. The complexity itself that makes integration a significant challenge is unavoidable. However, this chapter takes a closer look at a single small engineering

team as an example.

Section 3.1 develops the academic background and foundation driving this study. Then in

the second section the approach and scope of the study is discussed. Section 3.3 discusses the

results of the study whereas section 3.4 puts forward the conclusions and recommendations.

Systems engineering as a discipline is dedicated to understanding the complexity of

systems which are defined as a set of interacting components

technical artifacts

with

well-defined behavior and a well-defined function or purpose, like the individual technical

artifact. [9]

This thesis relies on Spear's definition of systems

[25] as a pathway of connected activities

producing a measured output. The great emphasis on measured outputs and clear activities

is articulated in this case study through breaking down the process into simple stages: input,

technical analysis, and output.

22

Case Study Scope and Approach

3.1

Scope

3.1.1

The study focuses on an engineering team of 5-7 engineers hereafter referred to as Team TA.

This team is considered a supporting function. Team TA is not responsible for developing

or designing any particular systems or components of the airplane. However, it's specialized

in an attribute, referred to as TA, required by all other engineering teams. For example, if

the avionics engineering system requires an analysis of TA attributes of its avionics systems,

it will request such analysis from Team TA.

The study reviewed all deliverables by Team TA performed for only one airplane development program over a time period of one year and 4 months. A cut-off date was determined

and no deliverables completed during the study were included.

Furthermore, the study's

goal was to understand Team's TA performance regarding unplanned rework.

Therefore,

there was a focus on the step during which the unplanned rework was caused rather than

the root cause of the problem such as tools or experience.

Approach

3.1.2

The study was done in collaboration with the senior managers in Team TA. It followed the

following steps, figure 3-1:

1. Leadership buy-in: completion of this project required additional workload from Team

TA. Their senior leadership approval was critical engage with Team TA. The leadership

was interested in understanding and measuring the quality performance. Furthermore,

they were interested in setting-up a repeatable method to perform similar analysis with

other engineering teams.

2. Developed project baseline: A discussion of Team TA's own view of their performance

took place.

At that point, there were no metrics measuring adequately the perfor-

mance of the team. Therefore, it was essential to establish the Team's view of their

own performance regarding unplanned rework. Team TA also highlighted areas, they

believe, are the cause of all unplanned rework at this stage.

23

Leadership

Buy-in

Process

Mapping

Performance

Baseline

Review

Deliverables

Figure 3-1: The steps followed in studying the integration related case.

3. Mapped current process in detail: process mapping workshops were facilitated with

Team TA. Their process was mapped as practiced currently in details. It is very critical

for the study to eventually simplify the process into input-activity-output-customer

review; however, these workshops allowed Team TA to break down their processes to

their very details before grouping them again in the input-output categories.

4. Reviewed deliverables within the scope: Finally, all of the deliverables, defined in

the scope above, were reviewed individually. First, the unplanned rework deliverables

were identified. Second, the source error that caused each deliverable was determined.

Finally, the step at which the causing error occurred was established. If an unplanned

rework had several errors, only the error relating to the earliest step was considered.

The rational is that errors occurring in later stages are most probably caused by errors

made in earlier steps.

24

79% First Pass Yield

% of Rework Total

21%

4.9

2.7

Hours/rework*

Hours have been normalized for proprietary reasons

Figure 3-2: The results of the case study. The data here is normalized.

3.2

Case Study Results

Figure 3-2 shows the simplified version of the process. In this, the Inputs step is the step

where Team TA receives tasks requests from other teams. The requests are usually a set of

information defined by the customer (Engineering teams requesting analysis are referred to

as customers). Team TA currently may either request some additional information or move

forward using knowledge and experience based assumptions. The modeling stage is where

the engineering analysis takes place. After the analysis is completed, the engineers document

their analysis to communicate to the customer. The customers, upon receiving the analysis,

review the results and either accept or not accept.

