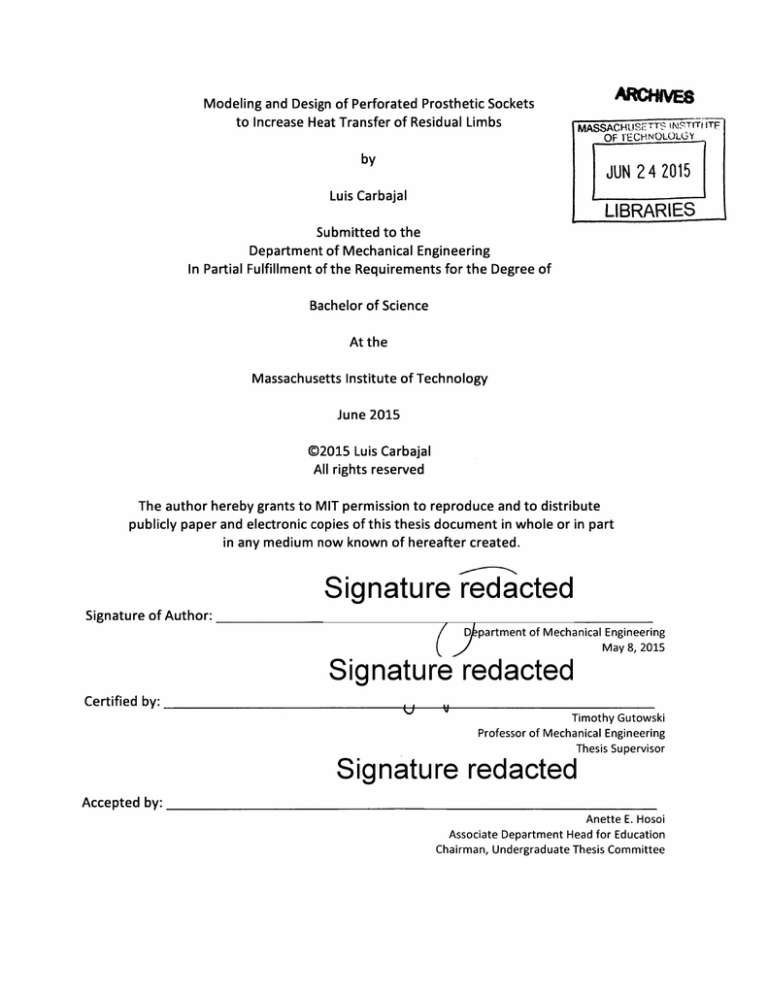

Modeling and Design of Perforated Prosthetic Sockets

ARCHM

to Increase Heat Transfer of Residual Limbs

MASSACHUSF: TTS INS7rT

OF -ECHNOLOLGY

by

JUN 2 4 2015

LIBRARIES

Luis Carbajal

Submitted to the

Department of Mechanical Engineering

In Partial Fulfillment of the Requirements for the Degree of

Bachelor of Science

At the

Massachusetts Institute of Technology

June 2015

02015 Luis Carbajal

All rights reserved

The author hereby grants to MIT permission to reproduce and to distribute

publicly paper and electronic copies of this thesis document in whole or in part

in any medium now known of hereafter created.

Signature redacted

Signature of Author:

D partment of Mechanical Engineering

May 8, 2015

Signature redacted

Certified by:

V

Timothy Gutowski

Professor of Mechanical Engineering

Thesis Supervisor

Signature redacted

Accepted by:

Anette E. Hosoi

Associate Department Head for Education

Chairman, Undergraduate Thesis Committee

2

Modeling and Design of Perforated Prosthetic Sockets

to Increase Heat Transfer of Residual Limbs

by

Luis Carbajal

Submitted to the Department of Mechanical Engineering

On June 5, 2015 in Partial Fulfillment of the

Requirement for the Degree of Bachelor of Science in

Mechanical Engineering

Abstract

Heat build-up in prosthetic sockets is a significant problem experienced by many

amputees in America, with no central solution in sight. Heat and discomfort accounts for over

