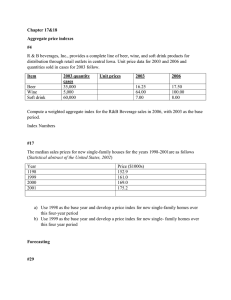

AN ABSTRACT OF THE THESIS OF

advertisement