The team had at first created a baseline assumption that unplanned rework is majorly due

to communication errors as well as documentation errors. There was an apparent sentiment

that unplanned rework is mostly caused by customers.

The result of the study is highlighted in figure 3-2.

Of all the deliverables completed

in the determined scope, 21% of all deliverables were unplanned reworked. New requests of

Team TA that were not planned and not an iteration on a planned task are not considered in

this percentage. The term Firstpass Yield refers to all tasks completed without unplanned

iterations. Therefore, in this case, Team TA achieved 79% Firstpass Yield. The figure also

25

shows the amount of hours spent on average per each unplanned rework.

The hours per

rework are normalized for confidentiality reasons.

Of all unplanned rework 21% were caused by errors at the data input stage. This means

that engineering work was commenced without the availability of all required information.

Further analysis found out that in 66.7% of incidents in this particular step, Team TA did

not request the data required. This was caused by multiple factors: 1) Team TA used own

knowledge and experience to fill in the gaps.

2) Specific data inputs were not identified

as required. 3) Procedural and human errors. In the remaining 21% unplanned rework, in

16.7% incidents the data was requested but was not available, and in 16.67% data provided

to Team TA was invalid. Average hours per rework for unplanned rework caused at the

data input stage is highest at 8.4 hrs/rework. This is anticipated as an error here means

engineering rework has to start from the very first step of identifying required data input.

Engineering and modeling errors accounted for 25% of unplanned rework. In this case, the

actual modeling and engineering analysis didn't meet the customer's requirements. Average

hours per rework caused at this step is 2.7 hours per rework.

The majority of unplanned rework was caused at the Documenting step. Errors in this

stage meant that the analysis and engineering work itself was sufficient; however, the documents, templates, and actual communication of the analysis was not sufficient. Unplanned

rework caused at this step has the lowest number of hours per rework.

The last step that may cause an unplanned rework is the customer review step.

In

these incidents, Team TA delivered exactly what the customer requested. However, upon

reviewing the deliverables, the customer realizes that they themselves didn't request fully the

analysis they needed. Therefore, they request a rework of the same deliverable explaining

in details the analysis they are hoping for. Unplanned rework due to customer review could

require varying amount of hours depending on the change in scope the customer is requesting.

Therefore, average hours per rework caused in this step is 4.9 hrs/rework which is second

largest relative to all other steps.

26

3.3

Conclusions and Recommendations

This case study highlights the importance of integration through clear understanding of the

inputs and the outputs of the each given task. Team TA's unplanned rework was 85% within

their own control.

Furthermore, 60% of unplanned rework was attributed to procedural

errors (data input, and documentation) rather than technical errors. Therefore, the following

procedural recommendations will have a significant impact on improving the quality of the

engineering teams.

1. Measure team's first pass yield at an aggregate and step level.

This study

contradicted the team's understanding of resources of unplanned rework. Team TA

had thought a majority of unplanned rework was due to Customer's review. However,

that accounts to only 15% of unplanned rework.

This study, therefore, serves as a

baseline measurement of the performance. This baseline could be used to set targets

for the performance of the team. In addition, these metrics and measurements must

be included in the performance evaluation of the team's management.

2. Develop an engineering full kitting tool. As defined earlier, full kitting in this

context refers to having all required information and data input to a given design or

engineering stage. The unplanned rework caused at the data input stage constituted

21% of all unplanned rework.

Furthermore, it had the highest average hours per

rework with 66.7% easily avoidable if Team TA requested the required data. Within

the context of larger teams and more complicated processes, rework due to errors at

the data input stage becomes more determinant to the quality of rework. Focusing

on the data input stage would also improve the communication between teams. This

study is a significant first step to implement full kitting. The next two steps:

(a) Develop an internal tool/template identifying the input data required under several circumstances.

(b) Implement required fields requesting data needed by Team TA in the project

management system used.

27

3. Perform analysis and recommendations 1 and 2 above to other Engineering

teams.

Team TA is a small team. The exercise of performance analysis, including

process mapping, allowed the team to better understand the value stream of their

activities and areas of improvement.