70% of problems experienced by lower limb amputees in America. Although there have been

advances in prosthetics in the active-power knees and ankles, not even cybernetics can improve

the comfort of the prosthesis if there is still a socket. The materials in prosthetic sockets are not

conductive enough to relieve the heat inside of the socket. The purpose of this study is to

model the temperature variance and heat transfer of an amputee's residual limb and design

ways to improve current prosthetic socket technologies. With the addition of small holes, or

perforations, in the socket, there will be an increase in the heat transfer by convection, while

still maintaining the strength of a carbon fiber prosthesis. Through the use of discrete

approximation modeling, the transient temperature inside of the socket layers can be identified

and improved through design patterns cut into the socket. Increased heat transfer can be

observed as the perforations in the socket become larger, although the larger the holes, the

larger the stresses are in the prosthesis. Non-intrusive designs were developed for sockets

before and after they are made to increase convection surface area. More modeling needs to

be done in 3-dimensional polar coordinates.

Thesis Supervisor: Timothy Gutowski

Title: Professor of Mechanical Engineering

3

Acknowledgments

I have been inspired by so many here at MIT. My dedication has been to the improved

rehabilitation for people around the world. I am inspired to do more to help out each and every

individual who is in need, because regaining the reins of one's life is the ultimate

accomplishment.

I would first like to thanks my parents and my brother, who have always believed in me

no matter what challenge I face. Their full support is one of the reasons I have strived to do

more and was able to attend such a magical school. There are no words to describe the

sincerity of the smile they put on my face.

Many thanks to my advisor through my Mechanical Engineering experience, Professor

Timothy Gutowski, who so graciously allowed me to pursue my own interests for the my Course

2 career. I would also like to thank Brandy Baker, who works so hard to keep Mechanical

Engineering from falling apart, and most of all from keeping me from losing my mind.

I am so thankful for the instructors that I have had over the years. I wouldn't be able to

call myself a Mechanical engineer without the help of Barbara Hughey, David Wallace, Danny

Braunstein, Warren Seering, Dawn Wendell, Bill Cormier, James Dudley, Steve Haberek, and

Tasker Smith. I would also like to thank any other instructor that has been so patient with me as

I've come in for classes or random questions. I would also like to thank everyone at the

Biomechatronics group at the MIT Media Lab, for if it were not for our paths crossing, I would

not be as involved in the field as I am today.

There's nothing that makes you prouder to be an MIT student than the people that you

get to meet on a daily basis. Who would think there would be so many students to thank during

my time here. I would like to thank Douglas Sanchez for his increased support and amazing job

as a teaching assistant. There was not a day that I wasn't happy to see Doug during my time

taking 2.009, which seems like a forever ago, now. Many thanks to Angel Diaz, for his

computational wisdom during the early stages of this thesis.

I would also like to thank Mitali Kini, for helping me keep my cool here at MIT. The

school looks filled the science and fun, but there are many a times I've been at my wit's end

and she's always been there to bring me back.

I would like to thank every single person at MIT and back home for making my dreams

come true. I promised I wouldn't let you down and I plan to keep it.

4

Contents

1. Introduction

6

2. Background

7

3. Thermal Elements

a. Estimation of Temperature Gradient using Numerical Methods

b. Experiment Setup and Design

c. Results of Experiment Trials

8

12

13

4. Socket Redesign

a. Perforated Socket

14

5. Discussion

17

6. Conclusion

17

7. References

18

8. Appendix

19

5

Introduction

While the commercial technologies available for amputees is drastically advancing with

new active and quasi-passive prosthetics and orthopedics, there are still areas in the field that

have been ignored and have been too difficult to innovate in. Amputees with even the most

high tech and modern prosthetics still find it difficult to use their prosthetics over time because

they become uncomfortable and can develop skin irritation from prolonged use, disrupting the

user's gate, no matter how good the algorithm in the prosthesis is to correct it. Heat build-up in

prosthetic sockets is a significant problem experienced by many amputees in America, with no

central solution in sight. Developing prosthetic sockets that are strong and allow the user to

cool off during use will be an important step forward and will help amputees wear their

prosthetics more often and maybe even permanently, improving their current and developing

healthy lifestyles.

