GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY TECHNICAL DATASHEET eDrive

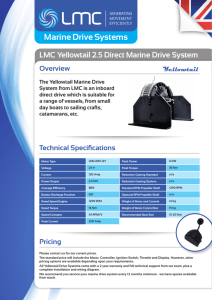

advertisement

TECHNICAL DATASHEET eDrive GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY Engineering that moves the world A global leading supplier of technology differentiated power management solutions and services. GKN Land Systems is a global leading supplier of technology differentiated power management solutions and services. We design, manufacture and supply products and services for the Agritechnical, Construction, Mining and Utility vehicle markets and key Industrial segments, offering integrated PowerTrain solutions. WHAT WE DO: As a leading partner in the off highway industry GKN Land Systems works closely with Global Original Equipment Manufacturers to meet the needs of the ever changing and demanding operating environment. Extensive R & D in increasingly intelligent and integrated engineering solutions ensures that we supply products that are efficient, enable increased productivity of machinery and take into consideration requirements for lighter weight and increased payloads. GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY GKN Land Systems, a global Engineering Group and technology leader is bringing electric motor and generator technology to the commercial, off highway and marine industries. GKN has worked closely with research and development centres as well as OEM’s to innovate and develop a range of off-highway electric drive systems, from in-hub motors to low voltage drive systems and power generators. Technological developments in the off-highway industries are driven by the need to increase power whilst lowering operating costs. The synergies across its Divisions combined with innovative thinking enables GKN to leverage technology already tried, tested and accepted by the world’s automotive OEM’s. Technical Information AF-130 AF-140 AF-230 AF-240 Maximum Speed 8000 rpm 5000 rpm 8000 rpm 5000 rpm Nominal Torque 145 Nm 260 Nm 290 Nm 520 Nm Peak Torque (for up to 60s*) 250 Nm 400 Nm 500 Nm 800 Nm Peak Torque (for up to 20s*) 350 Nm 600 Nm 700 Nm 1200 Nm Nominal Output Power 64 kW 94 kW 128 kW 188 kW Peak Output Power (for up to 60s*) 100 kW 150 kW 200 kW 300 kW Peak Output Power (for up to 20s*) 140 kW 200 kW 280 kW 400 kW Peak Efficiency 95.1% 96.2% 95.1% 96.2% Dimensions (L x D) mm 110 x 300 at 30.5 kg 115.2 x 380 at 42.5 kg 211.8 x 300 at 57.5 kg 224 x 380 at 82 kg Inverter Supply Voltage 320V dc — 600V dc 320V dc — 600V dc 320V dc — 600V dc 320V dc — 600V dc *Seconds The AF-130/140/230 and 240 electric motors are three-phase permanent magnet motors that use proprietary axial flux technology to deliver very high torque and power density in a compact and light-weight unit. This makes them particularly suitable for use in electric and hybrid vehicles, where low weight and compact packaging are important for delivering optimum efficiency in performance and design. Key benefits include: • Very high torque and power density • Low cogging torque • Compact design with flat front and back faces for mounting • Integrated resolver for rotor position feedback • Liquid cooling for enhanced performance GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY AF-130 Winding configurations Technical Information MOTOR CONSTANT MOTOR TYPE BASE SPEED/INVERTER SUPPLY VOLTAGE KR (NM/A) KG (VS/RAD) 320 VDC 360 VDC 480 VDC 600 VDC AF-130-3 0.8 0.65 3800 rpm 4400 rpm 6000 rpm n/a AF-130-4 1.07 0.86 2850 rpm 3300 rpm 4500 rpm 5750 rpm1 AF-130-5 1.34 1.08 2300 rpm 2600 rpm 3600 rpm 4600 rpm AF-130-6 1.6 1.29 1900 rpm 2200 rpm 3000 rpm 3800 rpm 1 Actual values are temperature dependant, data shown for 55°C motor temperature. Base speed at no load. KT in Arms, KE in VPK, L-L Standard winding configuration shown. Other configurations are available 1 Limited suitability Motor performance and efficiency 400 350 70% 300 80% 85% 90% 91% 92% 93% Torque (Nm) 250 Peak Torque 94% 200 95% 150 Continuous Torque 100 50 0 0 1000 2000 Data for AF-130-5 with KEB 27 inverter on 600Vdc at 55˚C C inlet coolant temperature 3000 4000 5000 Speed (rpm) Motor shown is equipped with 2 resolvers. Single resolver version identical but flat back face. Standard Spline to BS3550:1963, 16/32 pitch, 21 teeth, fillet root side fit, class 1 fit. Effective length: 55 mm. Hollow Shaft and Double Shaft versions are also available. 