28

Chapter 4

Applying System Dynamics to

Airplane Development Process

This chapter discusses the effects of propagating rework across several airplane development

stages on the overall time-line and schedule of the development. The first section will discuss

the academic literature regarding the use of system dynamics in product development. The

second section will detail the scope and approach of this project. The results will be discussed

before a final results section concludes this chapter.

4.1

System Dynamics in Product Development

The study of System Dynamics use in project management and product development had

come to life by the work of Pugh-Roberts Associates and KG Cooper work in 1980.[7]

Cooper's work was the first to formulate the rework loop. Abdel Hamid analyzed the dynamics of software development in project management in his PhD thesis. [1] He built on the

formulation used by KG Cooper and introduced quality assurance in product development

context.Ford and Sterman have built on the rich history of product development. [12] The

paper "Dynamic Modeling for Product Development Processes" by Ford and Sterman is

the core of modeling performed in this thesis. It details the impact of concurrences between

multiple project phases as well as the use of quality assurance and rework cycles. Pena-Mora

and Park have included the effects of rework due to internal errors as well as rework due to

29

external factors in their 2003 paper. [20] Modeling approaches make the assumption that

it is only possible that one rework is required per task in a given cycle. Rahmandad and

Hu's 2010 work considers multiple rework per given task in a single loop.[21] Lyneis provides an in-depth study of the literature relating to the use of System Dynamics in product

development broken down by unique model structures.[19]

The following two subsections provides examples of successful use of system dynamics in

project management and product development. Then, it highlights the modeling foundation

upon which this thesis work is built.

4.1.1

Applications of System Dynamics in Product Development

This section will highlight two examples of applying system dynamics to address organizational challenges. The two examples present two very different approaches to the application

of System Dynamics.

Olivier de Weck develops a tailored model to study application of

META design to speed systems development.[8] The purpose of the study is to validate an

hypothesis. In the second example, KG Cooper utilizes the rework loop formulation to improve change management at some of the most complex projects at Flour Corporation. [14]

In this example, the model is used repeatedly for many projects.

The 2012 conference paper by Oli de Week studies the feasibility of speed-up in systems

development through the use of META design. META design is an mechanism that includes

three approaches: the use of layers of abstractions, the use of extensive and trusted component model library, and use of virtual Verification and Validation. However, the focus here is

the use of system dynamics. The model built shown in figure 4-1 represents the model used

in this project. This model uses simple separate stock and flow structures that represent

the multiple stages of a given development project.

These stock and flow structures are

connected through causal loops that represent the various factors at play in the development

process.

At such macro level of representations, this modeling technique uses aggregate

mathematical formulations.

In this case, the model was validated against data from the

Boeing 777 Electric Power System design project at UTC. Such validation is critical due to

the significant use of aggregate formulations to represent. The model represents a rework and

change loop that is integral to the model. In this particular case, the model has successfully

30

Ri~ Sa~Ri~

F~

1

CaRA

lVc

CYv

*

*~

H1 IA

T.-0

Ubiraput

/

0

'~

Poxty~l)A

0

Q

0wch

aa

Rutmd

Figure

~

Ia A %

~

t' 4-:)eScks ysemdyamc odl.8

served

its biCo.TesseOyaisweemdlda

purpse to validate he feasibilityosee-p

onaint

illonand$1

$0

rap he

eneisof

sinfn

th

s

trainin

of

thes=

tween $10illionuan $10 billion.The

thoerayi and

laa

Figure~~~~~~o 4-:deek' ysewynmcodl[8

t projets whch

each poject Fthrore

uly

~~ ~

La do Pa

tu

mangeentprctsacrsstedvreprflo

twen

Vldldmd

ftaarmod

Ctu-mt

0

Lvwm=

luft 0

Avetap

LAW

ca

z

rag

e

intessesdvlpetpoes

off

the prj. aaeswa

model.w

system dynamicwr modeled

asa[ondtont

tlen aSproess anatoos weredeised to quicklyr cteoiecth

mde

forng

each project. Furthermore, significant training of the project managers was undertaken to

fully reap the benefits of the use of the model.