In conventional prosthetics, especially lower limb prosthetics, the amputee wears a

silicone liner inside a harder socket, usually made with carbon fiber. In some cases, an added

soft socket made out of polymers will allow the user to a more comfortable. The limiting factor

to having so many different configurations of prosthetic sockets, is that users have to substitute

initial comfort for long term usage. Heat build-up from non-breathable materials in the

prosthetic sockets cause users to sweat, causing the loss of suction and control of their

prosthesis. This can be seen more and more today with the rise of prosthetic devices used for

running and other intensive sports. The body needs a way to expel the heat in the residual limb,

and the user needs a way to feel secure in their own feet.

In this thesis, I present a design improvement to prosthetic socket fabrication process

for use on trans-femoral and some trans-tibial amputees that will increase heat diffusivity of

the residual limb through the layers of prosthesis. This approach looks to add an additional

step to the fabrication of prosthetics by certified prosthetists that can be implemented in both

pre- and post-curing of a carbon fiber socket. This technique should prove to be non-invasive to

the gait cycle and biomechanics of the amputee, but should improve the homeostasis of the

prosthetic socket, nonetheless.

First we will address the design of the prosthetic socket and its improvement. The

importance of the increased heat transfer, and the reliability of the new geometry.

6

Background

As of 2008, there are 1.7 million amputees in America, with that number looking to

increase to 2.4 million by the year 2020. With over 300,000 of these amputees having transfemoral amputations, and an additional 30,000 trans-femoral amputations being conducted

each year, there is a general need for the advancement of prosthetic technology.11

Current prosthetic sockets are made custom to the user, requiring a certified prosthetist

to measure and develop solutions for each amputee. There are several different kinds of

prosthetic sockets that lower limb amputees use. For trans-femoral amputees, sockets are

made so that the amputee carries most of their weight on the upper posterior side of their

femur, allowing extra support from pelvic bones and gastronomic muscles. Most trans-femoral

amputees need full hydrostatic pressure from their prosthesis in order to have control of their

prosthesis, so the leg needs to be flush against the residual limb and there should not be room

for piston-like movement or rotation in the socket.

Figure 1: Examples of current technologies for socket prostheses. Most Prosthetic and Orthopedic clinics can

fabricate these sockets for individuals to shape and support their residual limb.

Trans-tibial amputees also need to have tight fitting sockets to help control the below

knee prosthesis. The loads in the prosthesis are concentrated along the lower patella tendon

and the upper calf. To address these there are several different types of suspension systems for

prosthetics. There are silicone liner based systems that use a roll one silicone sleeve to adhere

to the skin of the user and can be connected to the socket with a variety of mechanical locks

like pin ratchet systems or lanyards. For other prosthetic socket users, direct suction between

the skin and the socket is the most comfortable option and allows the distal end of the residual

limb to float above the bottom of the socket.

The proposed method is designed for amputees who use liners along with their

prosthetic sockets as to not affect the interface and pressure against the residual limb. It is a

common practice to use a liner along with the prosthetic socket to cushion the user because

most are not able to handle the pressure applied by the carbon fiber.

7

The most common problem with lower limb amputees is that they suffer from skin

irritation and sweating in the prosthesis due to the increased temperature inside of the socket.

The metabolic costs to move increase for lower limb amputees, meaning walking at the same

pace as a non-amputee will waste more energy and fatigue sooner.

