PFC/RR-84-17 AND FY1984 REPORT J.V.

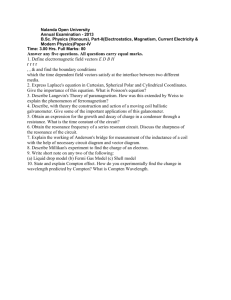

advertisement