31

netk

t

The rework cycle of projects

Staff on

project

Productivity

Progress

Work to be

done

Known

rework

Work really

ACAdone

ZZ

Undiscovered

4,1rework

Rework

discovery

Figure 4-2: The foundation of Cooper's models, the rework loop. [14]

4.1.2

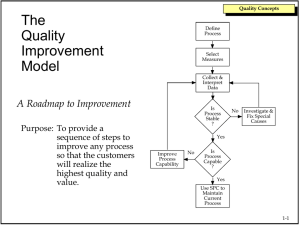

System Dynamic Model Structure for Product Development

The rework loop is critical to understand issues of quality in airplane development. This

section will discuss the modeling and formulation fundamentals based on Ford and Sterman

work. [12] The case study discussed in this chapter is heavily based on these fundamentals.

Any product development project includes multiple phases that are connected through

deliverables and rework errors.

Each phase produces deliverables that form the input to

later phases. Furthermore, each phase may detect errors that require rework and send back

to earlier phases. This dynamic is presented in figure 4-4.[12]

Each single phase is based on the stock and flow structure presented in Figure 4-5. This

structure assumes that tasks are moved through several steps until approval.

The tasks

begin in a stock of uncompleted tasks. These tasks are then completed and awaiting to be

checked. Upon quality assurance of these tasks, these tasks either move towards approval or

move towards a stock for rework.[12]

There are two quality assurance variables of critical importance at this stage: probability

of rework existing, and probability of discovering such rework. The probability of rework

existing refers to the chance that an error that requires rework may be made at the completion

stage. However, not all errors are discovered all the time. The probability of discovering

rework indicate how many of the errors made are caught in quality assurance.[12]

Concurrence is critical to each development stage.

32

Internal concurrence refers to the

~.

-H

/

Worker

, *

\

staff

Vendor

design

information

Siaffing

.o

. requested

Hours expended

to date

Pr

W

time

-Sta-on

pr

Productivity

o

s

korbe

Work ialy

done

edone

completion

4

Turmover

-

*. Overtime

.

Quality

Scheduled / e X

completion

/

Out-of-Sequence

time

work

Expected

_

.-

Schedule

pressure

-0-

rn

-

Worker

experience

morale

/

-

-

-

-

-

-

-

-

A

Expected

hours at

completion

d

Known

UndiScovered

rework

_Engineering

Rework

revisions

CISCOveyA.

rework

o 0

Perceived

-

progress

Figure 4-3: The causal loops presented by Cooper which tells the story of project management at Flour. [14]

Product

e

n.

PrototypePof

Testing

Derfinition

Reliability/

Design

Quay

OoProdcts

of Development Phase

..

-

LEGEND

Return Errors for Correction

[J3

Development Phase

Figure 4-4: Multiple phases representation of any product development project as shown by

Ford's 1997 work. [12]

33

TtCh (3)

Tasks to be Changed

Changes

rate

(8)

IDiscover

IDIscCh

ApprT (9)

C h a n g e T a s k rote

ChT (6)

Tasks

A ppr.v.

asks Complete

TCnotCk (2)

I Checked

T

RelT (11)

es :

ra

Tasks Approved

TAppr (4)

s

rooks Released

TRel (5)

TnC (1)

not Completed

Completion rate

CT (13)

Figure 4-5: The basic stock and flow structure of a single product development phase as

shown in Ford's 1997. [12]

amount of tasks available to complete at a given time within the same phase. For example,

at the requirements development phase the high level product definition requirements must

be completed before detailed performance requirements can be completed.