Temperature of Socket

36.5

Skin Surface

Socket Surface

Liner Surface

35.5 F

-

36

35

34.5 F

Ea)

~ilLA~~l~j~-

34 I33.5 F

33

F

-V.

A A-

32.5

32

0

50

100

150

seconds(s)

Figure 2: Above is a graph of sitting temperature inside of a prosthetic socket while the user is wearing it. The

temperature change between the skin and the outer socket is over 4 degrees at times.

Improvements to the temperature gradient of the socket will have a significant effect on the

user, because their skin will be able to return to a normal skin temperature and will reduce

sweat, preventing other problems, like rashes and sores, from developing.

Thermal Elements

Estimating Heat Conduction through Numerical Methods

When analyzing the heat transfer through the prosthetic socket, a number of factors

come to mind. Since each residual limb comes in a different shape and size, the use of a

cylindrical model to visualize the heat transfer through a hard socket is not warranted. Instead,

2D visualization of heat transfer through a plate is preferred as the wall thicknesses and

variations in material are small. Using plates allows for the consideration of heat transfer in

other directions and allows for the control of boundaries.

8

Simulating the plate as a rectangular region in which heat conduction is significant in x

and y directions, the plane of the region can be made into a mesh of nodal points that will be

spaced out as Ax and Ay apart in the x and y directions. To eliminate a third dimension, Az = 1.

Finding the temperature at these nodes will give an estimate of what the temperature is in the

material. Using the logical numbering scheme for two dimensional problems, double subscript

notation(m, n), where x = mAx and y = nAy and the temperature at node (m, n) is denoted

by Tm,nt

I

T M+ 1

T -+

T *IhI

At

AAt

Axx

Figure 3: Depiction of the nodes for the approximation of heat transfer and temperature using numerical methods.

Nodes examine all boundary conditions around it in order to understand its own property.

The volume element for each node will be AxAyAz = AxAyl in a region which heat is

is a

generated at a rate of 4 in ( ) and k, the thermal conductivity of the material (

constant. Assuming the direction of heat conduction is toward the node under the

consideration at all surfaces, energy balance on the volume element can be expressed as

Qcondleft +

Ocond,top + Qcond,right + Ocond,bottom + Qelement

-

AEelement =

At

o

(1)

for steady state cases. Where Qcond is the heat transfer rate from the edge conditions and

Qelement is the rate at which the element generates heat. AEelement is the change of energy in

the node (J) and At is the amount of time that has passed. Since the heat transfer area of

AX = Ay *l in the x direction and AY = Ax * in the y direction, the above equations can be

reduced. In the finite difference analysis, using a square mesh simplifies the spacing of the

nodes and Ax = Ay = 1. This simplifies the above equation to

9

Tm-,n + Tm+i,n + Tm,n-1

+

Tm,n+1 - 4Tm,n +

k"

=

(2)

0

where Tm+i,n+jis the temperature of a nodes around Tm,n, in (K) and Om,n is the rate at which

w by the element. To understand what is happening to the nodes in the plate during

heat

At, the energy balance on the volume element can be expressed as:

Zaul sides 0

+

Qelement = AEelement

=

(3)

PVelement CT

where p is the density of the material (k), Veement is the volume element of the node

and AT is the change in temperature (K).

C is the specific heat of the element (-)

kg K

In this numerical method to measure heat transfer, the temperature change of plates of

silicone rubber and carbon fiber were modeled to have two boundary conditions at the top and

at the bottom of the plates that were completely insulated, so the only conditions that were

acting on the plates were the left and right boundaries. The left boundary provided a hot gas

(310 K) for convection while the right boundary provided a cold gas (290K), keeping the transfer

at steady state. This is believable because in the figure above, even through activities and

exercise, the temperature inside the socket stayed at 35 C and room temperature did not

change.

