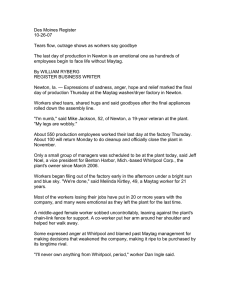

Des Moines Register 10-25-07 What's next for Maytag workers

advertisement

Des Moines Register 10-25-07 What's next for Maytag workers By WILLIAM RYBERG REGISTER BUSINESS WRITER As the doors to the former Maytag plant close, some employees still aren’t sure what the future holds. Ted Johnson, president of the plant’s union, Local 997 of the United Auto Workers union, said he doesn’t have a breakdown on what the newly jobless workers will do. Some have jobs lined up and others don’t. Some will have to find jobs in other cities and commute to work. Still others will have to move to other parts of Iowa or other states, Johnson said. Many, however, plan to go back to school to train for a new career with help from a federal program, Johnson said. A new factory could offer job opportunities. TPI Composites Inc. of Warren, R.I., has expressed interested in opening a plant to make blades for wind turbine electrical generators. Wages for many production jobs would start at $12.25 an hour, and the overall average pay would be $14 to $15 an hour. The average wage in the Maytag factory was $19 an hour, and highly skilled workers such as electricians and pipe fitters made up to $24, Johnson said. David Swenson, an economist at Iowa State University, said the Des Moines metro area and towns such as Pella will offer job opportunities to the permanently laid off workers. Swenson, however, expects that many will have to leave the area to find jobs. “Those with the skills in the greatest demand regionally or nationally, and with the highest amount of personal motivation, will migrate soonest,” Swenson said. Kim Didier, executive director of the Newton Development Corp., is more optimistic. Newton has 20 smaller manufacturers, is being considered as a site by other employers and has already attracted new companies such as Caleris, an information technology company, Didier said. Many previously laid off Maytag employees have continued to live in Newton, while commuting to new jobs at central Iowa manufacturers, such as window and door-maker Pella in Pella, the Lennox furnace and air conditioner factory in Marshalltown and Deere Co.’s farm equipment plant in Ankeny. Jeff Noel, a Whirlpool vice president, said earlier in the week that Newton’s Maytag employees were “wonderful people who make great products,” and Whirlpool realizes that the closing will have an impact on their lives. “It’s a somber day,” he said. Closing the factory and the headquarters, however, were decisions that had to be made, Noel said, adding that financially struggling Maytag had been cutting jobs long before Whirlpool entered the picture. Work from the Newton factory was transferred to Whirlpool plants in Ohio that were more cost-efficient because of their size and production volume capability. Whirlpool has said in the past the nonunion plants can make appliances five times as quickly factory in Newton. He said union wages and benefits in Newton weren’t a significant factor. Maytag’s Newton factory and headquarters work force reached about 4,000 as recently as 2001, before a series of job cuts. The total was down to 1,800 — split about evenly between the headquarters and the washer/dryer factory — when Whirlpool announced in May 2006 that it planned to shutdown all Newton operations. Whirlpool trimmed the work force in the months that followed. About 650 employees were working in the factory on Thursday, with 550 scheduled for permanent lay off. The remaining 100 will stay on for several weeks to help with clean-up and other parts of the closing process. Reporter William Ryberg can be reached at (515) 284-8104 or bryberg@dmreg.com