In this model,

concurrence is defined by a percentage of work available to complete at a given time.[12]

Given that this structure represents a single phase, it is connected with other phases

through three mechanisms: external concurrence, rework discovered downstream, and rework discovered of upstream phases. External concurrence define how much work is available

for completion in phase B based on the percentage of completion of tasks in phase A where

phase A precedes phase B in this example. If a rework relating to this phase is discovered

in a downstream phase, it is returned to this stock to rework. Furthermore, there is the

possibility that a rework of upstream phases is discovered in this phase at the quality assurance step. Both downstream and upstream reworks are moved into a stock of tasks to be

coordinated. [12]

34

probability Discover Change

p(DiscCh)

probability Change Req'ired

p(t~h

Discover Cans

Avg Quality Assurance Duration

Fraction

AA

DiacChFrac (10

Tasks

to be Changed

Quality Assurance Resource constraint

Discove

hanges ret

RCOA

Qualtty Assurance

QA (7)

Nominal Release Time

NomReMme

Phas

Avg Cheng Duration

AMh

Re PN

Change Resource onstraint

RQ-'hT

-

Change Test rate

AP

easks Completel not Ch

Roekm

(12)

CkSl e

Raises

ova ask rats

Teas

pproved

Scope

Task

rate

""""'

asks Released

completion Resource constraint

AC

Avg Completion

DuretIOn

Tasks Perceived

Satisfactory

Tasks not Completed

Completion ra

Fraction Percerive Sotisfactory

FPS (17)

e

Phase Scope

PS

Tasks Available for Completion

CTAval (14)

ternal Process Concurrence

%Avail Internal Concurr (16)

Total Tasks Avaialable

TTA(1 5)

Figure 4-6: Quality factors affecting the basic single product development phase in Ford's

1997 work. This graph also shows the internal concurrences. [12]

35

Avg Coordination Duration

ACoordD

Coordinat Ion resourse constraint

RE)Cord

TtCoord (21)

CDQA (23)

Tasks to Coordinate

Coord (2/4)

Coordination due to Downstream Ouaiiy Assurance

Coordinate asks

probablit tof Discovering Change

p(DIscCh)

probability of InterPhase Change

p(InterPhaseCh)

probablility o ntraPhese Change

p(intraPhaseCh)

Tasks

hanged

Discover InterPhase Changes

DisclnterPhaseCh (22)

Discover IntrPhas hanges

DisclntrafhaseCh (8

Qualit

pro

Change Task

ApprT (9a)

ask rat

Release Task rate

-

Assu ance

rate

asks Complete ot Che

TCnotCk (2a)

Teasks

Tasks Perceived

pproved

Tasks Released

TROI (5a)

Satisfactory

Tasks not Completed

Fraction Percerive

Completion rate

Phase

Tasks Available

Scope

for Completion

nternal

Min

etisfactorg

Process Concurrence

Total Teasks AvoalaSble

TTA (15a)

External Process Concurrence

% Avag Exiernal Concurr (19)

Figure 4-7: The addition of upstream and downstream quality effects. This figure shows

how a single product development phase connects with other phases through stocks of tasks

to be coordinated. [12]

36

4.2

Modelling Approach and Scope

Section 4.1.2 is a brief discussion of the modeling foundation upon which the detailed modeling was based in the following case study. Due to confidentiality and copyright reasons, the

details of the model which had to be tailored to the specifics of the case are not presented

in this thesis.

4.2.1

Approach

Three clear steps were followed in the study of this case. The first step was to define the

scope and stakeholders.

New airplane development is an enormous scope.

A very high

level model encompassing all stages and functions will lose much of its credibility. On the

other hand, choosing an extremely detailed stage of the development process will prevent the

analysis of rework effect on multiple stages. The second step was group modeling. During

the group modeling stage, stakeholders were involved in modeling exercises and involved in

providing direct feedback on the details of the model. Last is an analysis and check of results

applicability. It is important to note that the lack of available comparable data did not allow

to calibrate the model against current process behavior. However, the model's behavior was

acknowledged by stakeholders to be qualitatively similar to the experience.

4.2.2

Scope

This exercise focuses on the design and development of airplane components in collaboration

with suppliers.