Temperature Gradient Through Carbon Fiber

'1945

292 2

2932-_

02

00

93 5

01

Depth (mreters)

0 05

01

01

02

0'

3

055

Wdthb (moters)

Figure 4: Above is an estimate of temperature through silicone rubber and carbon fiber using a numerical method

of approximation. Both materials were allowed to sit through convection at boundaries for 10 seconds.

10

In the first model, there were two solid plates: one of silicone rubber and one of carbon

fiber. The change of material can be seen at the depth of 0.04 meters. This meant that the

temperature change through the layers could be calculated by the sum of the thermal

properties of each plate. The silicone rubber showed to have greater conductance and heat

transfer capabilities than the carbon fiber.

Temperature Gradient Through Perforated Carbon Fiber

293

29429

293,

292.5

-

2292

E

291-1-

291.5

290

--

0.02

291

....

-

0.04

- -0.3

0.08

Depth (meters)

0.2

290.6

Width (meters)

Figure 5: Above is an estimate of temperature through silicone rubber and perforated carbon fiber using a

numerical method of approximation. Both materials were allowed to sit through convection at boundaries for 10

seconds. Gaps were simulated in the carbon fiberfor increased convection.

The second model that was made to simulate perforated carbon fiber. The carbon fiber

plate had chunks cut out of it where it was just air. This allowed the silicone rubber to reach the

edge boundary conditions and for a larger surface area for convection to take place. Notice that

the overall temperature throughout the layers are lower than the model with solid carbon

fiber. The gaps in the carbon fiber creates a variance in the temperature in both the x and y

directions of the plates when there was only change in the x in the first model.

Although the model only showed an x and y direction, this was enough evidence to

continue on to experiment with the different size perforations and look into the effect of those

holes on the structural integrity of the materials.

11

Experimental Setup

An experimental system was developed in order to test the effects of different sized

perforations on the temperature gradient of the socket. Without having the standard carbon

fiber for sockets, ABS was used in replacement for the hard socket. To match the temperature

of the skin inside the socket and still provide the same convection as the room, the layers of

silicone rubber and ABS were placed and secured atop a container full of hot water. This

allowed the air between the water and the rubber to heat up and when the temperature

reached close to that of the human body, the experiment would commence.

Hard Socket

I

Hot Air

Figure 6: Diagram of experimental setup. Heat is transferred through the hot air by convection into the silicone

rubber sheet and then transferred into the carbon fiber and out into the room. Thermistors were placed on both

sides of the silicone rubber sheet. Two were exposed to air, while the other one sat underneath the hard socket, like

conventional prosthetics.

The container was insulated along the walls, as to mimic the model where the top/bottom

boundaries do not provide any sort of heat transfer onto the materials, as well as to keep the

water from cooling. Three Vernier STS (Surface Temperature Sensor) were used in order to

measure the temperature change at the surface of the silicone sheet when it was exposed to air

(the boundary condition) or when it was covered by the hard socket. Weight was not applied to

the plate because the thermistors were sensitive to touch.

12

Figure 7: Actual experimental setupfor the temperature change of the silicone due to the design and perforation of

the hard socket.

Results of Experimental Trials

Temperature of Socket

Temperature of Socket

40

I

40

Inner Socket

-_-- Surface Cove red

39

Surface Exp

osed

-

39

Inner Socket

Surface Covered

Surface Exposed

36

38

37

37

E

E36

36

35

35

34

331

0

1000

500

1501

4L

600

800

seconds(s)

1000

1200

1400

1600

seconds(s)

1800

2000

2200

2400

Figure 8: Comparison of temperature change between layers of different size perforations. Left: Holes were drilled

into the ABS at the size of 5/16". Right: Holes were drilled into the ABS at the size of Y2".

