Design of a Human Factors Procedure Analysis Tool (PAT) for... System Engineering & Operations Research, George Mason University Approach Context

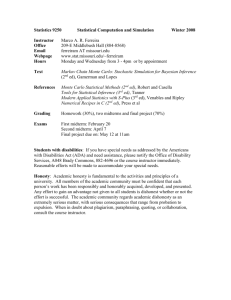

advertisement

Design of a Human Factors Procedure Analysis Tool (PAT) for FAA Certification Process Heather Johnson Houda Kerkoub Shaida Latifi Mumtahina Mahmud Alexis Nittoli System Engineering & Operations Research, George Mason University Context Approach Gap Analysis Flight demand increase 1 From a Procedure… Initial Approach Procedure Problem Air traffic modernization Program (NextGEN) New devices to be installed on aircraft More devices to be certified Capacity for flights is constant Opportunity for improved certification process • Federal Aviation Regulations are now requiring all functions to be evaluated. If certification process remains constant, it will be expensive and time consuming. • Current Certification Process is performed by a limited number of Human Factors Inspectors and Designated Engineering Representatives. These inspectors lack objective and quantifiable means to evaluate the devices. • Current process is paper based, manual, and lacks cockpit interaction. • There is an increasing amount of operational improvements needed to be certified. A gap is produced when the the number of years it takes to certify all new devices, takes longer than the number of years available for certification. Procedure • Task • Operator Action • • Task Specification Language Used to decompose tasks within a Standard Operating Procedure into Operator Actions Each Operator Action Category is mapped to a statistical distribution input to the simulation. The output of the simulation shows a distribution of time of multiple operators performing the task The probability of Failure to Complete the Task is a decision support tool for certification 2 Create a Sequence Diagram 3 Perform a Monte Carlo Simulation 𝟏. 𝟕𝟓 ∗ # 𝒐𝒇 𝑶𝑰𝒔 GAP Accidents human errors as main factors New regulation (FAR25.1302) include human factors in device certification Requirement: analysis of ALL tasks and functions Additional work for FAA Human Factors inspectors Monte Carlo Simulation Histogram Number of available FAA Human Factors inspectors constant Operator Action Need A Procedure Analysis Tool is needed to improve the certification process by applying an objective, efficient, cost effective, and accurate test. Business Case Example Procedure Prototype Cost for Procedure Analysis Tool Cost for Means of Compliance (MOC) 𝑪𝑻𝒓𝒂𝒊𝒏𝒊𝒏𝒈 = 𝑪𝒕𝒓𝒂𝒊𝒏𝒆𝒓 + 𝑪𝒄𝒐𝒖𝒓𝒔𝒆 ∗ 𝒏𝒖𝒎𝒕𝒓𝒂𝒊𝒏𝒆𝒆𝒔 = $𝟔𝟎𝟎 + $𝟏, 𝟑𝟎𝟎 ∗ 𝟑 = $𝟒, 𝟓𝟎𝟎 Monte Carlo Simulation will show a distribution of operators performing the Hold at Present Postion Prototype models a perceptual, cognitive, and motor processes to simulate Time to Complete the Task (TCT) 𝑪𝒕𝒓𝒂𝒊𝒏𝒆𝒓 = 𝒏𝒖𝒎𝒉𝒐𝒖𝒓𝒔 ∗ 𝑪𝒉𝒐𝒖𝒓 = 𝟐𝟎𝒉𝒓𝒔 ∗ $𝟑𝟎𝒉𝒐𝒖𝒓 = $𝟔𝟎𝟎 𝑪𝒑𝒓𝒆𝒗𝒆𝒏𝒕𝑴𝒂𝒊𝒏𝒕 = 𝑪𝒅𝒆𝒗𝒆𝒍𝒐𝒑𝒆𝒓/𝒉𝒐𝒖𝒓 ∗ 𝑯𝒚𝒆𝒂𝒓 = $𝟐𝟕𝒉𝒐𝒖𝒓 ∗ 𝟏𝟐𝟎 𝒉𝒓𝒔 = $𝟑, 𝟐𝟒𝟎 𝒚𝒆𝒂𝒓 Time to Complete the Task 𝑪𝑹𝒆𝒏𝒆𝒘𝒂𝒍 = 𝑪𝒑𝒓𝒆𝒗𝒆𝒏𝒕𝑴𝒂𝒊𝒏𝒕 ∗ 𝑴𝒖𝒍𝒕𝒊𝒑𝒍𝒊𝒆𝒓𝑶𝒗𝒆𝒓𝒉𝒆𝒂𝒅 = $𝟑, 𝟐𝟎𝟎 ∗ 𝟐. 𝟒 = $𝟕, 𝟔𝟓𝟎 Year 1: 𝑪𝒄𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟏 = 𝑪𝒑𝒓𝒐𝒅 + 𝑪𝑻𝒓𝒂𝒊𝒏𝒊𝒏𝒈 + 𝑪𝑹𝒆𝒏𝒆𝒘𝒂𝒍 = $𝟏𝟎𝟖, 𝟎𝟎𝟎 + $𝟒, 𝟓𝟎𝟎 = $𝟏𝟏𝟐, 𝟓𝟎𝟎 Year 2: 𝑪𝑪𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟐 = 𝑪𝒄𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟏 + 𝑪𝑹𝒆𝒏𝒆𝒘𝒂𝒍 = $𝟏𝟏𝟐, 𝟓𝟎𝟎 + $𝟕, 𝟔𝟓𝟎 = $𝟏𝟐𝟎, 𝟎𝟎𝟎 Number of operators performing the Task Year 5: Monte Carlo Simulation of Hold at Present Position Task Year 10: 𝑪𝑪𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟓 = 𝑪𝒄𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟏 + 𝟓 𝑪𝑹𝒆𝒏𝒆𝒘𝒂𝒍 = $𝟏𝟏𝟐, 𝟓𝟎𝟎 + $𝟑𝟖, 𝟎𝟎𝟎 = $𝟏𝟓𝟎, 𝟎𝟎𝟎 𝑪𝑪𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟏𝟎 = 𝑪𝒄𝒐𝒎𝒑𝒂𝒏𝒚𝒚𝟏 + 𝟏𝟎 𝑪𝑹𝒆𝒏𝒆𝒘𝒂𝒍 = $𝟏𝟏𝟐, 𝟓𝟎𝟎 + $𝟖𝟎, 𝟎𝟎𝟎 = $𝟏𝟗𝟐, 𝟎𝟎𝟎 Savings in Cost Cumulative Hours PAT 2500000 Cumulative Current System Cost/Year $250,000,000.00 $200,000,000.00 2000000 Cumulative Hours Current System 1500000 1000000 500000 $150,000,000.00 $100,000,000.00 Cumulative Alternative Cost/OI per Year $50,000,000.00 $0.00 0 Years Time to Complete the Task [sec] $300,000,000.00 Cost in Millions Time to Complete Task 3000000 2008 2011 2014 2017 2020 2023 2026 2029 Human Factors Metrics Database Perception, Cognition, Motor Probability of failure to complete the task Number hours saved Savings in Time 2008 2011 2014 2017 2020 2023 2026 2029 Perform a Procedure (SOP) Replication Standard Operating Procedures (SOP) Years