The four main stages involved in component development are highlighted

in figure 4-8. An assumption was made that detailed rework due to high-level requirements

is completely caught at the component level requirements. Though this assumption is very

significant and not in-line with actual incidents, it was agreed upon for purposes of simplification of the model. All other rework incidents of other stages are ultimately discovered at

the compliance stage.

37

M~ng41or~TicTh rr~lonM9

Requirements

Change

Component level

requirements

Contract

Design

Change

4

CDepingn stage inComponent

Build

Desabaign t

collabr

suppliers

Airplane Level

Requirements

Development

h

W-----

....

Performance

Compliance and

Testing

Concurrence

Rework

Figure 4-8: The stages represented in the model built for this case

4.2.3

The Model

Figure 4-8 represents a macro level representation of the structure of the system dynamic

model built for this case study. Three of the four stages were represented by a single structure

similar to the one presented in figure 4-7. One of the stages, component level requirements,

was represented by multiple sub-stages.

Average duration of a given task, Figure 4-6, was an input to the model and not variable

through the simulation. However, in the component level requirements stage, the functionality of simulating schedule pressure was added to this stage. The average duration inputs were

collectively calibrated to make the whole process run at a similar duration to the time-line

expected from experience.

Similar the work of Ford [12], parallel structures were built into the model for rework.

These parallel structures simulate the time it takes to complete a rework item and release it

back into the process.

38

4.3

Results

The analysis of the model looks into two characteristics that determine the quality at each

stage in addition to the effects of schedule pressure on the quality:

1. The probability of creating rework (Prob.Cr): this probability determines the percentage of all work done at a given stage that will ultimately require rework.

2. The probability of discovering rework (Prob.Di):

this characteristic determines the

percentage of all rework discovered at a given stage. This includes rework carried on

from previous stages. In discussing the results, 'quality' refers to both Prob.Cr and

Prob.Di together. Discussing a quality of a stage means the changes in both of the

metrics. Any change to a single metric will be identified individually.

3. Sch.P effects are only studied for the requirement development stage. Schedule pressure (Sch.P) refers to the pressures to complete tasks in a given time. It is always

calculated as the ratio between amount of time remaining and the amount of time

required to complete a given task. Schedule pressure in this model can only be applied

to the requirement development stage. First, it affects the quality of the requirement

development stage; an increase in schedule pressure increases Prob.Cr. Second, Sch.P

affects the time it takes to complete a task; if Sch.P increases the the time spent on a

given task decreases. Third, Sch.P affects the time available in a given week; if Sch.P

increases the amount of overtime increases.

The model was run to understand the changes of Prob.Cr and Prob.Di over three scenarios; changes in the requirement development stage only, changes in the design stage only,

changes in both stages at the same time.

4.3.1

Quality of the Requirement Development Stage

This scenario studies the effects of quality metrics (Prob. Di and Prob. Cr) in the requirements development stage on the overall time to completion as well as amount of work done

till completion.

Furthermore, the effects of schedule pressure in this stage are studied as

39

Time to Complete due to Quality at Requirements Stage

571%

600%

500%

Time to

completion

400%

334%

294%

relative to base 300%

case

200%

100%

115%

104%

127%

105%

10%

50%

90%

Probability of Discovering Rework

10% Prob of Rework

-4-30% Prob of Rework

-A-

50% Prob of Rework

Figure 4-9: The results of varying quality factors in components requirement stage while

quality is constant in other stages. This figure shows the effects on time of completion. The

time of completion is normalized against an ideal quality case of zero errors.

well. Both Prob.Di and Prob.Cr are changed while quality in the design stage is constant.

The results are shown in figures 4-9 through 4-12.

Figure 4-9 looks at the effect of quality on time to completion of the process. The results

are in comparison to the planned situation (ideal situation with zero probability of creating

rework). At 10% Prob.Cr, the effect of Prob.Di is limited to a approximately 30% increase

in time to completion. However, at 50% Prob.Cr only a 10% decrease in the Prob.Di will

add 68% to the time to completion.