The time to see a significant change in temperature was longer than the model before,

but that may be due to the type of silicone rubber. The silicone rubber is for high temperatures

rather than platinum cured silicone for the skin. The available silicone rubber may not have

been as conductive as that modeled. The increased size of the holes in the perforations allowed

1

for greater temperature change in a shorter amount of time. The plate with the in holes was

5

3-6% more efficient at changing temperature than the -16 in. Seeing that there was 2.56 times as

much surface area of the silicone exposed, this does not look to be a significant amount

between the holes, although they both were much lower than their covered counterparts.

13

Socket Redesign

Perforated Socket

One way of perforating the socket to increase the surface area for convection would be

to machine through the existing carbon fiber sockets and allow it to breath. For some sockets,

where there is a hard socket (carbon fiber) and a soft socket (polypropylene shell), the

prosthetist is able to machine through and cut large pieces of the hard socket off, allowing the

hard socket only for support areas. This method does not work for users who needs all around

support of their prosthesis.

Below is an example of a process that can be done before the carbon fiber shell is made.

To create the carbon fiber shell, the prosthetists covers a cast of the amputee's limb in carbon a

carbon fiber weave and then applies resin to strengthen it and complete the shell. Below, the

prosthetists would be able to apply removable plugs onto the cast which will allow the

perforation holes to automatically form in the shell as the plug can easily find its way through

the braid of carbon fiber. After the socket has cured, removal of the plugs from the cast will

leave a carbon fiber shell that was set with holes, having all of its fibers uncut.

Figure 9: Example of plug system for making the carbon fiber cost. The carbon fiber will be able to weave around

the plugs before curing and then after will be set in that shape.

14

Figure 10: Above are samples of what the prosthetic socket may look like. The size of the holes have been

exaggerated. Left would allow users who do not need support all around the residual limb. Right will cater to those

who need complete hydrostatic pressure.

'K,

Figure 11: Above ore two instances of holes that con be set into the carbon fiber socket. Left: Fibers that hove a hole machined

through. The red indicators show cuts in the fibers and a reduction in tension. Right: Fibers that are weaved around pegs in the

cost to create holes allow the carbon fiber to stay in tension while laminated.

15

Prosthetic sockets can be machined through, but the removal of material creates stress

concentrations at different areas and tension changes at the break points of the fibers. To

resolve this issue, weaving the carbon fibers around the plug, or merely pushing them aside to

create the hole would prove to keep the integrity of the carbon fiber tension, while still creating

pathways for heat to escape. The bundling of the carbon fiber at the edge of the hole would

thicken the weave, which would counteract increased stress concentrations.

The strength of carbon fiber changes when it is notched. The notched holes in carbon

fiber reduce the yield strength of the composite at the edge, but increasing the distance

between the holes will allow the strength of the carbon fiber to be restored. Increasing the

plies of composites and distances between the holes, will allow reduce the effect of notches in

the system.

The strength of the notched hole follows the order of

(4)

a

where bo is the characteristic length of the carbon fiber, where the strength is measured, and a

is the given radius of the notch. For example, the notched strength at the edge of 714 carbon

fiber is 180 (MPa), but once the characteristic length reaches an another radius from the

center (bo = a), it increases to 600 (Mpa).14 ' This assumes that the characteristic length does

not change given the size or the number of plies of carbon fiber. Smaller perforations in the

prosthesis will prove to reduce the effect on the structural integrity but still increase the heat

transfer of the prosthesis.

16

Discussion

In the models, the addition of perforation to the plates vastly increased the temperature

gradient through the layers of silicone rubber and carbon fiber. The increased surface area

increased the heat transfer through convection. While there was almost a linear temperature

gradient through the x direction, there was no variance in temperature for the y direction

because there was no heat transfer through that boundary condition. It was not until the

silicone was exposed to air, and there were gaps in the carbon fiber that there was any variance

in the y direction. The problem with the accuracy of this model was that two boundary

conditions were zero and the heat transfer remained at steady state because it was assumed

that both boundary temperatures on the left and right side were constant. To improve upon

this model, it will be important to look at the temperature gradient when there are transient

temperatures at the boundary conditions. The next step for this process would be to model the

temperature gradient through a cylinder over time and then apply that to the shapes of

residual limbs.