6000 7000 8000 AF-140 Winding configurations Technical Information MOTOR CONSTANT MOTOR TYPE BASE SPEED/INVERTER SUPPLY VOLTAGE KR (NM/A) KG (VS/RAD) 320 VDC 360 VDC 480 VDC 600 VDC AF-140-3 1.34 1.08 2300 rpm 2600 rpm 3600 rpm n/a AF-140-4 1.78 1.44 1700 rpm 1950 rpm 2650 rpm 3400 rpm AF-140-5 2.23 1.81 1350 rpm 1550 rpm 2150 rpm 2700 rpm AF-140-6 2.68 2.17 1100 rpm 1300 rpm 1750 rpm 2250 rpm Actual values are temperature dependant, data shown for 55°C motor temperature. Base speed at no load. KT in Arms, KE in VPK, L-L Standard winding configurations shown. Other configurations are available Motor performance and efficiency 600 70% 500 80% 90% 85% 91% 92% 94% 400 Torque (Nm) Peak Torque 93% 95% 300 Continuous Torque 200 96% 100 0 0 500 1000 1500 Data for AF-140-4 with KEB inverter on 600Vdc at 55˚C inlet coolant temperature 2000 2500 3000 3500 Speed (rpm) Standard spline to BS 3550:1963, 16/32 pitch, 27 teeth, fillet root side fit, class 1 fit. Effective length: 55 mm. Hollow Shaft and Double Shaft versions are also available. 4000 4500 5000 GKN ELECTRIC MOTOR AND GENERATOR TECHNOLOGY AF-230 Winding configurations Technical Information MOTOR CONSTANT MOTOR TYPE BASE SPEED/INVERTER SUPPLY VOLTAGE KR (NM/A) KG (VS/RAD) 320 VDC 360 VDC 480 VDC 600 VDC AF-230-3 0.8 0.65 3800 rpm 4400 rpm 6000 rpm n/a AF-230-4 1.07 0.86 2850 rpm 3300 rpm 4500 rpm 5750 rpm1 AF-230-5 1.34 1.08 2300 rpm 2600 rpm 3600 rpm 4600 rpm AF-230-6 1.6 1.29 1900 rpm 2200 rpm 3000 rpm 3800 rpm 1 Actual values are temperature dependant, data shown for 55°C motor temperature. Base speed at no load. KT in Arms, KE in VPK, L-L Standard winding configurations shown. Other configurations are available 1 Limited suitability Motor performance and efficiency 800 700 70% 600 80% 90% 91% 85% 92% 93% Torque (Nm) 500 Peak Torque 94% 400 95% 300 Continuous Torque 200 100 0 0 1000 2000 3000 Data for AF-230-5 with 2x KEB 27 inverter on 600Vdc at 55˚C inlet coolant temperature ° 51 5000 6000 ° 61 ° 344 310 4x M10x1.5 310 20 55.60 2x 8H7 13 2x 45° 45° 51 8H7 13 51° ° 300 8000 51 ° 61 20 7000 62 4x M10x1.5 4000 Speed (rpm) 211.80 230.70 Motor shown is equipped with 2 resolvers. Single resolver version identical but flat back face. Standard spline to BS 3550:1963, 16/32 pitch, 21 teeth, fillet toot side fit, class 1 fit. Effective length: 45 mm. Hollow Shaft and Double Shaft versions are also available. 45° 51° 45° 51° AF-240 Winding configurations Technical Information MOTOR CONSTANT MOTOR TYPE BASE SPEED/INVERTER SUPPLY VOLTAGE KR (NM/A) KG (VS/RAD) 320 VDC 360 VDC 480 VDC 600 VDC AF-240-3 1.34 1.08 2300 rpm 2600 rpm 3600 rpm n/a AF-240-4 1.78 1.44 1700 rpm 1950 rpm 2650 rpm 3400 rpm AF-240-5 2.23 1.81 1350 rpm 1550 rpm 2150 rpm 2700 rpm AF-240-6 2.68 2.17 1100 rpm 1300 rpm 1750 rpm 2250 rpm Actual values are temperature dependant, data shown for 55°C motor temperature. Base speed at no load. KT in Arms, KE in VPK, L-L Standard winding configurations shown. Other configurations are available Motor performance and efficiency 1200 70% 1000 90% 85% 80% 91% 92% 94% 800 Torque (Nm) Peak Torque 93% 95% 600 Continuous Torque 96% 400 200 0 500 1000 1500 2000 ° 3000 3500 4000 ° 28.50 28.50 28.50 ° 33 3° 8x M10x1.5 25 ° 33 ° 8x M10x1.5 25 358 398.75 64 2x 69.85 ° 33 ° ° 33 33 ° 380 28.50 199 ° ° 28.50 5000 28.50 ° 358 8H7 14 4500 33 ° 3 2x 2500 Speed (rpm) 33 0 Data for AF-240-4 with KEB 27 inverter on 600Vdc at 55˚C inlet coolant temperature 224.30 243.20 Motor shown is equipped with 2 resolvers. Single resolver version identical but flat back face. Standard Spline to BS3550:1963, 16/32 pitch, 27 teeth, fillet root side fit, class 1 fit. Effective length: 55 mm. Hollow Shaft and Double Shaft versions are also available. 28.50 ° ° 28.50 8H7 14 GKN Land Systems Ipsley House, Ipsley Church Lane, Redditch, Worcestershire B98 0YL, United Kingdom Tel: +44 (0)1527 517715 INTEGRATED POWERTRAIN COMPONENTS, SYSTEMS AND SOLUTIONS Agriculture Construction Industry Centre for Engineering Innovation Hadley Castle Works, Hadley Telford, Shropshire TF1 6AF, United Kingdom Tel: +44 (0)1982 244 321 GKN EVO eDrive Systems develops and manufactures advanced electric motors, generators and inverters for a wide range of transportation and mobile power applications. For further information please visit us at www.gknlandsystems.com or email us at marketing.landsystems@gkn.com