Figure 4-10 shows a similar analysis with a focus on the amount of work done to completion relative to base case. This case shows that the percentage increase in amount of work

is more than that of time to completion.

Figures 4-11 and 4-12 repeat the simulations performed in figures 4-9 and 4-10 while

enabling the Sch.P effects. In both cases, the effects of schedule pressure increase the amount

of work and time to completion. This indicates that the negative effects of schedule pressure

are more than the positive effects. It is noticeable that Sch.P affects the amount of work

much more than the time to completion. This indicates that the schedule pressure leads to

40

Amount of Work due to Quality at Requirements Stage

948%

1000%

800%

Amount of work

494%

600%

relative to base 400%

case

200%

447%

273%

244%

148%

1 2SO

0%

--

10%

50%

90%

165%

Probability of Discovering Rework

-- 1.0% Prob of Rewo rk

-*-30% Prob of Rework

---

50% Prob of Rework

Figure 4-10: The results of varying quality factors in components requirement stage while

quality is constant in other stages. This figure shows the effects on amount of work needed.

The amount of work is normalized against an ideal quality case of zero errors.

an increase amount of work over lengthy period of time. However, the model structure does

not account for burn-out and turn-over of workforce. The addition of those two features to

the model may change this observation.

4.3.2

Quality of the Design Stage

This scenario studies the effects of quality metrics (Prob. Di and Prob. Cr) in the design

stage on the overall time to completion as well as the amount of work done till completion.

Both Prob. Di and Prob.

Cr are changed while quality in the requirement development

stage is constant. The results are shown in figures 4-13 and 4-14.

The system's response to the change in quality metrics in this stage is similar to the

response of the system to quality metrics in the requirement stage. However, changes in

quality metrics in this stage has a more limited impact than a previous stage.

This is

expected as rework created in this stage travels to the next stage where it is discovered.

Rework created in the requirement stage travels two stages before completely discovered.

41

-

Time to Complete due to Quality at Requirements Stage

Schedule Pressure

700%

578%

600%

500%

Time to

completion 400%

relative to base

300%

361%

301%

188%

208%

109%

104%

105%

127%

90%

50%

10%

case

200%

100%

V70

Probability of Discovering Rework

-10%

Prob of Rework

--

30% Prob of Rework

-r-

50% Prob of Rework

Figure 4-11: The results of considering schedule pressures while varying quality factors in

components requirement stage with quality is constant in other stages. This figure shows

the effects on time of completion. The time of completion is normalized against an ideal

quality case of zero errors.

4.3.3

Quality of Both Stages

In this scenario, both Prob.

Cr are changed simultaneously for both the

Di and Prob.

requirement development and design stages.

The results are shown in figure 4-15.

The

results show the compounded effect of poor quality in both stages. It increases the time to

completion significantly.

4.4

4.4.1

Conclusions and Recommendations

Conclusion

The results of the model scenarios show that quality in an early development stage, the

requirement development in this case, affects the completion time significantly more than

quality in other stages. Both quality factors, Prob.Cr and Prob.Di, have a significant impact

on the completion time. Furthermore, schedule pressure is only beneficial given small amount

42

-

Amount of Work due to Quality at Requirements Stage

Schedule Pressure

1400%

1153%

1200%

1000%

675%

Amount of work 800%

relative to base 600%

case

400%

200%

553%

377%

36%

1775%

192%

146%

179%

0%

10%

50%

90%

Probability of Discovering Rework

-10%

Prob of Rework

-M-30%

Prob of Rework

-*-50% Prob of Rework

Figure 4-12: The results of considering schedule pressures while varying quality factors in

components requirement stage with quality is constant in other stages. This figure shows

the effects on amount of work needed. The amount of work is normalized against an ideal

quality case of zero errors.