In the trials, the increased hole diameter allowed for an increased change in

temperature of 3-6% when switching from 16 in to the 2 in. Although this showed signs of

improvement, the area increase was over a twice the original. The temperature did not change

as quickly as hoped, unfortunately. The silicone rubber might have been the culprit, as it might

not have been up to the correct specifications for platinum cured silicone for liners. A next step

for this process would be to perforate a carbon fiber socket and see how the temperature and

yield strength changes before and after it is perforated and do cost analysis on the amount of

effort and money it would take to improve the socket.

-

Conclusion

Single digit percentage change to temperature variance were scene in both the model

and the experimental trials. The model with holes always kept a lower temperature all around

than the fully insulated model. It was noticed that the increase in thicknesses of layers in the

models would improve the change from insulated to perforated sockets, so thinner sockets

would see a diminishing return as there is not enough material to conduct through. The model

and the experiments did not show the same temperature change. This might just be the

materials that were used in the experiments, but an investigation into different prosthetic

materials is required to find liners and sockets that have increased thermal conductivity. It

should also be noted that the alterations done to prosthetic sockets to improve mobility and

heat transfer are safe for they would not usually come within an order of magnitude of stress in

the most extreme cases (running).If the heat transfer through convection is improving the

temperature gradient, then circles might not be the right shape of perforation for the socket

prosthesis. A change in shape to a star for more exposed surface area would allow for greater

heat transfer. This coupled with new materials, even only at places exposed by the hard socket

could create a new breed of prosthetic sockets that allow user residual limbs to breathe and

cool down quickly.

17

References

1. Villalpando, E. (2012). Design and evaluation of a biomimetic agonist-antagonist active

knee prosthesis (pp. 8-21). MIT.

2. Ik, M. (1994). Finite difference methods in heat transfer. Boca Raton: CRC Press.

3. Sengeh, D., & Herr, H. (2013). A Variable-Impedance Prosthetic Socket for a Transtibial

Amputee Designed from Magnetic Resonance Imaging Data. JPO Journal of Prosthetics

and Orthotics, 129-137.

4. Tsai, S. (1988). Notched Strength. In Composites design (4th ed.). Dayton, Ohio: Think

Composites, 20-7.

18

Appendix A

Matlab Code for Discrete Approximation of Heat Transfer

% Modeling the heat transfer between silicone liner/ carbon fiber socket/

% air

clear all

close all

clc

%properties of carbon fiber socket

k_s_cf = .25; %W/(m*K)

rhocf = 1880; %kg/mA3

Cpcf = .71; %J/(g*K)

alpha-cf = k_s-cf/(rho-cf*Cp-cf);

h_air = 1;

%properties of silicone rubber liner

k_s_s = 1.2; %W/(m*K)

rhos = 1100; %kg/m^3

Cps = 1.05; %J/(g*K)

alpha-s = k_s_s/(rho-s*Cp-s);

L_i = 0.4; %m

length in verticle direction

length in horizontal direction

L_j = 0.00625; %m

= 40; %"

Number of nodes in i direction

ni

Number of nodes in j direction (adjusted to keep constant

n_j = 10; %

spacing)

Spacing of nodes

delx = L_i/(nJi-1); %m

Temperature of skin

T_skin = 310.3; %K

Temperature of Cold gas

T_cg = 290.3; %K

Temperature of Cold side

T_1 = 293.3; %K

Stopping time

%Seconds

t_2

= 10;

t(l)= 0 ;

Change in time each iteration

delt = 0.01; %seconds

%Initial Temperature Matrices

T(l:nJi+2,1:nj) = Ti;

Fos = alpha-s*del-t/(delx.^2);

Bis = hair*del-x/ks-s;

Focf = alpha-cf*delt/(del-x.^2);

Bicf = hair*del-x/k-s-cf;

if Fos > 0.25 11 Fo-cf > 0.25

fprintf('Fourier number is too big, code is unstable \n \n')

elseif Fos*(l-Bis) > 0.25 11 Focf*(l-Bicf) > 0.25

fprintf('Biot Number too big, code unstable')

end

19

.. .. .. ..