Time to Completion - Quality of Design Stage

329%

350%

300%

250%

Time to

completion 200%

relative to base

150%

case

100%

232%

204%

156%

163%

145%

121%

137%

137%

90%

50%

10%

50%

0%

Probability of Discovering Rework

-

10% Prob of Rework

-- 30% Prob of Rework

-Lr50% Prob of Rework

Figure 4-13: The results of varying quality factors the design stage while quality is constant

in other stages. This figure shows the effects on time of completion. The time of completion

is normalized against an ideal quality case of zero errors.

43

Amount of Work - Quality of Design Stage

273%

300%

250%

206%

198%

200%

Amount of work 150%

relative to base

100%

case

148%

164%

110%

113%

118%

90%

70%

50%

143%

50%

0%

Probability of Discovering Rework

10% Prob of Rework

30% Prob of Rework

--

-*-50% Prob of Rework

Figure 4-14: The results of varying quality factors in the design stage while quality is constant

in other stages. This figure shows the effects on amount of work needed. The amount of

work is normalized against an ideal quality case of zero errors.

Time to Complete Quality of Both Stages

362%

400%

350%

Time to

completion

relative to base

case

300%

250%

200%

150%

100%

50%

0%

277%

196%

199%

171%

158%

130%

137%

142%

-

4

~~

-

50%

70%

90%

Probability of Discovering Rework

-10%

Prob of Rework

-4-30% Prob of Rework

*50%

Prob of Rework

Figure 4-15: The results of varying quality factors in both the components requirement

stage and the design stage. This figure shows the effects on time of completion. The time of

completion is normalized against an ideal quality case of zero errors.

44

of rework only.

In the first scenario, Quality changes within the Requirements Development stage shows

a non-linear growth of the time required to complete project as both Prob.Di decreases

and Prob.Cr increases. At low Prob.Cr of 10%, the time to complete the full phase only

increases by 27% by the decrease of Prob.Di. However, at 30% Prob.Cr, time to completion

increases by 194% as Prob.Di decreases to 10%. Similar results appear when considering the

number of requirements work. There is a non-linear behavior with much larger percentages

of increase in-comparison to time.

A factor of 2 differentiate the impact of Prob.Cr and

Prob.Di. Changes in Prob.Cr impacts the overall time of completion by approximately twice

as much as a similar change of Prob.Di.

When schedule pressure effects are taken into account, there is an increase in completion

time only at poor quality levels. This is due to the fact that increase in errors overwhelm

the schedule pressure impact on time to perform each task. Ultimately, the large increase of

rework leads to a longer completion time.

In the last scenario, when quality was changed across both stages it was expected that

time to completion would increase significantly more than previous stages.

However, the

increase was comparable to that of changing quality in the Requirement Development stage.

This supports our findings of the importance of the requirements quality stage.

4.4.2

Recommendations

This model assumes a very small scope and an ideal scenario where change management

is perfected. Therefore it is expected that the impact of propagating poor quality to later

stages is much larger than shown in this limited model. However, in this case three factors

are deemed critically important: 1) The probability of creating rework. 2) The probability

of discovering rework.

3) The impact of schedule pressure. Boeing has significant effort,

many of which are very successful, to improve the first factor. Nonetheless, this model shows

the significant impact on later stages even at low Prob.Di.

Furthermore, improving the

probability of discovering rework is closely related to anticipating rework within the project

planning by increasing the margins for possible rework.

Another approach to addressing

Prob.Di is to integrate clear and strong stages of development iterations at each stage.

45

Schedule pressure adds very little value to completion of development stages. Completion of

any particular stage must be completely reliant on a thorough review of the deliverables.

46

Chapter 5

Conclusions

This study assessed the hypothesis that integration and process discipline are determinantal

to the quality of airplane development at Boeing. This thesis focused on the rework necessary

and completion time of any engineering development stage or activity. Two case studies completed in collaboration with Boeing gave support to the hypothesis. The recommendations

and opportunities for next steps are the following:

1. Process discipline is engineering quality: large engineering projects such as new

airplane developments require a significant magnitude of integration between multiple

teams. Clear definitions of inputs and outputs of each team, stage, and activity are

a first step to improve the integration of engineering teams.

Each stage must have