....

..

.... ..

. .. . . . .. .......

............

k = 1;

while t

< t_2

for i = 2:ni+1

if i <8

1i

for

> 14 && i < 26

11

i> 32

j = 1:n_j

%Hot edge at skin

if j==1

= Fo_s*(2*T(iT(i,j,k+l)

1,j,k)+T(i+1,j,k)+T(i,j+1,k)+2*Bis*T_skin)+(1-4*Fo_s-2*Bis*Fo-s)*T(i,j,k)

%Middle of material

elseif j > 1 && j < n-j/2

= Fos*(T(i+l,j,k)+T(iT(i,j,k+l)

1,j,k)+T(i,j+1,k)+T(i,j-1,k))+(1-4*Fo_s)*T(i,j,k);

elseif j == n-j/2 % change to carbon fiber

= Fo_cf*(2*T(iT(i,j,k+l)

1,j,k)+T(i+l,j,k)+T(i,j+l,k)+2*Bicf*T(i,j-l,k))+(1-4*Focf2*Bicf*Fo-cf)*T(i,j,k) ;

elseif j > n-j/2 && j < nj %middle of carbon fiber

= Fo_cf*(T(i+l,j,k)+T(iT(i,j,k+1)

1,j,k)+T(i,j+1,k)+T(i,j-1,k))+(1-4*Fo_cf)*T(i,j,k);

% Exposed to air for carbon fiber

elseif j==n-j

= Fo_cf*(2*T(i-1,j,k)+T(i+1,j,k)+T(i,jT(i,j,k+1)

l,k)+2*Bicf*Thcg)+(1-4*Focf-2*Bicf*Focf)*T(i,j,k)

end % ( if statement)

end % (j loop)

else

for

j = 1:n-j

%Hot edge at skin

if j==1

= Fo_s*(2*T(iT(i,j,k+l)

1,j,k)+T(i+l,j,k)+T(i,j+1,k)+2*Bis*Tskin)+(1-4*Fo_s-2*Bi-s*Fos)*T(i,j,k)

%Middle of material

elseif j > 1 && j < n-j/2

= Fo_s*(T(i+l,j,k)+T(iT(i,j,k+l)

1,j,k)+T(i,j+1,k)+T(i,j-1,k))+(1-4*Fo_s)*T(i,j,k);

elseif j == n-j/2

= Fos*(2*T(i-1,j,k)+T(i+1,j,k)+T(i,jT(i,j,k+l)

l,k)+2*Bis*Tcg)+(1-4*Fo_s-2*Bis*Fo_s)*T(i,j,k)

elseif j > n-j/2

T(i,j,k+1) = Thcg;

end % ( if statement)

end % (j loop)

end

end % (i loop)

20

....

...

....

.

....

.

% Resetting top and bottom no flux boundry conditions

for j = 1:nfj

T(1,j,k+l)

= T(3,j,k) ;

T(n_i+2,j ,k+1)

= T(n_i,j,k) ;

end

t (k+1)

k

end % (while loop)

Temp(l:n_i,l:nj)

=

t(k)

+ delt;

= k + 1;

= T(2:ni+1,1:nj,k-1)

%Creating x direction position matrix

for i = 1:n_i

= del-x*(i-1)

x(i)

end

%Creating y direction position matrix

for j = 1:n_j

= del-x*(j-l)

y(j)

end

surf(y,x,Temp(:,:)),

2D temp matrix)

shading interp,

;

;

;

%surf(column matrix, row matrix,

21

..

....

......

...........

. .........

...